Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Moderate bulk density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

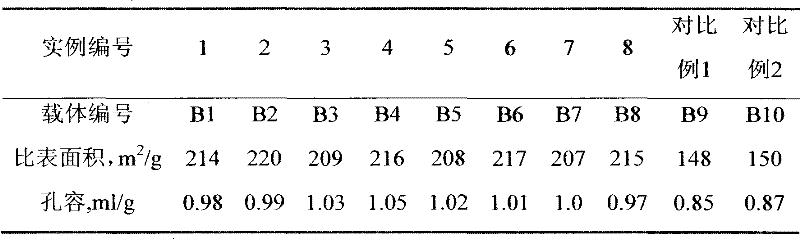

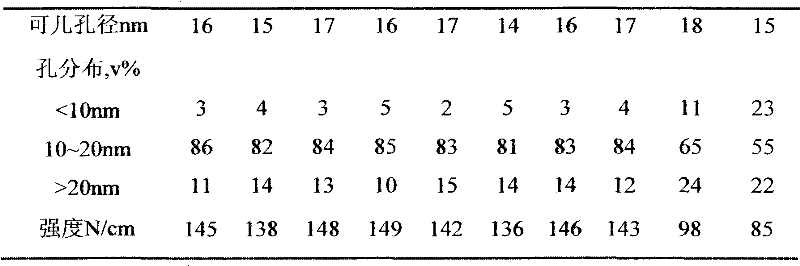

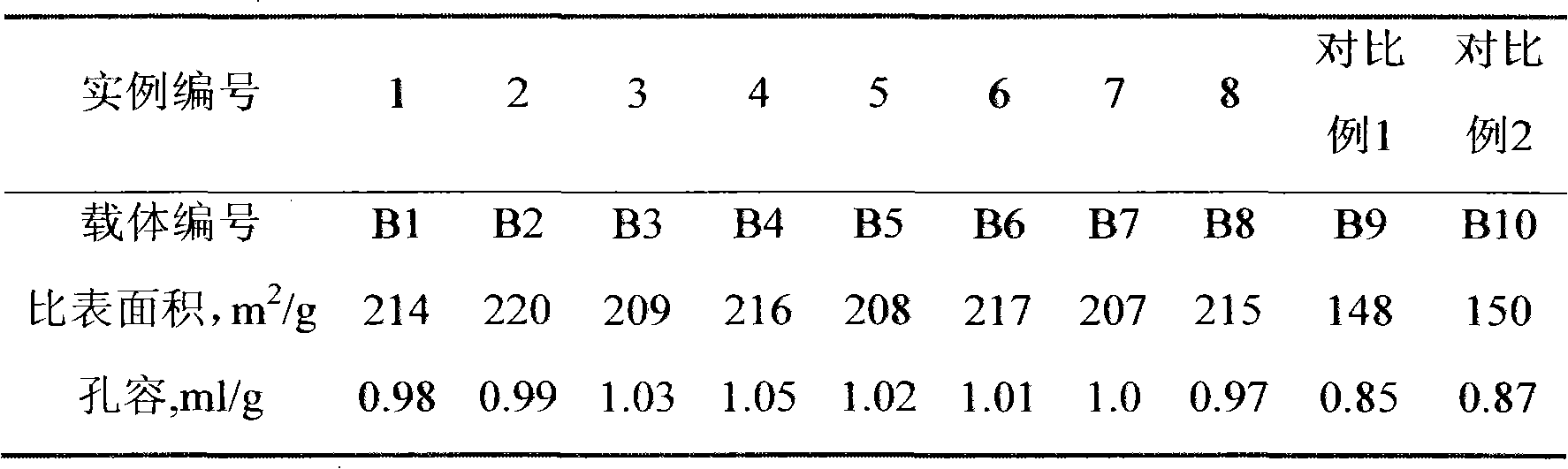

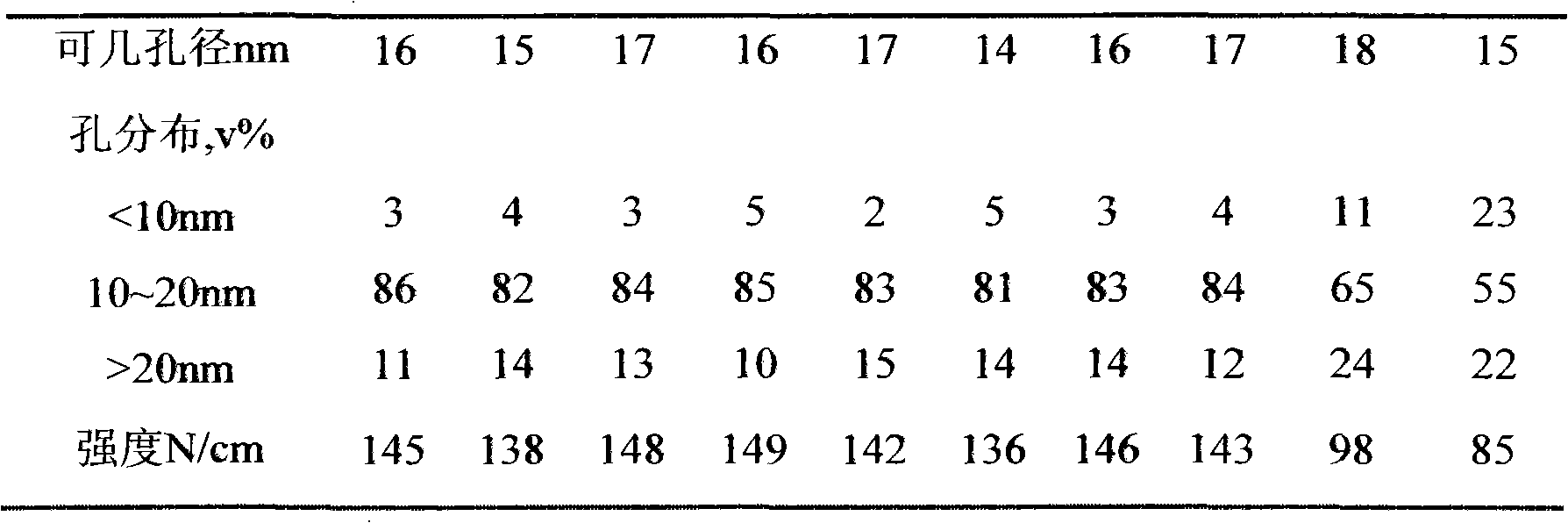

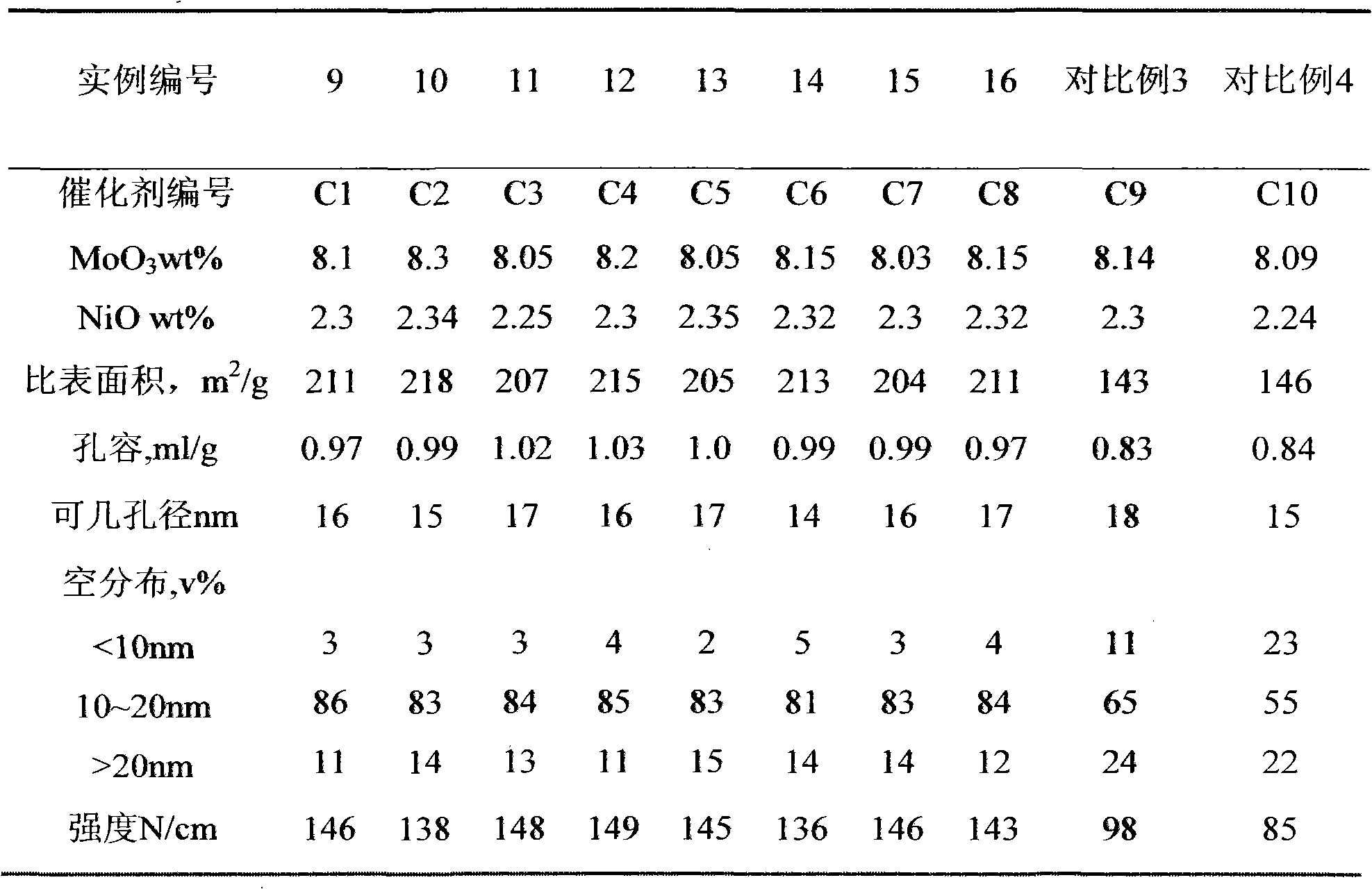

Preparation methods for macroporous alumina carrier and hydrodemetallization catalyst

ActiveCN102441437AModerate mechanical strengthModerate bulk densityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPseudoboehmiteMetal catalyst

The invention discloses preparation methods for a macroporous alumina carrier and a hydrodemetallization catalyst. The preparation method for the macroporous alumina carrier includes the following steps: (1) dry pseudoboehmite gel powder is hydrothermally processed under high pressure; (2) the dry pseudoboehmite gel powder obtained in step 1 is kneaded into a plastic, and pore-expanding agent is added in step 1 or step 2; (3) the plastic obtained in step 2 is shaped, the shaped material is dried and baked, and thereby the macroporous alumina carrier is obtained. The impregnation method is adopted to prepare the hydrodemetallization catalyst. The hydrodemetallization catalyst prepared by the method has large pore volume and pore diameter, centrally distributed pores, moderate mechanical strength and high activity and activity stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

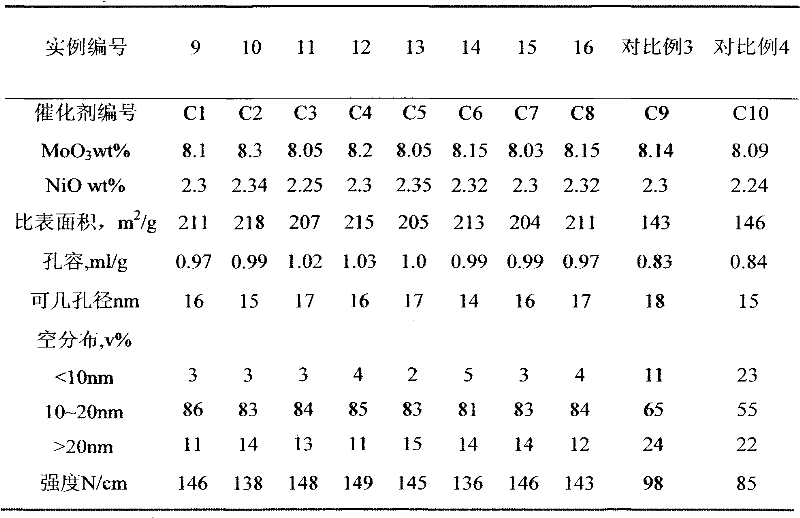

Catalyst component used for vinyl polymerization, preparation method and application

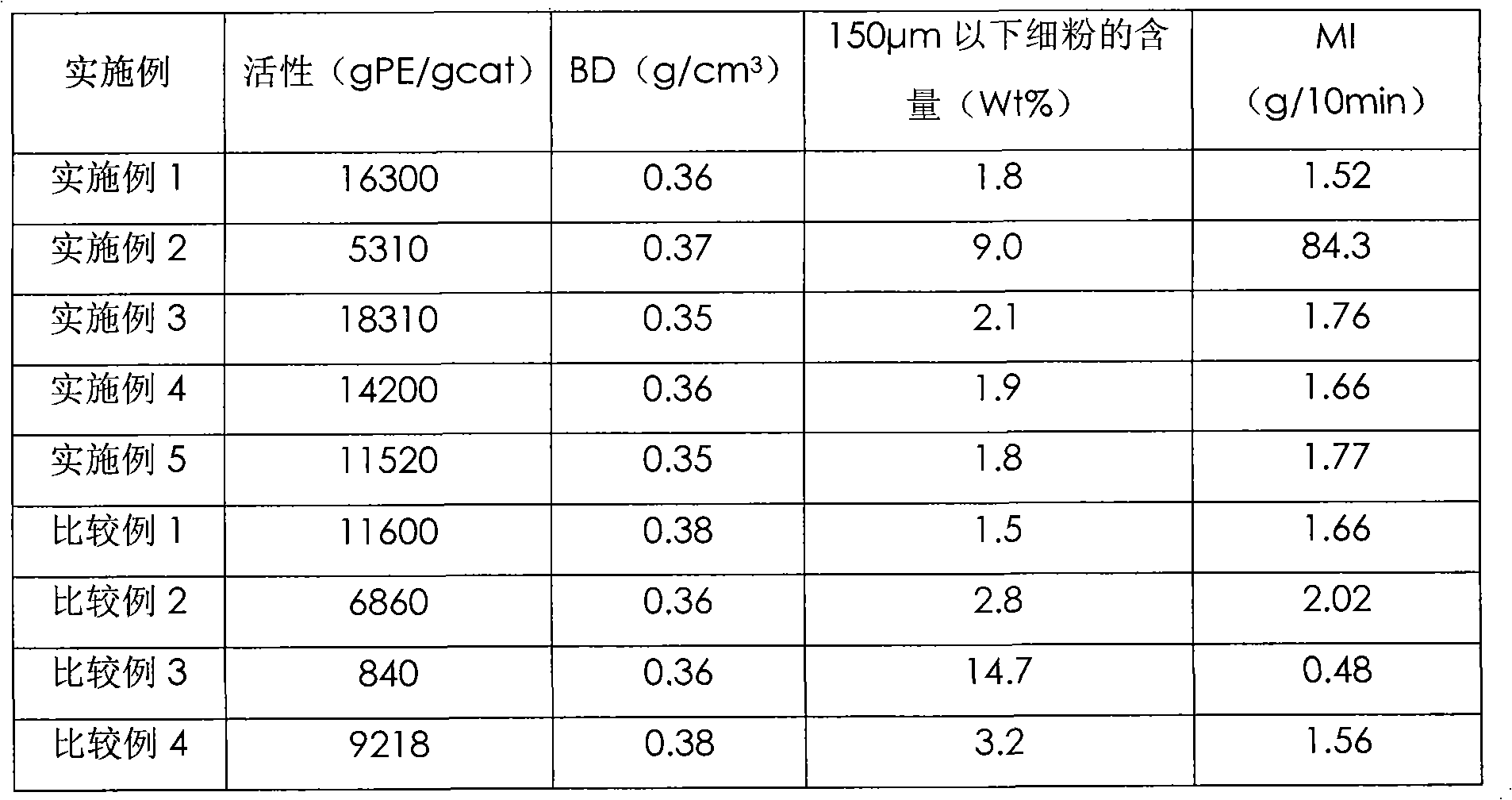

The invention provides a titaniferous solid catalyst component used for vinyl polymerization and a preparation method. The titaniferous solid catalyst component is prepared according to the following three continuous steps: 1) under the existence of halogen or halogen-containing compound, reacting metal magnesium with alcohol, thereby preparing a magnesium-containing solid; 2) utilizing an organic metallic compound or a mixture of the organic metallic compound and an electron donor compound to process the magnesium-containing solid, thereby obtaining a magnesium-containing catalyst carrier; and 3) under the existence of an inert organic solvent, utilizing a compound of transition metal titanium to process the magnesium-containing catalyst carrier, and then utilizing a halogenated alcohol compound to process, thereby obtaining the catalyst component. The preparation method has the characteristics of simple process, convenience in operation, low investment in industrial equipment, easiness in controlling the product quality, and the like. The titaniferous solid catalyst component has the characteristics of high vinyl polymerization catalytic activity, high copolymerizing capacity, high stacking density of polymer, less subdivision, and the like. The titaniferous solid catalyst component is suitable for slurry polymerization or gas-phase polymerization of vinyl, and is especiallysuitable for a gas-phase fluidized bed polymerization process for the vinyl, in which the catalyst is fed in a slurry form.

Owner:CHINA PETROLEUM & CHEM CORP +1

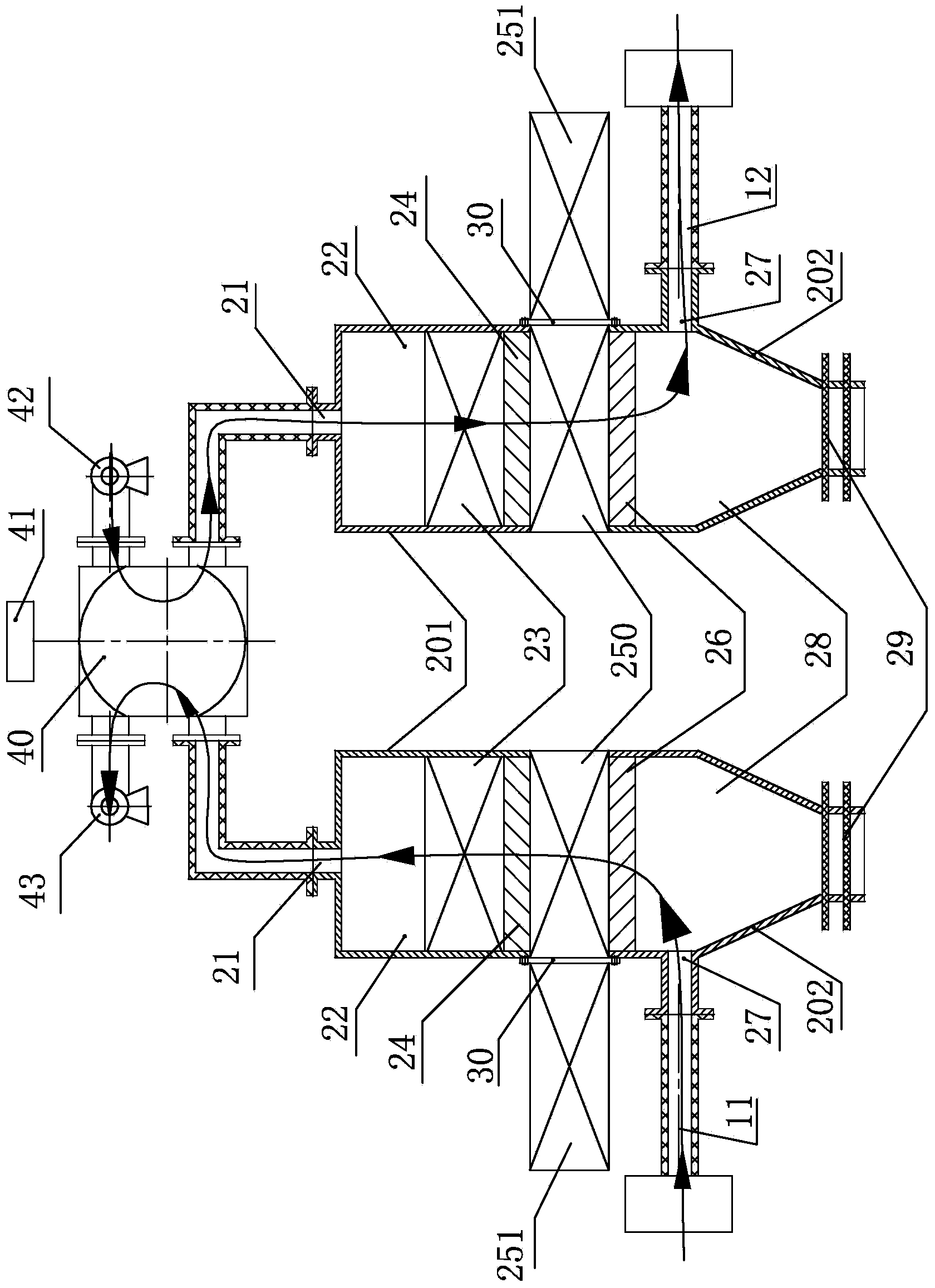

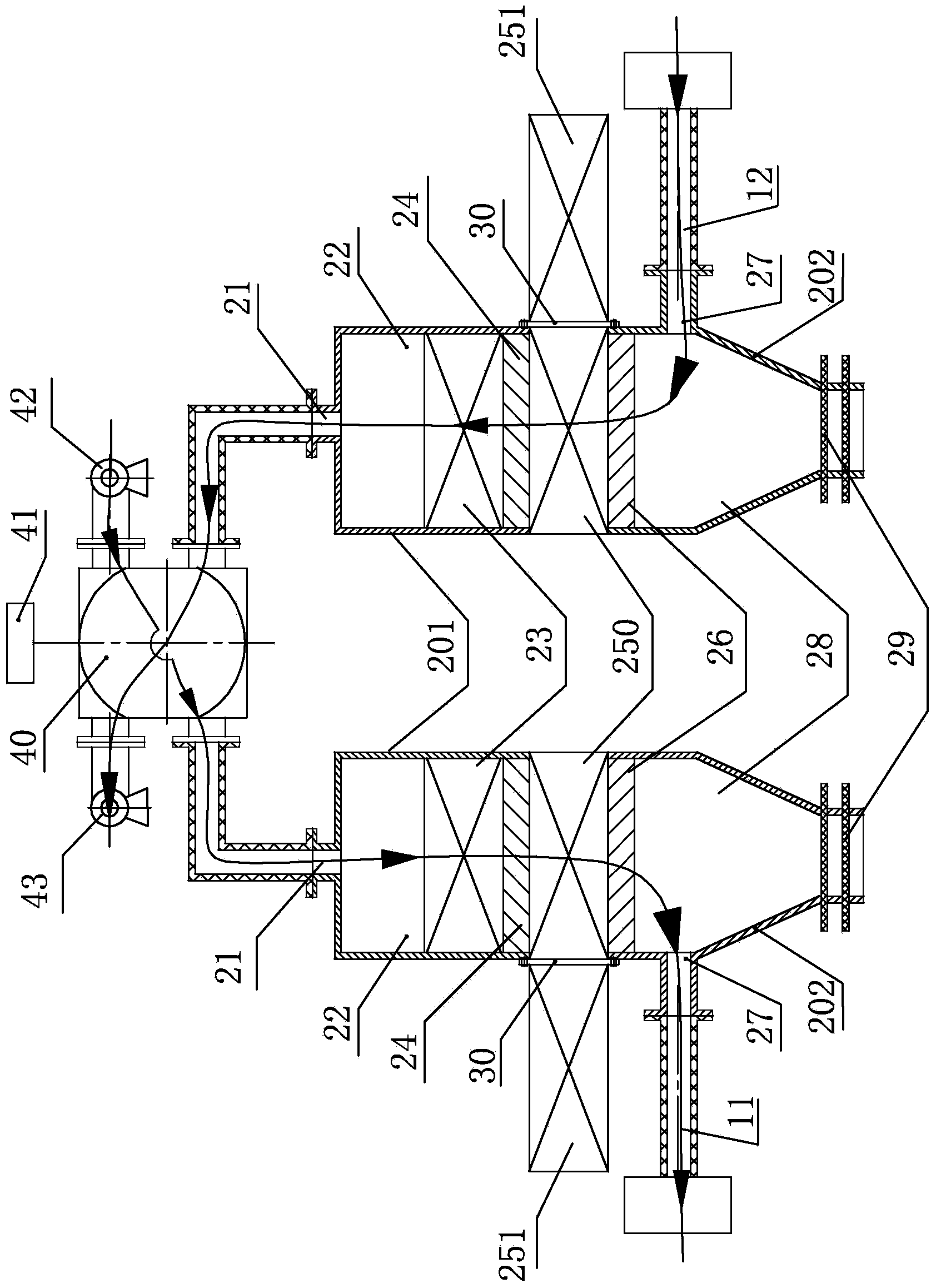

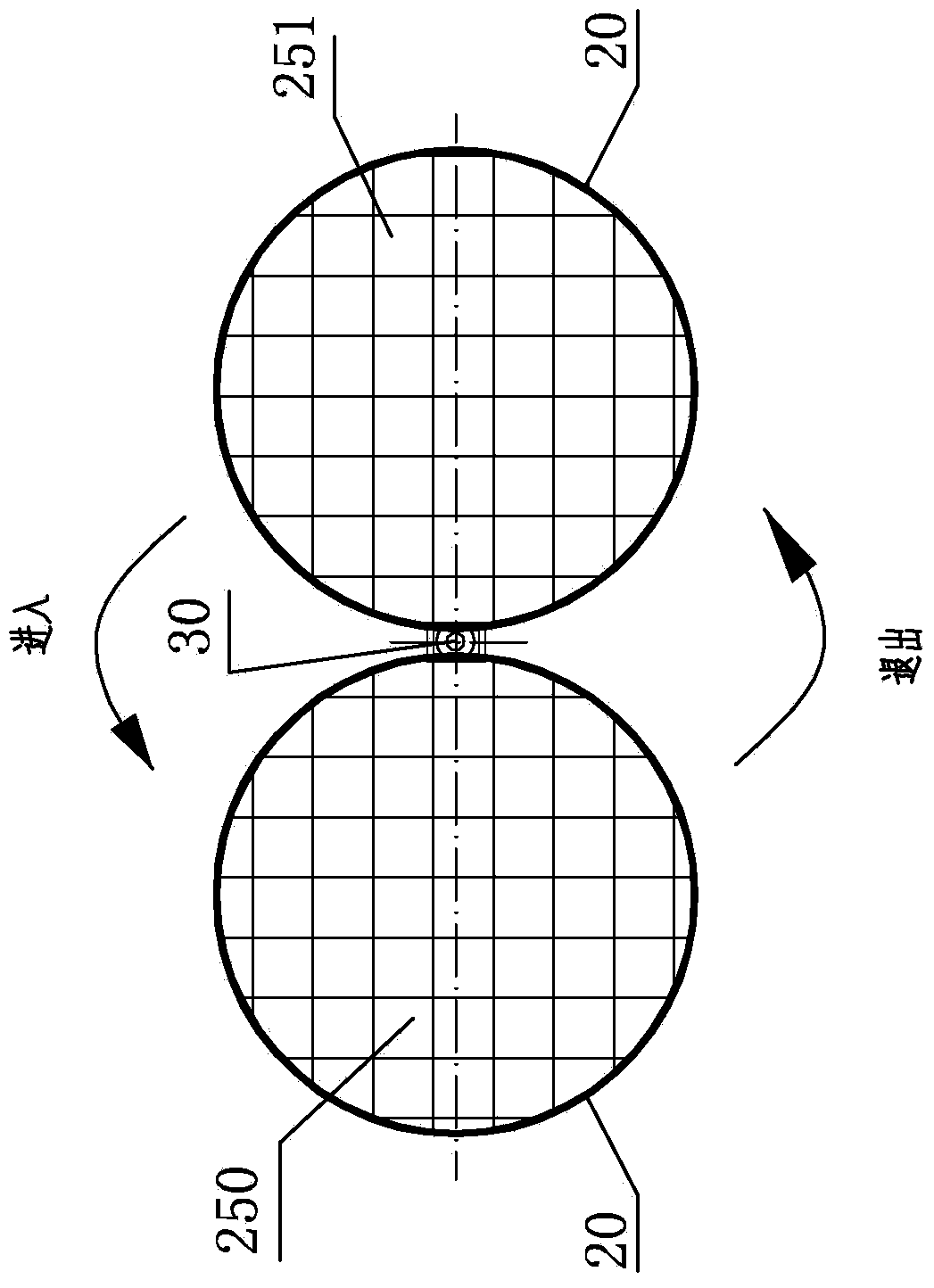

High-temperature flue gas waste heat recovery and dust extraction all-in-one device

ActiveCN103673643ALarge heat capacityModerate bulk densityDispersed particle filtrationCombustion processCombustionFiltration

The invention relates to a high-temperature flue gas waste heat recovery and dust extraction all-in-one device. The high-temperature flue gas waste heat recovery and dust extraction all-in-one device comprises furnace connectors, material filtering beds, a left wind passing unit, a right wind passing unit and a four-way reversing valve, wherein the furnace connectors and the material filtering beds are connected with air flues on the two sides of a high-temperature kiln. Each wind passing unit comprises an upper wind opening, the corresponding low-temperature area material filtering bed, a low-temperature area frame, the corresponding high-temperature area material filtering bed, a high-temperature area frame, the corresponding furnace connector, a dust collection box and an ash outlet with movable partition plates from top to bottom. Each material filtering bed comprises accumulated ceramic balls. The high-temperature flue gas waste heat recovery and dust extraction all-in-one device allows filtration and ash removing to be conducted in a mode that the leftward direction and the rightward direction are switched in a timed mode and filtration and ash removing are periodically and alternately conducted, and allows ash removing and heat absorption to be achieved in a mode that high-temperature flue gas from one side passes through the corresponding material filtering beds from bottom to top so that filtration and heat accumulation can be achieved, and air from the other side reversely blows the corresponding material filtering beds from top to bottom so that ash removing and heat absorption can be achieved. The ash-laden gas flue can be unceasingly filtered, waste heat in the high-temperature gas flue can be unceasingly recovered, meanwhile, function regeneration and fresh air preheating can be simultaneously conducted, cooling and dirt removing of the high-temperature flue gas are achieved, and combustion efficiency is improved.

Owner:宝武集团中南钢铁有限公司 +1

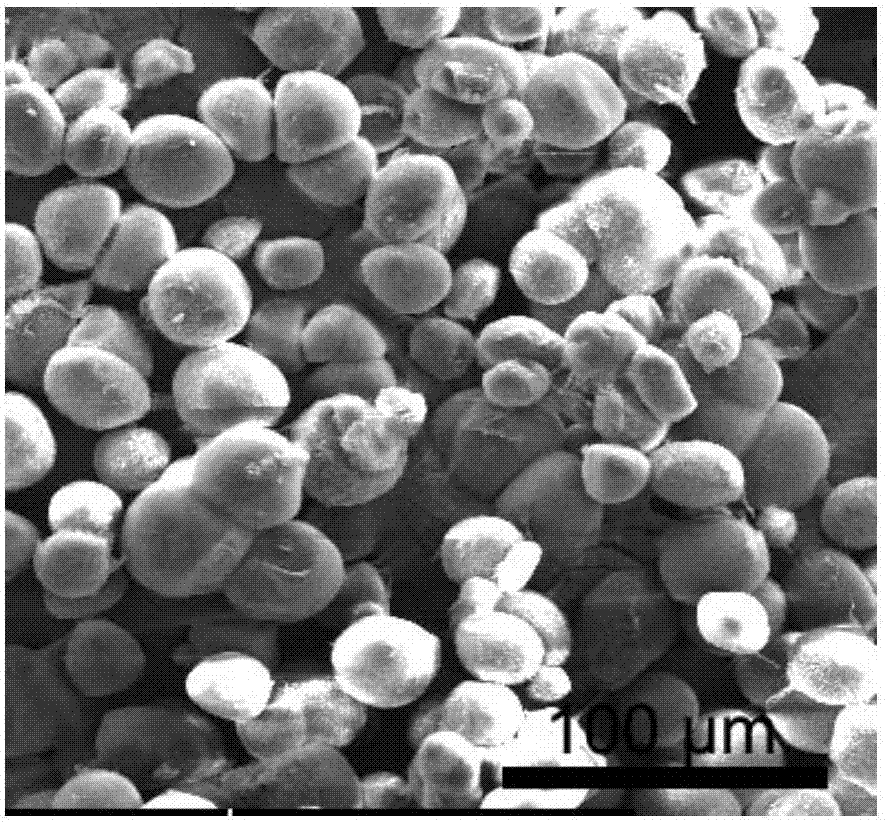

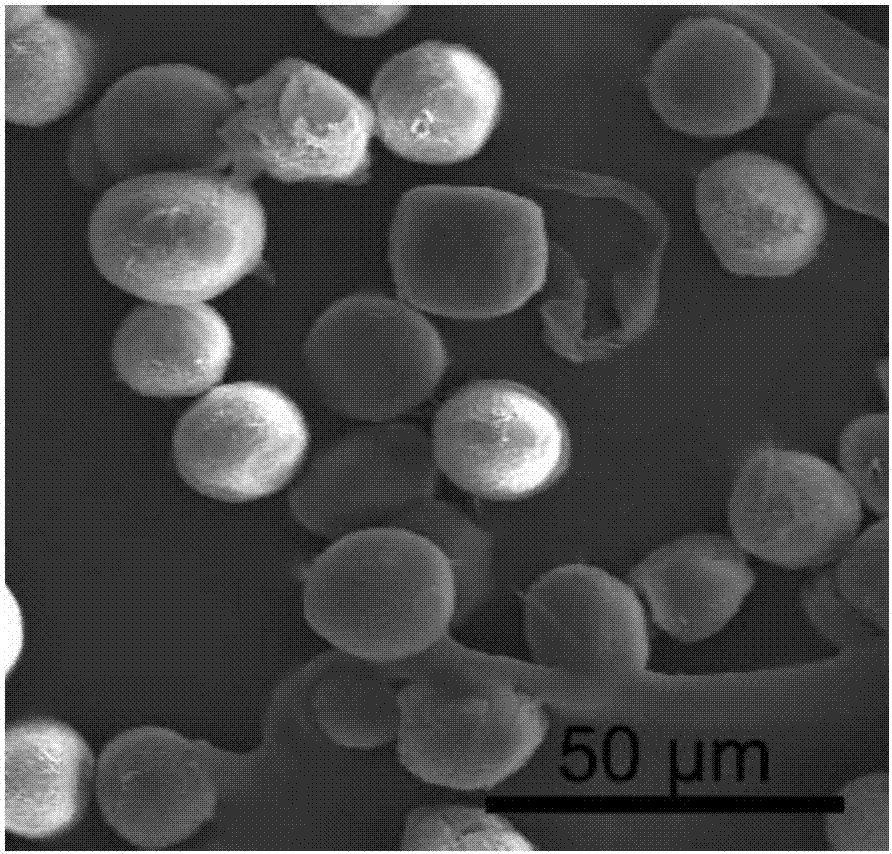

Polypropylene powder for selective laser sintering and preparation thereof

InactiveCN107304251AFlat surfaceUniform shapeAdditive manufacturing apparatusSelective laser sinteringOrganic solvent

The invention provides polypropylene for selective laser sintering, which is spherical and / or sphere-like granules having a degree of sphericity of 0.6-1.0, sizes of 10-100mu m and grain distribution D10 of 10-25mu m, D50 being 30-60mu m and D90 being 70-95mu m. The invention further provides a method for preparing the polypropylene powder, which comprises the following steps: mixing a polypropylene material with an organic solvent for dissolving the polypropylene material, heating under a stirring state to a target heating temperature, and continuing stirring at constant temperature to form a polypropylene solution; (2) quenching the polypropylene solution to the target quenching temperature, standing at a constant temperature until precipitate is generated in the solution; and (3) separating the precipitate, washing and drying to obtain the polypropylene powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

Shampoo containing hyaluronic acid

InactiveCN104069019AHigh yieldHigh light transmittanceCosmetic preparationsHair cosmeticsHyaluronic acidPharmacology

The invention discloses shampoo containing hyaluronic acid. The hyaluronic acid contained in the shampoo disclosed in the invention is high in yield, good in transmittance, low in protein content, high in glucuronic acid content, easy to dissolve and good in moisturizing effect, the prepared shampoo containing hyaluronic acid is good in stability, good in decontamination effect, free of toxic side effect, mild and free of stimulation to skin, good in moisturizing and hair protection effects while being used for cleaning hairs and is capable of protecting the hair from damage.

Owner:SHANDONG AWA BIOPHARM

Preparation method of high-temperature structure and function integrated B4C (boron carbide)-enhanced Al (aluminum)-based neutron absorbing material

ActiveCN108130438AHigh alumina contentImprove sintering performanceNuclear energy generationReactor fuel elementsMicrometerStructure and function

The invention discloses a preparation method of a high-temperature structure and function integrated B4C (boron carbide)-enhanced Al (aluminum)-based neutron absorbing material, and belongs to the technical field of neutron absorbing materials and Al-based composite materials. The preparation method comprises the following steps of (1) pre-oxidizing the surface of superfine aluminum powder to increase the content of aluminum oxide; (2) uniformly mixing the superfine aluminum powder and micrometer-level B4C particles; (3) performing compression moulding on the powder, and sintering a pressed compact; (4) forging the sintered billet, extruding or rolling, so as to obtain a high-temperature structure and function integrated B4C / Al neutron absorbing profile or sheet. The preparation method hasthe advantages that in the final material, the aluminum oxide is distributed into crystal interfaces of material, and the pining is performed, so as to obviously enhance the high-temperature propertyof the material; by adding the B4C particles, the room-temperature and medium-temperature strengths can be further improved, and the neutron absorbing function is realized; the technology is simple and convenient and is easy to implement; the strength of the material at the room temperature to high temperature are higher than the actual use requirements, and the material can be applied to the storage and transportation of the spent fuel.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

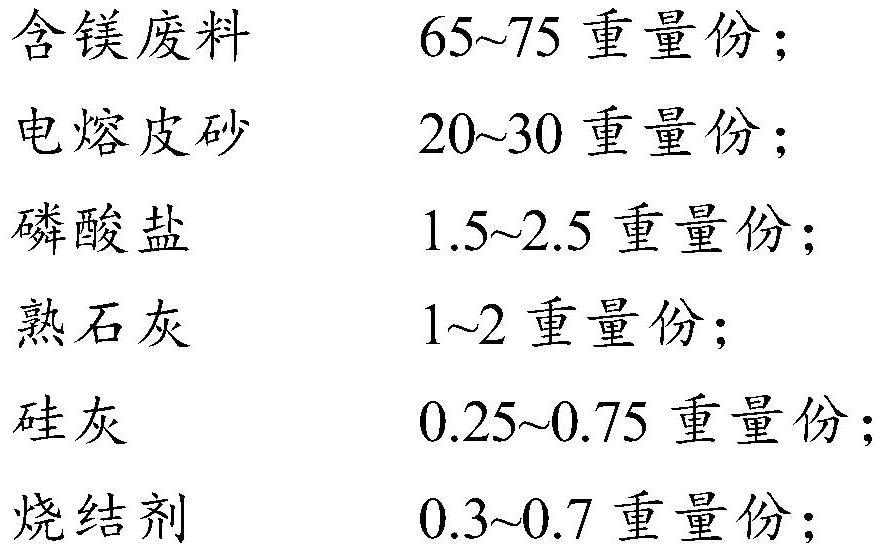

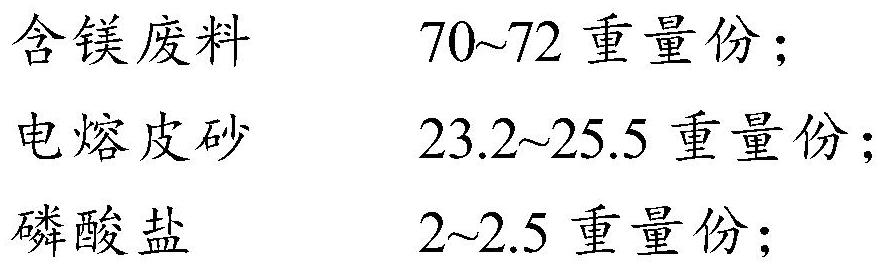

Converter tapping hole gunning mix and preparation method thereof

ActiveCN112142448AFast sinteringImprove slag erosion resistanceProcess efficiency improvementPhosphateSlag

The invention provides a gunning mix for a tapping hole of a converter. The gunning mix comprises the following components in parts by weight: 65-75 parts of magnesium-containing waste; 20 to 30 partsby weight of fused skin sand; 1.5 to 2.5 parts by weight of phosphate; 1-2 parts by weight of slaked lime; 0.25 to 0.75 part by weight of silica fume; and 0.3-0.7 part by weight of a sintering agent,wherein the content of MgO in the magnesium-containing waste is not lower than 80%. Compared with the prior art, the gunning material has the advantages that the magnesium-containing waste is used asaggregate, the fused skin sand is added to promote sintering of a matrix phase of the gunning material, phosphate is used as a binding agent to enable the gunning material to have high strength at medium and low temperatures, and meanwhile silica fume is added into the gunning material to fill part of gaps of the matrix and compact the gunning material; and the additive can react with MgO and CaOat a high temperature to generate high-temperature phases such as forsterite or calcium forsterite, so that the slag corrosion resistance of the gunning material is improved, and the gunning materialhas the advantages of low cost, moderate volume density, high sintering speed, moderate sintering strength, easiness in drilling and long service life.

Owner:HUNAN XIANGGANG RUITAI TECH

Anti-allergy skin moisturizer

ActiveCN104055702AImprove permeabilityImprove anti-allergic effectCosmetic preparationsToilet preparationsAllergy skinDermatomal

The invention discloses an anti-allergy skin moisturizer which is high in yield of hyaluronic acid, good in light transmittance, low in content of protein, high in content of glucuronic acid, easy to dissolve and good in moisturizing effect. The prepared anti-allergy skin moisturizer is good in permeability of the skin, capable of quickly and effectively moisturizing the skin, strong in anti-allergy effect, safe and free of toxic and side effect.

Owner:SHANDONG AWA BIOPHARM

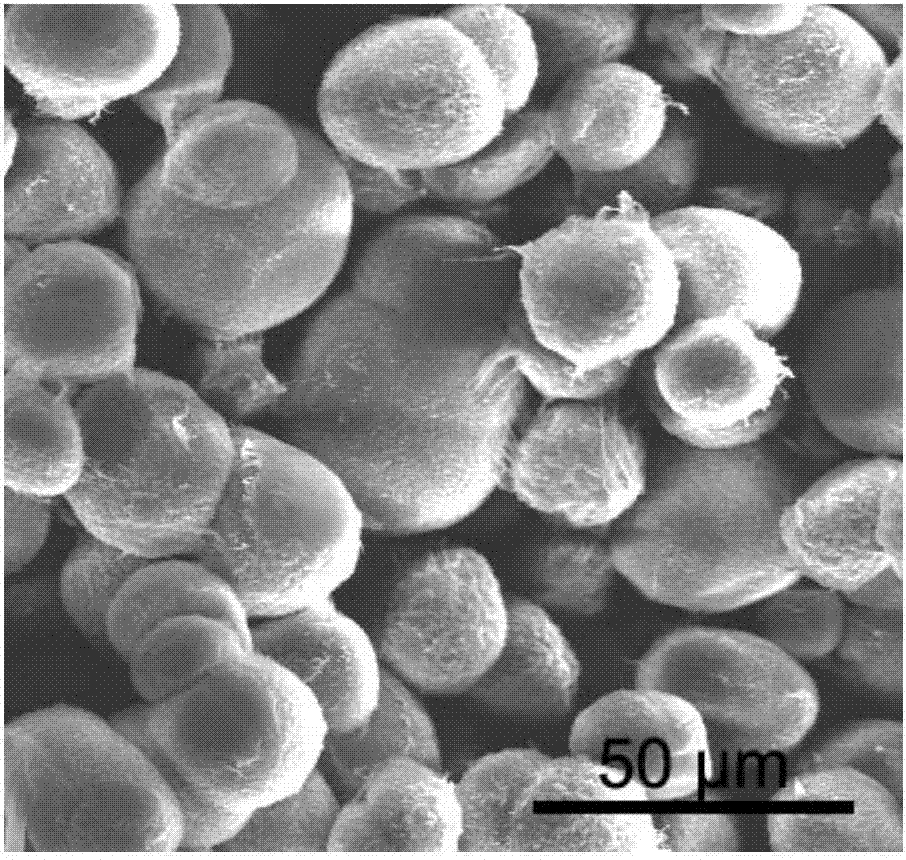

Microsphere fluidizing reagent for start debugging of fluidized bed reactor and preparation method of microsphere fluidizing reagent

The invention relates to a microsphere fluidizing reagent for start debugging of a fluidized bed reactor and a preparation method of the microsphere fluidizing reagent. The microsphere fluidizing reagent comprises the following components in percentage by mass: 70-95 percent of SiO2 and Al2O3, 0.05-15 percent of CaO and MgO, 0.1-10 percent of Na2O and 0-5 percent of P2O5. The preparation method comprises the following steps: performing spray granulation on clay, silicon oxide, silicon aluminum oxides, limestone, dolomite, calcite, chalk soil and magnesite serving as matrixes and water glass, silica sol, alumina sol, silica-alumina gel, phosphorus-aluminum gel and pseudo-boehmite serving as adhesives, and roasting at the temperature of 800-1,200 DEG C. The cost is low.

Owner:SHANGHAI XIANJIA CHEM

Castable material for hanging bricks of partition walls of heating furnaces

The invention provides a casting material for hanging bricks for partition walls of heating furnaces, and the casting material is prepared from the following raw materials in parts by weight: 20-50 parts of light mullite, 30-60 parts of mullite, 1-20 parts of cement, 1-10 parts of an expansion agent and 0.1-0.2 part of a water reducing agent. The casting material has the following beneficial effects: by using the mullite as a main raw material and adding a reasonable expansion material, a prepared hanging brick product has the characteristics of moderate volume density, excellent thermal shockstability, good volume stability, long service life and the like, and the service life can reach more than one year.

Owner:北京利尔高温材料股份有限公司

Blast furnace air duct castable and preparation method thereof

The invention relates to a blast furnace air duct castable and a preparation method thereof, and belongs to the field of inorganic non-metal materials. The blast furnace air duct castable is preparedby adding 5 to 9% by mass of Al2O3 micro powder, 0-4% by mass of silicon micro powder, 2-5% by mass of Secar71 cement binder and a small amount of water reducing agent into 40% by mass of 5-1mm titanium calcium aluminate hollow spheres, 0-30% by mass of 1-0mm titanium calcium aluminate hollow spheres, 0-30% by mass of 1-0mm titanium calcium aluminate, 10 to 16% by mass of 200-mesh titanium calciumaluminate fine powder and 0 to 6% by mass of 200-mesh corundum fine powder for premixing, adding 3-5% by mass of water, stirring, and casting for molding to obtain the titanium calcium aluminate hollow sphere blast furnace air duct castable. The castable has the advantages of good fluidity, compact structure, high strength, good wear resistance, low thermal conductivity, good heat preservation effect, and the like, and can be used to replace the existing blast furnace air duct castable.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparing method of hydrocarbon cracking catalyst

ActiveCN100377782CMedium bulk densityModerate bulk densityCatalytic crackingMolecular sieve catalystsAdhesiveFuel oil

The hydrocarbon cracking catalyst consists of molecular sieve 10-60wt%, clay 0-75wt%, silicon adhesive accounting in silica 5-40wt%, alumina 0.1-10wt%, and modifying component accounting in oxide 0-10wt%. The catalyst is prepared through the sol-gel process of maintaining the catalyst in sol state before formation and spray drying at 50-150 deg.c to create microball gel, and subsequent ageing and pore expanding treatment. The catalyst has high matrix cracking activity and is favorable to the cracking of heavy oil and residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

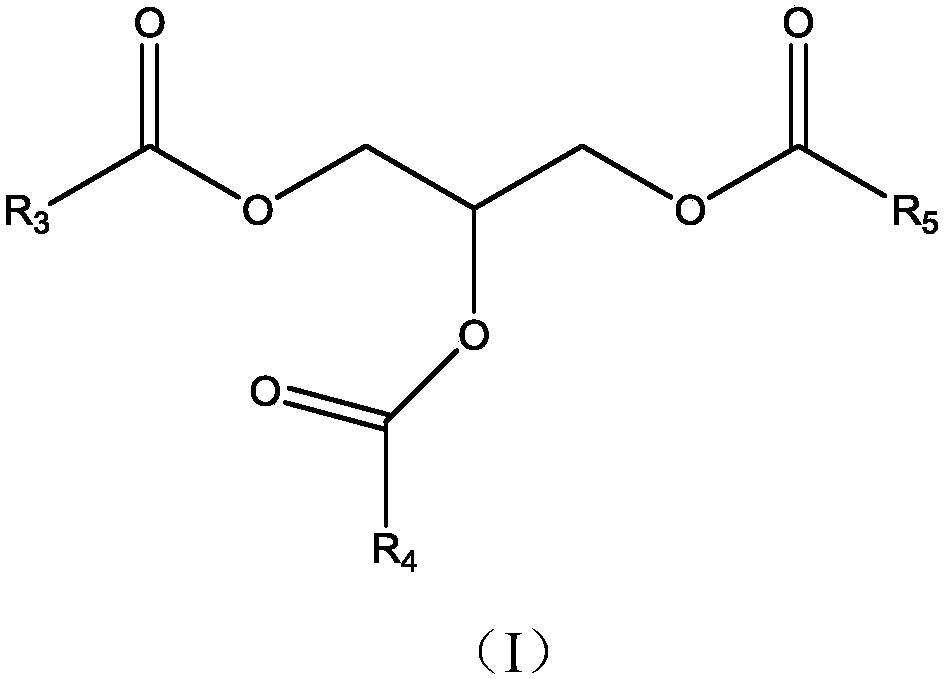

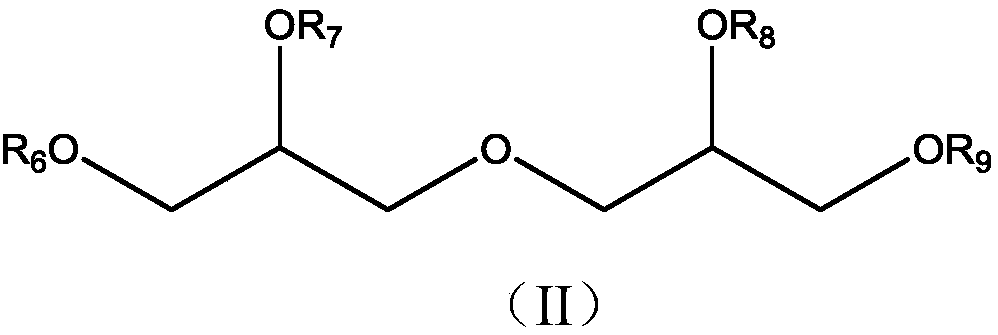

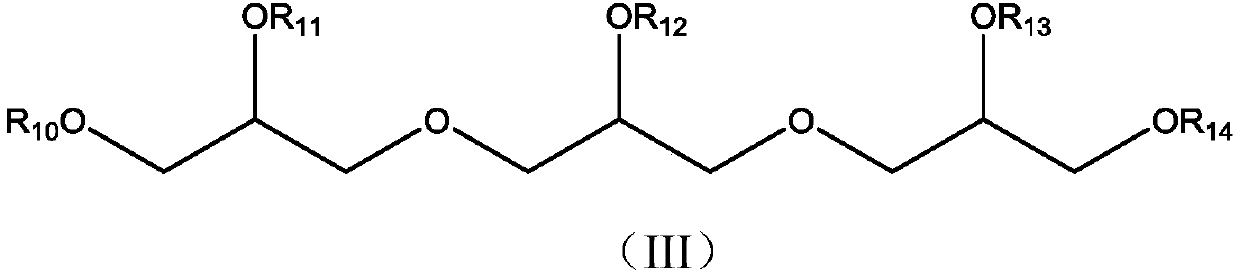

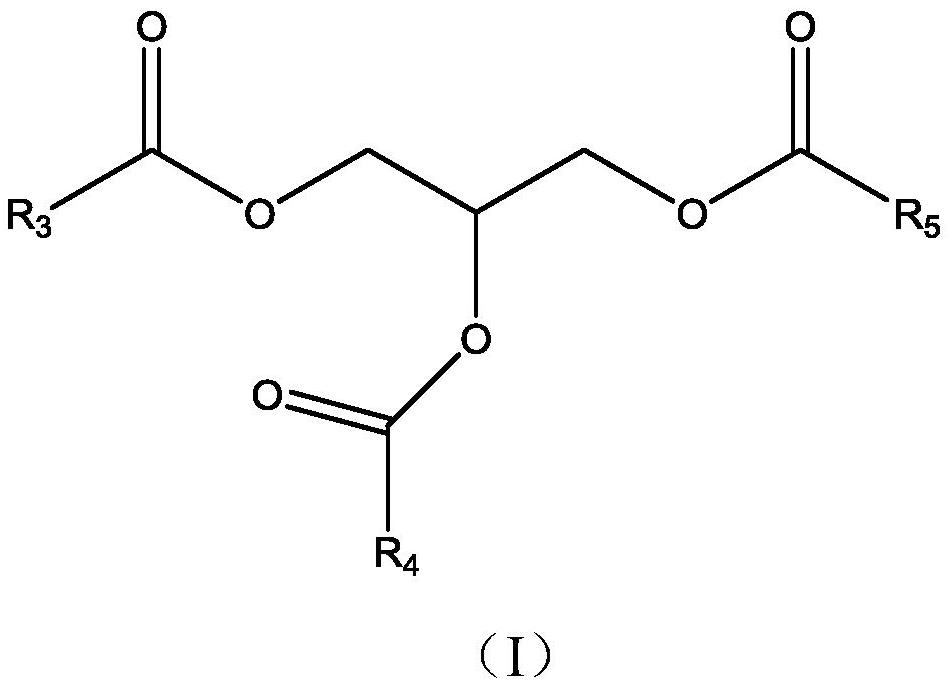

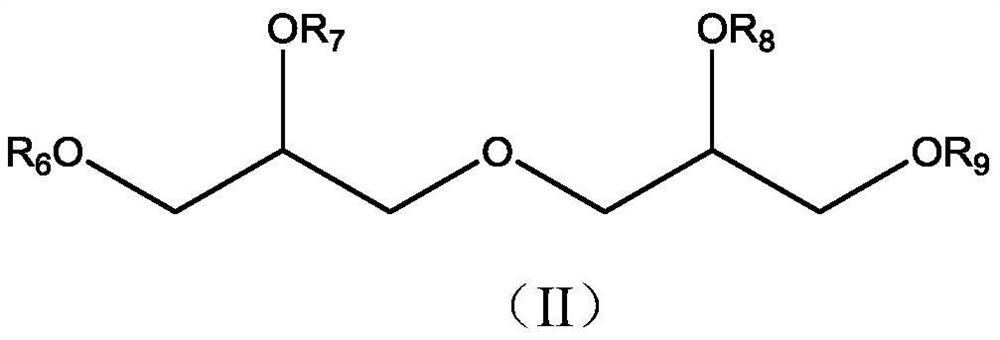

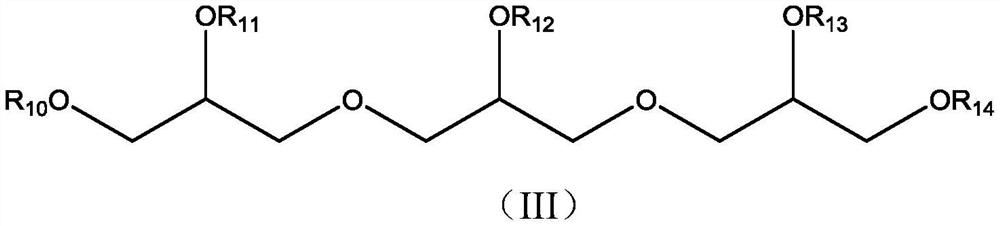

External electron donor of catalyst for propylene polymerization, catalyst system for propylene polymerization, and preparation method and application of external electron donor and catalyst system

The embodiment of the invention discloses an external electron donor of a catalyst for propylene polymerization. The external electron donor comprises siloxane, glycerol fatty acid ester and polyglycerol fatty acid ester, wherein the molar ratio of the siloxane to the glycerin fatty acid ester to the polyglycerol fatty acid ester is (0.01-0.8):(0.09-0.9):(0.09-0.9). According to the invention, a catalyst system comprising the external electron donor which is the mixture of the siloxane, the glycerin fatty acid ester and the polyglycerol fatty acid ester is a high-efficiency propylene polymerization catalyst, and the polymerization activity is high. The glycerin fatty acid ester and the polyglycerol fatty acid ester containing polar groups are selected as external electron donor components,and the problem of activity advancing caused by ethers to catalytic polymerization is successfully solved. The advantages are as the follows that a polymerization process is stable, static fluctuation does not occur easily, the polymerization product is not agglomerated easily and is not easily hung on a wall, and the like, so that long-term stable operation of polymerization production is ensured, and meanwhile, the amount of the obtained polymer fine powder is small, the bulk density is moderate, and the particle size distribution of particles is reasonable. The catalyst system is wide in application range and is suitable for propylene polymerization in various processes.

Owner:锦州英诺威科技服务有限公司

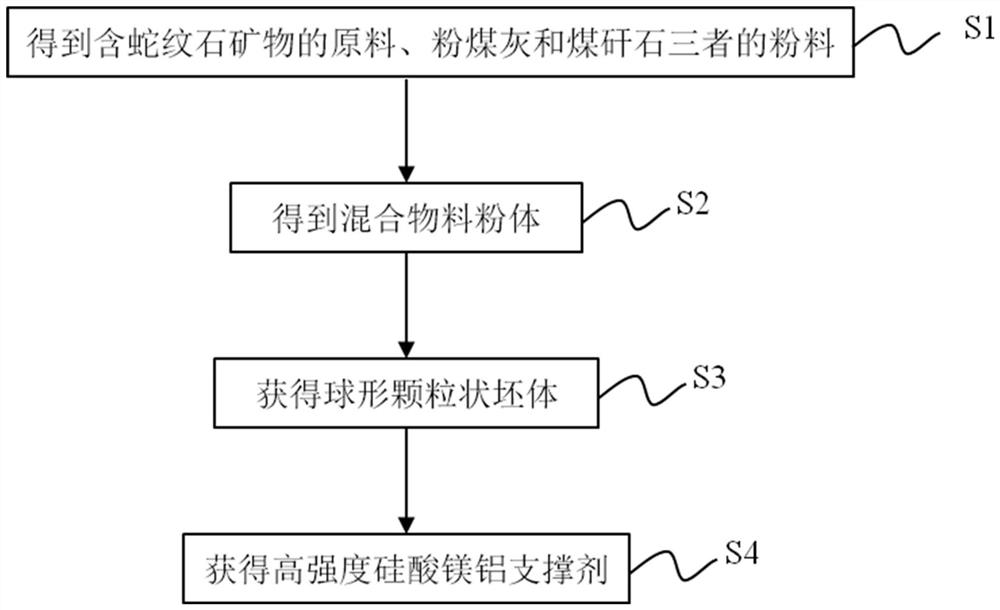

High-strength magnesium aluminum silicate proppant and preparation method thereof

ActiveCN113563867ARealize resource utilizationImprove product added valueFluid removalDrilling compositionSilicic acidAluminum silicate

The invention provides a high-strength magnesium aluminum silicate proppant and a preparation method thereof. The preparation method comprises the following steps: respectively drying, crushing and roasting a raw material containing serpentine minerals, fly ash and coal gangue to obtain powder of the three materials; mixing and grinding the powder of the three materials and an auxiliary agent to obtain mixed material powder; granulating the mixed material powder to obtain a spherical granular green body; and drying and sintering the spherical granular green body to obtain the high-strength magnesium aluminum silicate proppant. The diameter of the high-strength magnesium aluminum silicate proppant ranges from 106 microns to 3350 microns, the sphericity and the roundness are not lower than 0.9, the volume density is 1.3-1.8 g / cm<3>, and the breakage rate under the closing pressure of 86 MPa to 103 MPa is smaller than or equal to 9%. The high-strength petroleum fracturing magnesium aluminum silicate proppant is produced by taking the rock, the barren rock and the tailings which mainly contain serpentine as raw materials, so that resource utilization of various solid wastes is realized.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Cracking catalyst and its application

ActiveCN1332757CMedium bulk densityWear-resistantCatalytic crackingMolecular sieve catalystsMolecular sievePolymer science

A cracking catalyst is prepared from molecular sieve (10-60 Wt%), clay (0-75), Si adhesive (5-40), Al adhesive (5-40) and modifier (0-10) through preparing slurry in sol state, spray drying to become gel, ageing and forming big pores. Its advantages are high strength, stack density and pore volume, high conversion rate of hydrocarbon oil, and high cracking power and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

MgO-CePO4 material and preparation method thereof

ActiveCN110436957APromote sinteringImprove mechanical propertiesCeramicwareThermal conductivityMagnesite

The invention relates to a MgO-CePO4 material and a preparation method thereof. The technical solution is that the method comprises the following steps: firstly mixing 50-70 wt% of sintered magnesite,20-40 wt% of magnesium hydroxide, 5-10 wt% of cerous phosphate and 1-10 wt% of aluminate, performing uniform stirring, and performing compression moulding; and performing natural drying for 20-24 h,performing drying at 110-200 DEG C for 8-24 h, performing firing at 1300-1600 DEG C, performing heat preservation for 3-6 h, and performing cooling to obtain the MgO-CePO4 material. According to the method provided by the invention, the MgO-CePO4 material prepared by the method has thermal-insulating properties, mechanical properties and erosion resistance, has the characteristics of good thermalresistance performance, a moderate bulk density, moderate strength, low thermal conductivity and strong anti-erosion ability, and can meet the requirements of saving energy and reducing consumption ofindustrial equipment.

Owner:WUHAN UNIV OF SCI & TECH

Anti-allergic hair care shampoo

ActiveCN104055701BHigh yieldHigh light transmittanceCosmetic preparationsHair cosmeticsSide effectHair loss

Owner:SHANDONG AWA BIOPHARM

Catalyst carrier for heavy oil hydrogenation treatment and preparation thereof

InactiveCN1098731CHigh mechanical strengthLarge apertureCatalyst carriersCatalyst activation/preparationFuel oilOrganic chemistry

The present invention relates to a heavy oil hydrogenation treatment catalyst carrier and its preparation method. In the course of preparation the pseudo-thin empholite and aluminium oxide are mixed according to a certain proportion,then mixed with compound pore-expanding agent and kneaded to mouldable body, then strip-extruded and formed by means of strip-extruding machine, then dried and roasted at high temp. so as to obtain the required carrier.

Owner:CHINA PETROCHEMICAL CORP +1

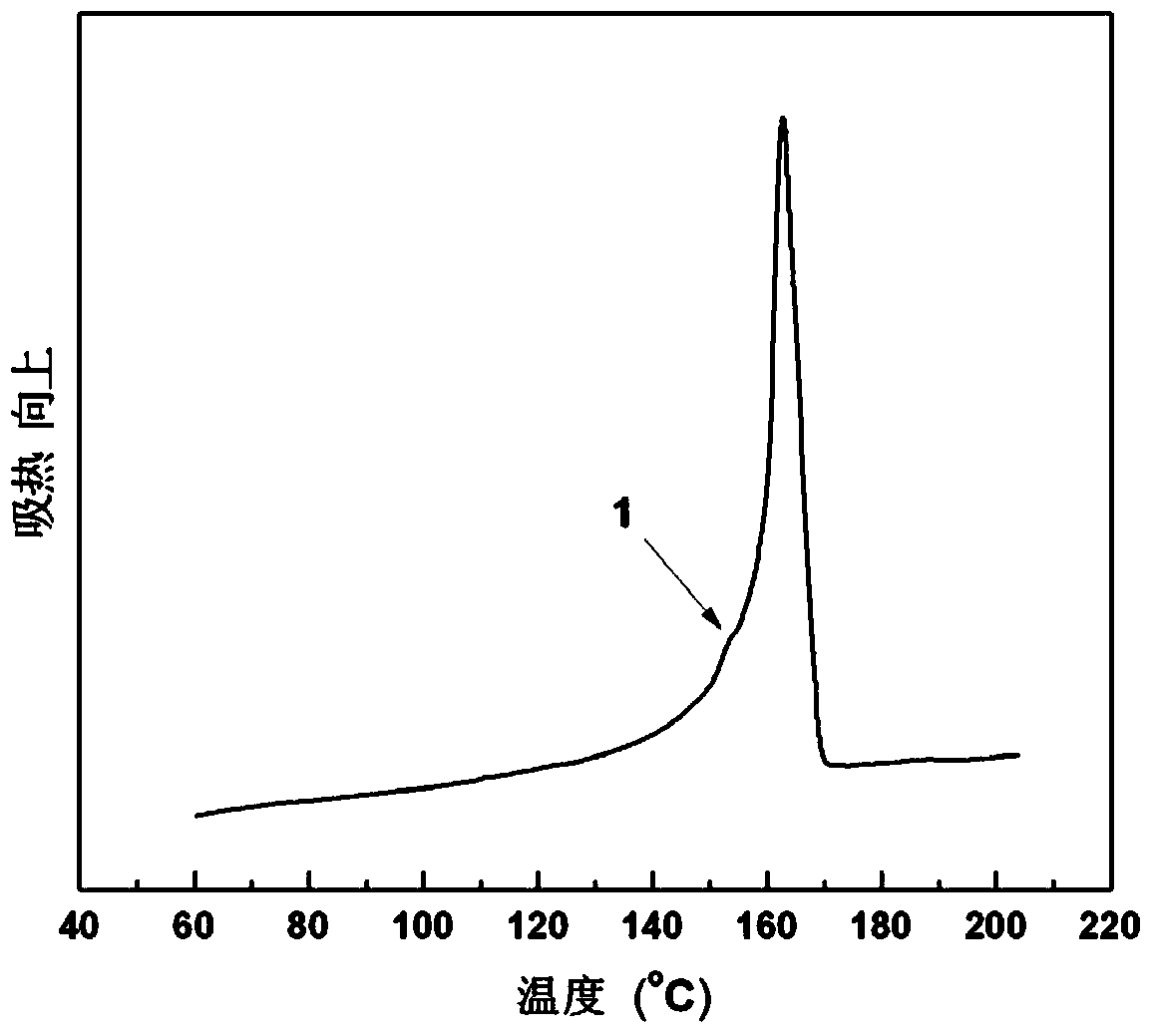

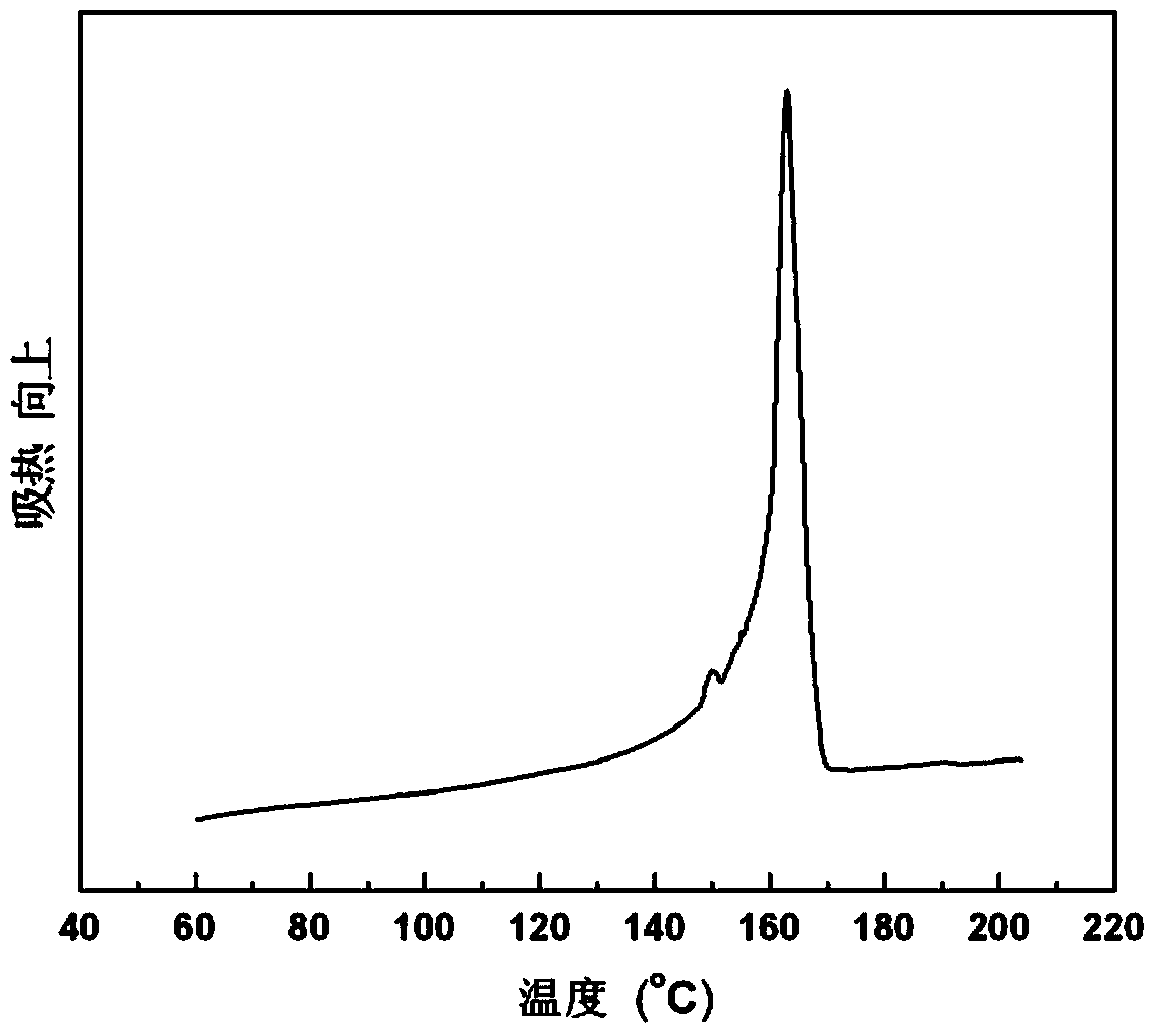

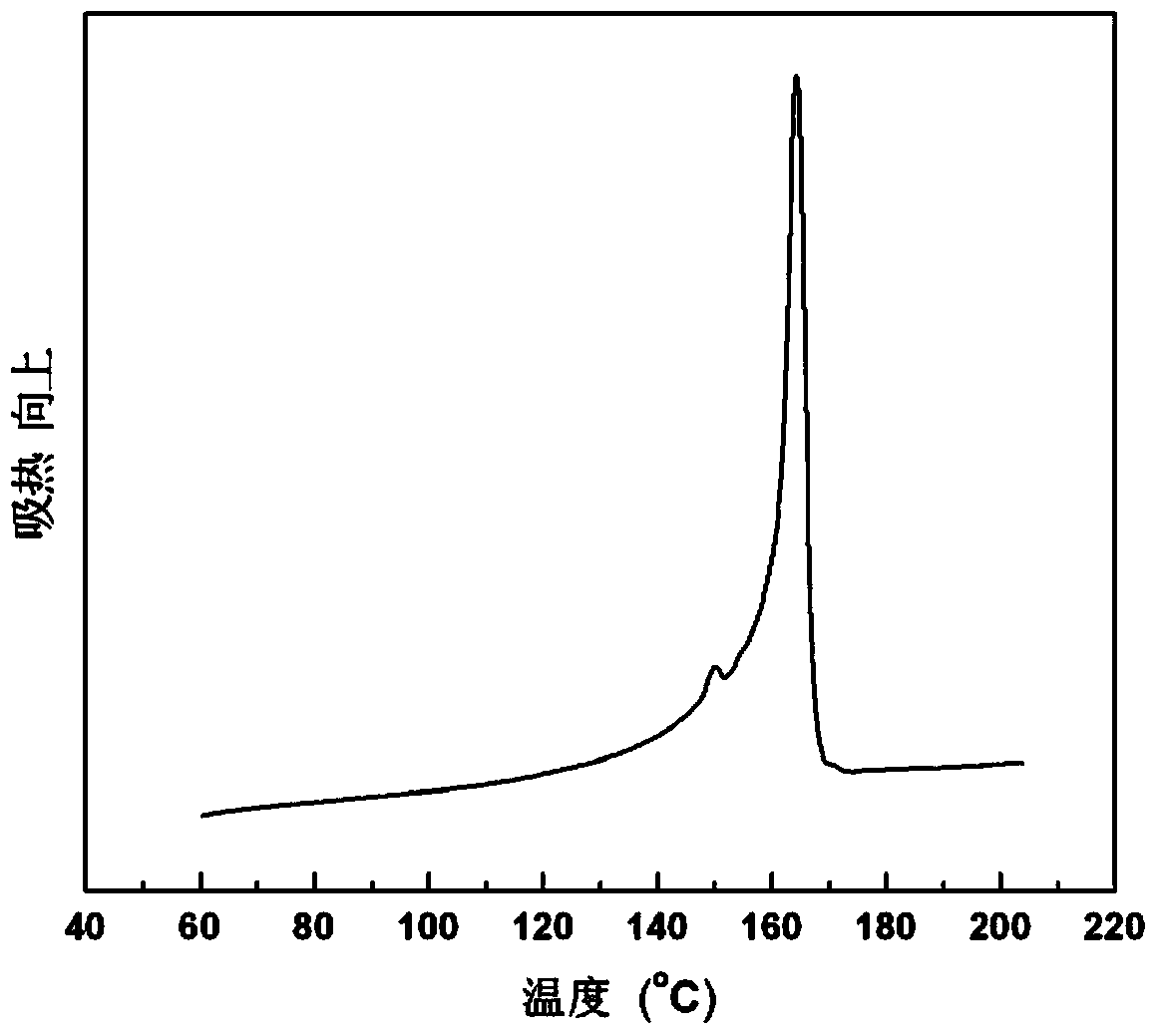

Polypropylene powder for selective laser sintering and its preparation

ActiveCN107304270BHigh sphericityFlat surfaceAdditive manufacturing apparatusSelective laser sinteringOrganic solvent

The invention provides polypropylene powder for selective laser sintering. The polypropylene is prepared from a polypropylene material and a surfactant, wherein the polypropylene powder is analyzed by a differential scanning calorimetry method, and an obtained DSC analyzing curve has a melting peak respectively between 145 and 155 DEG C and between 160 and 170 DEG C. The invention further provides a method for preparing the polypropylene powder. The method comprises the following steps: (1) mixing the polypropylene material, the surfactant and an organic solvent, heating under a stirring state to a target heating temperature, and continuing stirring at constant temperature to form a polypropylene solution; (2) quenching the polypropylene solution to the target quenching temperature, standing at a constant temperature until a precipitate is generated in the solution; and (3) separating the precipitate, and washing and drying to obtain the polypropylene powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

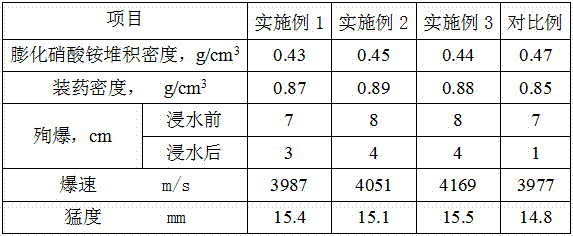

A water-resistant composite oil phase specially used in the production process of liquid-mixed puffed explosives

ActiveCN105294369BReduce dependenceHigh bonding strengthNon-explosive/non-thermic compositionsMelting tankFiltration

The invention discloses a water-resistant composite oil phase specially used in the production process of liquid-mixed expanded explosives, using decompression wax paste, tar, fatty acid, surface treatment agent, paraffin and anti-caking agent as raw materials in separate melting tanks Internally heat up and melt, and then pump each material into the reaction kettle after being measured by the oil pump and electronic scale according to the ratio requirements, and then raise the temperature to 100-110°C and keep the uniform stirring state in the reaction kettle, and turn on the vacuum pump at the same time to evacuate the reaction kettle Dehydration and filtration are carried out in sequence, and the filtered material is formed and packaged to obtain the water-resistant composite oil phase product. The puffed explosive produced by the composite oil phase of the present invention has good explosive performance, and its biggest advantage is that the puffed explosive has excellent water resistance, and the bulk puffed explosive can be insoluble in water for several hours to tens of hours when sprinkled on the water surface.

Owner:LIUYANG JINKE NEW MATERIAL CO LTD

Preparation methods for macroporous alumina carrier and hydrodemetallization catalyst

ActiveCN102441437BLarge hole volumeLarge apertureCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPseudoboehmiteMetal catalyst

The invention discloses preparation methods for a macroporous alumina carrier and a hydrodemetallization catalyst. The preparation method for the macroporous alumina carrier includes the following steps: (1) dry pseudoboehmite gel powder is hydrothermally processed under high pressure; (2) the dry pseudoboehmite gel powder obtained in step 1 is kneaded into a plastic, and pore-expanding agent is added in step 1 or step 2; (3) the plastic obtained in step 2 is shaped, the shaped material is dried and baked, and thereby the macroporous alumina carrier is obtained. The impregnation method is adopted to prepare the hydrodemetallization catalyst. The hydrodemetallization catalyst prepared by the method has large pore volume and pore diameter, centrally distributed pores, moderate mechanical strength and high activity and activity stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

An external electron donor of a catalyst for propylene polymerization, a catalyst system for propylene polymerization and its preparation method and application

The embodiment of the present invention discloses an external electron donor for a catalyst for propylene polymerization, including siloxane, glycerin fatty acid ester and polyglycerol fatty acid ester, the molar ratio of which is (0.01-0.8):(0.09-0.9):( 0.09‑0.9). In the present invention, the catalyst system comprising a mixture of siloxane, glycerol fatty acid ester and polyglycerol fatty acid ester as an external electron donor is a high-efficiency polymerization catalyst for propylene, and has high polymerization activity. Glycerin fatty acid ester and polyglycerol fatty acid containing polar groups are selected Ester, as an external electron donor component, successfully solves the problem of the activity of ethers on catalytic polymerization. Long-term stable operation, and at the same time, the obtained polymer fine powder is less, the bulk density is moderate, and the particle size distribution is reasonable. The catalyst system has a wide range of applications and is suitable for propylene polymerization in various processes.

Owner:锦州英诺威科技服务有限公司

a skin moisturizer

ActiveCN104055686BImprove permeabilityPrevent drynessCosmetic preparationsToilet preparationsDermatomalOrganic chemistry

The invention discloses a skin moisturizing agent. The hyaluronic acid of the present invention has high yield, good light transmittance, low protein content, high glucuronic acid content, easy dissolution, good moisturizing effect, and the prepared skin moisturizer has good permeability to the skin, and can quickly and effectively moisten and dry the skin Skin, non-sticky.

Owner:SHANDONG AWA BIOPHARM

A preparation method of high-temperature structure-function integrated boron carbide reinforced aluminum-based neutron absorbing material

ActiveCN108130438BHigh alumina contentImprove sintering performanceNuclear energy generationReactor fuel elementsAl powderAluminium oxides

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Skin cleaning cosmetics

InactiveCN104069021AEasy to cleanImprove solubilityCosmetic preparationsToilet preparationsSkin permeabilityMedicine

The invention discloses skin cleaning cosmetics. The skin cleaning cosmetics disclosed by the invention is high in yield of hyaluronic acid, high in transmittance, low in protein content, high in glucuronic acid content, easy to dissolve and good in moisturizing effect, the prepared skin cleaning cosmetics achieves a good moisturizing effect while cleaning the skin, has good skin permeability to moisturize the dry skin and is free of dry or sticky feeling after cleaning.

Owner:SHANDONG AWA BIOPHARM

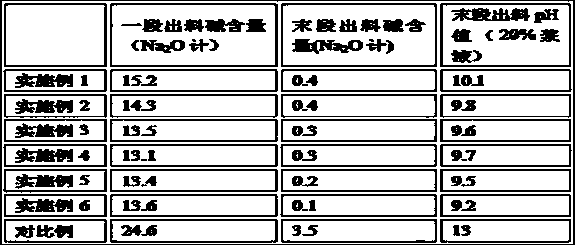

A production method for synthesizing calcium silicate with high activity and low alkali content

ActiveCN107697923BImprove dehydration efficiencyHigh solid contentAlkaline-earth metal silicatesAluminium hydroxide preparationCalcium silicateWater saving

The invention discloses a production method for synthesis of high activity and low alkali content calcium silicate. Based on the traditional 3-5 stages of washing, a water repellent agent and a dealkalization assistant are respectively added during the first stage of washing and dehydration and the last stage of washing and dehydration to reach the purposes of water saving and efficient removal ofalkali, wherein the water repellent agent added in the first stage of washing and dehydration is an alkali-resistant and hydrophobic high polymer, aluminum ions in the aluminum salt of the dealkalization assistant added in the last stage of washing and dehydration can react with sodium hydroxide in calcium silicate to produce water and aluminum hydroxide precipitate, thus reaching the dealkalization purpose. The preparation method provided by the invention has the advantages of simple and flexible operation, no influence on the existing calcium silicate synthesis process, and no need for adding of extra large equipment, and only needs adding of storage and adding equipment for corresponding assistant. At the same time, the method provided by the invention can substantially reduce the washing water consumption for synthesis of calcium silicate and reduce the consumption emission of water in the production process. In general, the method provided by the invention is highly operable andis easy for industrialization popularization and use.

Owner:临沂三禾生物质科技有限公司

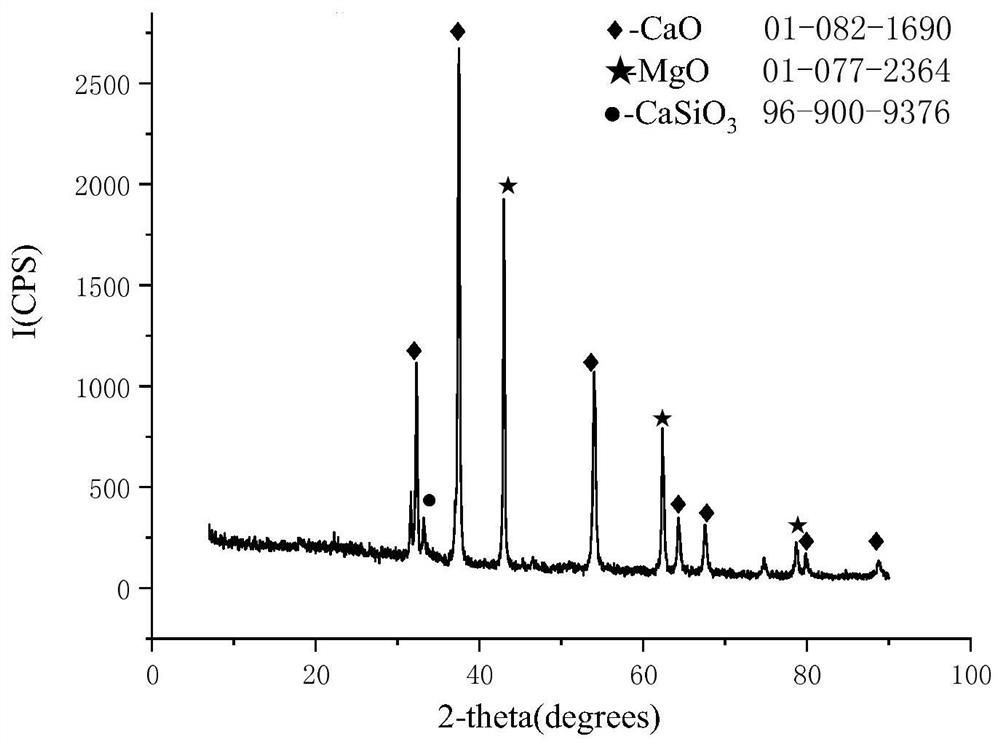

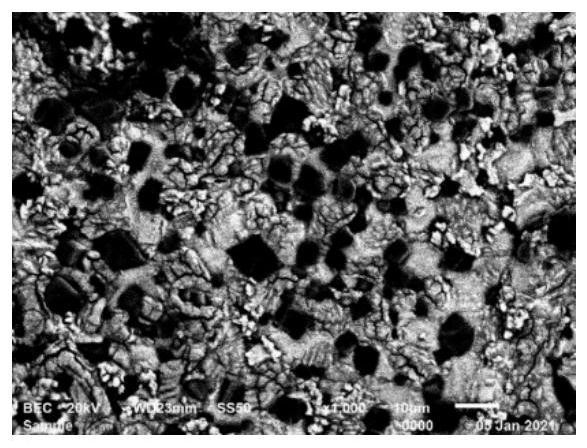

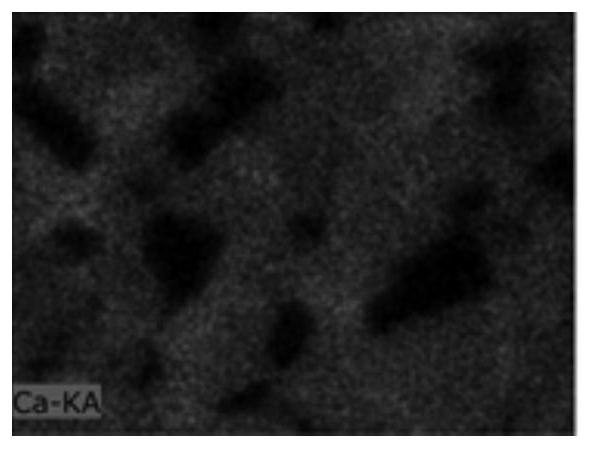

Phosphate tailing-based magnesium-calcium particle and preparation method thereof

The invention relates to a phosphate tailing-based magnesium-calcium particle and a preparation method thereof. According to the technical scheme, the method comprises the following steps: firstly, putting a phosphate tailing powder into a charging basket of granulation equipment, starting the granulation equipment, then adding water which is 12-32wt% of the phosphate tailing powder into the charging basket, and performing granulation; after the phosphate tailing powder in the charging basket is completely converted into particles, stopping the granulation, taking out particles, and performing standing and drying; and then in a heating furnace, preserving heat at 1500-1700 DEG C for 1-5 hours, and performing cooling to obtain the phosphate tailing-based magnesium-calcium particle. The particle size of the phosphate tailing powder is 1-200 [mu]m; and in the phosphate tailing powder, the content of P2O5 is not more than 2wt%, the content of MgO is not less than 15wt%, and the content of CaO is not less than 25wt%. The method is simple in process, low in cost, environmentally friendly and high in phosphorus tailing recycling degree, and the prepared product is good in hydration resistance, low in phosphorus content, high in porosity, moderate in volume density and high in alkaline slag erosion resistance, has heat insulation performance and fire resistance at the same time, facilitates energy conservation and consumption reduction and meets the requirement for light weight of materials.

Owner:WUHAN UNIV OF SCI & TECH

Catalyst component used for vinyl polymerization, preparation method and application

The invention provides a titaniferous solid catalyst component used for vinyl polymerization and a preparation method. The titaniferous solid catalyst component is prepared according to the following three continuous steps: 1) under the existence of halogen or halogen-containing compound, reacting metal magnesium with alcohol, thereby preparing a magnesium-containing solid; 2) utilizing an organic metallic compound or a mixture of the organic metallic compound and an electron donor compound to process the magnesium-containing solid, thereby obtaining a magnesium-containing catalyst carrier; and 3) under the existence of an inert organic solvent, utilizing a compound of transition metal titanium to process the magnesium-containing catalyst carrier, and then utilizing a halogenated alcohol compound to process, thereby obtaining the catalyst component. The preparation method has the characteristics of simple process, convenience in operation, low investment in industrial equipment, easiness in controlling the product quality, and the like. The titaniferous solid catalyst component has the characteristics of high vinyl polymerization catalytic activity, high copolymerizing capacity, high stacking density of polymer, less subdivision, and the like. The titaniferous solid catalyst component is suitable for slurry polymerization or gas-phase polymerization of vinyl, and is especiallysuitable for a gas-phase fluidized bed polymerization process for the vinyl, in which the catalyst is fed in a slurry form.

Owner:CHINA PETROLEUM & CHEM CORP +1

A mgo-cepo 4 Materials and their preparation methods

ActiveCN110436957BLow thermal conductivityHigh activityCeramicwareCerium phosphateIndustrial equipment

The present invention relates to a kind of MgO-CePO 4 Materials and their preparation methods. The technical solution is: first mix 50-70wt% of sintered magnesia, 20-40wt% of magnesium hydroxide, 5-10wt% of cerium phosphate and 1-10wt% of aluminate, stir evenly, and press to form; Dry for 20 to 24 hours, then dry at 110°C to 200°C for 8 to 24 hours, then burn at 1300 to 1600°C, keep warm for 3 to 6 hours, and cool to obtain MgO‑CePO 4 Material. MgO-CePO prepared by the present invention 4 The material takes into account heat insulation performance, mechanical performance and corrosion resistance, and has the characteristics of good thermal resistance, moderate bulk density and strength, low thermal conductivity and strong corrosion resistance, which can meet the requirements of energy saving and consumption reduction of industrial equipment.

Owner:WUHAN UNIV OF SCI & TECH

A kind of purification process of hyaluronic acid

ActiveCN104059169BEasy to separate and purifyShorten the production cycleMicroorganism based processesFermentationActivated carbonBiochemical engineering

The invention discloses a purification process of hyaluronic acid. The present invention removes impurities in hyaluronic acid by adding activated carbon, perlite, white diatomaceous earth, and EDTA combined with large plate and frame filtration technology. The additives are common and easy to obtain, the operation is relatively simple, and the impurity content is lower. The production is easy to control, suitable for large-scale industrial production, the yield is high, and the production cost is greatly reduced.

Owner:SHANDONG AWA BIOPHARM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com