Furniture assembling plate and furniture producing method

A technology of furniture and flat panels, which is applied in the field of furniture assembly boards and furniture production. It can solve the problems of complicated processing technology, indoor space pollution, time-consuming and labor-intensive, etc., and achieve the effects of simple manufacturing technology, saving wood resources and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

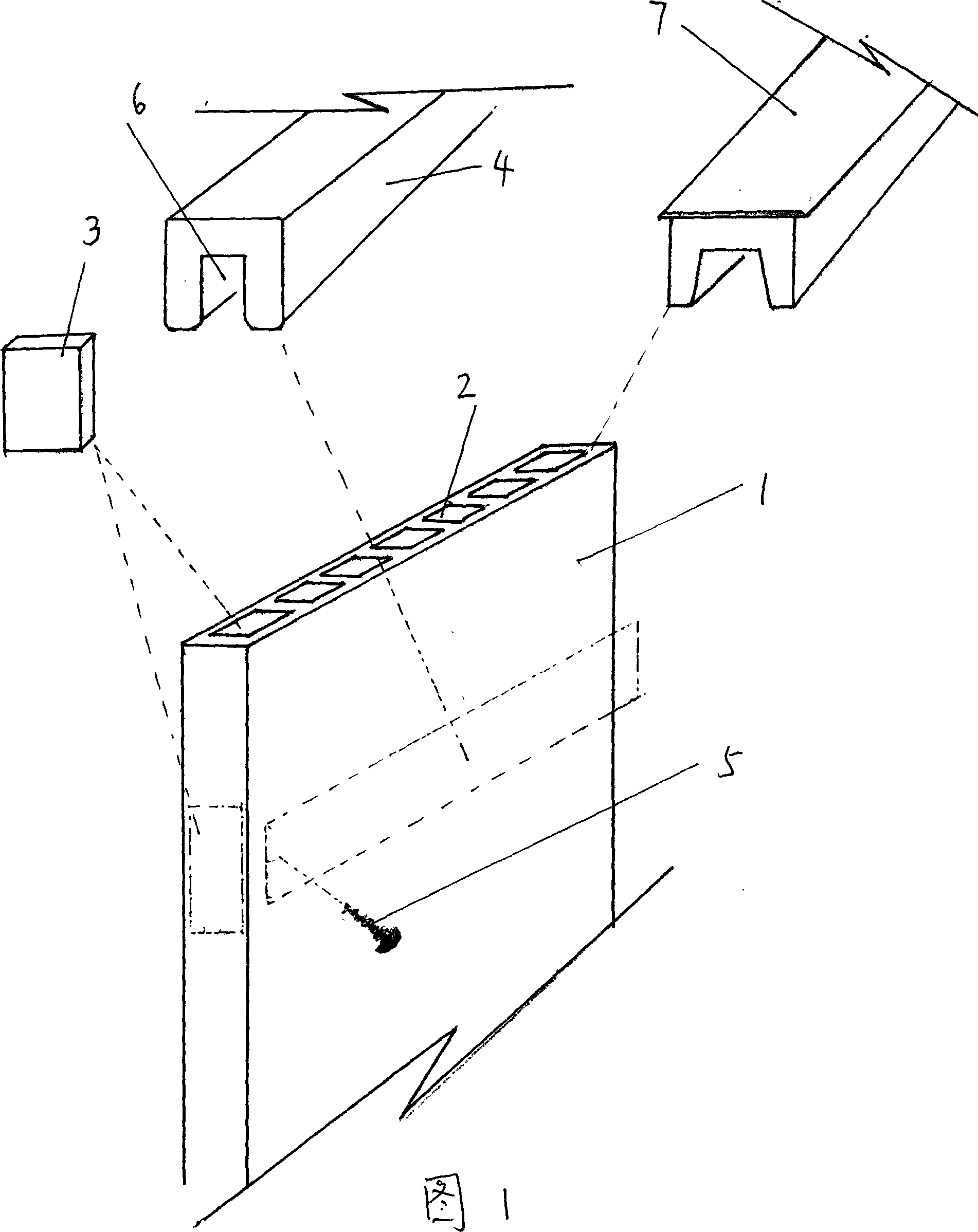

[0021] The present invention will be described in detail below in conjunction with accompanying drawing: As shown in accompanying drawing 1, the present invention comprises a flat plate 1 that a cross section is flat rectangle, is shaped on a plurality of holes 2 adjacently arranged in the described plate 1 and Constitute a hollow profile-like plate.

[0022] The flat plate 1 is a plastic plate, and the holes 2 provided in it are round holes or square holes.

[0023] The flat plate is made of PVC as the main material, and at least the following auxiliary materials are injection molded, and its composition and weight ratio are:

[0024] PVC (SG4-5) 100 parts

[0025] Dibasic lead sulfate 1-3 parts

[0026] Tribasic lead phosphite 3-5 parts

[0027] Lead stearate 0.5-1.5 parts

[0028] Calcium stearate 0.5-1.5 parts

[0029] Active ground calcium carbonate 46-53 parts

[0030] Plasticizer (DOP) 3-5 parts

[0031] Chlorinated polyethylene (CPE) 4-6 parts

[0032] Titanium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com