Composite decorative sheet

A decorative board and surface decoration technology, which is applied in the field of building decoration materials, can solve problems such as poor bonding performance, uneven glue application, and complexity, and achieve the effects of wear resistance, moisture resistance, water resistance, wood resource saving, and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments, but not intended to limit the present invention.

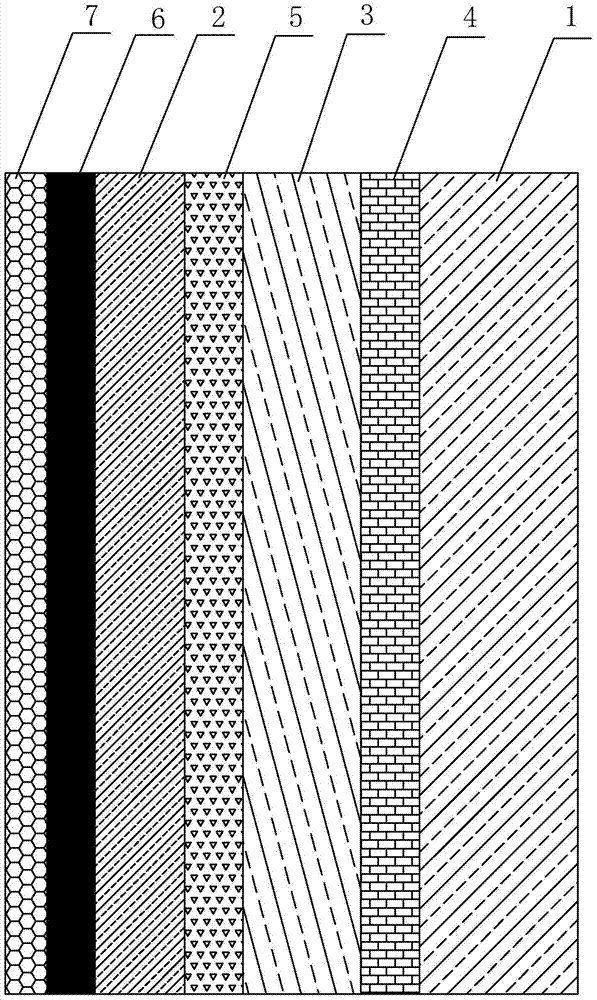

[0017] Such as figure 1 As shown, a composite decorative board includes a substrate 1, a surface decoration layer 2 and a surface layer 3 arranged between the substrate 1 and the surface decoration layer 2, and a waterproof coating is coated between the surface layer 3 and the substrate 1 4. A protective layer 5 is coated between the surface layer 3 and the surface decoration layer 2, the substrate 1 is a polyurethane foam board, and the outer surface of the surface decoration layer 2 is also coated with a flame-retardant and fireproof layer 6.

[0018] In this embodiment, preferably, the surface layer 3 is a metal plate or a fiberboard, the protective layer 5 is a fluorocarbon paint, and a transparent protective film 7 is provided on the surface of the flame-retardant and fire-resistant layer 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com