A production method for synthesizing calcium silicate with high activity and low alkali content

A production method and technology of alkali content, applied in the field of calcium silicate, can solve the problems of high residual alkali content of synthetic calcium silicate, large amount of washing water, etc., and achieve well-developed pore structure, water-saving alkali removal, and high whiteness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

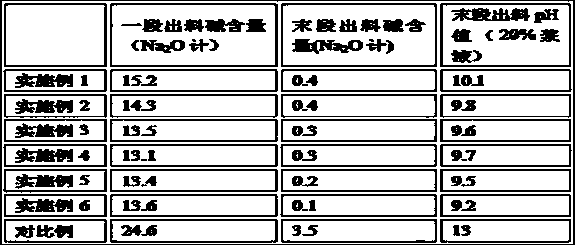

Examples

preparation example Construction

[0044] A further preferred preparation method comprises the following steps:

[0045] ①Mix milk of lime, water glass and water and react at 45°C for 100 minutes to obtain a reaction liquid; wherein the mass ratio of milk of lime, water glass and water is 1:1:25; the solid content of the milk of lime is 160g / L;

[0046] ②One-stage washing and dehydration: add water-resistant agent to the reaction solution obtained in step ①, stir evenly, and dehydrate to the first centrifuge until the solid content of the filter cake is 30%; the mass ratio of the reaction solution obtained in step ① to the water-resistant agent is 100:0.3%; the water repellent is polyacrylate;

[0047] The lye obtained by dehydration can be reused in the following steps: add water glass to the lye after a section of washing and dehydration for pretreatment, the modulus of the water glass solution after pretreatment is 0.8, and the concentration is 20g / L in terms of silicon dioxide , and then return to step ①...

Embodiment 1

[0055] A production method for synthesizing high-activity, low-alkali-content calcium silicate, comprising the following steps:

[0056] 1. 75kg milk of lime, 100kg water glass and 2000kg water were mixed, and reacted for 90 minutes at 30°C to obtain a reaction solution; the solid content of the milk of lime was 150g / L;

[0057] ② One-stage washing and dehydration: add water-resistant agent to the reaction solution obtained in step ①, stir evenly, and dehydrate to the first centrifuge until the solid content of the filter cake is 15%; the mass ratio of the reaction solution obtained in step ① to the water-resistant agent is 100:0.1%; the water-resistant agent is polyacrylate;

[0058] ③ Multi-stage washing and dehydration: put the filter cake from the first centrifuge into the dispersion tank, add 3 times the weight of water to it, redisperse into a slurry, and then dehydrate. After each dehydration operation, the solid content of the filter cake reaches 15 %, repeated operat...

Embodiment 2

[0061] A production method for synthesizing high-activity, low-alkali-content calcium silicate, comprising the following steps:

[0062] ①Mix milk of lime, water glass and water and react at 60°C for 120 minutes to obtain a reaction liquid; wherein the mass ratio of milk of lime, water glass and water is 1.5:1:30; the solid content of the milk of lime is 180g / L;

[0063] ② One-stage washing and dehydration: add water-resistant agent to the reaction solution obtained in step ①, stir evenly, and dehydrate to the first centrifuge until the solid content of the filter cake is 45%; the mass ratio of the reaction solution obtained in step ① to the water-resistant agent is 100:0.5%; the water-resistant agent is melamine formaldehyde resin;

[0064] ③Multi-stage washing and dehydration: put the filter cake from the first centrifuge into the dispersion tank, add 3~10 times the weight of water to it, re-disperse into a slurry, and then dehydrate. After each dehydration operation, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com