Flame-retardant and high-temperature composite plastic for resistor shell

A technology of composite plastics and resistors, applied in the coating and other directions, can solve the problems of extremely strict structural requirements, complex glaze production process and high production cost, and achieve the effects of low production cost, simple preparation method and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

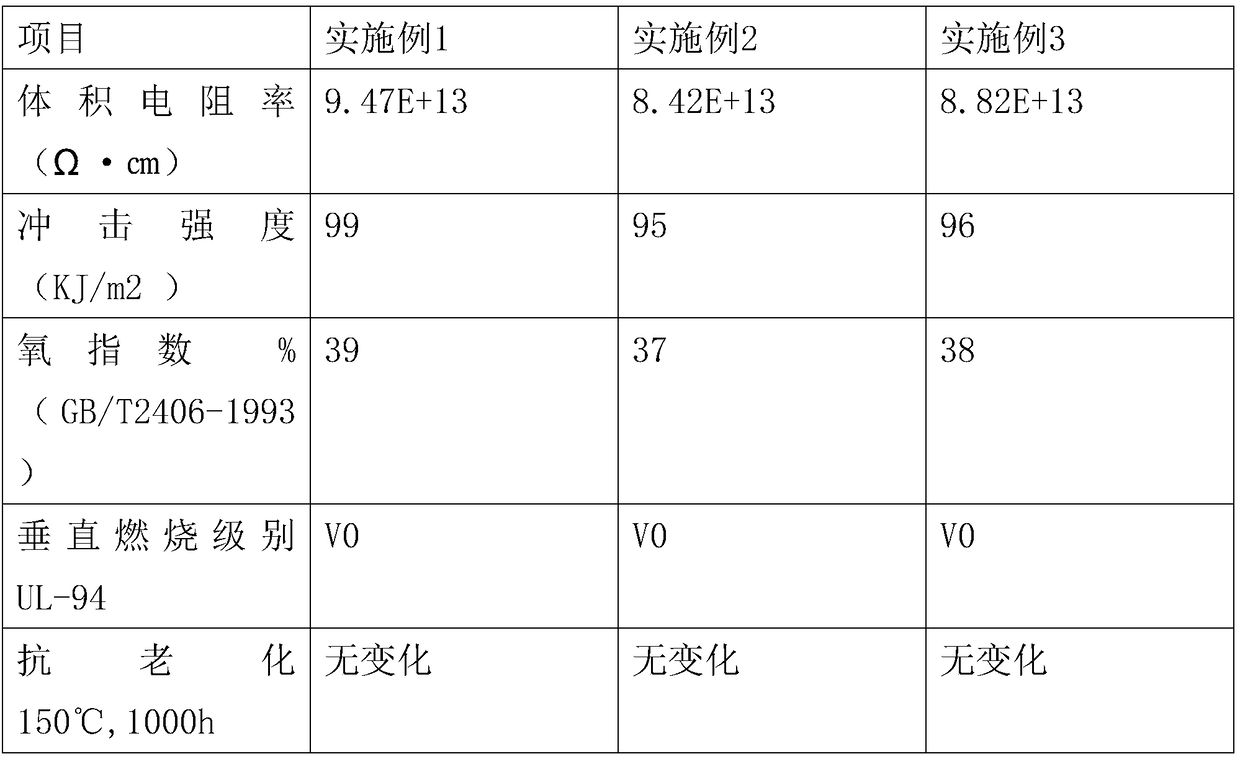

Examples

Embodiment 1

[0019] A flame-retardant and high-temperature-resistant composite plastic for resistor shells, which consists of the following components according to weight ratio: polybutadiene rubber 50kg, vinylidene fluoride 40kg, trichloroethylene 15kg, polyamide resin 15kg, bisphenol A type 15kg of epoxy resin, 10kg of polycarbonate, 8kg of polytetrafluoroethylene, 10kg of magnesium hydroxide, 3kg of mullite powder, 2kg of graphite powder, 0.5kg of antioxidant;

[0020] A method for preparing a flame-retardant and high-temperature-resistant composite plastic for a resistor housing, comprising the following steps:

[0021] a. Set the temperature of the reactor to 220°C, take 50kg of polybutadiene rubber, 40kg of vinylidene fluoride, 15kg of trichloroethylene, 15kg of polyamide resin, and 8kg of polytetrafluoroethylene, and put the above ingredients into the reactor evenly , stirring at high temperature under the protection of nitrogen until uniform;

[0022] b. Take 15kg of bisphenol A e...

Embodiment 2

[0028] A flame-retardant and high-temperature-resistant composite plastic for resistor shells, which consists of the following components according to weight ratio: 60kg of polybutadiene rubber, 50kg of vinylidene fluoride, 20kg of trichlorethylene, 20kg of polyamide resin, bisphenol A type Epoxy resin 20kg, polycarbonate 15kg, polytetrafluoroethylene 12kg, magnesium hydroxide 15kg, mullite powder 5kg, graphite powder 5kg, antioxidant 1.5kg;

[0029] A method for preparing a flame-retardant and high-temperature-resistant composite plastic for a resistor housing, comprising the following steps:

[0030] a. Set the temperature of the reactor to 250°C, take 60kg of polybutadiene rubber, 50kg of vinylidene fluoride, 20kg of trichloroethylene, 20kg of polyamide resin, and 12kg of polytetrafluoroethylene, and put the above ingredients into the reactor evenly , stirring at high temperature under the protection of nitrogen until uniform;

[0031] b. Take 20kg of bisphenol A type epox...

Embodiment 3

[0037] A flame-retardant and high-temperature-resistant composite plastic for resistor shells, which consists of the following components according to weight ratio: polybutadiene rubber 55kg, vinylidene fluoride 45kg, trichlorethylene 16kg, polyamide resin 16kg, bisphenol A type 16kg of epoxy resin, 12kg of polycarbonate, 10kg of polytetrafluoroethylene, 12kg of magnesium hydroxide, 4kg of mullite powder, 4kg of graphite powder, 1kg of antioxidant;

[0038] A method for preparing a flame-retardant and high-temperature-resistant composite plastic for a resistor housing, comprising the following steps:

[0039] a. Set the temperature of the reactor to 240°C, take 55kg of polybutadiene rubber, 45kg of vinylidene fluoride, 15-20 parts of trichloroethylene, 16kg of polyamide resin, and 10kg of polytetrafluoroethylene, and put the above ingredients evenly In the reaction kettle, under the protection of nitrogen, carry out high-temperature stirring, and stir until uniform;

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com