Phosphate tailing-based magnesium-calcium particle and preparation method thereof

A technology for phosphorus tailings and particles is applied in the field of magnesium-calcium particles based on phosphorus tailings and their preparation, so as to achieve the effects of improving hydration resistance, low production cost and realizing resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A magnesium-calcium particle based on phosphorus tailings and a preparation method thereof. The preparation method described in this embodiment is:

[0032] First place the phosphorous tailings powder in the hopper of the granulation equipment, start the granulation equipment, then add 12-20wt% water of the phosphate tailings powder into the hopper, and granulate; After all the phosphorous tailings powder in the process is converted into granules, the granulation is stopped, the granules are taken out, left to stand for 24-26 hours, and kept at 100-110°C for 10-12 hours; then placed in a heating furnace, heated at 1500- Keep the temperature at 1600° C. for 4 to 5 hours, and cool to prepare magnesium-calcium particles based on phosphorus tailings.

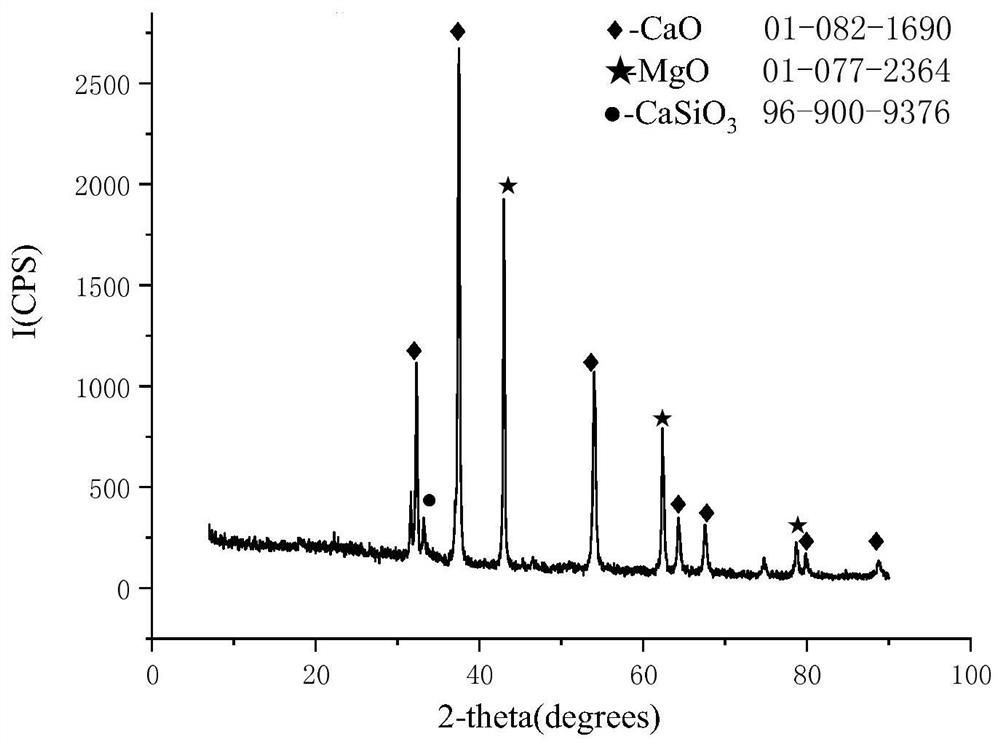

[0033] The magnesium-calcium particles based on phosphorus tailings prepared in this example are tested: the particle size of the magnesium-calcium particles based on phosphorus tailings is 0.1-5mm; the CaO content of the ma...

Embodiment 2

[0035]A magnesium-calcium particle based on phosphorus tailings and a preparation method thereof. The preparation method described in this embodiment is:

[0036] First place the phosphorous tailings powder in the hopper of the granulation equipment, start the granulation equipment, then add 20-26wt% water of the phosphate tailings powder into the hopper, and granulate; After all the phosphorous tailings powder in the process is converted into granules, the granulation is stopped, the granules are taken out, left standing for 25-27 hours, and kept at 105-115°C for 10-12 hours; then placed in a heating furnace, at 1600- The temperature is kept at 1650° C. for 3 to 4 hours, and then cooled to prepare magnesium-calcium particles based on phosphorus tailings.

[0037] The magnesium-calcium particles based on phosphorus tailings prepared in this example are tested: the particle size of the magnesium-calcium particles based on phosphorus tailings is 2 to 9 mm; the CaO content of th...

Embodiment 3

[0039] A magnesium-calcium particle based on phosphorus tailings and a preparation method thereof. The preparation method described in this embodiment is:

[0040] First place the phosphorous tailings powder in the hopper of the granulation equipment, start the granulation equipment, then add 26-32wt% water of the phosphate tailings powder into the hopper, and granulate; After all the phosphorous tailings powder in the process is converted into granules, the granulation is stopped, the granules are taken out, left to stand for 26-28 hours, and kept at 110-120°C for 10-12 hours; then placed in a heating furnace, at 1650- The temperature is kept at 1700° C. for 1 to 3 hours, and then cooled to prepare magnesium-calcium particles based on phosphorus tailings.

[0041] The magnesium-calcium particles based on phosphorus tailings prepared in this example are tested: the particle size of the magnesium-calcium particles based on phosphorus tailings is 6-12 mm; the CaO content of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com