Converter tapping hole gunning mix and preparation method thereof

A technology of tapping hole and gunning material, which is applied in the field of converter refractories and can solve the problems of long time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

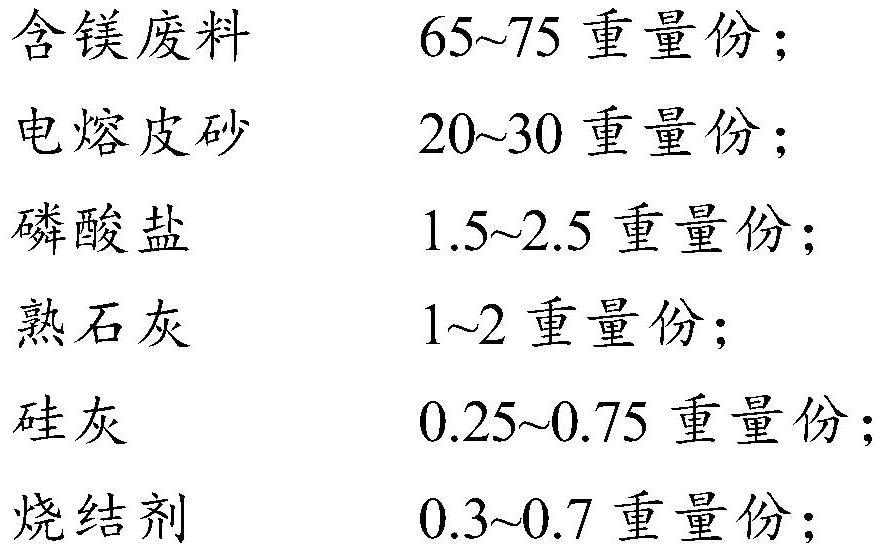

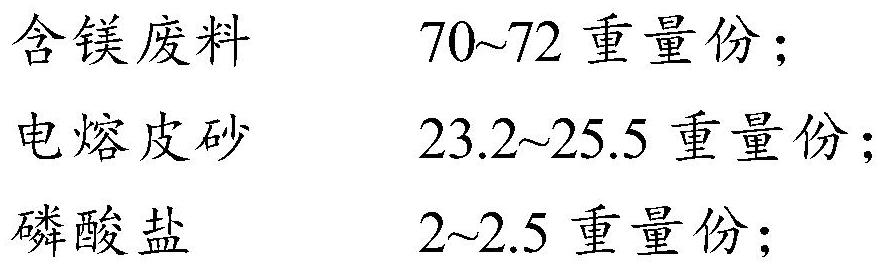

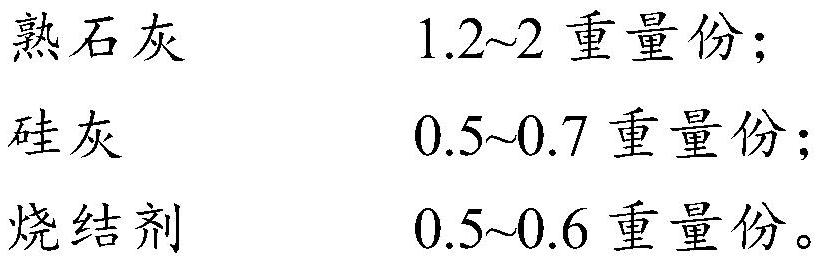

[0045] The present invention also provides a method for preparing the above-mentioned converter tapping hole gunning material, which includes: mixing magnesium-containing waste, fused leather sand, phosphate, slaked lime, silica fume and sintering agent to obtain converter tapping hole gunning material.

[0046] Wherein, the magnesium-containing waste, fused leather sand, phosphate, slaked lime, silica fume and sintering agent are all the same as above, and will not be repeated here.

[0047] In the present invention, the magnesium-containing waste is preferably prepared according to the following method: recycle the magnesium-containing waste bricks after thermal equipment is used, remove impurities and sort them, and crush them into three kinds of grains: 5-3mm, 3-1mm, and 1-0mm. grade, to obtain magnesium-containing waste.

[0048] It is also preferred that the phosphate is crushed separately from the sintering agent and sieved through a 2 mm screen before mixing.

[0049...

Embodiment 1

[0057] In a 210-ton converter in a steel plant, magnesia-iron-aluminum spinel waste 5-3mm15%, magnesia-iron-aluminum spinel waste 3-1mm30%, magnesia-iron-aluminum spinel waste 1-0mm25%, fused sand fine Powder 25.5%, sodium tripolyphosphate 2%, slaked lime 1.5%, silica fume 0.5%, boric acid 0.3%, citric acid 0.2% gunning material 800kg is loaded into the 210-ton converter on-site gunning machine in the steel plant, and the new Wet gunning is carried out on the replaced slide plate slag-stopping outlet. The temperature in the furnace is 1200 ℃ ~ 1400 ℃, and the gunning time is 15 minutes. After the slag mechanism is subjected to molten iron steelmaking, the steel type is low-carbon steel. The gunning material MgO+Al 2 o 3 88.64%, 1500℃*3hr cold compressive strength is 32.4MP a , the bulk density is 2.42g / cm 3 , The service life of the tap hole is 262 furnaces, the steel receiving time is 175h, and the tapping hole and gunning material drilling time is 12min.

Embodiment 2

[0059] In a 120-ton converter in a steel plant, magnesia-alumina spinel waste 5-3mm12%, magnesia-alumina spinel waste 3-1mm35%, magnesia-alumina spinel waste 1-0mm23%, fused sand fine powder 24.3% , sodium hexametaphosphate 2.5%, slaked lime 2%, silica fume 0.7%, boric acid 0.2%, citric acid 0.3% gunning material 600kg is loaded into the 120-ton converter on-site gunning machine in the steel plant, and the newly replaced slide plate Wet gunning is carried out at the slag-stopping outlet, the temperature in the furnace is 1100°C-1300°C, the gunning time is 12 minutes, after gunning, the gunning material is baked in high fire for 10 minutes, the converter is shaken to the front of the furnace, and the slag-stopping mechanism is installed The steel is made by molten iron, and the steel type is ordinary construction steel. The gunning material MgO+Al 2 o 3 89.29%, 1500℃*3hr cold compressive strength is 30.8MPa, bulk density is 2.38g / cm 3 , The service life of the tap hole is 32...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com