Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Moisture-proof and waterproof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-caking agent for fertilizer and preparation method and applications thereof

InactiveCN101555178APrevent the intrusion of environmental moistureStrong crystal growthFertilizer mixturesParaffin waxFertilizer

The invention discloses an anti-caking agent for fertilizer, the components of which comprise (mass percentage): 5 percent to 20 percent of dodecafluoro-heptanol sulfosuccinate, 9 percent to 30 percent of primary amine salt or secondary amine salt with the carbon atom number of 6 to 40, 10 percent to 50 percent of phospholipid oil, 10 percent to 40 percent of fatty acid ester, 5 percent to 30 percent of fatty acid, and 1 percent to 20 percent of paraffin, and the sum of each component is 100 percent. When the anti-caking agent for fertilizer is mixed with the fertilizer, a film which has stronger moistureproof and waterproof capacity than the existing anti-caking agent for fertilizer can be formed on the surfaces of fertilizer particles, thereby being capable of effectively preventing the particles of compound fertilizer from being adhered to a whole during the storage period, simultaneously preventing the invasion of environmental moisture, having very strong capacity for inhibiting the growth of fertilizer crystals, leading the fertilizer to keep loose for a long time during the storage period and greatly improving the effect so as to ensure the quality of the fertilizer. The invention also discloses a preparation method and applications of the anti-caking agent for fertilizer.

Owner:四川鸿康科技股份有限公司

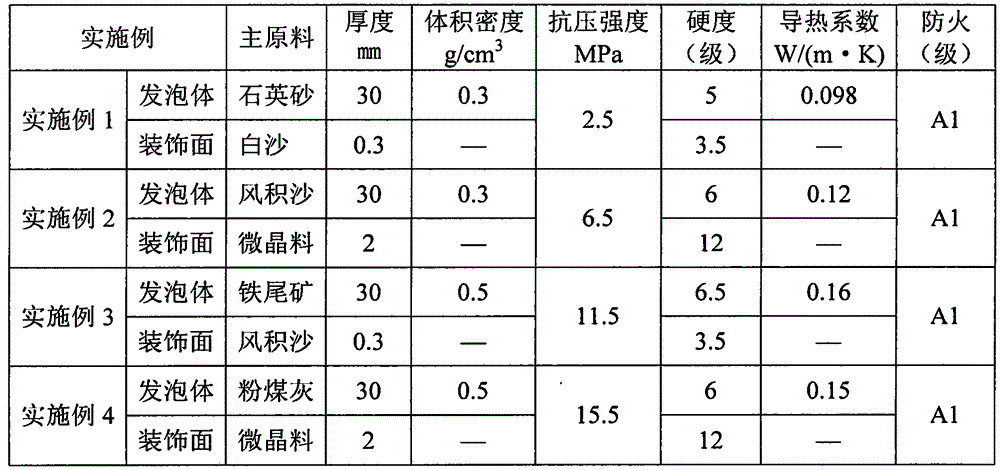

Microcrystalline foamed wall block produced by use of tailings and manufacturing method of microcrystalline foamed wall block

ActiveCN104631688AProduced noRelieve pressureBuilding componentsCeramicwareWeather resistanceSurface layer

The invention discloses a microcrystalline foamed wall block produced by use of tailings and a manufacturing method of the microcrystalline foamed wall block. According to the microcrystalline foamed wall block, a decorative surface layer is sintered on a tailing microcrystalline foamed base body manufactured by use of a tailing composite material at a high temperature. The manufacturing method comprises the following steps: (1) preheating, namely increasing the temperature to the range of 800-950 DEG C and preserving heat for 10-40 minutes; (2) integrated sintering, namely increasing the temperature to the range of 1000-1350 DEG C and preserving heat for 30-120 minutes; (3) annealing cooling, namely cooling to below 280 DEG C and then taking out of a kiln; (4) naturally cooling to below 100 DEG C and then performing mold stripping, thereby obtaining a microcrystalline foamed wall block board; naturally placing the microcrystalline foamed wall block board for more than 60 hours to eliminate stress, and then grinding or polishing, cutting and drying to obtain the microcrystalline foamed wall block. The microcrystalline foamed wall block has a plurality of functions of high strength, fire resistance, heat preservation and thermal insulation, moisture and water proofing, decoration, light weight, weathering resistance, environmental protection and the like.

Owner:BEIJING HUIERJIU MATERIAL TECH

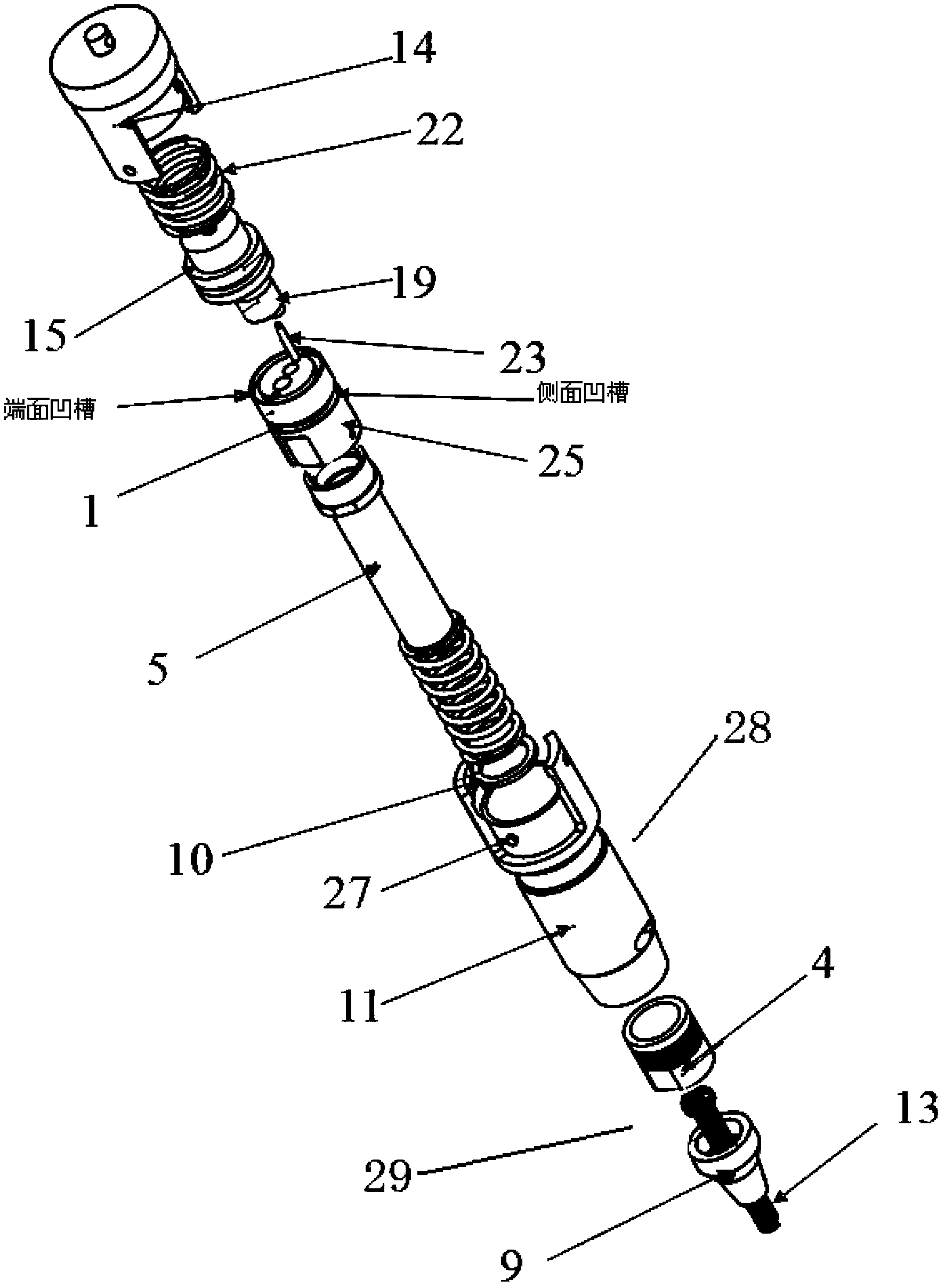

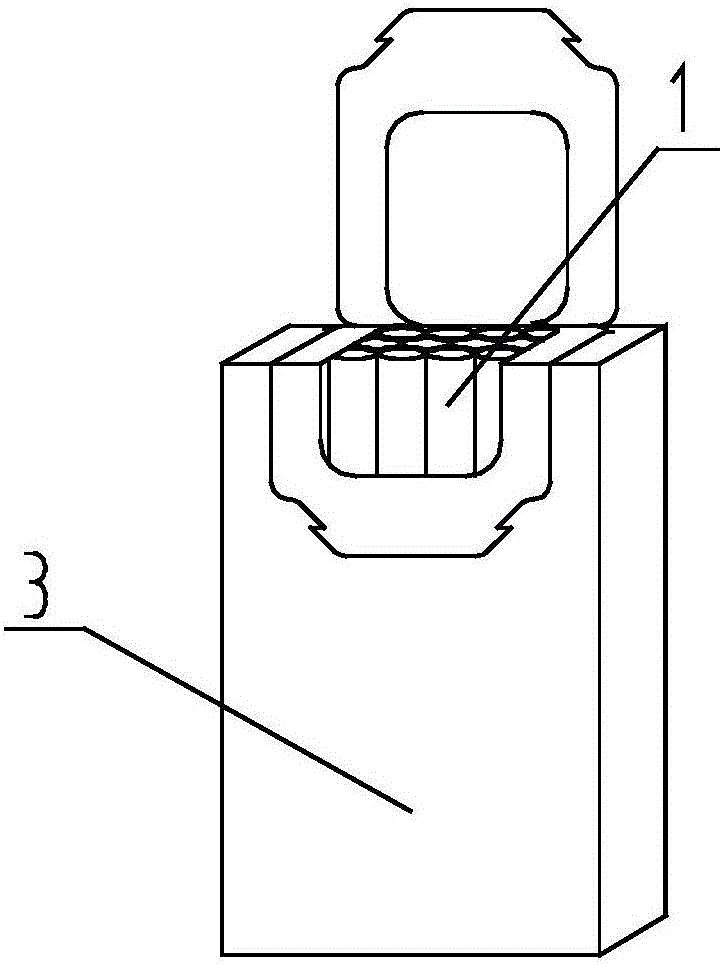

Optical cable assembly connector

InactiveCN103353635AQuick connectionFirmly connectedCoupling light guidesFibre mechanical structuresEngineeringOptical fiber cable

The invention relates to an optical cable assembly connector which comprises a plug body, a housing, an optical cable access apparatus and an optical cable locking apparatus. One end of the plug body is connected with the housing, and the other end of the plug body is used for connecting with other plug bodies. One end of the housing is connected with the plug body and the other end of the housing is connected with the optical cable access apparatus. The housing conveys an optical cable accessed from the optical cable access apparatus. One end of the optical cable access apparatus is connected with the housing, and the other end of the optical cable access apparatus is used for receiving the inserted optical cable and conveying the optical cable to the housing. The optical cable locking apparatus is disposed at a joint of the housing and the optical cable access apparatus, and is used for fixing the connection between the housing and the optical cable access apparatus and locking the optical cable inside the housing and the optical cable access apparatus. The optical cable assembly connector realizes ensures simultaneous rapid connection between two optical fibers and simultaneous reception and transmission of optical signals, is relatively good in quality of optical signal transmission, and can satisfy use demands of different users.

Owner:SHANDONG INTELLIGENT OPTICAL COMM DEV

Preparation method of ceramic plate decorative painting through colored engraving

The invention relates to a preparation method of a ceramic plate decorative painting through colored engraving. The method comprises the following steps: 1), a protective film is attached to the surface of a ceramic plate; 2), sidelines of a specified figure are engraved on the surface of the ceramic plate by a laser engraving machine; 3), the protective film at a to-be-etched part is removed so as to expose an engraving surface; 4), the surface of the ceramic plate is eroded by an abrasive material at a high flow rate, so that an uncolored solid figure is formed through engraving on the ceramic surface with the protective film removed, the pressure is 1-10 kg / m<3>, and the flow is 5-20 m<3> / min; 5), sand blasting is at least performed on a to-be-colored part of the surface of the ceramic plate so as to at least remove a glaze layer of the to-be-colored part and form a frosted surface, the sand blasting pressure is 1-10 kg / m<3>, and the flow is 5-20 m<3> / min; 6), the frosted surface of the ceramic plate prepared in the step 5) is cleaned and dried, a pattern is spray-printed and drawn, and a protective glaze layer is spray-printed; 7), the ceramic plate prepared in the step 6) is sintered rapidly.

Owner:MONALISA GRP CO LTD

Integral moisture-retention cigarette case adopting annular opposed die cutting wrapping composite and manufacturing method of integral moisture-retention cigarette case

ActiveCN106672373AEasy accessSolve the shortcomings of high cost and waste of resourcesContainers for flexible articlesPackaging cigaretteMoisture retentionEngineering

The invention discloses an integral moisture-retention cigarette case adopting an annular opposed die cutting wrapping composite. The case structurally comprises a content, a paper inner frame and a wrapping composite material from inside to outside sequentially. A manufacturing method of the integral moisture-retention cigarette case comprises the following steps that A1, the paper inner frame wraps cigarettes and is made into a packaging inner container for standby application; and A2, the wrapping composite is folded and molded to wrap the packaging inner container, and then fixed in an adhesion mode or a local heat-sealing mode, so that the integral cigarette case is manufactured. The moisture-retention cigarette case adopting the annular opposed die cutting wrapping composite has the beneficial effects that the structure is concise; in the repeated opening and closing process, influence of the external temperature and humidity can be effectively prevented, destructive packaging protection is provided, the annular opposed die cutting wrapping composite replaces multiple materials of existing cigarette cases, and the opening process is smooth and convenient; the wrapping composite is good in printing adaptivity and excellent in processing resistance; and the moisture-retention cigarette case has the functions of damp prevention, moisture retention, fragrance retention, bacteria resistance and bacteriostasis, counterfeiting and copying are difficult, national tax erosion is effectively reduced, and the national economic benefits are protected effectively.

Owner:CHINA TOBACCO YUNNAN IND

Sand picture making process

ActiveCN105599525AGood molding effectPerfect expression of detailsSpecial ornamental structuresSpecial artistic techniquesMaterials scienceHigh heat

The invention belongs to the field of artistic sand picture making and particularly relates to a sand picture making process. The sand picture making process comprises the following steps: S1, putting a sand picture plate on a sand picture table; S2, drawing on the sand picture plate by using drawing sand to obtain a sand picture blank; S3, spraying coating glue to the sand picture blank; S4, standing and drying to obtain a shaped sand picture; and S5, mounting the picture to obtain a formed sand picture with a mounting frame. The invention has the technical benefits as follows: the sand picture making process provided by the invention can enable a sand picture maker to draw by adopting various methods at will; the preparation steps are concise and no high-temperature baking for shaping is required; the sand picture forming effect is good and the detail expression is perfect; and meanwhile, the coating glue forms a layer of protective film on the surface of the sand picture to achieve moistureproof and waterproof effects, thereby prolonging the works storage time.

Owner:李慧

Preparation method for decorative picture of thousand-layer carved ceramic plate

The present invention relates to a preparation method for a decorative picture of a thousand-layer carved ceramic plate. The method comprises: 1) covering a layer of protective film on a surface of a ceramic plate; 2) using a laser carving machine to carve edge lines of a predetermined pattern on the surface of the ceramic plate, wherein the pattern comprises a plurality of parts; 3) removing the protective film gradually from each part of the pattern, and carving with sandblast until a complete multi-layer carved pattern is formed, wherein a sandblasting pressure adopted in the sandblasting carving is 1-10 kg / m<3>, and a flow rate is 5-20 m<3> / min; 4) sandblasting the surface of the ceramic plate to remove a glazed layer on the surface of the ceramic plate and form a frosted surface, wherein the sandblasting pressure is 1-10 kg / m<3>, and the flow rate is 5-20 m<3> / min; 5) after the frosted surface of the ceramic plate prepared in the step 4) is cleaned and dried, jet printing and drawing the pattern, and then jet printing a protective glazed layer; and 6) sintering the ceramic plate prepared in the step 5) rapidly.

Owner:MONALISA GRP CO LTD

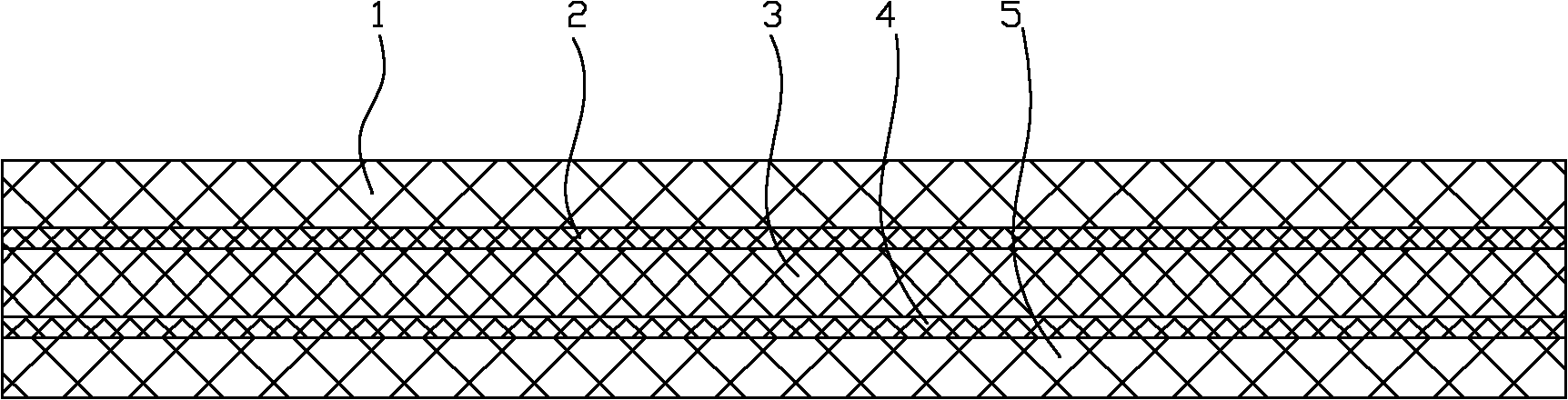

Composite decorative sheet

InactiveCN103572930ASave wood resourcesStable structureCovering/liningsSynthetic resin layered productsSurface layerProtection layer

The invention discloses a composite decorative sheet which comprises a base plate, a surface decoration layer, and a surface layer arranged between the base plate and the surface decoration layer, wherein a waterproof coating is coated between the surface layer and the base plate, a protection layer is coated between the surface layer and the surface decoration layer, the base plate is a polyurethane foaming plate, and the outer surface of the surface decoration layer is further coated with an flame retarding fireproof layer. Compared with the prior art, the composite decorative sheet has the characteristics of corrosion resistance, strong wear resistance, solid durability, non-deformation, dampproofness and waterproofness.

Owner:GUILIN JINSHUIMU DECORATION DESIGN ENG

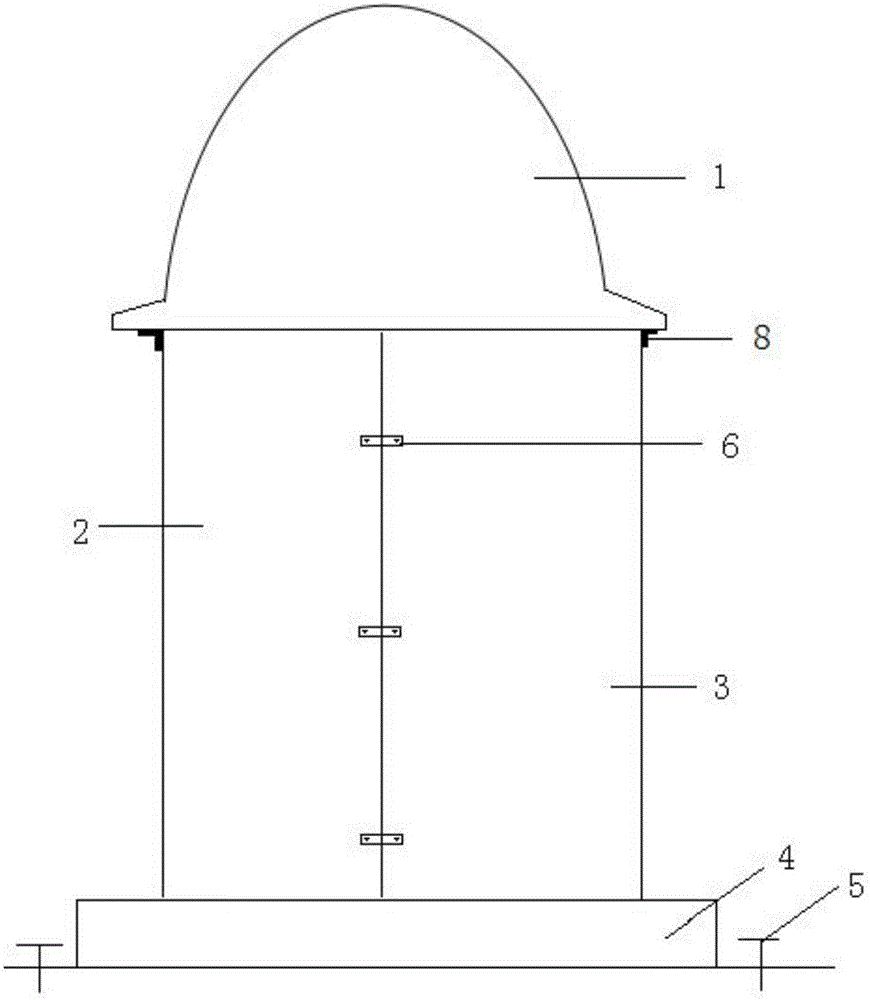

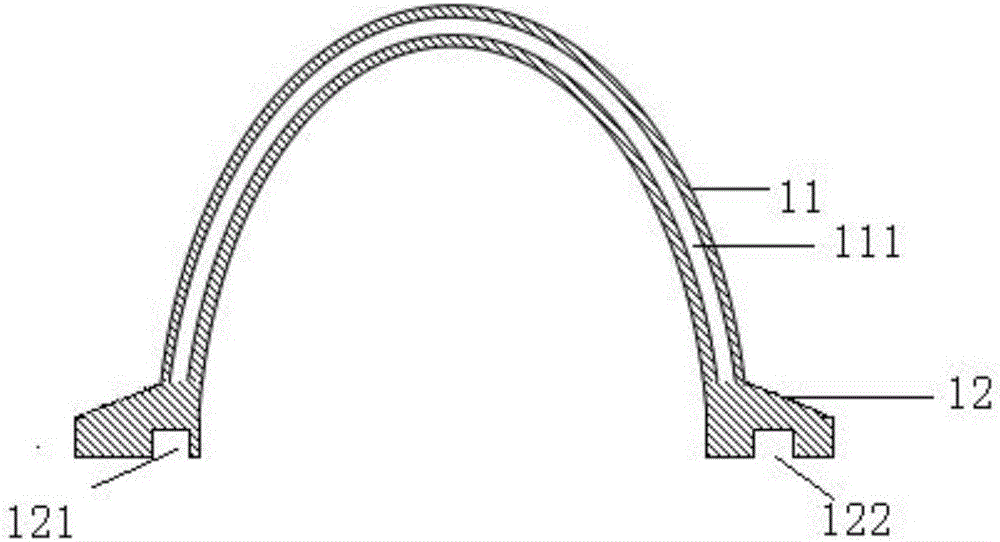

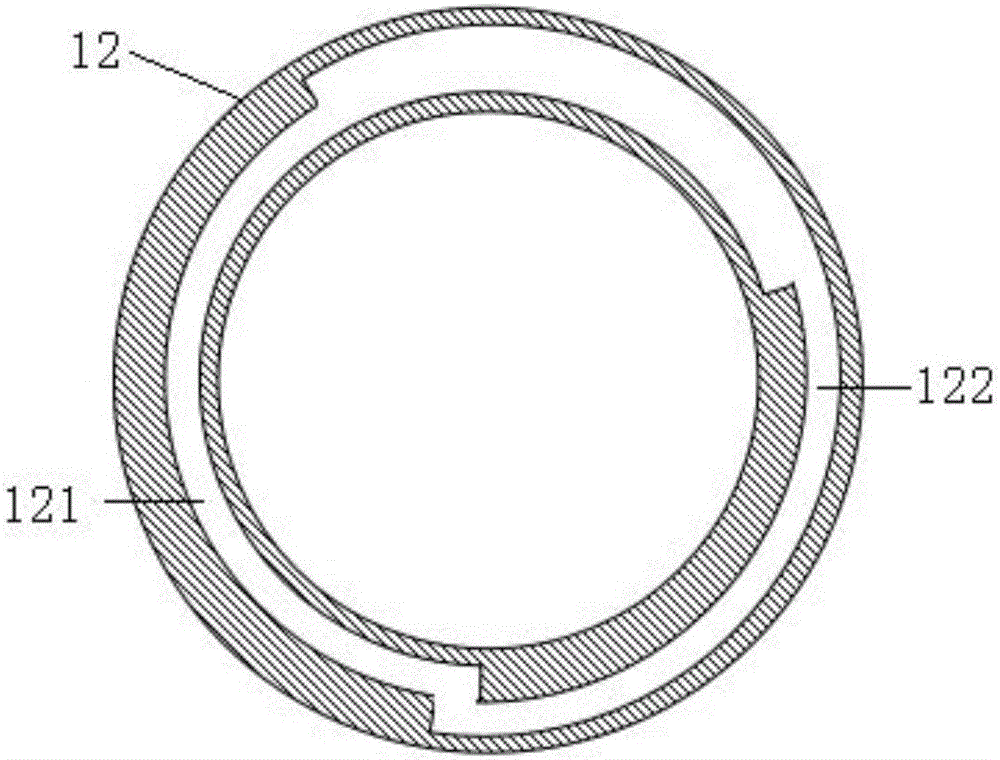

Radome

PendingCN106450743AMoisture-proof and waterproofImprove heat resistanceRadiating element housingsHeat resistanceAgricultural engineering

The invention relates to a radome which belongs to the technical field of antenna protection equipment. The radome can resist wind, sand, water, moisture and heat, is easy to disassemble, and is easy to maintain an antenna. The radome provided by the invention comprises a top casing, a left casing, a right casing and a base. The top casing is composed of a top casing body and a top casing seat. The top casing seat and the base are provided with a first arc-shaped groove and a second arc-shaped groove respectively, wherein the first arc-shaped groove and the second arc-shaped groove are opposed to each other and are arranged from the inside to the outside. The left casing and the right casing can be arranged in the first arc-shaped groove and the second arc-shaped groove respectively. The right casing can slide along the second arc-shaped groove to open and close the left casing and the right casing. The radome can resist wind, sand, water, moisture and heat, has the advantages of great mechanical strength and easy installation and disassembly, and is not easy to damage. The antenna is maintained without removing the radome. The radome has the advantages of low production costs and long service life.

Owner:CHINA TOWER CO LTD

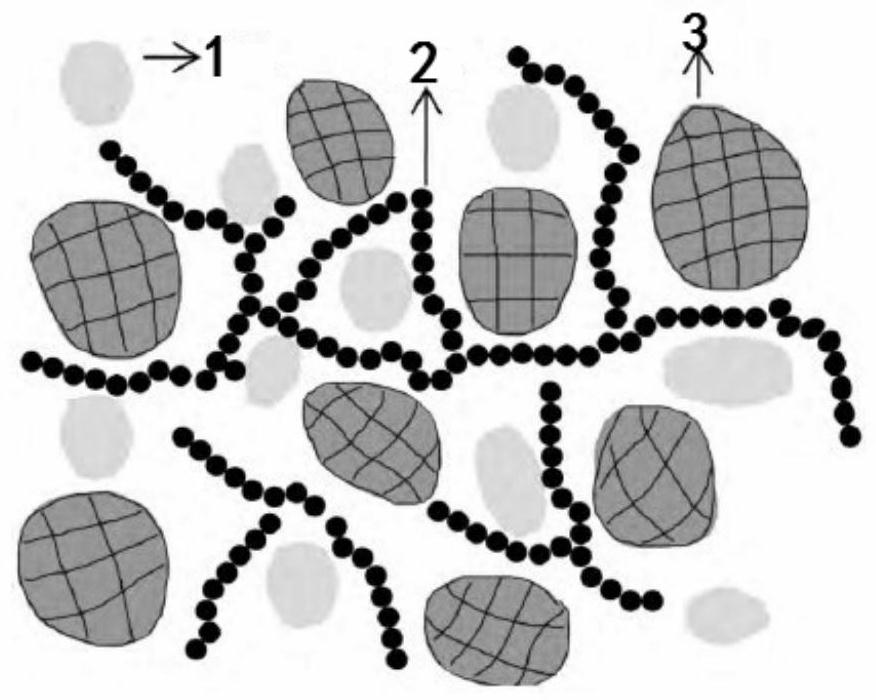

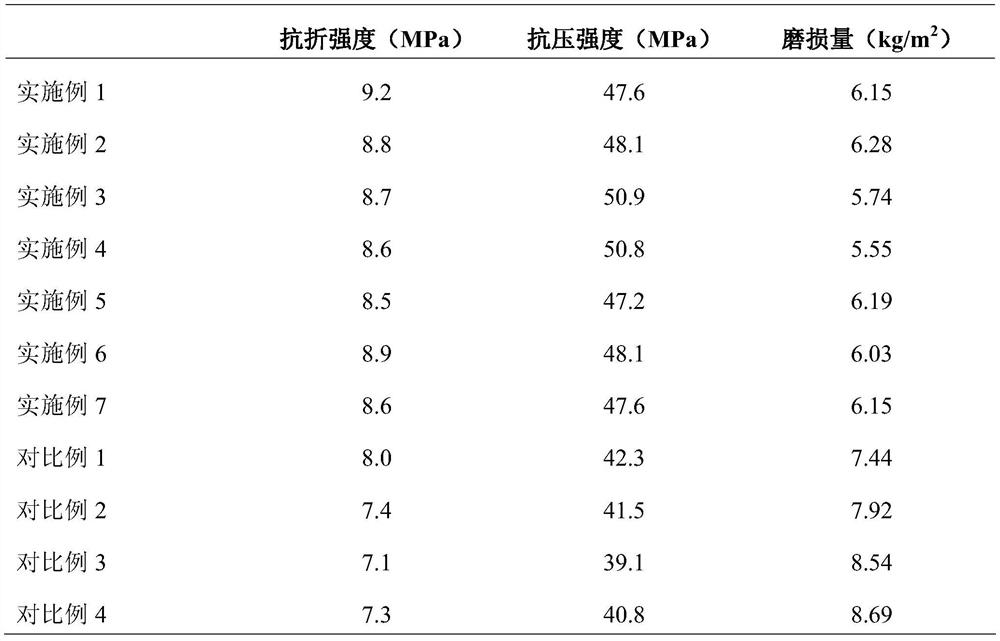

Limestone machine-made sand concrete modifier and concrete containing limestone machine-made sand concrete modifier

InactiveCN112225478AHigh compressive and flexural strengthImprove wear resistanceHydration reactionCompressive resistance

The invention discloses a limestone machine-made sand concrete modifier and concrete containing the limestone machine-made sand concrete modifier. The limestone machine-made sand concrete modifier isprepared from the following raw materials in parts by mass: 5-7 parts of nano colloidal silicon dioxide with the solid content of 15-50% and 4-7 parts of a water repellent agent, wherein the water repellent agent is selected from one of a lotus leaf type water repellent agent and a water-based wax-based water repellent agent. The preparation method comprises the following steps of carrying out fusion stirring according to 5%-7% of the mass of the cement, and uniformly stirring to obtain the novel limestone machine-made sand concrete modifier. According to the limestone machine-made sand concrete modifier, through the secondary hydration reaction, the crystal nucleus effect and the micro-aggregate filling effect of the material, the compressive strength, the breaking strength and the durability of concrete can be improved, and the limestone machine-made sand concrete modifier is simple in preparation process, low in cost and wide in application range.

Owner:GUANGXI COMM PLANNING SURVEYING & DESIGNING INST

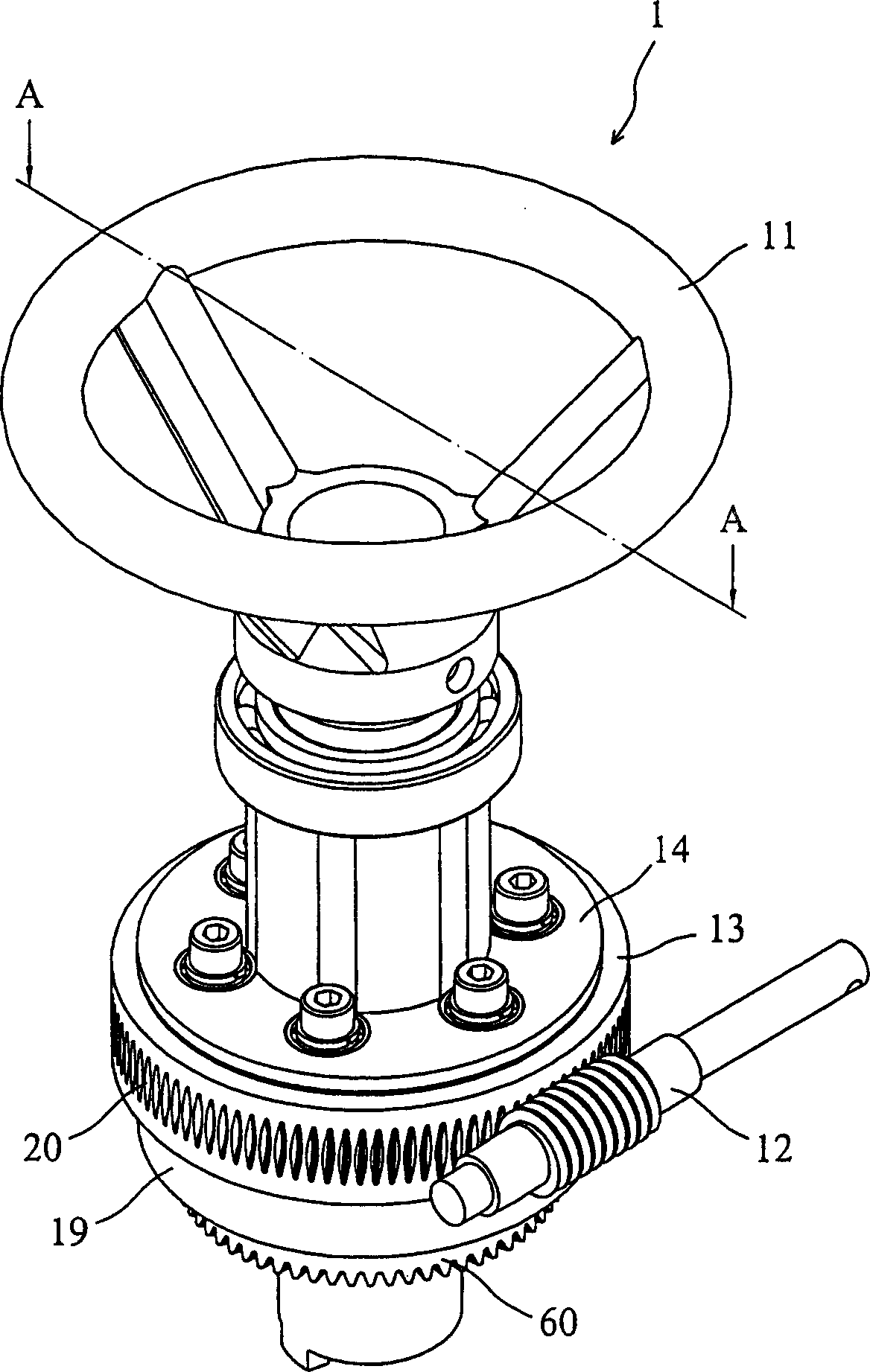

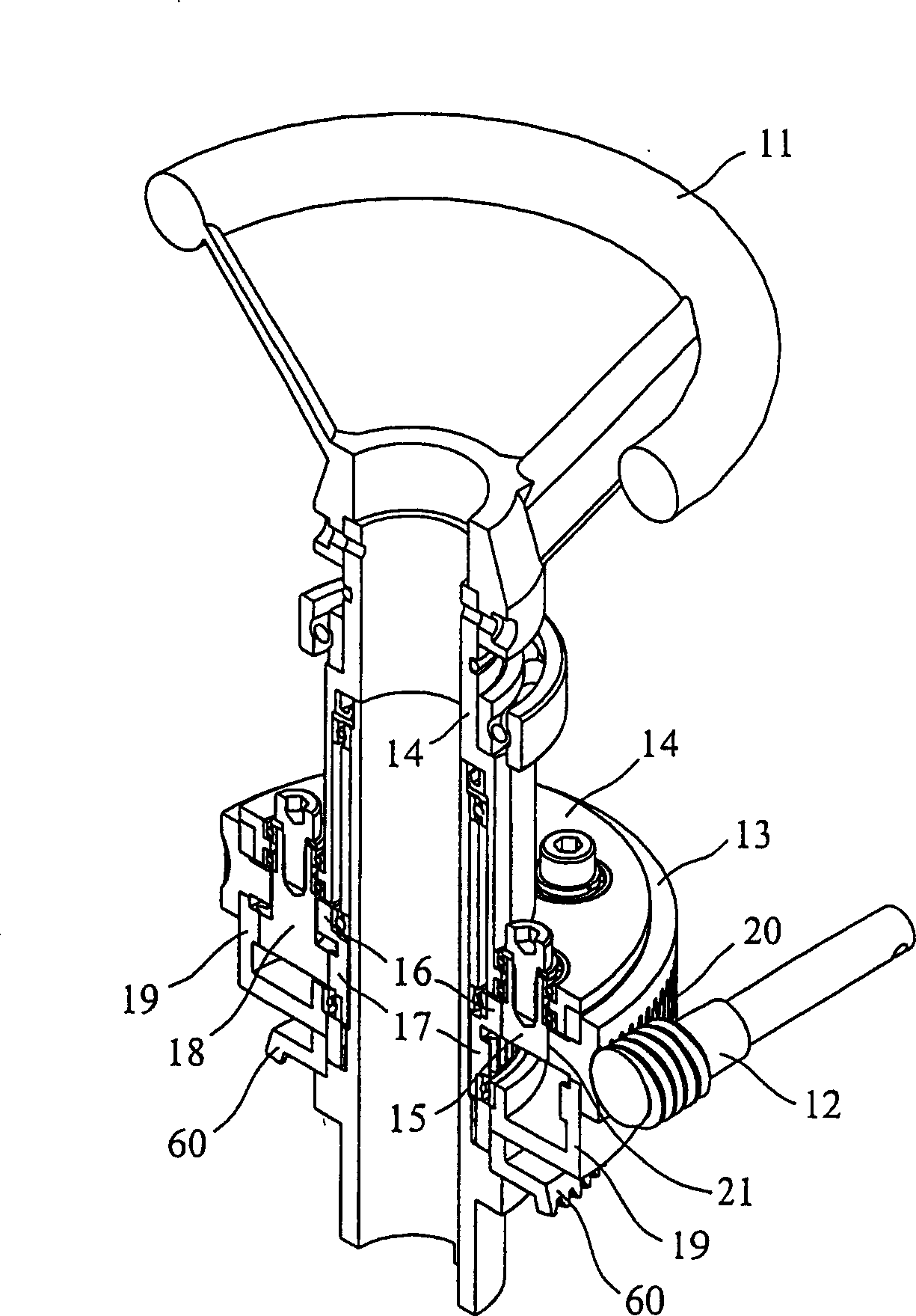

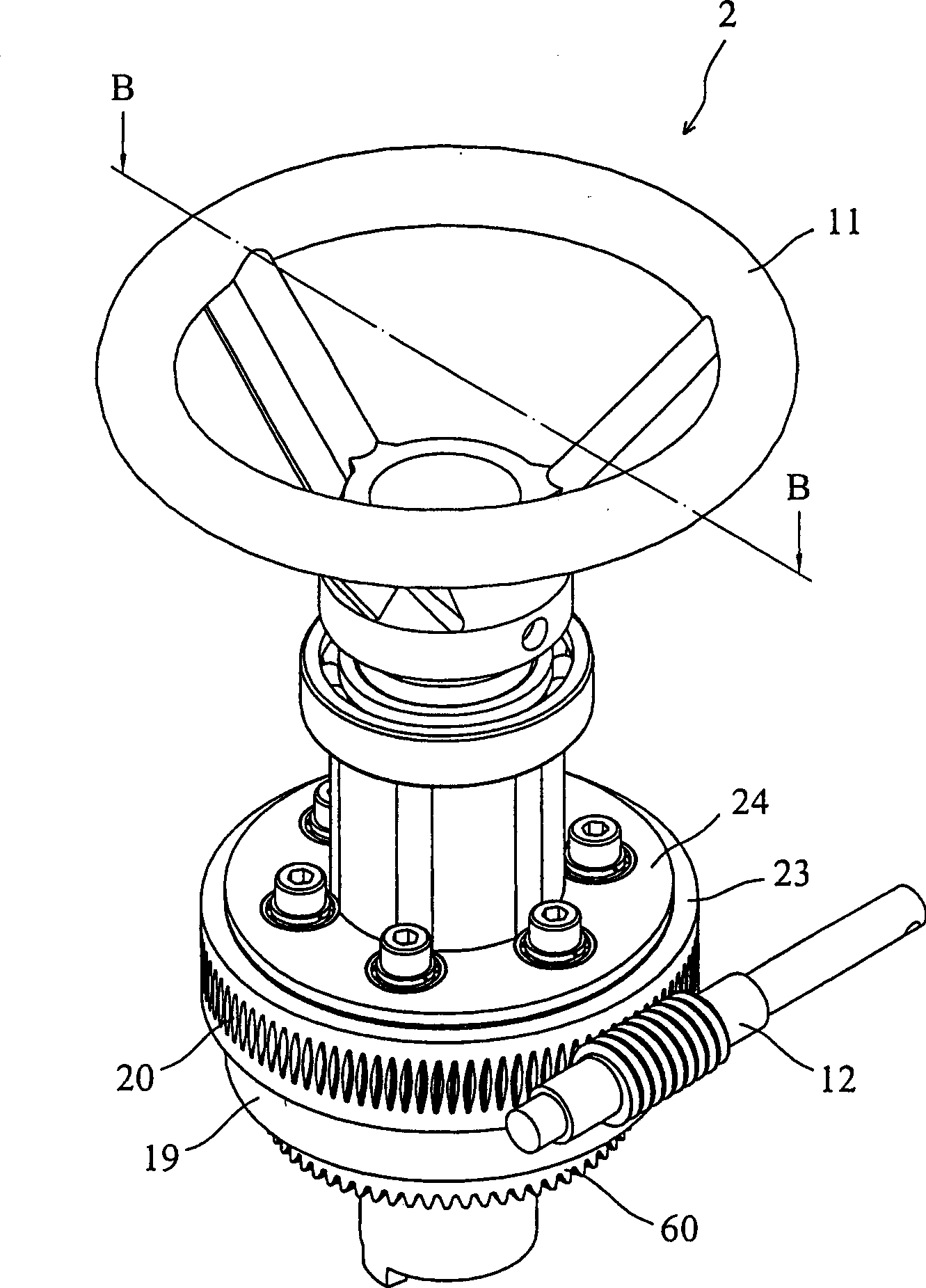

Two-segment differential type planetary gear train driver

InactiveCN1804429AWith anti-reverse functionHigh reduction transmission efficiencyToothed gearingsGear wheelEngineering

The invention discloses a two-stage differential planetary gear driver, which comprises the first planetary gear group and the second planetary gear group. Wherein, the first planetary gear group comprises a fixing element, a drive element, the first driven element and the second driven element; the second planetary gear group comprises the first drive element, the second drive element and one driven element, while the first and second driven elements of said first planetary gear group are connected to the first and second drive elements of said second planetary gear group. The invention is a device with high flexible reducing rate without clutch while it can be handful operated and automatically operated synchronously. The output axle of said invention has the retaining function with high reducing transmission efficiency which can apply the 1 / 4 rotational or multi-rotational driver.

Owner:METAL INDS RES & DEV CENT

Making method of bamboo root carving

InactiveCN109177631AAvoid crackingPrevent moisture absorptionRadiation/waves wood treatmentElectric wood treatmentSurface cleaningPreservative

The invention discloses a making method of a bamboo root carving. The making method includes the steps that a bamboo root is excavated, dried and irradiated with gamma rays, and pretreated bamboo rootis obtained by surface cleaning after mud removal; the pretreated bamboo root is carved to obtain a root carving original product; the root carving original product is put into water of 45-55 DEG C and stands for 20-30 min, standing for 3-5 h after boiling is carried out, heat treatment for 1-2 h under 115-125 DEG C is carried out, heat treatment for 50-75 min under 135-155 DEG C is carried out,heat treatment for 10-30 min under 160-170 DEG C is carried out, and a heat treated root carving is obtained; and the heat-treated root carving is added in a preservative to soak for 2-3 h, then superheated steam treatment for 2-4 h is carried out, drying and then polishing are carried out, cold plasma treatment for 60-80 s is carried out, and the bamboo root carving is obtained by lacquer primingand curing. According to the making method of the bamboo root carving, the process is simple, the obtained bamboo root carving has good mildew resistance, excellent aging resistant performance, and is not prone to being cracked.

Owner:广德竹之韵工艺品厂

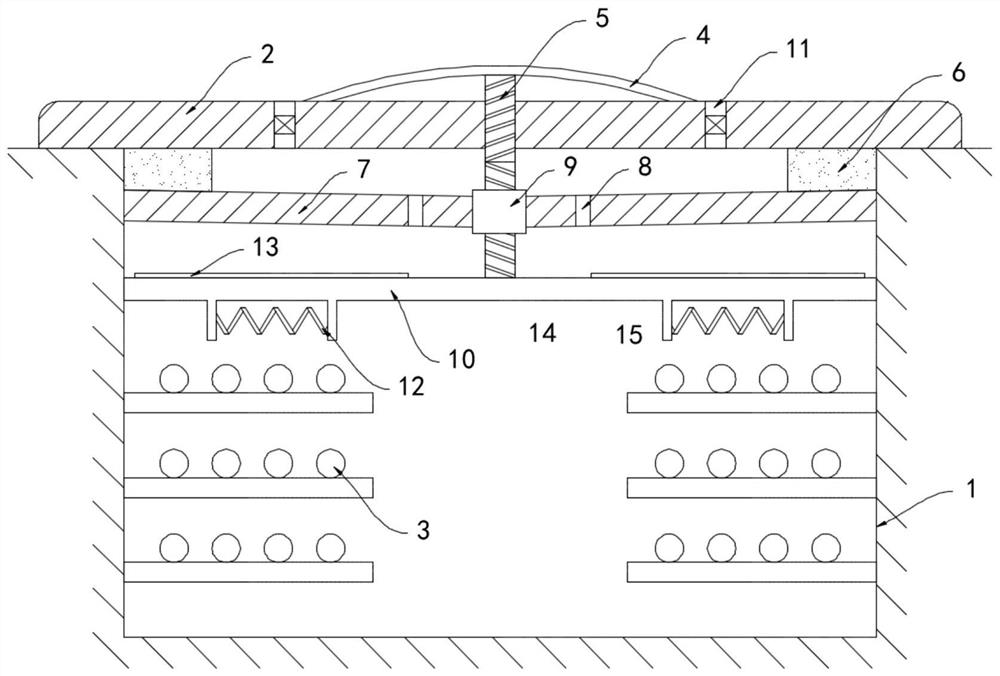

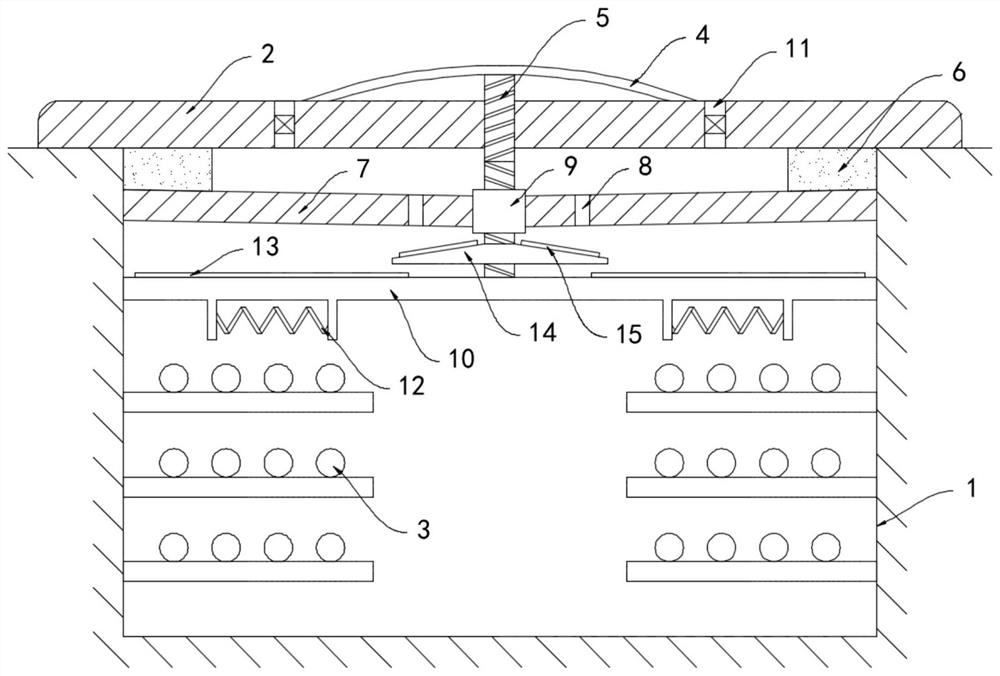

Moisture-proof and water-removing cable trench for communication base station

InactiveCN112217170AAvoid corrosionMoisture-proof and waterproofCable installations on groundScrew threadThreaded rod

The invention belongs to the field of communication facilities, and particularly relates to a moisture-proof and water-removing cable trench for a communication base station, which comprises a trenchbody, a cover plate and a cable arranged in the trench body. A flexible pedal is arranged on the upper surface of the cover plate and is in an upwards arched cambered surface shape. A threaded rod isfixedly connected to the lower surface of the flexible pedal, the lower end of the threaded rod penetrates through the cover plate and extends into the channel body, a thread is arranged in the coverplate and is in threaded fit with the threaded rod, a water absorption ring is fixedly connected to the lower surface of the cover plate, and a pressing plate is slidably connected to the inner side wall of the channel body; a plurality of drainage holes are formed in the pressing plate, a threaded cylinder is fixedly embedded in the pressing plate, and the lower end of the threaded rod penetratesthrough the threaded cylinder and is in threaded fit with the threaded cylinder. Rainwater entering the channel body can be rapidly electrolyzed, heated and evaporated, rainwater is effectively prevented from further permeating, the good moisture-proof and waterproof effects are achieved, and corrosion to a cable is avoided.

Owner:湖州浪佩智能科技有限公司

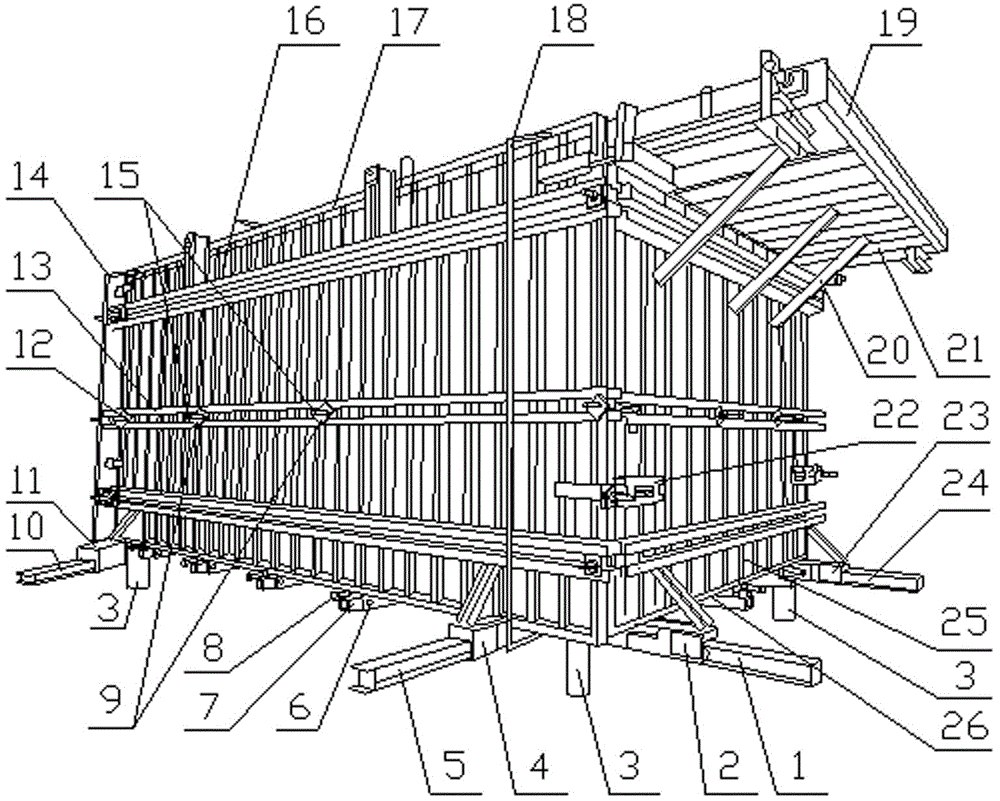

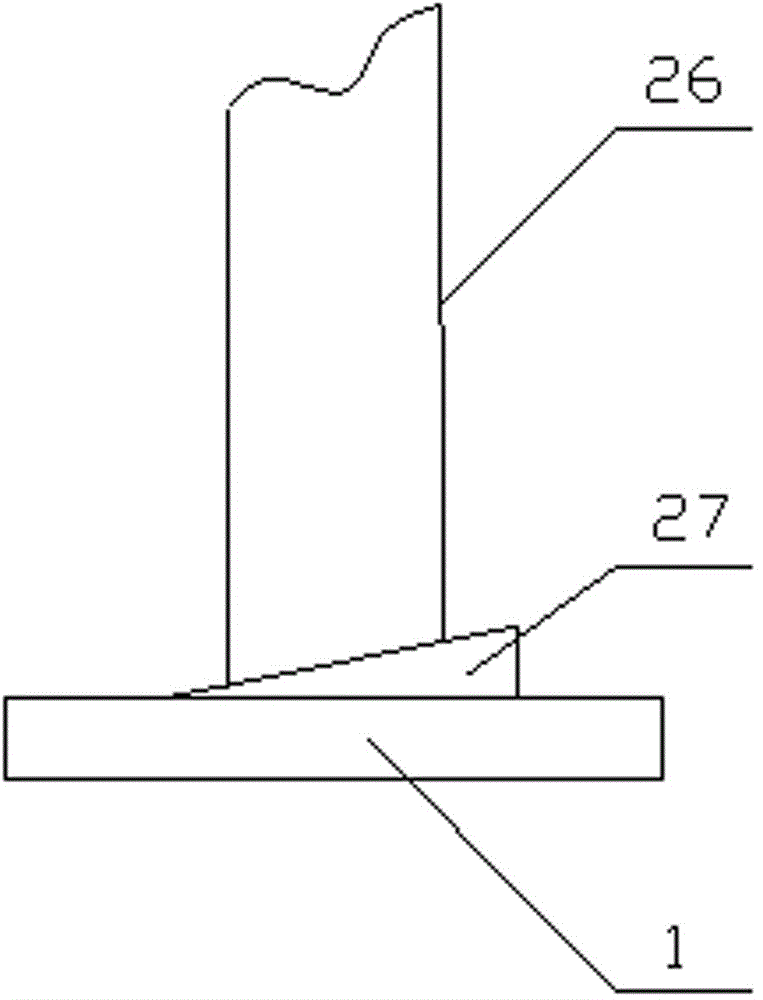

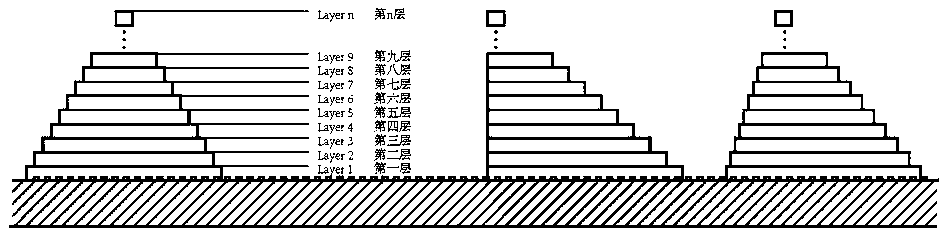

Energy saving environmental protection reinforced concrete one-piece house building die

InactiveCN106088577AWindproofFireproofForms/shuttering/falseworksHydraulic cylinderEnvironmental resistance

The invention provides an energy saving environmental protection reinforced concrete one-piece house building die comprising an outer die body, an inner die body, window die bodies, door die bodies and beam die bodies; the outer die body comprises four outer molds capable of being enclosed and separated; the inner die body a one-piece hollow cavity with sealed surroundings and top; four corner bottoms of the space formed by the outer die body and the inner die body are respectively provided with a hydraulic cylinder; a plurality of window die bodies and door die bodies are arranged in the space enclosed by the outer and inner die bodies; the upper portion of the space enclosed by the outer and inner die bodies is provided with a plurality of beam die bodies; peripheral surfaces of the inner die body, the window die body, the door die body and the beam die body respectively lean upwards, and the shape of big-bottom and small-top is respectively formed. The house built by the die is safe and firm, comfortable and environmental protection, low in cost, convenient in dismounting, and can be repeatedly used; the house can be built in industrial production, thus providing the cement movable house with high quality and low cost for building construction units.

Owner:南阳市互联易家实业有限公司

Multifunctional lathe for automobile part manufacturing and machining

InactiveCN112122963AGuaranteed stabilityCooling and lubricating effect is goodFeeding apparatusPositioning apparatusElectric machineryEngineering

The invention discloses a multifunctional lathe for automobile part manufacturing and machining. The multifunctional lathe comprises a workbench, wherein a first motor is arranged above the top end ofthe workbench, the output end of the first motor is connected with a drill bit, the drill bit is connected with a moving mechanism, a vertical plate is arranged above the top end of the workbench, aclamping plate is fixedly arranged in the position, located on one side of the drill bit, of the vertical plate, and an auxiliary clamping plate is arranged on one side of the vertical plate and located above the clamping plate. The multifunctional lathe for automobile part manufacturing and machining has the beneficial effects that clean water in a water cavity is pumped through a water pump until the water in the water cavity is completely pumped, it is guaranteed that dust generated by punching is subjected to dust falling through the water sprayed out in the working process, good cooling and lubricating effects can be achieved on a workpiece machined in the working process and the drill bit, and automobile parts are prevented from being damaged; and besides, water baffles are fixedly arranged on the two sides of the outer wall of the workbench, so that the pumped water is prevented from being splashed to the outside of the workbench, the splashed water is well blocked, and the water is guided through inclined plates which are arranged in an inclined manner.

Owner:NANJING SHILAIER AUTOMOTIVE ELECTRONICS CO LTD

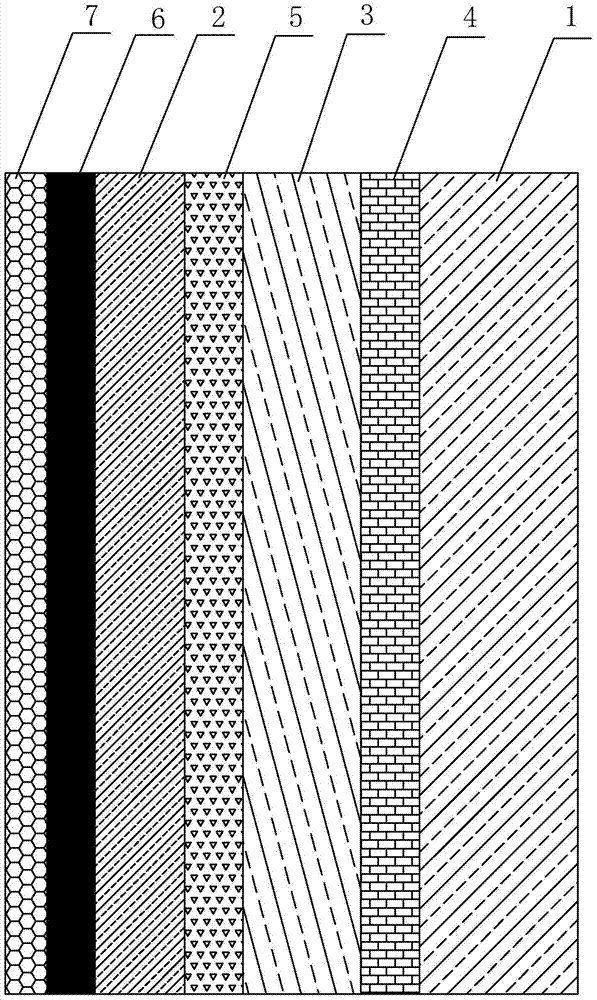

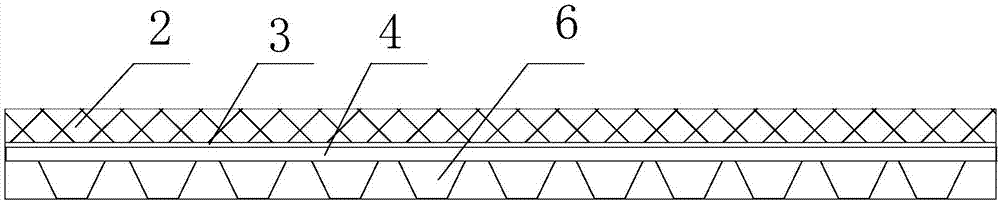

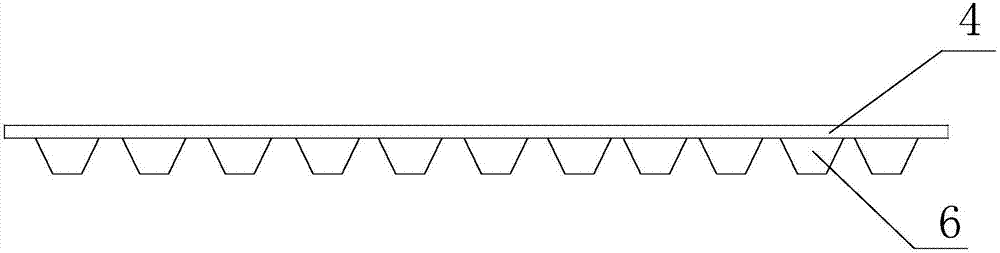

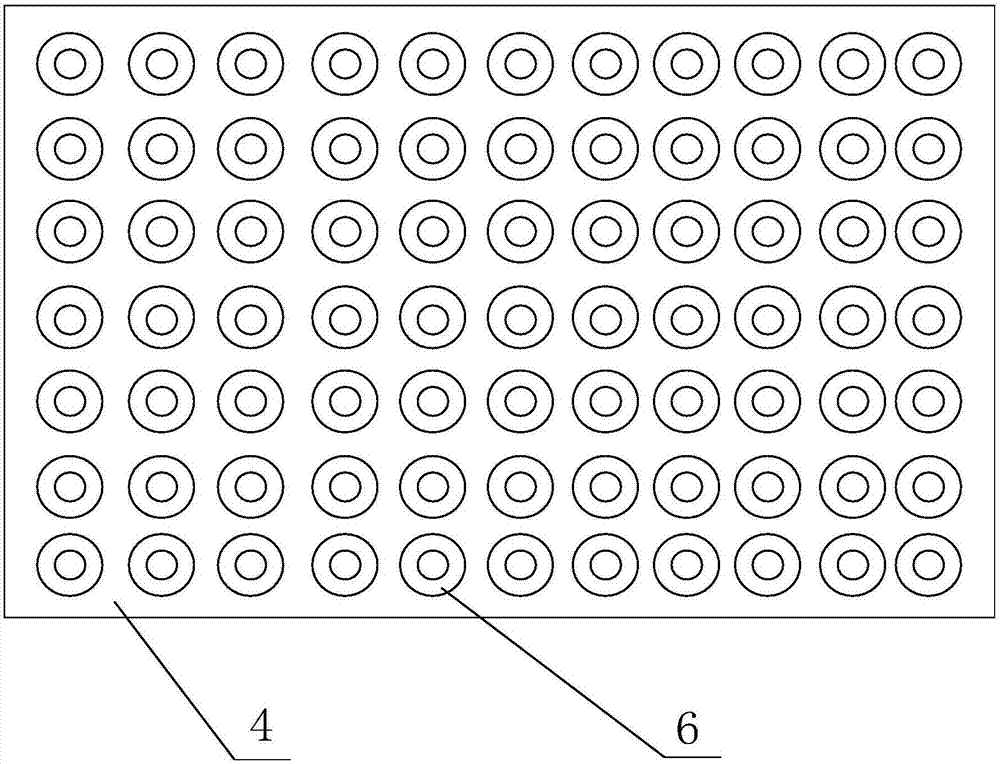

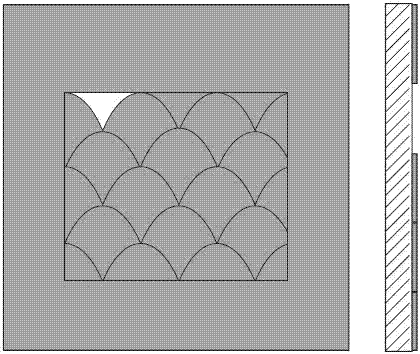

Moistureproof breathable ground mat

The invention discloses a moistureproof breathable ground mat. The moistureproof breathable ground mat is characterized in that the moistureproof breathable ground mat comprises an IXPE buffer layer (2) at the upper layer and a PE layer (4) at the lower layer, the bottom surface of the IXPE buffer layer (2) and the back surface of the PE layer (4) are bonded together through a bonding layer (3), the bonding layer (3) is provided with double faced adhesive tape, a plurality of circular truncated cones (6) are distributed on the front surface of the PE layer (4), the diameters of the top surfaces of the circular truncated cones (6) are 6-8 mm, the bottom surfaces of the circular truncated cones (6) are 14-16 mm, and the heights of the circular truncated cones (6) are 10-12 mm. The moistureproof breathable ground mat has good buffer and isolation functions and is breathable and moistureproof, floors can be effectively protected for a long time.

Owner:常州海辰装饰材料有限公司

A kind of preparation method of heap carving ceramic plate decorative painting

ActiveCN106915197BConvenient careStrong three-dimensional senseDecorative surface effectsSpecial ornamental structuresGlazeSand blasting

Owner:MONALISA GRP CO LTD

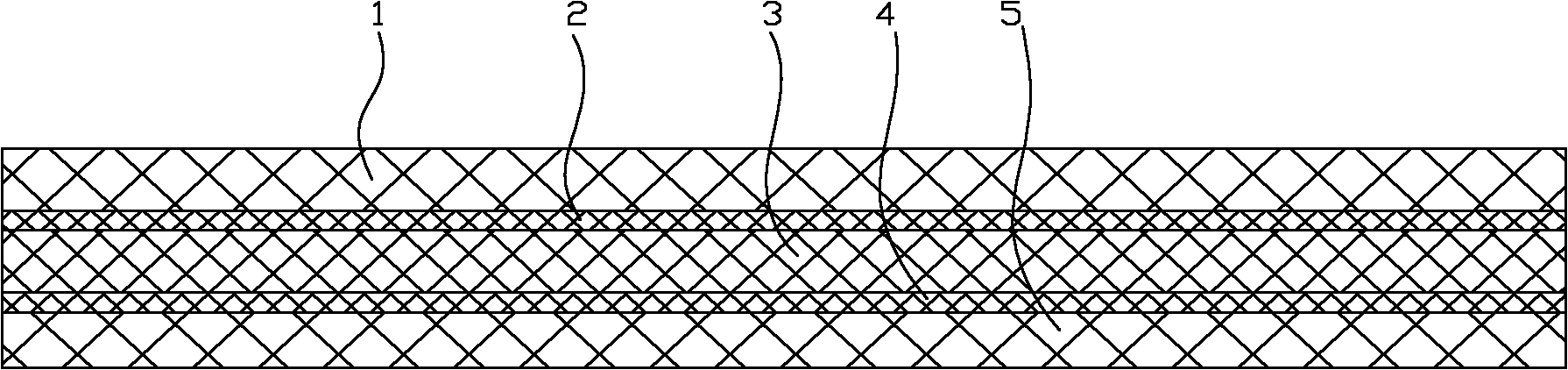

Novel reinforced composite paper

InactiveCN101974870AStrong toughnessStrong production efficiencySpecial paperPaper/cardboardPolyesterPolyvinyl chloride

The invention discloses novel reinforced composite paper. A layer structure of the novel reinforced composite paper comprises an upper paper layer, a polypropylene and polyethylene fusing and bonding layer, a PET (Polyester) or OPP (Oriented Polypropylene) or PVC (Polyvinyl Chloride) or plastic woven cloth enhanced layer, a polypropylene and polyethylene fusing and bonding layer and a lower paper layer. The invention can solve the technical problems of poor obdurability, moisture and water proofing, and the like of the traditional paper.

Owner:丘国慈

Light-steel house spray-building type bark-like wall paint

The invention discloses light-steel house spray-building type bark-like wall paint. The light-steel house spray-building type bark-like wall paint is prepared from 30-40 parts by weight of shell powder, 20-30 parts by weight of acrylic floor paint, 10-15 parts by weight of diatom mud, 5-10 parts by weight of plant fibers, 10-15 parts by weight of gypsum, 1-5 parts by weight of a pigment, 7-15 parts by weight of glue and 1-3 parts by weight of additives. The light-steel house spray-building type bark-like wall paint has composite colors, three-dimensional texture, luxurious and elegant decorative effects, realistic bark imitation effects and natural, beautiful and decent texture, can be used for imitation of various patterns of the bark, has strong moisture-proof, waterproof, fire-proof, mildew-proof and alkali-resistant functions, is environmentally friendly, does not contain any toxic or harmful substances after testing, does not influence the human health and realizes direct use after spraying.

Owner:黎金莲

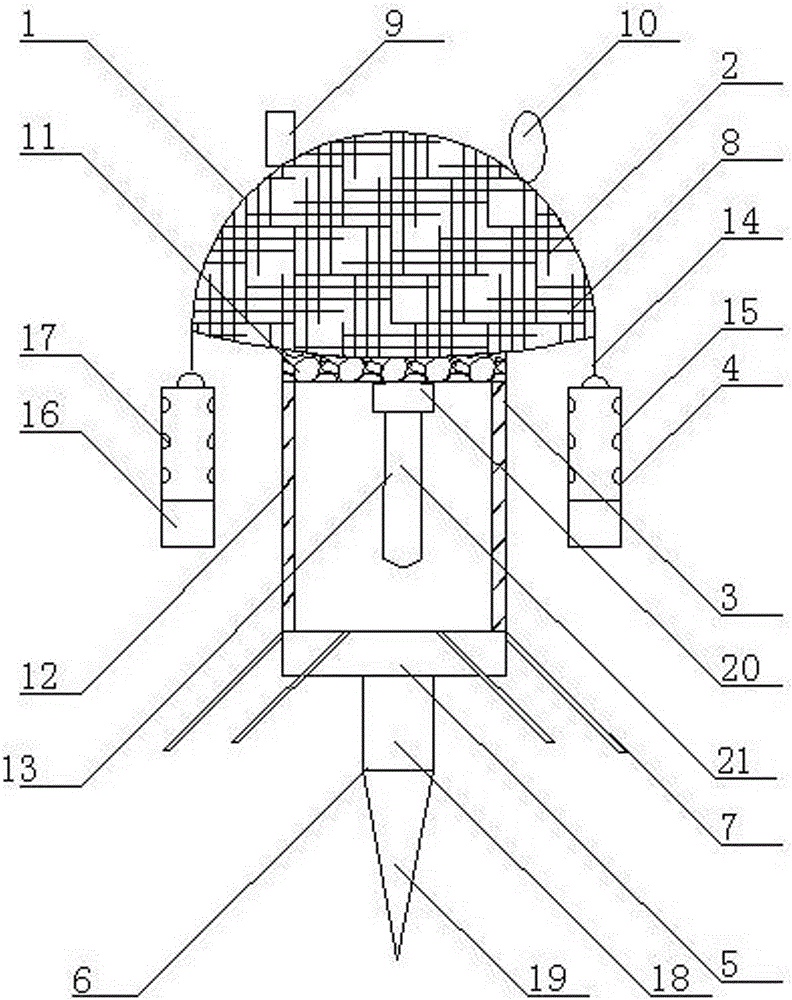

Novel disinfestation lamp

The invention provides a novel disinfestation lamp. The novel disinfestation lamp comprises a lamp body, wherein a top cover is arranged at the top of the lamp body; a disinfestation device is arranged in the middle of the bottom end of the top cover; insect luring devices are arranged on the left and right sides of the bottom end of the top cover; an insect receiving box is arranged at the lower end of the disinfestation device; a bracket is arranged at the bottom end of the insect receiving box; a plurality of supporting plates are arranged on the outer side of the insect receiving box in the peripheral direction. The novel disinfestation lamp provided by the invention has relatively good disinfestation effect on winged insects and peptile insects and a high automation degree, and is simple and convenient to use; meanwhile, the novel disinfestation lamp is powered by solar energy so that high efficiency, energy saving and environmental friendliness are realized.

Owner:哈尔滨尼亚农业有限公司

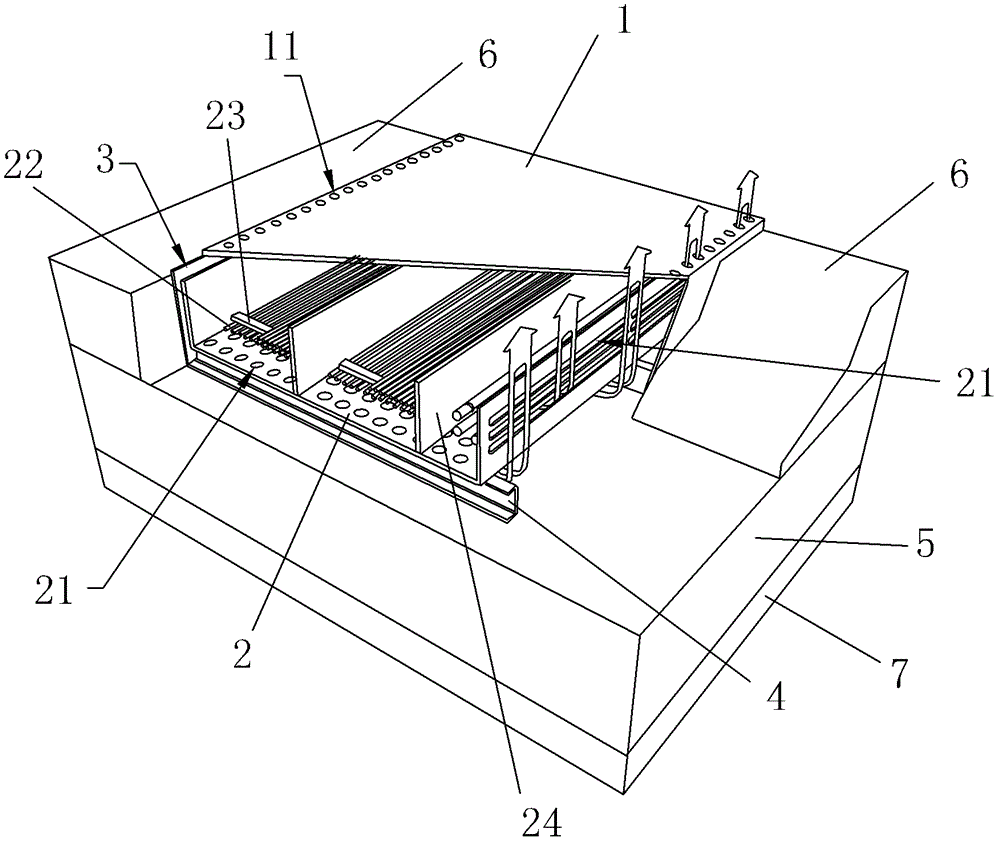

Transformer substation assembled type cable groove body and cable channel system thereof

InactiveCN102593781BMoisture-proof and waterproofDischarge in timeCable installations on groundWater vaporTransformer

The invention relates to a transformer substation assembled type cable groove body and a cable channel system thereof. The transformer substation assembled type cable groove body is formed by connecting waterproof groove bodies with a U-shaped cross section in sequence, and is characterized in that: a U-shaped moisture-proof supporting body is arranged in an inner cavity of each U-shaped groove body; and the U-shaped groove bodies are oppositely buckled with the U-shaped moisture-proof supporting bodies, and a cable paving channel is formed between the U-shaped groove bodies and the U-shaped moisture-proof supporting bodies. The cable channel system applying the transformer substation assembled type cable groove body comprises a base body, wherein the transformer substation assembled type cable groove body is arranged on the base body; and the base body comprises a soil filled layer and a water filtering layer arranged on the soil filled layer. The transformer substation assembled type cable groove body and the cable channel system using the same, provided by the invention, have the outstanding substantive characteristics as follows: the U-shaped groove bodies are oppositely buckled with the U-shaped moisture-proof supporting bodies, so that the cable paving channel has moisture-proof and waterproof effects; and supporting rods, moisture-proof separating bars, top air vents or ventilating grooves, middle air vents or ventilating grooves and the like are arranged, so that water, such as water vapor in the cable paving channel, can be discharged in time.

Owner:国网浙江省电力公司电动汽车服务分公司 +1

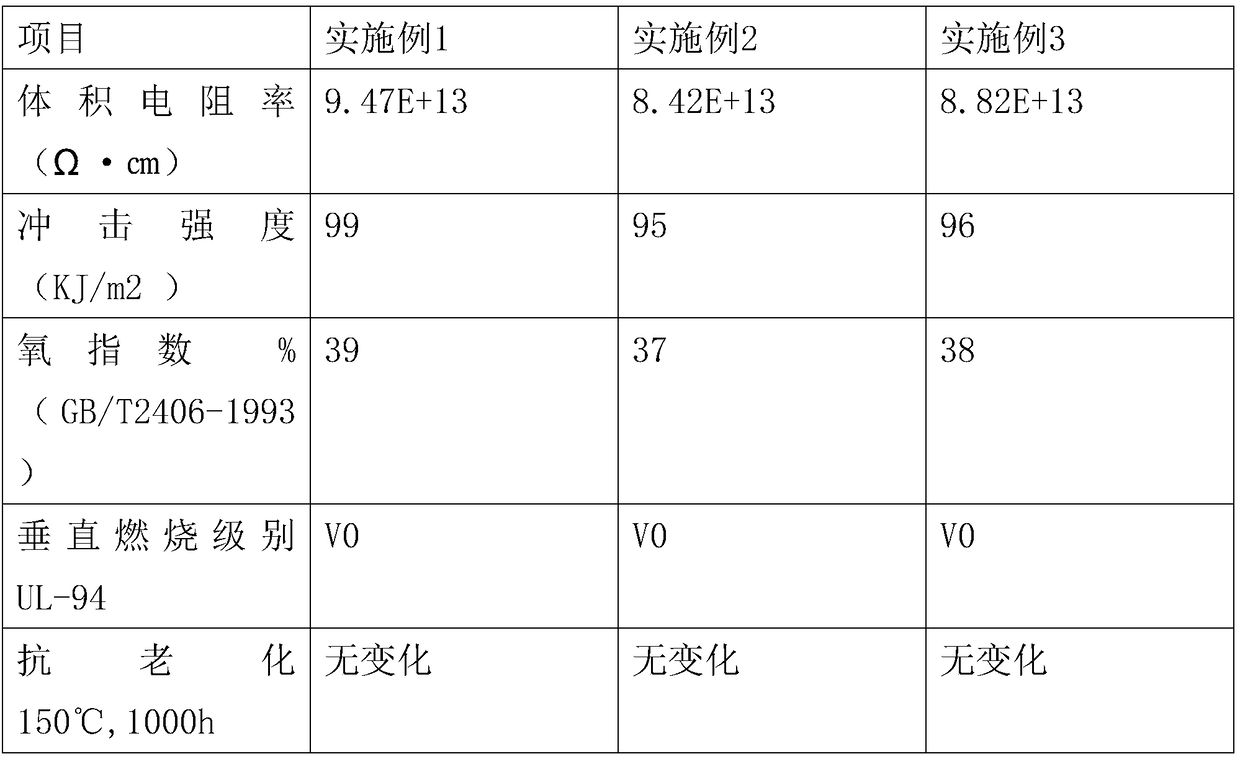

Flame-retardant and high-temperature composite plastic for resistor shell

The invention relates to flame-retardant and high-temperature composite plastic for a resistor shell. The composite plastic comprises the following components in parts by weight: 50-60 parts of polybutadiene rubber, 40-50 parts of vinylidene fluoride, 15-20 parts of trichloroethylene, 15-20 parts of polyamide resin, 15-20 parts of bisphenol A type epoxy resin, 10-15 parts of polycarbonate, 8-12 parts of polytetrafluoroethylene, 10-15 parts of magnesium hydroxide, 3-5 parts of mullite powder, 2-5 parts of graphite powder and 0.5-1.5 parts of an antioxidant. By virtue of a reasonable formula andproportion, the components are supplemented with each other to generate a synergistic effect, so that the composite plastic has the characteristics of high strength, good insulativity, good flame retardance, high heat dissipation speed, good high temperature resistance, strong ageing resistance and low cost, and the service life of a product is prolonged; and the preparation method is simple andlow in production cost.

Owner:安徽来福电子科技有限公司

An atrium barrage handrail structure and installation process with hidden lights

ActiveCN106150005BReduce weightImprove general performanceStairway-like structuresKeelFire resistance

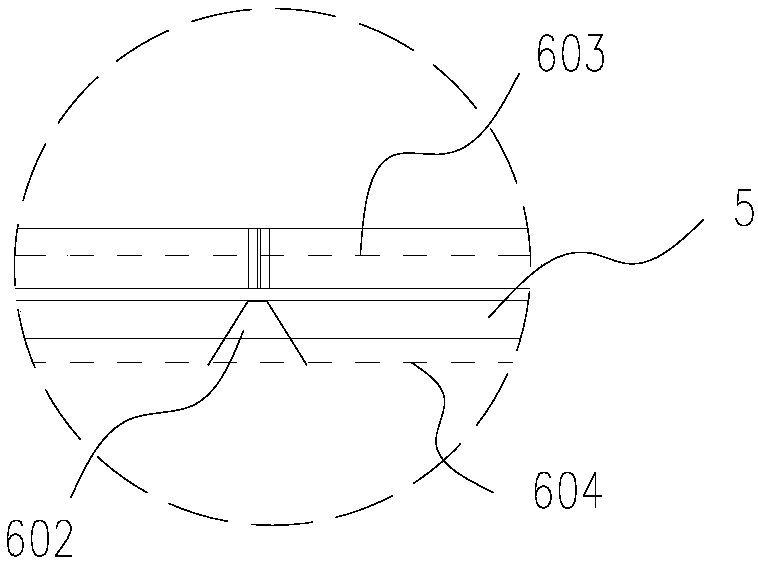

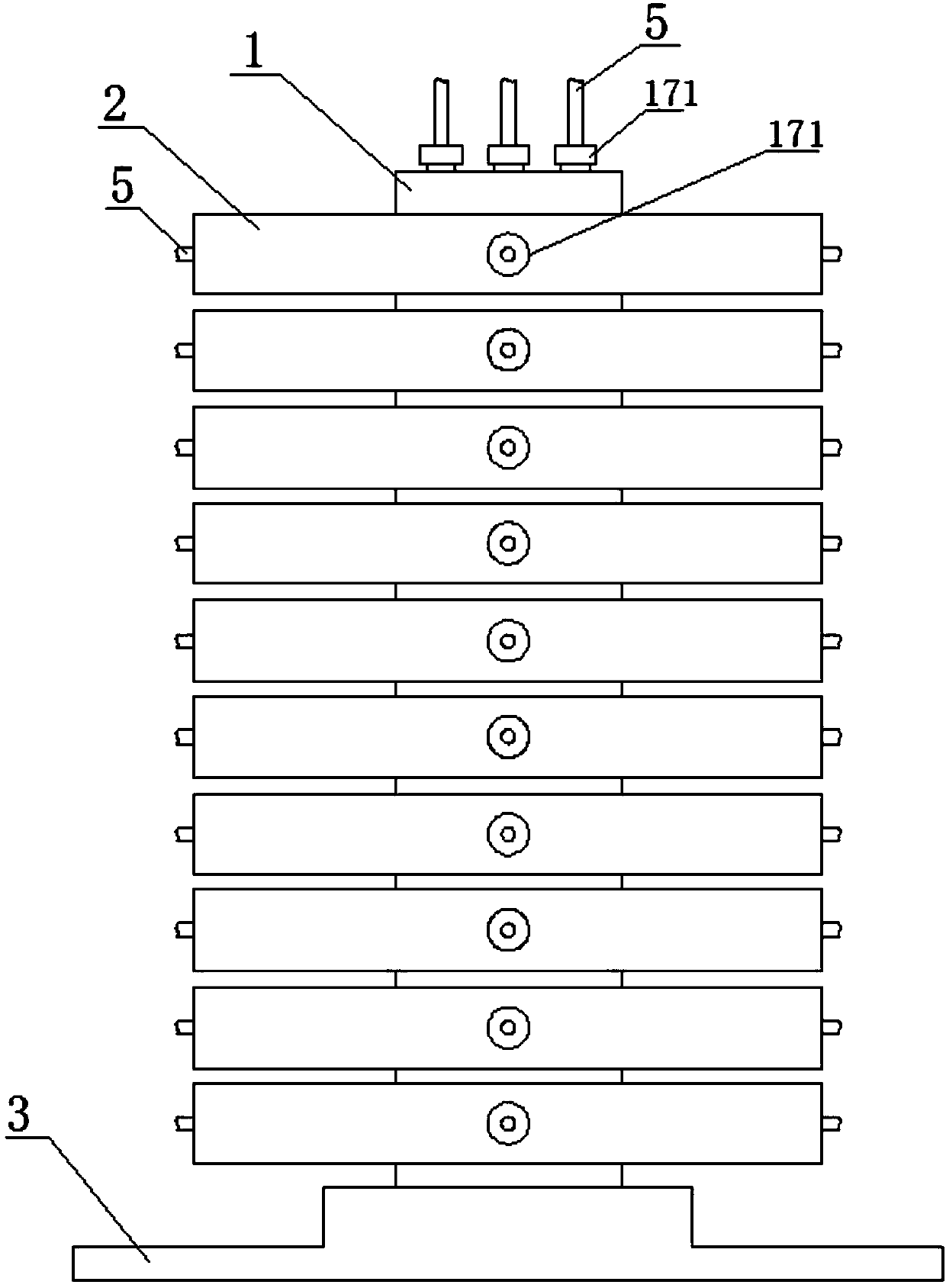

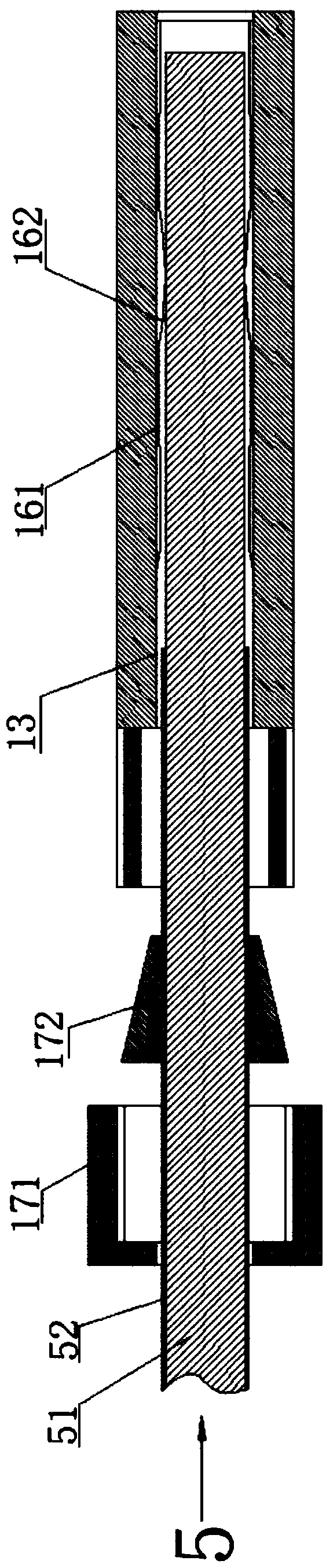

An atrium barrier handrail structure with a hidden lamplight, comprising a main skeleton (1) fixedly installed on a floor concrete layer, a secondary skeleton (2) and a covering keel (3) which are fixedly installed on the main skeleton (1), a base layer plate (4) fixedly installed on the covering keel (3), a handrail (5) fixedly installed at the top of the base layer plate (4), and lights (6) hidden in the base layer plate (4) and / or in the handrail (5), the main skeleton (1) and the secondary skeleton (2) both being steel skeletons. An installation process for an atrium barrier handrail structure with a hidden lamplight. The handrail structure has light weight, simple construction, and good decorative effect.

Owner:SHENZHEN ASIANTIME INTIAONAL CONSTR CO LTD

A bamboo-shaped free-steering junction box

ActiveCN107069611BExtended service lifeMoisture-proof and waterproofCouplings bases/casesFree rotationEngineering

The present invention relates to a bamboo-shaped free turning junction box. The bamboo-shaped free turning junction box comprises an insulated center cylinder and a plurality of outer cylinders rotationally sleeving on the center cylinder in order; three first raised lines are arranged at the outer portion of the center cylinder along the axis direction; the three first raised lines perform equal division of the outer circumference of the center cylinder; the outer surface of the center cylinder between two adjacent first raised lines is provided with arc first conducting strips; three second raised lines are arranged at the inner circles of the outer cylinders; the three second raised lines perform equal division of the circumference of the inner circles of the outer cylinders; the second raised lines are coated with second conducting strips; the second conducting strips are in respective sliding electrical contact with the first conducting strips; the center cylinder is provided with a main firing line hole, a main null line hole and a main ground wire hole along the axis direction; and the outer cylinders comprise branch firing line holes, branch null line holes and branch wire holes along the radial direction of the outer cylinders. The bamboo-shaped free turning junction box can allow each branching to have a free rotation angle approach to 120 degrees to facilitate wiring, and has moistureproof, waterproof and convenient dismounting and mounting, and the service life of the wire is long.

Owner:福建永坤电力设备有限公司

A kind of preparation method of decorative painting of thousand-layer carved ceramic plate

Owner:MONALISA GRP CO LTD

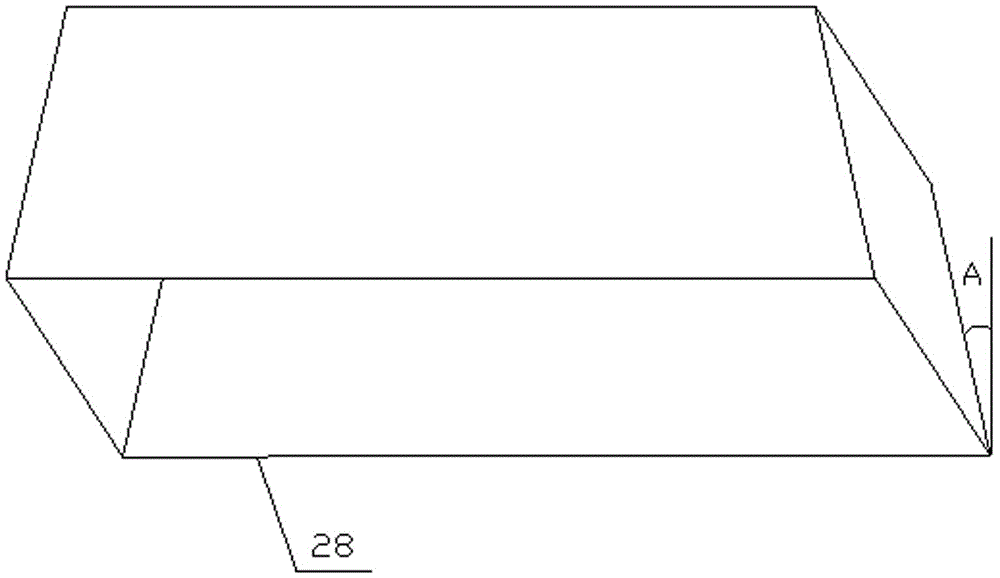

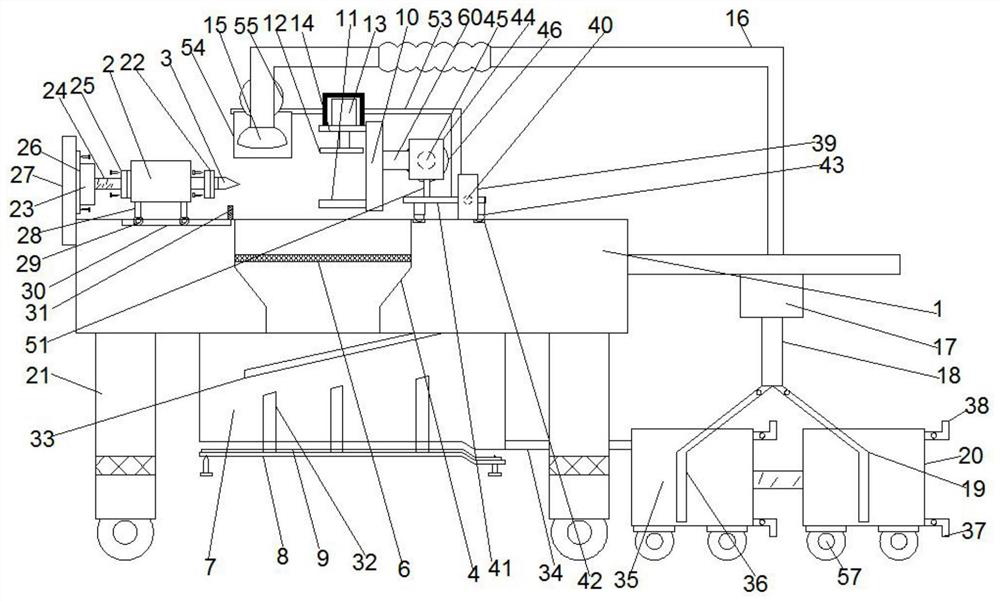

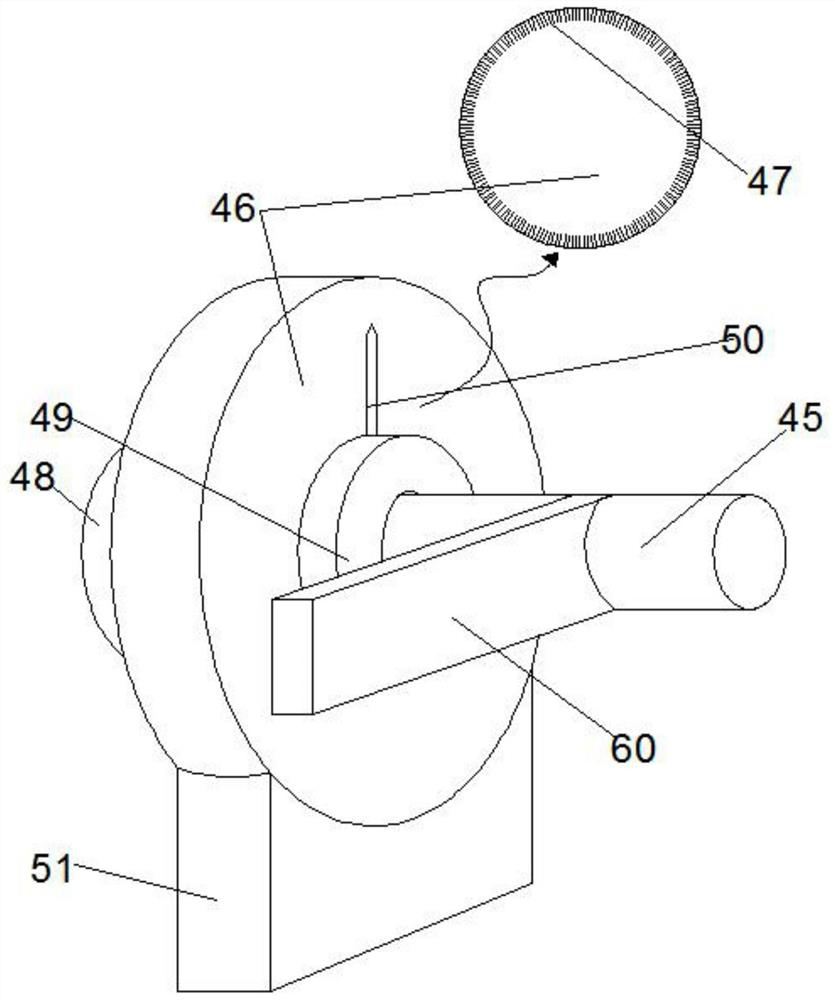

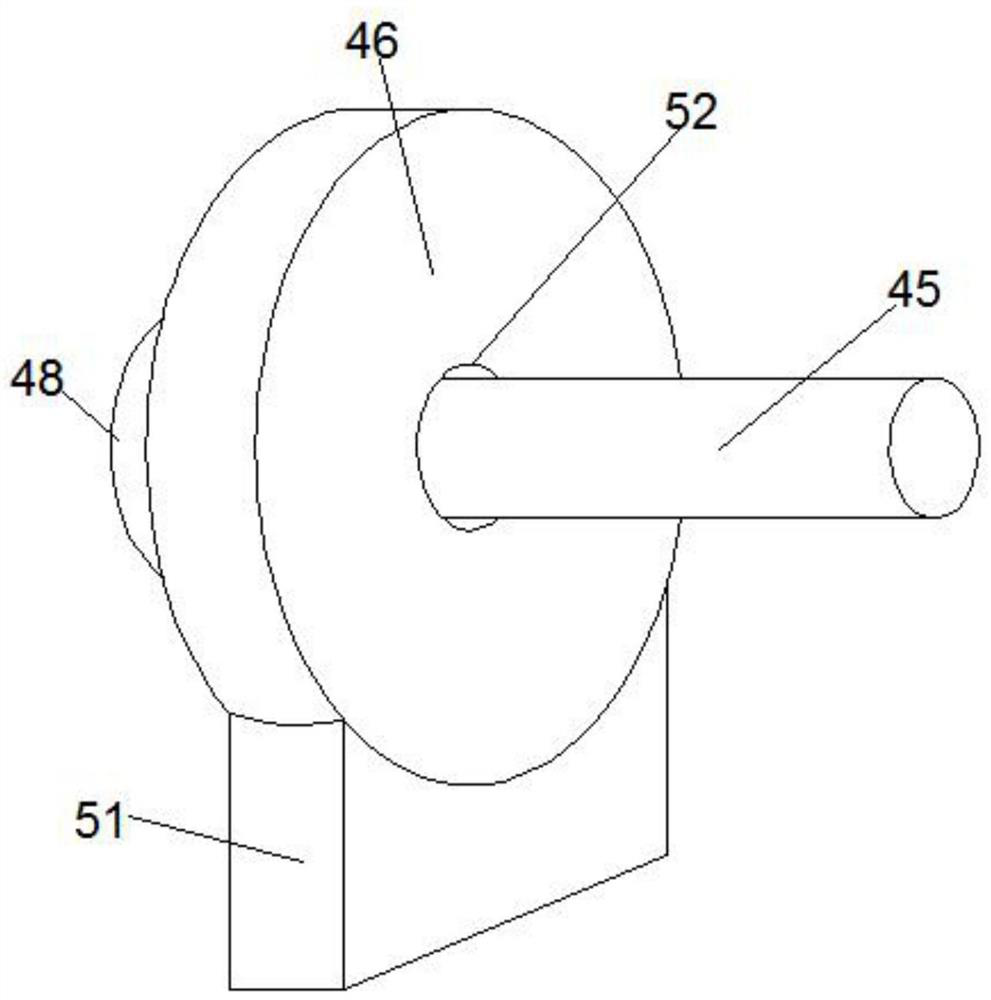

Multi-material structure of luggage case

InactiveCN108634513AEasy to completeImprove structural strengthLuggageCompression moldingMulti material

The invention discloses a multi-material structure of a luggage case. A process comprises the following steps that S1, a cutting sample plate and a processing sample plate are formed, wherein the cutting sample plate is mainly used as the mold for large-batch cutting, and is used for material discharging, material cutting, laying-down and the like, the cutting sample plate is basically a rough sample, the processing sample plate is mainly used for realizing correcting, positioning, sizing, quantifying and the like on semi-finished products during the sewing process; S2, for a shell fabric of acase shell, the material is ABS+PC resin, the devices adopted comprise an extruding machine (with a post film pressing device), a vacuum hotpressing forming machine and an edge trimmer, the forming process is as follows: a composite board is laminated through extruding and hot-pressing, the board is cut, compression molding is carried out, and edge trimming aftertreatment is carried out. Comparedwith the prior art, the technical scheme provided by the invention has the advantages that the structure is simple, the manufacturing is easy, the control is convenient, the needed movements can be well completed, the efficiency is high, the positioning is accurate, various materials are matched for use, so that the structural strength of the luggage case can be increased, thus the luggage case can bear the external pressure, and in addition, the luggage case also has the damp-proofing and water-proofing functions.

Owner:AIMEIDE JIAXING TOURIST ARTICLES

Colored sand-mud painting material as well as preparation method and application thereof

InactiveCN110525111AExtended shelf lifePrevent immersionDispersed particle separationSpecial ornamental structuresMucous membraneMaterials science

The invention discloses a colored sand-mud painting material as well as a preparation method and an application thereof. The colored sand-mud painting material comprises the following raw materials inparts by weight: 500-1000 parts of colored sand, 30-60 parts of plant mucous membranes, 20-40 parts of a waterproof agent and 10-30 parts of an adsorbent. The preparation method of the colored sand-mud painting comprises the following steps: adding water into a waterproof agent for dissolving to prepare a waterproof solution, uniformly spraying the waterproof solution on colored sand, and then drying the colored sand; and uniformly mixing the dried colored sand with the plant mucous membrane and the adsorbent to obtain the material for the colored sand-mud painting. The material for the colored sand-mud painting can be applied to drawing of the sand-mud painting, glass subjected to high-temperature treatment is used as a sand painting plate, and the material for the colored sand-mud painting is used for sand painting creation; after the sand painting is finished, drying and fixing the sand painting plate for bearing the sand painting; and drawing the muddy water on the sand painting by using a pen, drying and cooling to obtain the colored sand painting. The colored sand-mud painting prepared by the invention has the characteristics of being variable in color, waterproof, environment-friendly and long in storage life.

Owner:HUNAN UNIV OF TECH

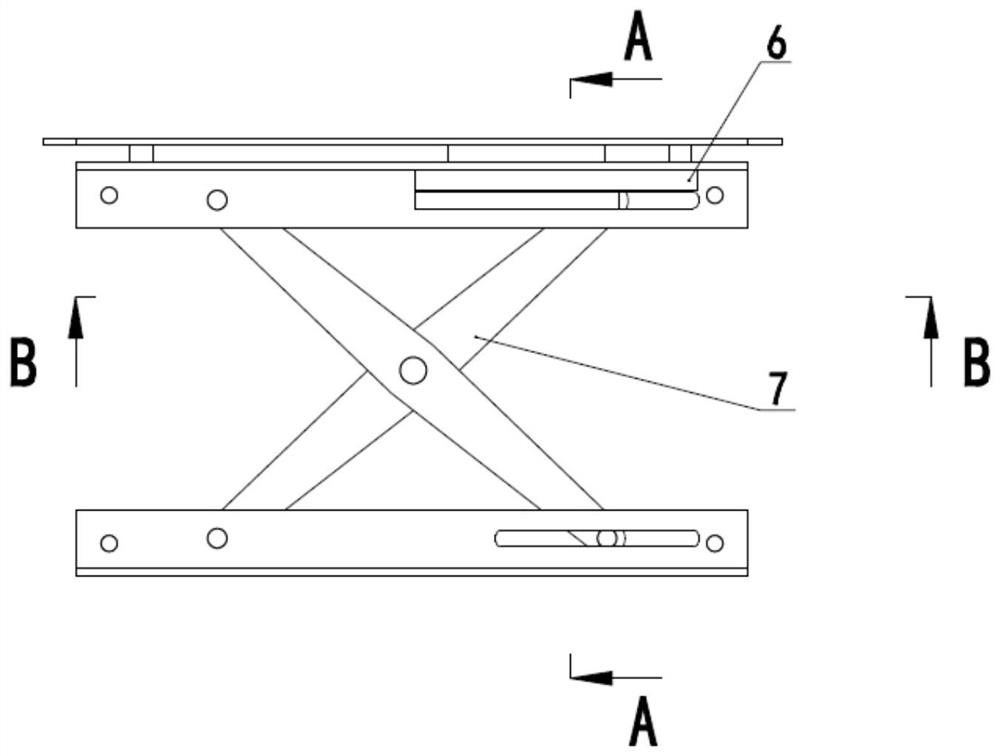

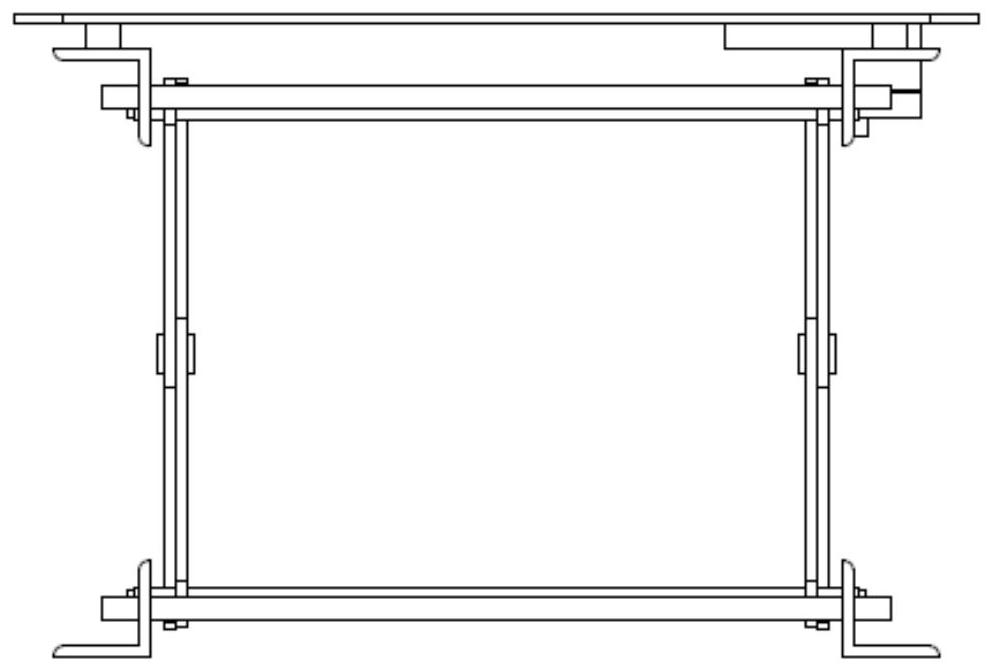

Mechanical lifting platform device convenient to operate and high in reliability

The invention discloses a mechanical lifting platform device convenient to operate and high in reliability. The mechanical lifting platform device comprises a handle (1), a platform cover plate (2), support cross beams (3), shear fork cross beams (4), angle steel supports (5), a fixing block (6), shear fork beams (7), a limiting pin (8), a spring (9) and a locking limiting block (10). The four upper and lower angle steel supports (5), the four front and rear support cross beams (3) and the platform cover plate (2) form a basic frame, and the four left and right shear fork beams (7) and the shear fork cross beams (4) form a movable lifting mechanism of the mechanical lifting platform device convenient to operate and high in reliability. The handle (1) is connected with the limiting pin (8) through a plug pin, the spring (9) is located in the fixing block (6), and the handle (1) drives the limiting pin (8) to compress the spring (9) to move between the fixing block (6) and the locking limiting block (10) to form a locking mechanism. The mechanical lifting platform device convenient to operate and high in reliability is simple in structure, convenient to operate, free of electrical components, high in moisture-proof and waterproof capability, and greatly improved in reliability and maintainability.

Owner:CHONGQING WANGJIANG IND

Special chemical fertilizer for gardens

InactiveCN106883014APromote growthMeeting nutritional needsCalcareous fertilisersMagnesium fertilisersManganesePotassium

The invention relates to the technical field of chemical fertilizers for garden cultivation, and discloses a special chemical fertilizer for gardens. The special chemical fertilizer is prepared from the following components of calcium, potassium, zinc, iron, magnesium, copper, manganese, cobalt, iodine, selenium, molybdenum, chromium, peptone, urea, an anti-caking agent, and water. The special chemical fertilizer has the advantages that the formula is reasonable; in combination with nutritional value of organic protein fertilizer and metal elements, the plant growth is promoted, the nutrient requirement of plant growth in each phase is met, the quality and survival rate of the plant are improved, the utilization rate of nutrients by the plant is improved, the fertility is improved, the easiness in caking of the prepared chemical fertilizer is avoided, and the growth of a harmful bacterial colony is inhibited. A preparation method has the advantages that the preparation method is simple, the fertilizer applying is convenient, the application range is wide, and the effect is obvious.

Owner:新昌县天姥园艺发展有限公司

A kind of preparation method of color-carved ceramic plate decorative painting

The invention relates to a preparation method of a ceramic plate decorative painting through colored engraving. The method comprises the following steps: 1), a protective film is attached to the surface of a ceramic plate; 2), sidelines of a specified figure are engraved on the surface of the ceramic plate by a laser engraving machine; 3), the protective film at a to-be-etched part is removed so as to expose an engraving surface; 4), the surface of the ceramic plate is eroded by an abrasive material at a high flow rate, so that an uncolored solid figure is formed through engraving on the ceramic surface with the protective film removed, the pressure is 1-10 kg / m<3>, and the flow is 5-20 m<3> / min; 5), sand blasting is at least performed on a to-be-colored part of the surface of the ceramic plate so as to at least remove a glaze layer of the to-be-colored part and form a frosted surface, the sand blasting pressure is 1-10 kg / m<3>, and the flow is 5-20 m<3> / min; 6), the frosted surface of the ceramic plate prepared in the step 5) is cleaned and dried, a pattern is spray-printed and drawn, and a protective glaze layer is spray-printed; 7), the ceramic plate prepared in the step 6) is sintered rapidly.

Owner:MONALISA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com