Extruding forming floor

A technology of extrusion molding and flooring, which is applied in the direction of floors, buildings, building structures, etc., can solve the problems of shortening the service life of the floor, difficult maintenance, and large consumption of wood resources, so as to save wood resources and increase the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

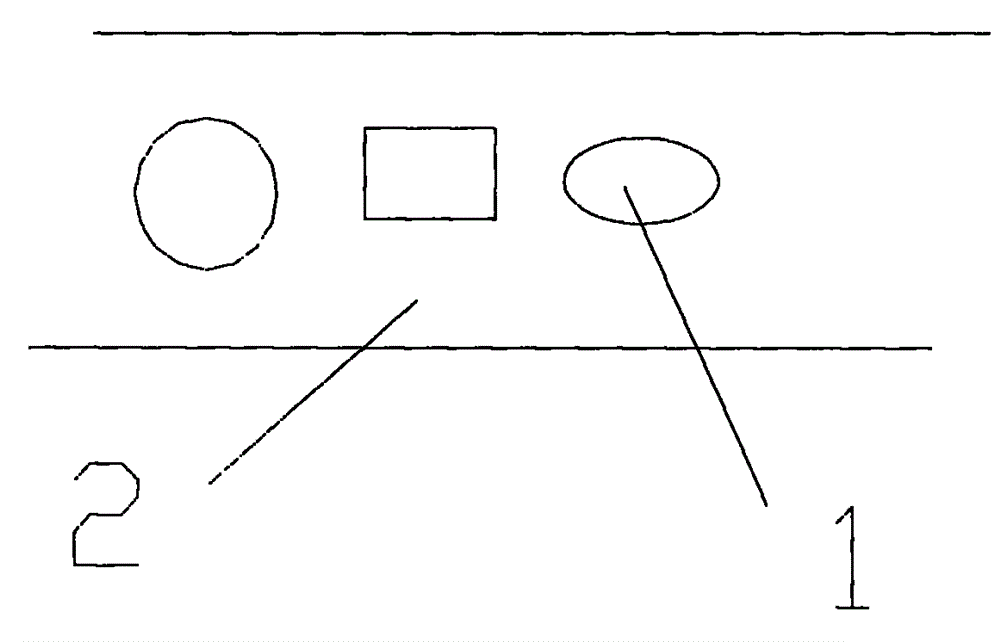

[0012] Such as figure 1 As shown, the present invention is an extruded floor, which includes a floor 2, and longitudinal air holes 1 are arranged inside the floor 2, and the air holes 1 are evenly distributed in the middle section of the body of the floor 2. The number of pores 1 is 6-10, preferably 8. The shape of the air hole 1 is a rectangle, a circle, a polygon, a semicircle or a combination of a circular arc at the top and a rectangle at the bottom.

[0013] The invention saves a large amount of wood resources for producing wooden floors, prevents deterioration and deformation of wooden floors in places with relatively high humidity, and prolongs the service life of the floors.

[0014] The embodiments of the present invention have been described in detail above in conjunction with the accompanying drawings, but the present invention is not limited to the above embodiments, and can also be made without departing from the gist of the present invention within the scope of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com