Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Low shot content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

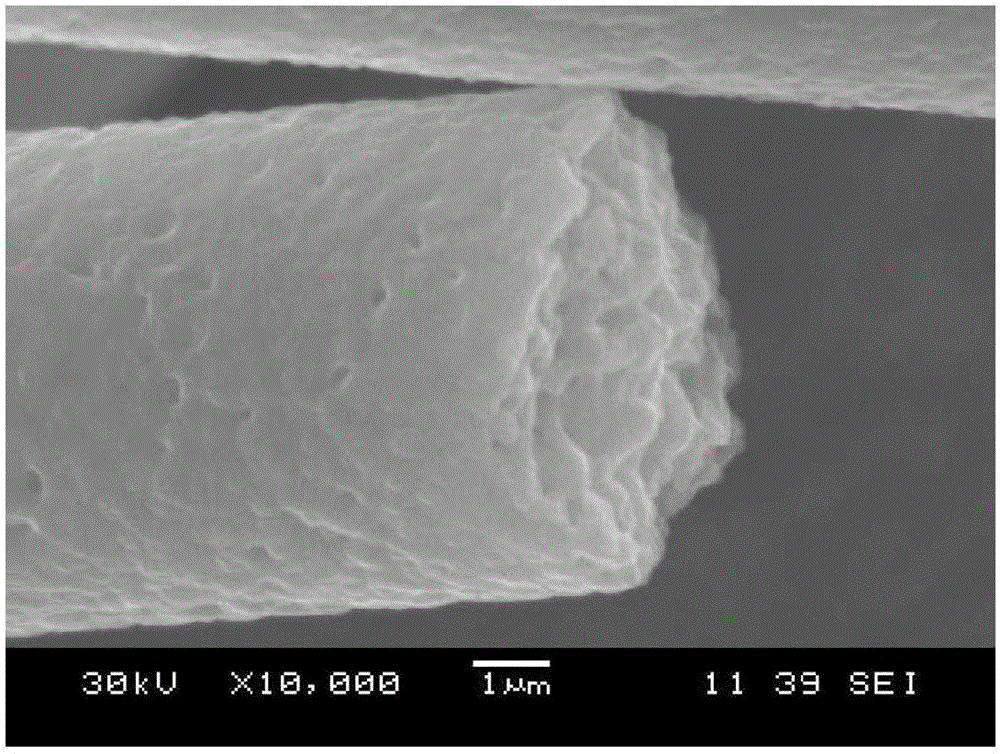

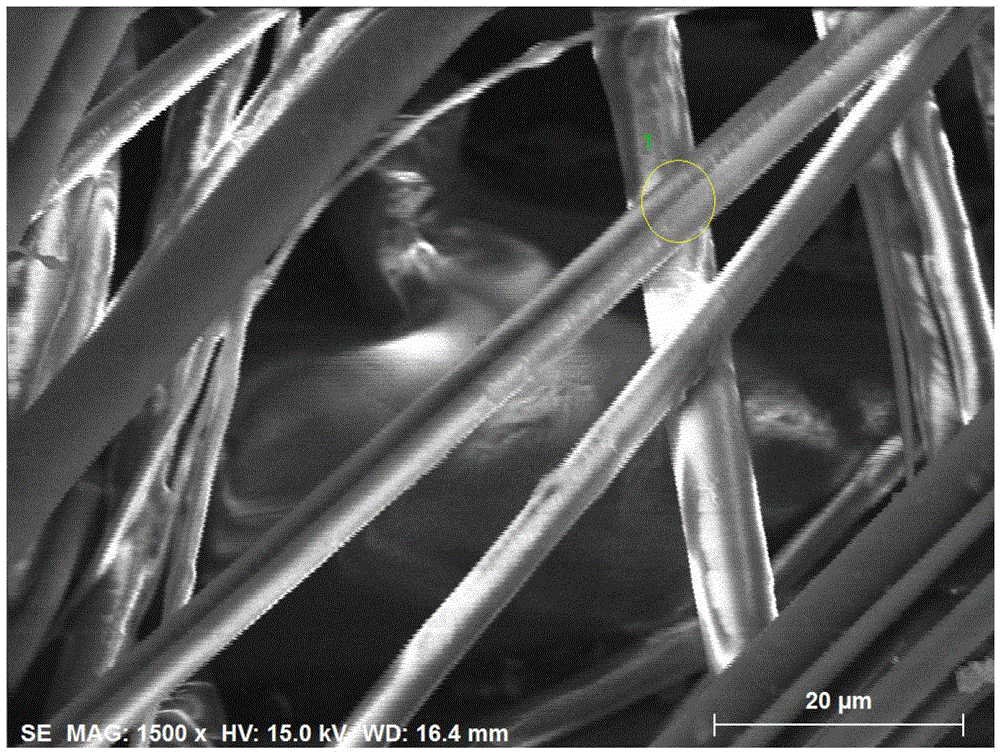

Preparation method of polycrystalline Al2O3-Y3Al5O12 complex-phase fibers or pure YAG fibers

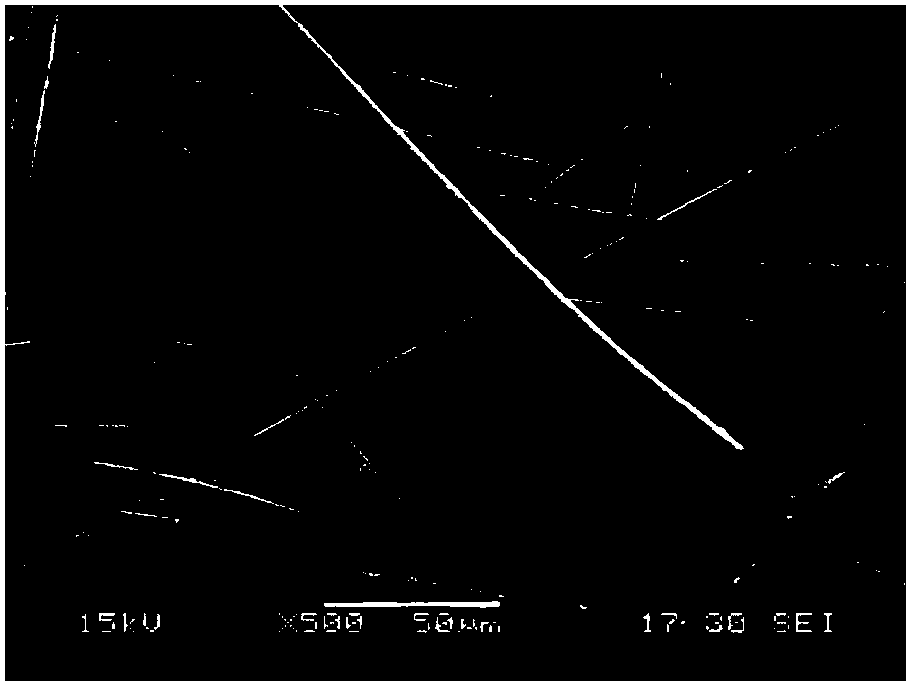

InactiveCN105002601AUniform diameterShort preparation timeInorganic material artificial filamentsArtifical filament manufactureFiberPolymer science

The invention discloses a preparation method of polycrystalline Al2O3-Y3Al5O12 complex-phase fibers or pure YAG fibers. The preparation method comprises the following steps that (1) precursor colloids of the polycrystalline Al2O3-Y3Al5O12 complex-phase fibers and the pure YAG fibers are prepared; (2) centrifugal spinning is performed, namely a home-made centrifugal spinning machine is adopted to perform centrifugal spinning so as to obtain uniform-diameter gel fibers under the conditions of appropriate wind seed, appropriate rotation speed and relative humidity; (3) the polycrystalline Al2O3-Y3Al5O12 complex-phase fibers and the YAG fibers are prepared, namely the obtained gel fibers are dried at the temperature of 55-75 DEG C for 12 hours, then heat processing is performed at the temperature interval of 800-1400 DEG C for 2 hours to obtain the required polycrystalline Al2O3-YAG complex-phase fibers and continuous YAG fibers. The fibers prepared by means of the preparation method have good flexibility, higher in high-temperature-resistance degree and better in creep resistance performance, and industrial production can be considered.

Owner:南京理工宇龙新材料科技股份有限公司

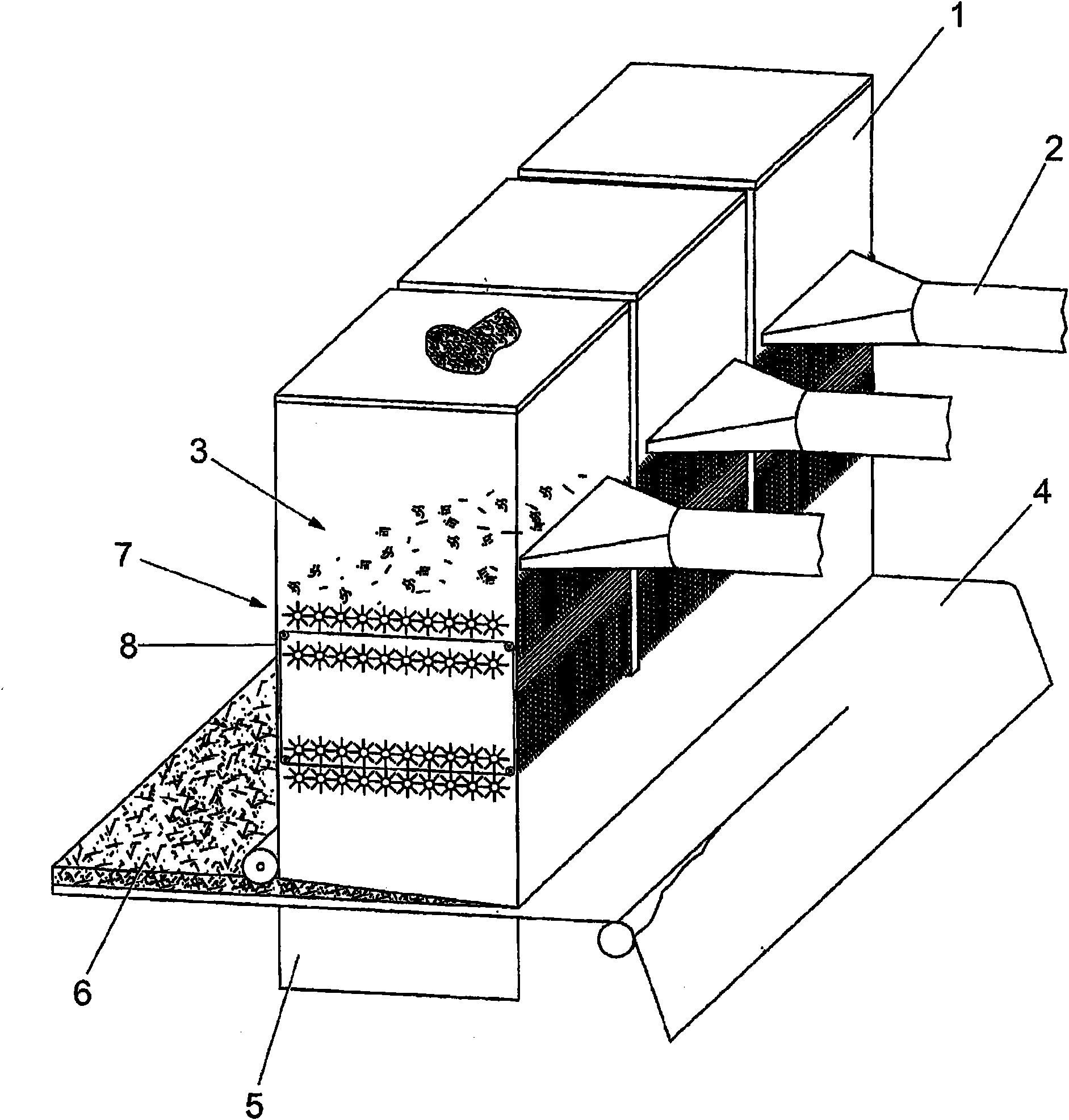

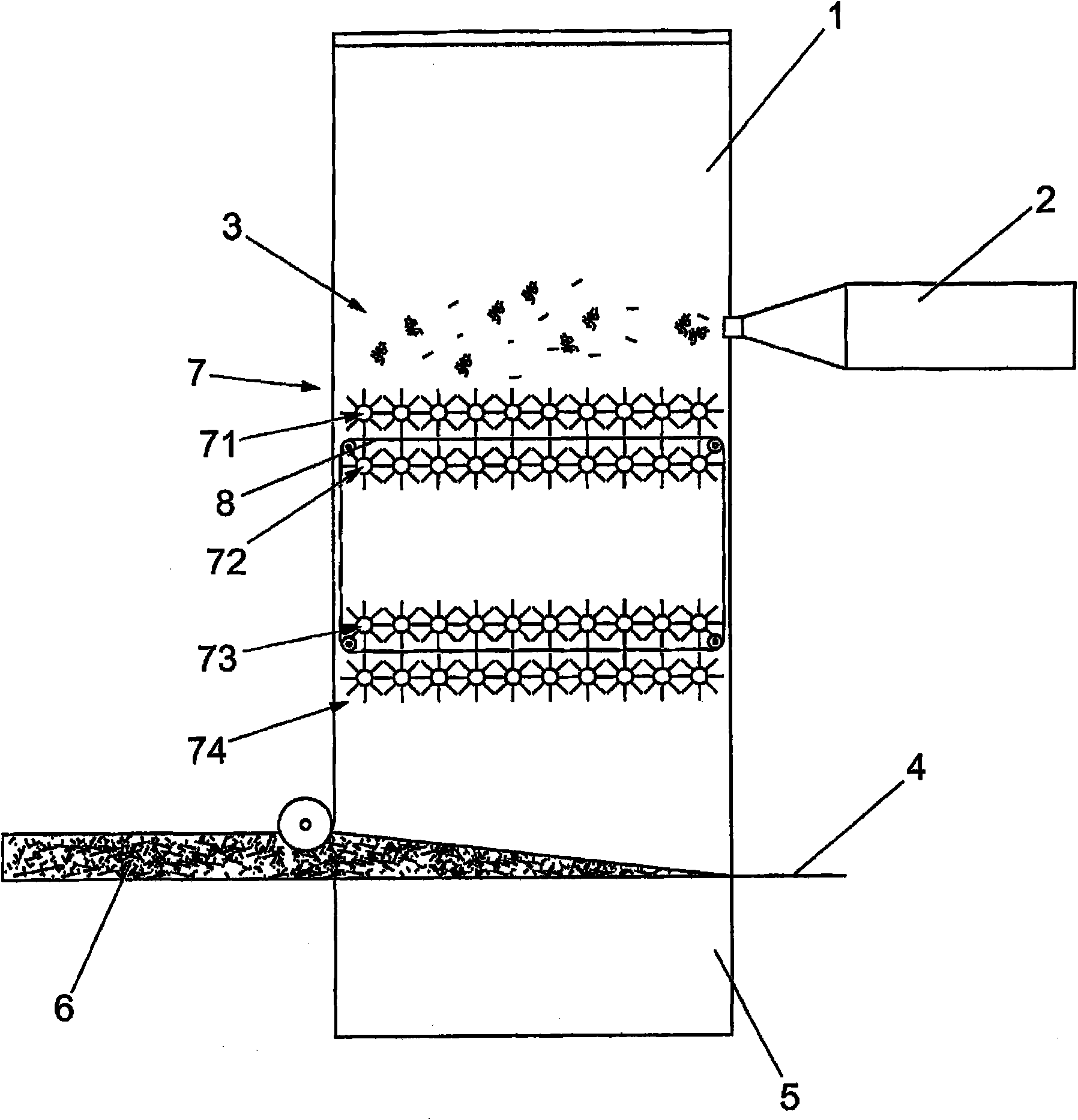

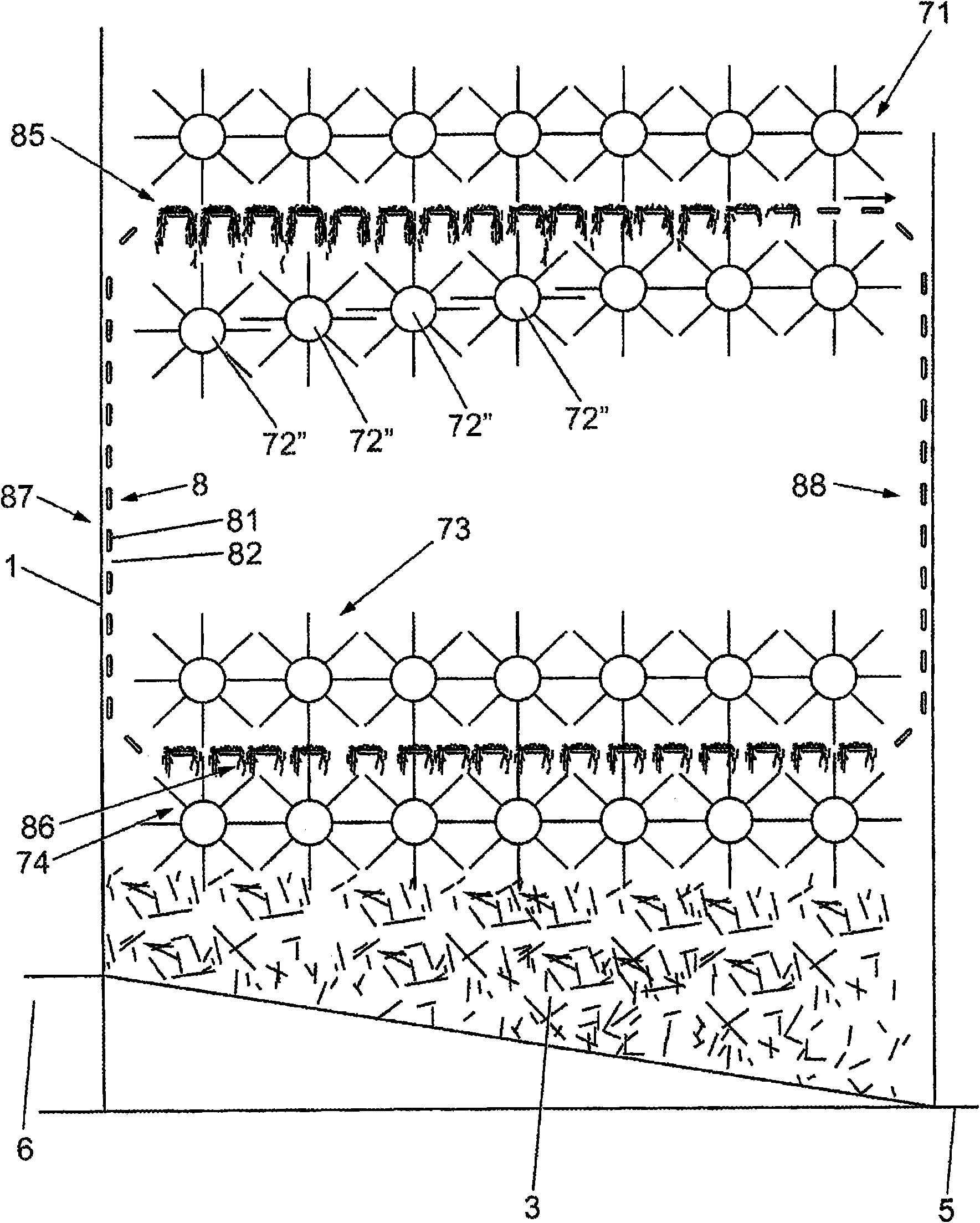

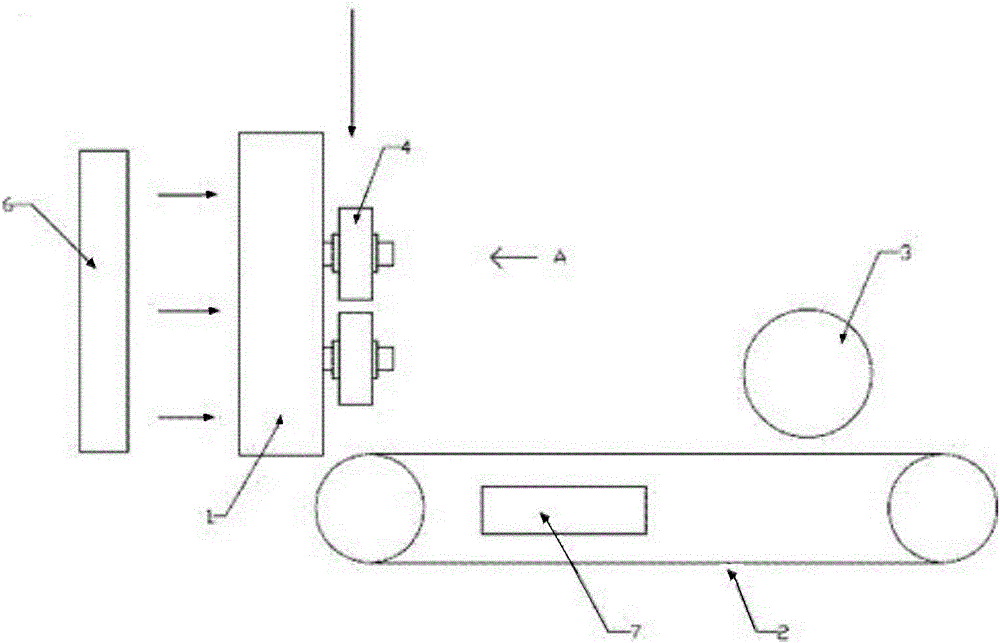

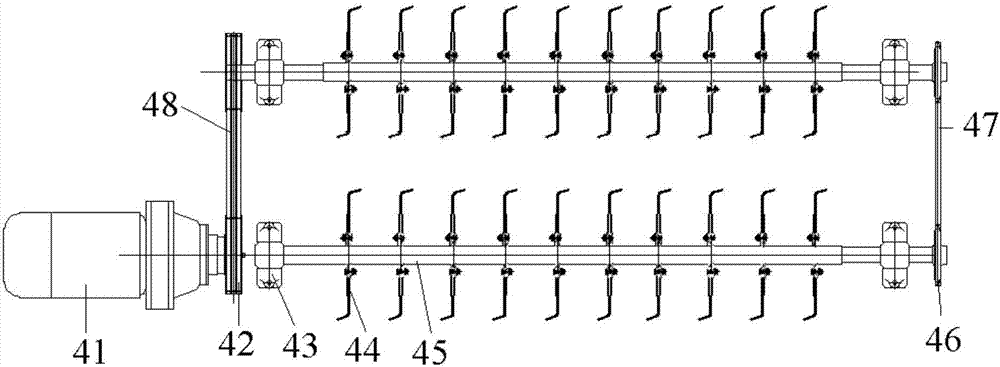

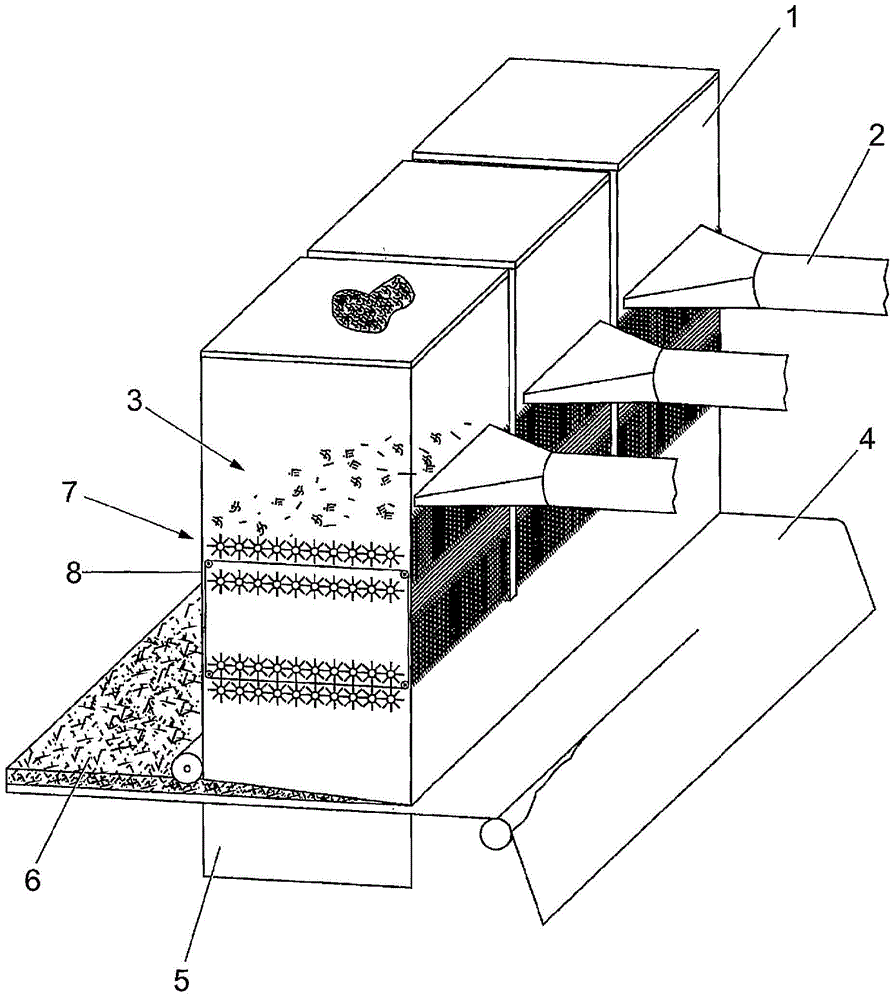

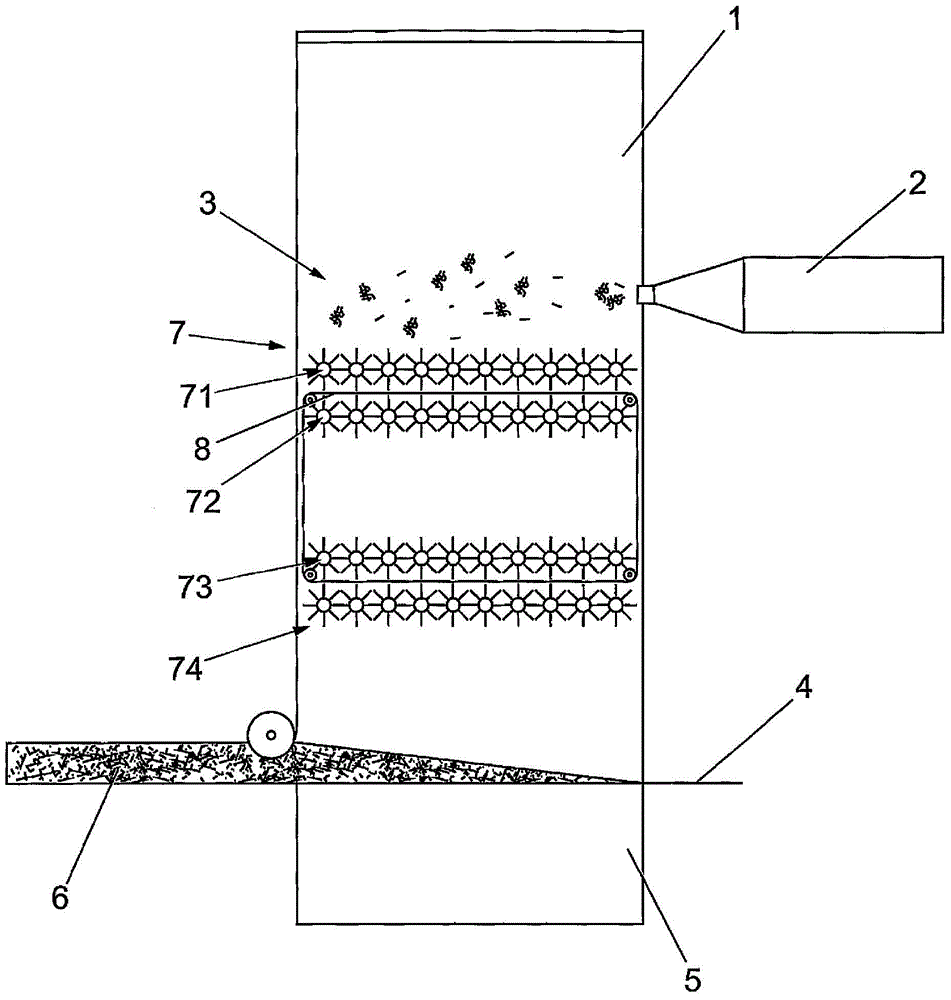

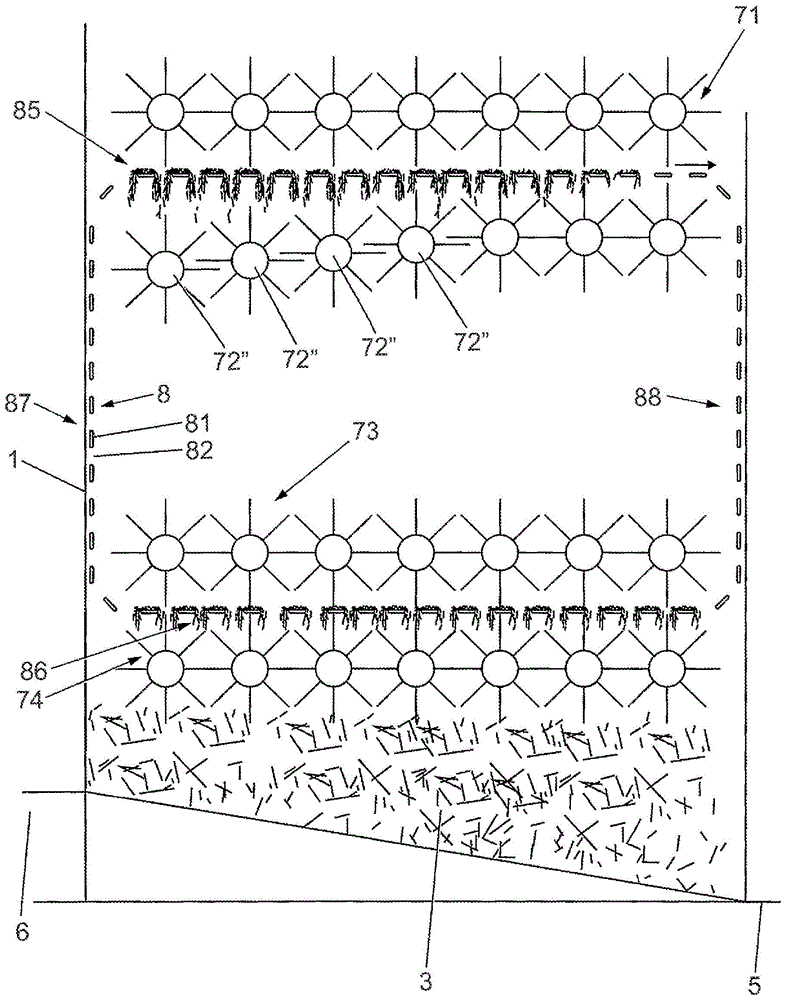

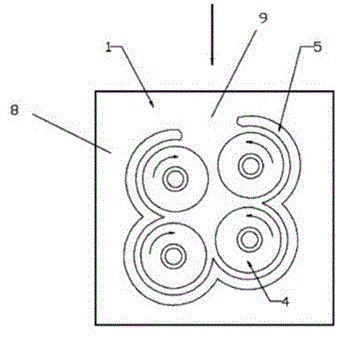

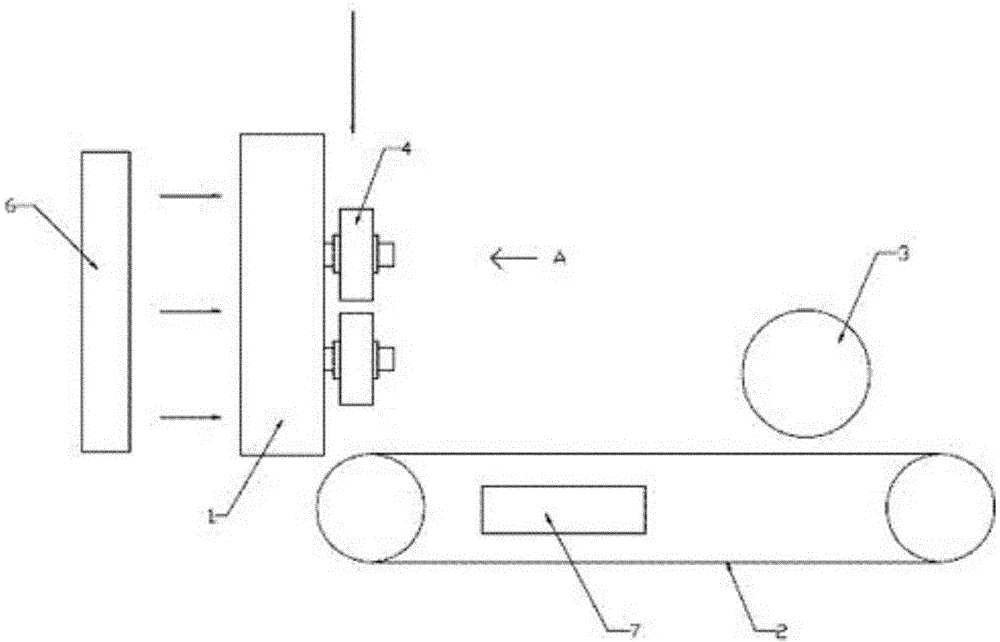

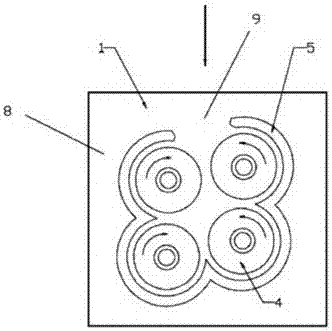

Method of making mounting mats for mounting pollution control element

InactiveCN101821070AEasy to prepareEasy to manufactureFibre cleaning and opening machine combinationsSilencing apparatusFiberMechanical engineering

The present invention relates to a method of making mounting mats for use in pollution control device. The method comprises the steps of: (i) supplying inorganic fibers through an inlet of a forming box having an open bottom positioned over a forming wire to form a mat of fibers on the forming wire, the forming box having a plurality of fiber separating rollers arranged in at least one row in the housing between the inlet and housing bottom for breaking apart clumps of fibers and an endless belt screen; (ii) capturing clumps of fibers on a lower run of the endless belt beneath fiber separating rollers and above the forming wire; (iii) conveying captured clumps of fibers on the endless belt above fiber separating rollers to enable captured clumps to release from the belt and to contact and be broken apart by the rollers; (iv) transporting the mat of fibers out of the forming box by the forming wire; and (v) compressing the mat of fibers and restraining the mat of fibers in its compressed state thereby obtaining a mounting mat having a desired thickness suitable for mounting a pollution control element in the housing of a catalytic converter.

Owner:3M INNOVATIVE PROPERTIES CO

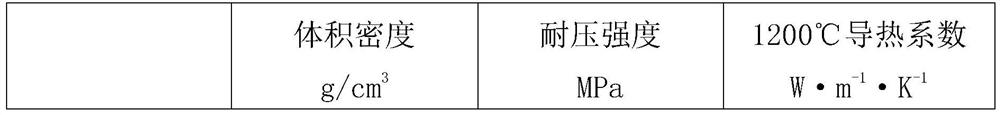

High-temperature-resistant thermal insulation material and preparation method thereof

ActiveCN111848106ALarge specific surface areaGood chemical stabilityZirconium oxidesThermal insulationPotassium titanate

The invention relates to the technical field of thermal insulation materials. The invention provides a high-temperature-resistant thermal insulation material and a preparation method thereof. The high-temperature-resistant thermal insulation material comprises the following raw materials in parts by weight: 55-75 parts of ceramic fiber cotton, 5-15 parts of potassium hexatitanate whiskers, 4-8 parts of modified expanded vermiculite, 5-18 parts of zirconium dioxide aerogel, 1-6 parts of a silane coupling agent, 2-5 parts of an inorganic binding agent, 1-3 parts of an organic binding agent, 1-5parts of a flocculating agent and 2-4 parts of a dispersing agent. The problems that in the prior art, a heat preservation and insulation material made of single ceramic fiber difficultly meets the requirement for high-temperature heat insulation, and the comprehensive performance of the ceramic fiber heat insulation material needs to be further improved are solved.

Owner:福建省中能泰丰节能环保科技有限公司

Biodegradable refractory ceramic fibre and preparation thereof

The invention relates to a biodegradable refractory ceramics fiber and a production method thereof. The technical proposal thereof comprises the following steps of: carrying out fine grinding treatment for the following materials according to the following mass ratio: 18-25 wt% of talcum powder or 28-33 wt% of dolomite, 15-40 wt% of wollastonite, 30-50 wt% of quartz sand, 0.5-3 wt % of industrial grade calcium chloride, 0.5-3 wt% of fluorite, 0.2-2 wt% of rare earth metal oxide and 0-3 wt% of zircon sand zircon sand; then adding 0.5-3 wt% of carboxymethyl cellulose or calcium lignosulphonate as a bonding agent; compressing the mixture into blank, then drying and crashing the mixture; heating the crashed mixture in a resistance furnace or an arc furnace at the temperature of 1500-1900 DEG C, then throwing fiber directly or forming fiber under the pressure of 0.3-0.7 Mpa by blowing after the mixture is smelted. The invention adopts natural minerals as raw materials and has low cost and simple technique, and the biodegradable refractory ceramics fiber produced by the invention has high mechanical strength, smooth surface, uniform chemical composition and can be used at the temperature of 1000-1200 DEG C or higher temperature for a long period and the harmfulness on the human body is reduced considerably.

Owner:WUHAN UNIV OF SCI & TECH

Inorganic fiber with solid waste as raw material and production method thereof

InactiveCN103539347AImprove water resistanceImprove acid resistanceGlass making apparatusFiberThermal insulation

The invention discloses an inorganic fiber with solid waste powder as a raw material and a production method thereof. After igniting for 30 minutes at 550 DEG C, the resulting residue comprises the following components by mass percent: 36 to 48% of SiO2, 8 to 21% of Al2O3, 22 to 32% of CaO, 2 to 12% of Fe2O3, 4 to 14% of MgO, 0.1 to 2% of Na2O, 0.1 to 2% of K2O and 0.5 to 3% of TiO. According to the production method, coal ash can be utilized to the maximum; the produced inorganic fiber product is outstanding in water resistance, acid resistance and durability, has a low shot content and is applicable to an external thermal insulation product of a building, a sound absorbing and insulating material, a heat insulation plate, a heat insulation material of an industrial pipeline, etc. The preparation method of the inorganic fiber overcomes the problems due to the melting of the raw material and the control of the molding viscosity and brings a feasible scheme for industrialized application of preparation of the inorganic fiber with coal ash as a raw material.

Owner:SHANGHAI HUAMING HI TECH GRP +1

Magnesium silicate fiber blanket and production method thereof

ActiveCN101706030AWith insulationWith sound-absorbing functionMagnesium silicatesThermal insulationFiberThermal insulation

The invention relates to a magnesium silicate fiber blanket belonging to the technical field of fire-proof heat preservation and insulation materials. The magnesium silicate fiber blanket is characterized by comprising the following materials with oxides in percentage by weight: 40%-85% of SiO2, 3%-40% of MgO, 2%-30% of CaO, and the balance of one or the any combination of B2O3, Al2O3, Fe2O3, Na2O and K2O, wherein the total amount of the SiO2, the MgO and the CaO is more than or equal to 85%. The magnesium silicate fiber blanket is processed through the procedures of material melt, centrifugal thread throwing or blowing fiber forming, cotton collection, pinprick, heat treatment, cutting, and the like. The magnesium silicate fiber blanket has functions of non-inflammation, heat insulation, sound absorption and fire prevention and is a fire-resistant heat-preserving heat-insulating fire-proof material which is widely suitable for various heat engineering equipment and pipelines.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Non-asbestos composite fiber and preparation method thereof

InactiveCN103194172AThe preparation process is simple and reliableLow costOther chemical processesFiber strengthPolyresin

The invention discloses a non-asbestos composite fiber and a preparation method of the on-asbestos composite fiber, and belongs to the technical field of chemical material manufacturing. The non-asbestos composite fiber has the main technical characteristics that: the fiber is composed of the following raw material compositions in percentage by weight: 62-80% of a fiber material, 17-34% of a powder material, and 3-6% of a modifier, wherein the fiber material is a non-natural fiber material subjected to high-temperature treatment, the powder material is selected from talcum powder, bentonite, vermiculite and mica powder and the like in silicate materials, the particle size of the powder material enables the powder material to achieve 100% of passing rate at 100 meshes, and the modifier is a polymer resin or a combination thereof. The composite fiber disclosed by the invention is simple in material production process and low in cost, and has good comprehensive performances such as low shot content, small fiber diameter and high fiber strength and the like; and the used fiber does not contain asbestos and asbestos fiber, therefore, the non-asbestos composite fiber is nonpoisonous, and has no harm to the human body and environment. Therefore, both in production and use, the safety and reliability can be ensured, so the non-asbestos composite fiber is an environmental-friendly novel composite fiber material.

Owner:咸阳非金属矿研究设计院有限公司

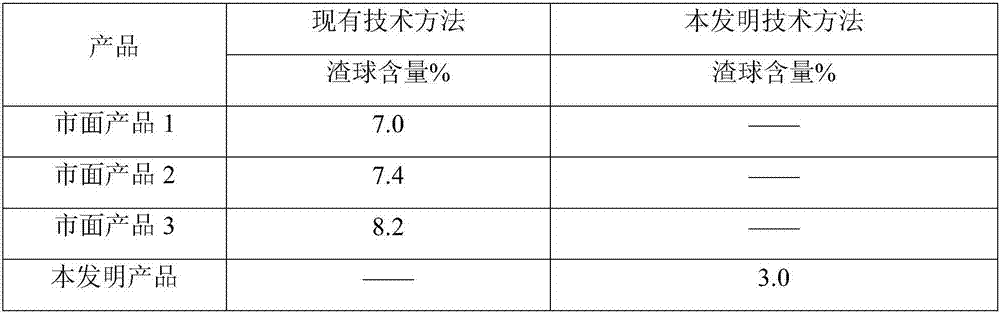

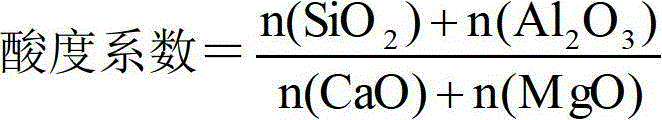

Slag ball content control method for preparation of mineral wool from silicon-manganese slag

The invention provides a slag ball content control method for preparation of mineral wool from silicon-manganese slag and relates to improvement of a technological method for preparing mineral wool from metallurgical slag, particularly from the silicon-manganese slag. The method is characterized in that a flux is added to hot melt slag of a silicon-manganese alloy in the preparation process, wherein the flux contains calcium fluoride and magnesium oxide, adding amount of calcium fluoride is 5%-8% by weight of the hot melt slag of the silicon-manganese alloy, and the adding amount of magnesiumoxide is 3%-5% by weight of the hot melt slag of the silicon-manganese alloy. According to the method, the slag is diluted by adding the flux to the hot melt slag of the silicon-manganese alloy, flowability of the hot melt slag is enhanced, fibers can become thinner due to wool forming in a high-speed centrifugation state, content of slag balls in the mineral wool is reduced, tensile strength of the mineral wool is improved, cost is lower, and operation is facilitated; glass state of high-temperature melt of the prepared mineral wool is good, fiber forming rate is high, fiber forming quality is excellent, slag ball content is lower than 8%, heat conductivity coefficient is low, tensile strength is high, and diversified market demands can be met.

Owner:NINGXIA JIYUAN JUNTAI NEW MATERIAL TECH CO LTD

Non-asbestos high-density temperature and wear resisting heat insulation plate and processing technology thereof

ActiveCN105084812AEliminate environmental risksHigh temperature resistantSolid waste managementFiberGlass fiber

The invention discloses a non-asbestos high-density temperature and wear resisting heat insulation plate. The heat insulation plate is characterized by comprising, by weight, 200-260 parts of kaolin, 15-40 parts of alumina powder, 200-260 parts of aluminum silicate refractory fiber, 10-20 parts of dry paper pulp, 5-15 parts of glass fiber, 10-20 parts of cationic starch, 1-1.5 parts of polyvinyl alcohol and 1-1.5 parts of high-elastic emulsion. The non-asbestos high-density temperature and wear resisting heat insulation plate completely has no asbestos, eliminates environment risks brought by asbestos fiber in the production, maintenance and cleaning processes, is environmentally friendly and has the advantages of resisting high temperature, high pressure, bending and wear, being high in density and good in tenacity and the like. The high temperature lower than or equal to 1200 DEG C can be resisted, and the density reaches up to 900-1100 kg / m<3>. The tenacity is good, and the compression ratio can reach 1:1.4. The shot content in the non-asbestos high-density temperature and wear resisting heat insulation plate is low, and it is ensured that products making contact with the heat insulation plate are not damaged in the using process.

Owner:JINGMEN KAIDI IND TECH CO LTD

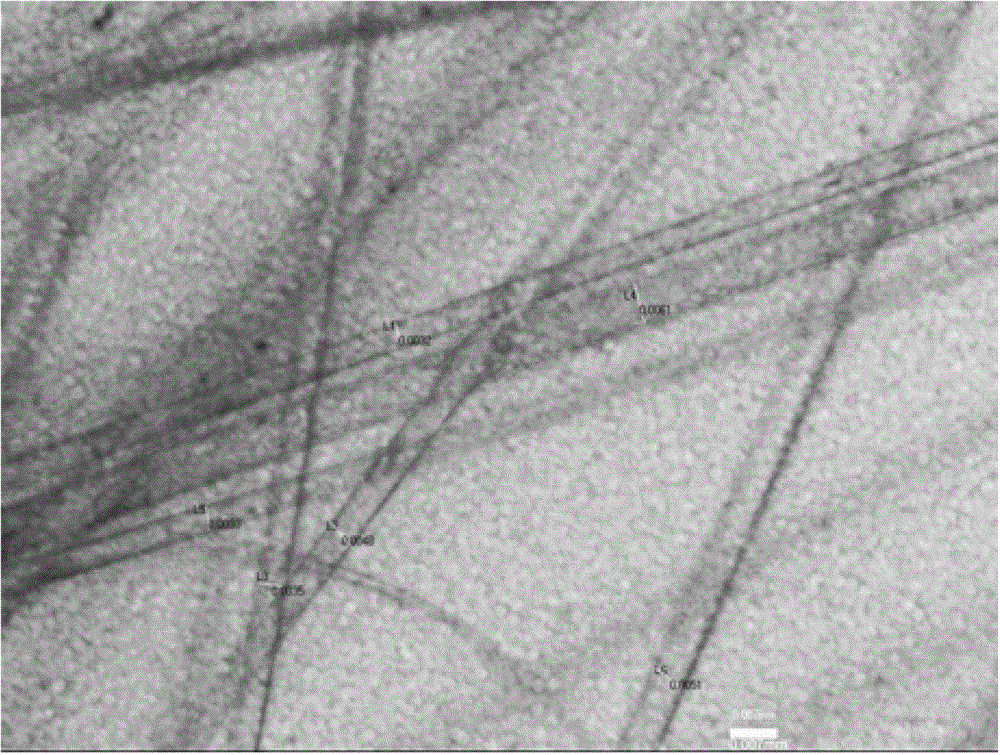

Method for preparing magnesium oxide fibers by ligand analysis technology

ActiveCN104404654ASolve easy pulverizationSolve the strength problemInorganic material artificial filamentsArtificial filament chemical after-treatmentFiberWater vapor

The invention relates to a method for preparing magnesium oxide fibers by a ligand analysis technology. The method comprises the following steps: putting fully dried magnesium oxide precursor fibers into an alkaline gas, alkaline steam or / and water vapor atmosphere, performing ligand analysis treatment under a condition that the temperature is higher than 100 DEG C, and performing dissociation reaction on the magnesium oxide precursor fibers to generate magnesium hydrate; enabling magnesium hydrate to be shrunk to form the magnesium oxide fibers. By the ligand analysis technology, the technical difficulties that the fibers are easy to pulverize and difficultly formed are solved; by an optimized thermal treatment program, the mechanical property of the magnesium oxide fibers can be effectively enhanced.

Owner:SHANDONG UNIV

Dreg ball free alumina silicate cotton velvet and its uses in brake field

ActiveCN1762870AStable coefficient of frictionImprove heat resistanceGlass making apparatusChemical compositionSlag

The present invention is one kind of aluminum silicate wool with few slag ball and its application in braking field. The aluminum silicate wool contains common, zirconium-containing and soluble aluminum silicate fibers, and has fiber length of 50-300 microns, fiber diameter of 2-5 microns, content of slag balls of diameter larger than 0.25 mm in 0-8 %, Mohs' hardness 5-7, use temperature 1000-1300 deg.c, thermal conductivity not higher than 0.153 W / mk at 500 deg.c, and tensile strength 1000-1600 MPa. It has chemical composition of Al2O3 43-55 wt% and SiO2 45-57 wt%; or Al2O3+SiO2+ZrO2 in 98.5-99.5 wt%, ZrO2 not less than 15 wt%, and impurity the rest; or SiO2 52-85 wt%, CaO 5-35 wt%, MgO 1-10 wt%, Al2O3 0-1 wt% and B2O3 1-2 wt%. The aluminum silicate wool is applied as reinforcing fiber material in braking field.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

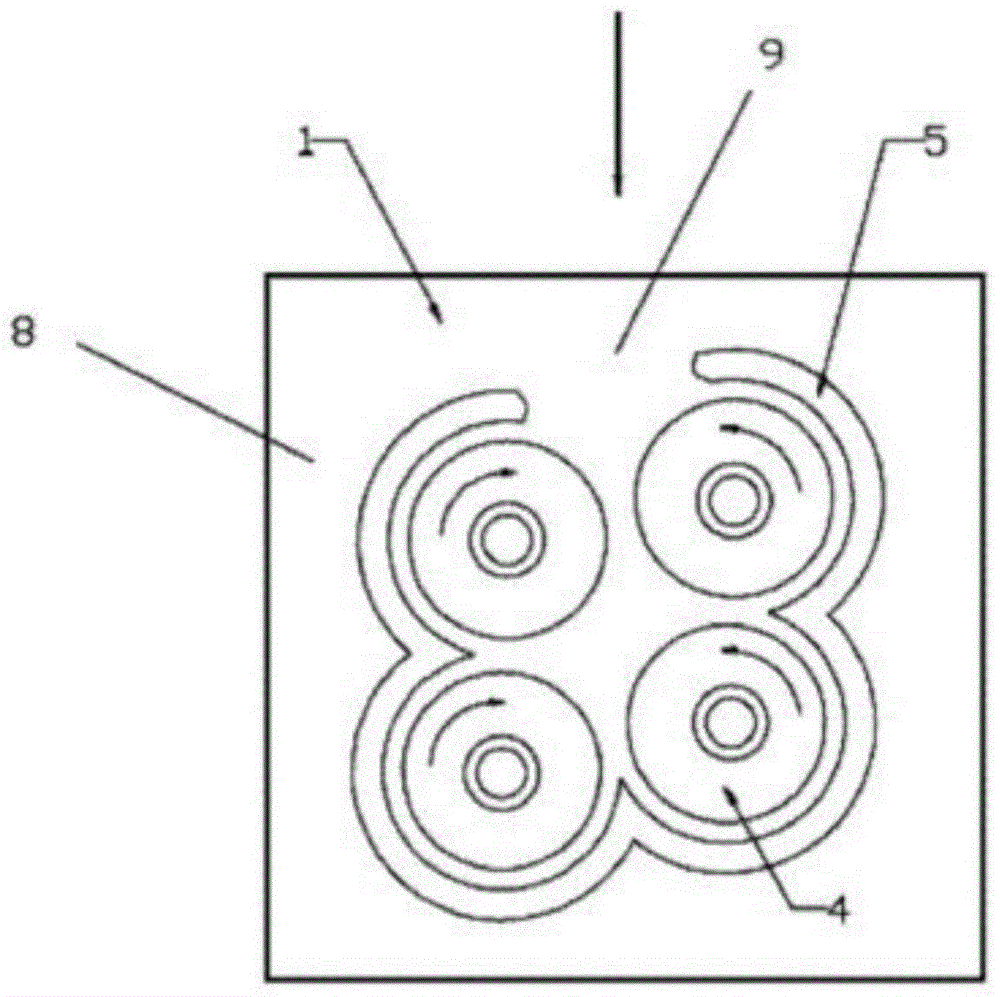

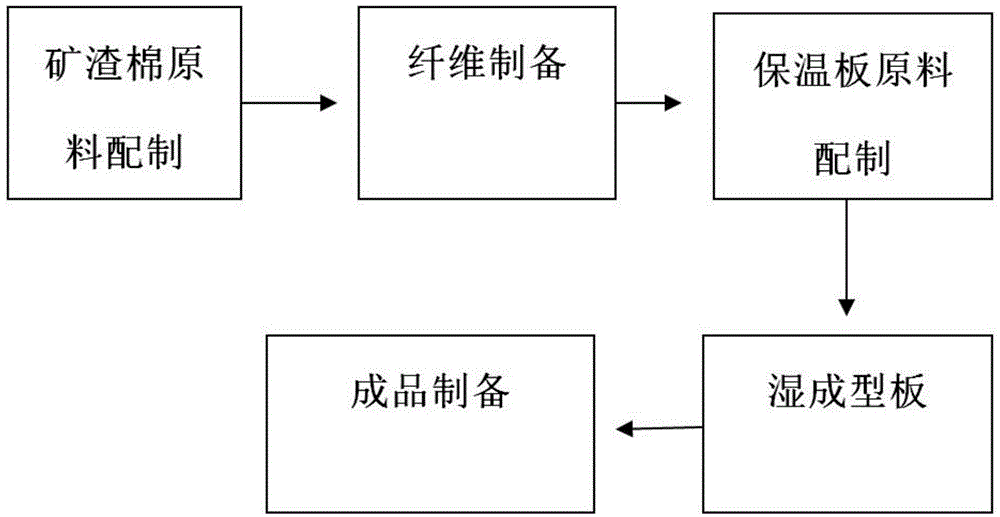

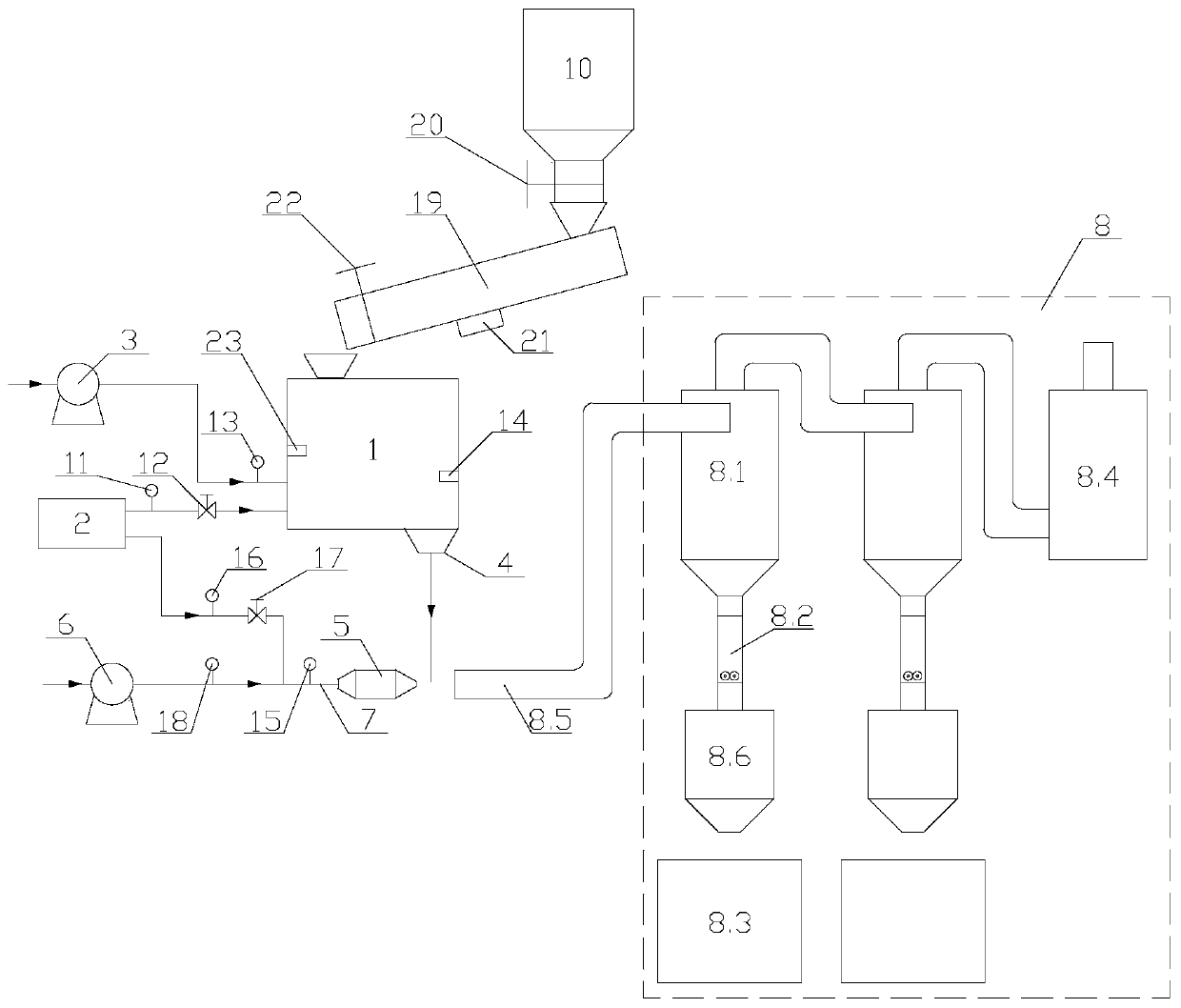

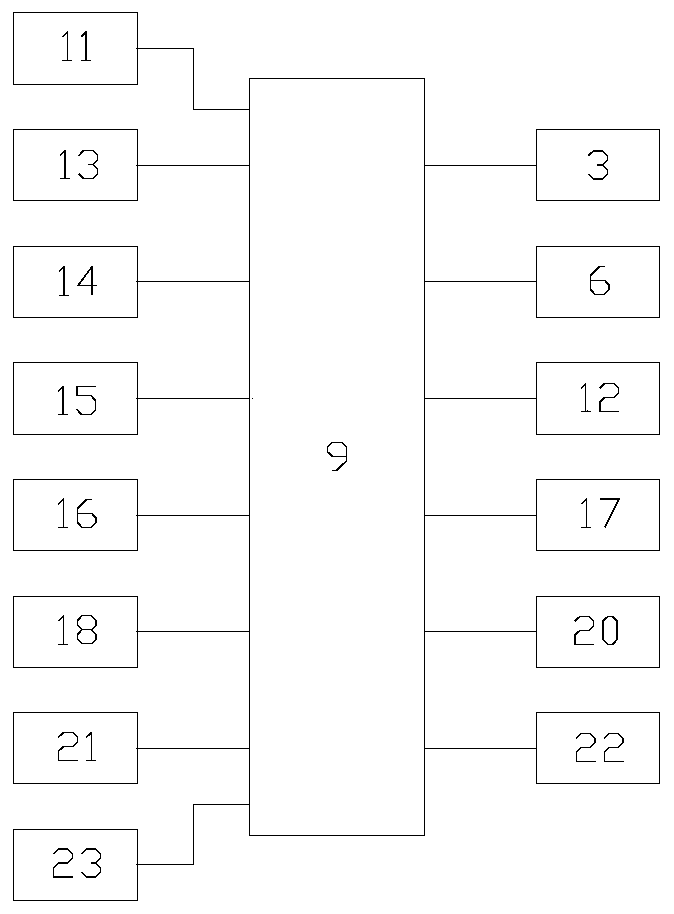

External wall fireproof thermal-insulation plate prepared by using slag cotton

The invention discloses a production method for preparing an external wall fireproof thermal-insulation plate by using slag cotton. The production method comprises: (1) slag cotton raw material preparation, wherein blast furnace slag, graystone, fly ash, magnesium oxide, calcium oxide and wollastonite are mixed and melt into a liquid mixture; (2) fiber preparation, wherein the liquid mixture continuously flows into a centrifugal roller rotating at a high speed, and condenses into filamentous fibers under the centrifugal throwing and air cooling effect, and the fibers are subjected to collecting molding under the air blasting effect of an air blower; (3) thermal-insulation material raw material preparation, wherein 50-65% of the prepared slag cotton, 3-6% of polycrystalline zirconia fibers, 15-20% of desulfurized gypsum, 10-15% of fly ash, and 10-15% of 425# cement are adopted; (4) wet molding plate preparation; and (5) finished product preparation.

Owner:马鞍山市北益环保科技有限责任公司

Aluminum oxide nascent fiber with low aluminum oxide content, aluminum oxide fiber, preparation method of aluminum oxide fiber, aluminum oxide fiber blanket and preparation method of aluminum oxide fiber blanket

ActiveCN112723866ALow shot contentReduce contentInorganic material artificial filamentsNon-woven fabricsPolyvinyl alcoholAluminium oxides

The invention provides an aluminum oxide nascent fiber with low aluminum oxide content. The aluminum oxide nascent fiber is obtained by carrying out fiber forming and cotton collecting treatment on aluminum oxide colloid, wherein the aluminum oxide colloid is obtained by reacting polymerized aluminum oxide sol, silica sol, an additive and a fiber reinforcing agent, the additive comprises lactic acid, polyvinyl alcohol, ethanol and water, and the fiber reinforcing agent is selected from copper oxide and / or lead oxide. Compared with the prior art, the fiber reinforcing agent is added in the preparation of the aluminum oxide colloid, so that colloid gelatinization is facilitated, the fiber toughness is improved, the tensile strength meets the requirements, the content of aluminum oxide is reduced, the production cost is reduced, and meanwhile, the obtained aluminum oxide fiber has relatively low slag ball content and relatively good heat insulation performance; and the tensile strength of the fiber is improved, so that the application field is wide.

Owner:山东鲁阳浩特高技术纤维有限公司

Centrifugal spinning preparation method for environment-friendly CMSP refractory fiber blanket

InactiveCN104556668ARaw materials are natural and easy to getLow costGlass making apparatusGlass productionSolubilityFiber

The invention belongs to the field of refractory fibers and particularly relates to a centrifugal spinning preparation method for an environment-friendly CMSP refractory fiber blanket. An alkali-free boron-free CMSP refractory fiber is produced from natural diopside, quartz sand, calcite, flint clay and phosphate ore which are subjected to iron removal treatment as raw materials by virtue of a centrifugal spinning method and has the characteristics of high refractoriness, high degradation rate in the lung fluid, energy conservation and environment friendliness. The refractory fiber has the advantages of natural and easily available raw materials, low cost, environment friendliness during the manufacturing process and no air pollution phenomenon; the product has good solubility in body fluids and refractoriness not less than 1000 DEG C and is an ideal environment-friendly energy-saving alternative, meets the thermal-insulation requirements of most pipes and devices and has wide market prospects and the risk of occupational health of workers is eliminated.

Owner:SHANDONG LIYOUN NEW MATERIAL

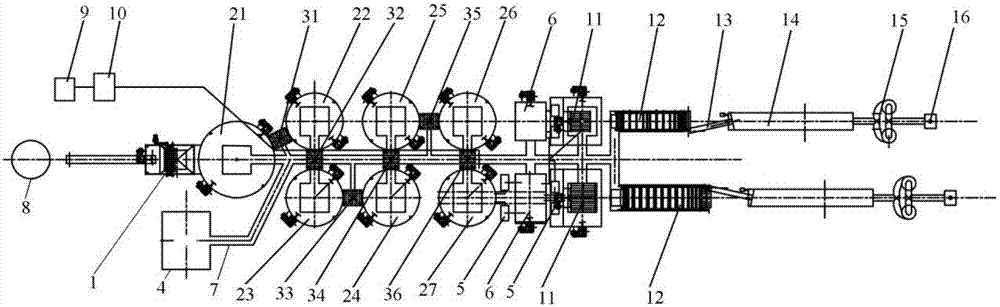

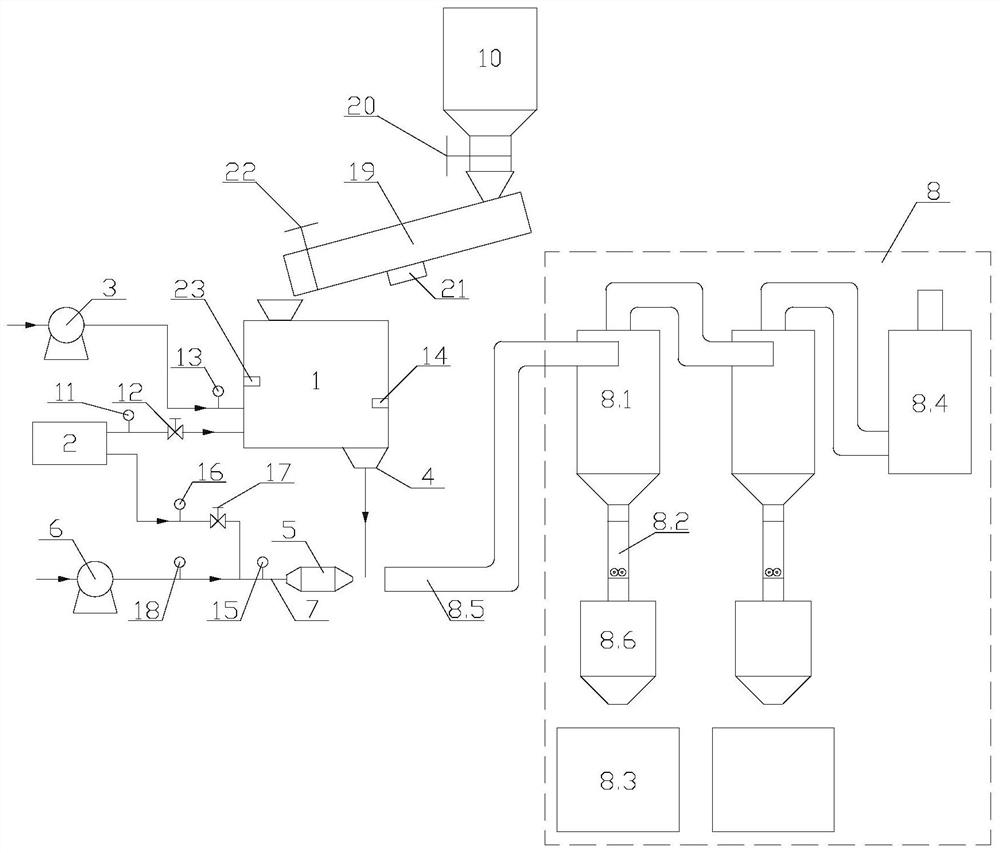

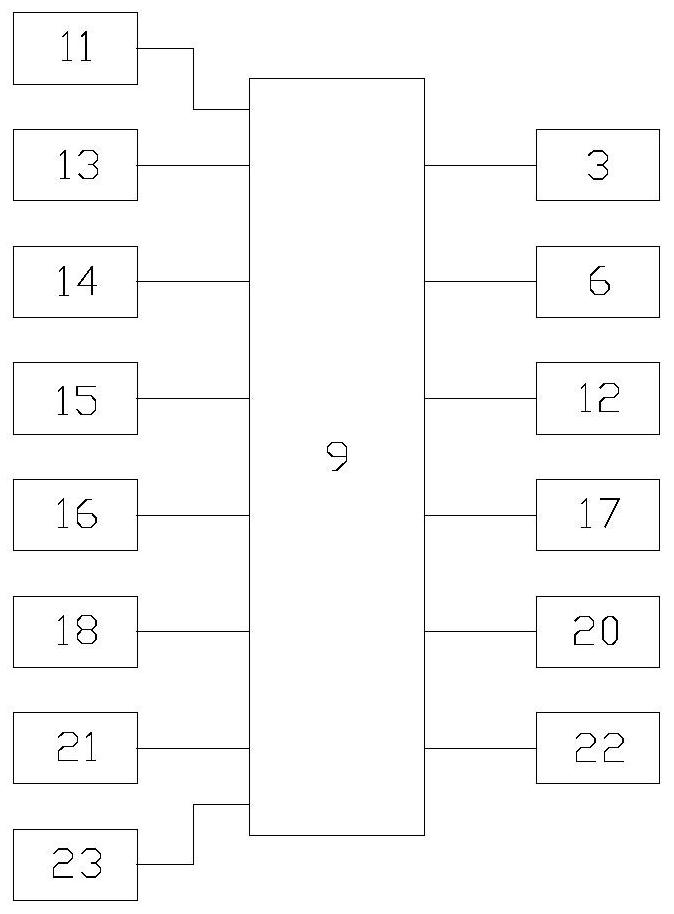

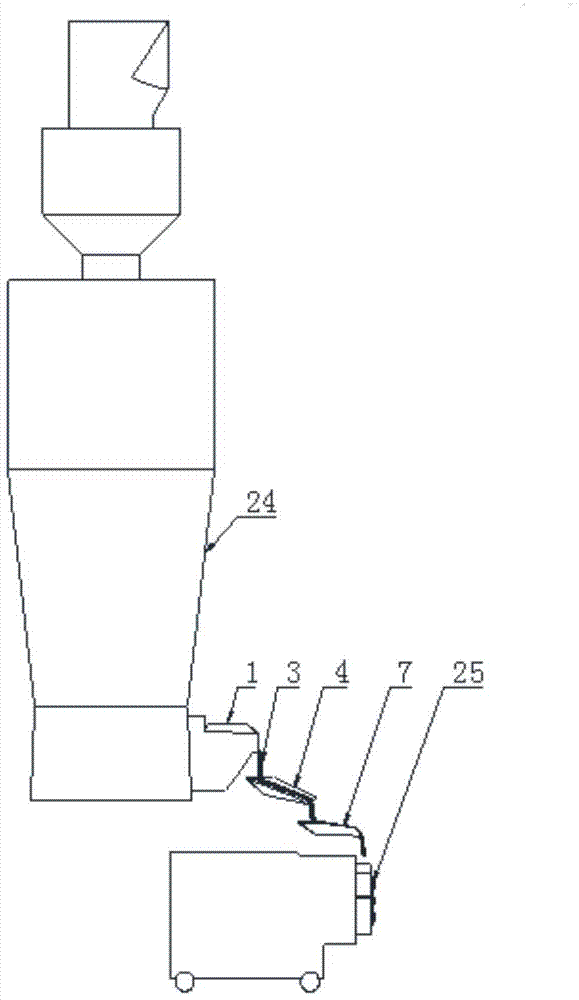

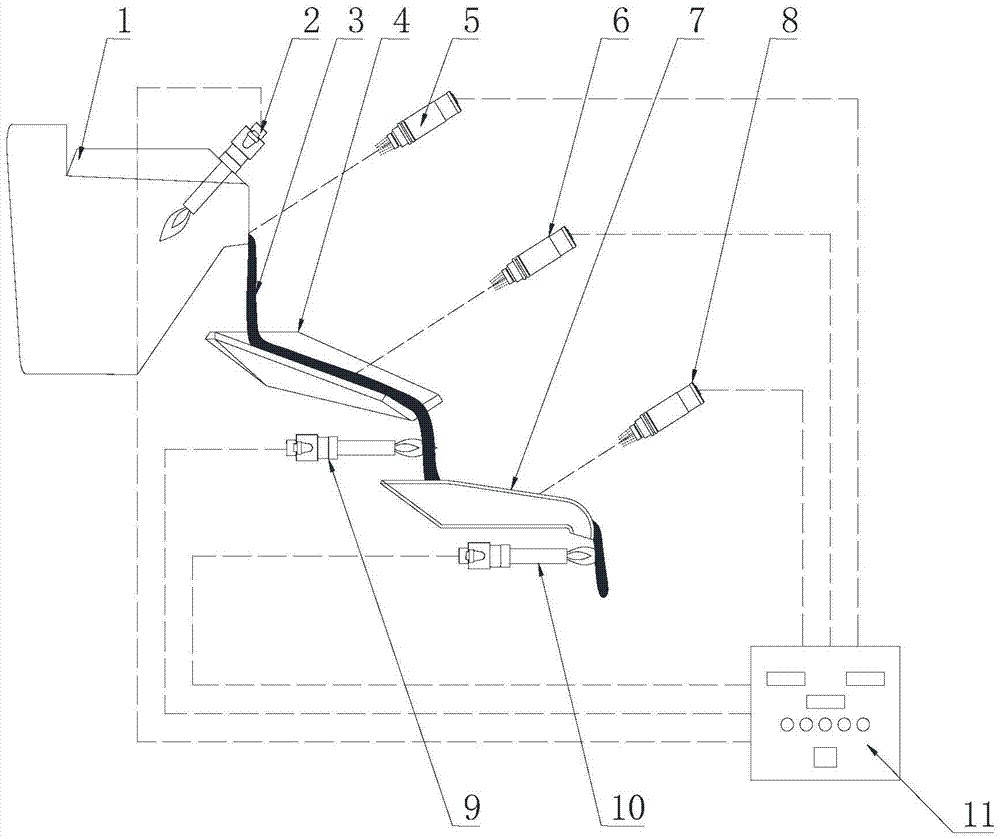

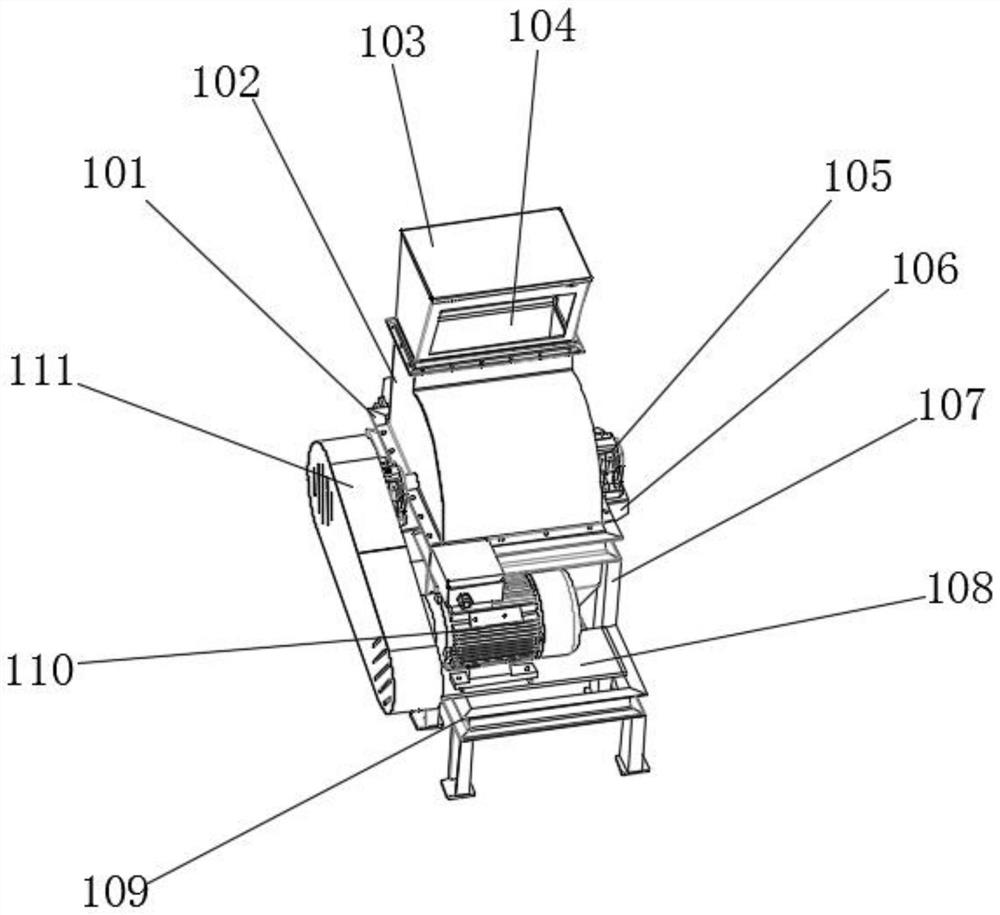

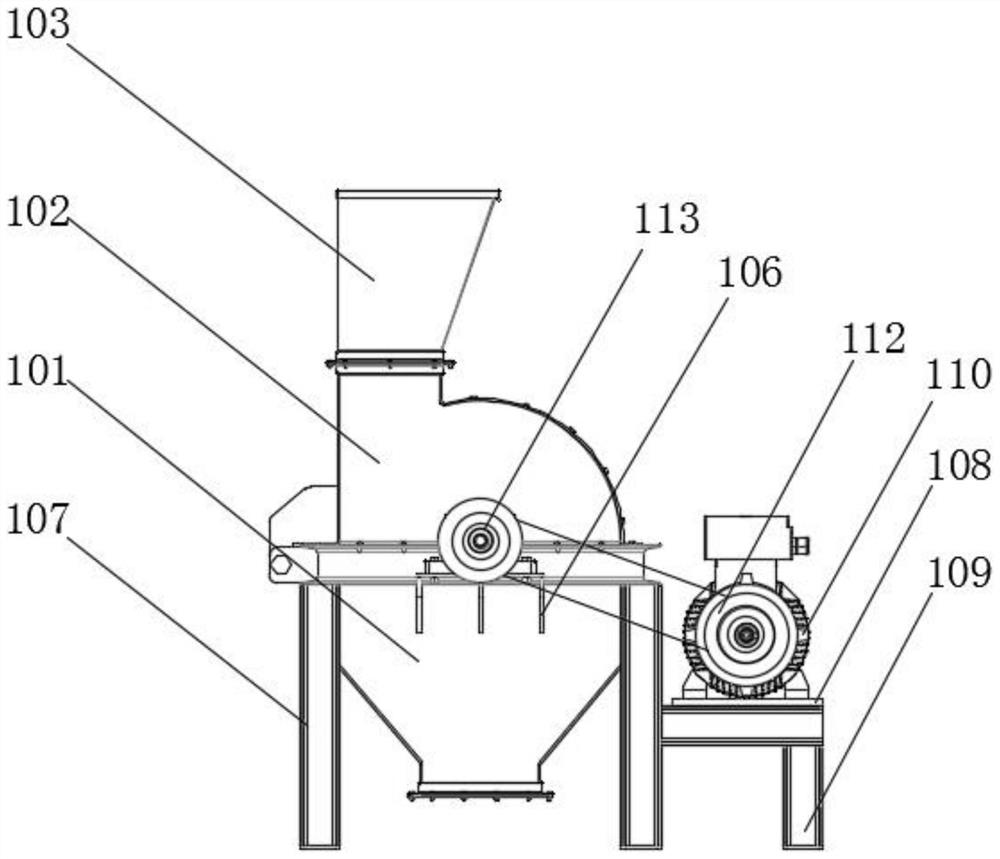

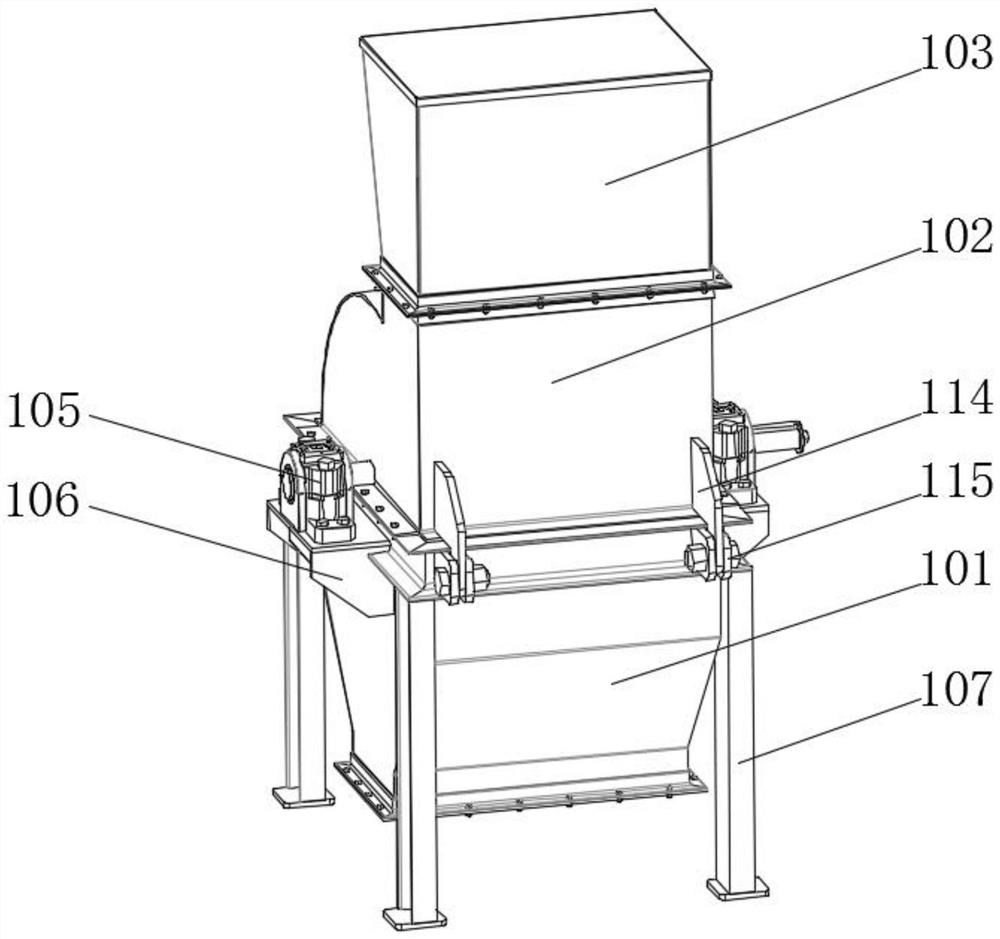

Production system and production method of micro fiber glass wool

The invention discloses a production system and a production method of micro fiber glass wool. The production system comprises a melting kiln, a fuel gas source, a first air blower, a wiredrawing leaking plate, a wool blowing device, a second air blower, a wool collecting device and a controller. The production method comprises the following steps: (1) performing heating melting; (2) performing wiredrawing; and (3) performing wool blowing. The production system and the production method have the beneficial effects of being simple in structure and easy to achieve, in addition, an automatic control function is achieved, the stability of the beating degree of the glass wool can be ensured, and furthermore, quality stability of the produced glass wool can be ensured; stability of pressure of ejected flame air flow can be ensured, furthermore, the shot content in the product, namely the glass wool, is reduced, and the quality of the glass wool can be improved; the use amount of a fuel gas can be reduced, electric energy consumption can be reduced, and the production cost can be lowered.

Owner:内蒙古海晟材料科技有限公司

Mineral compound fiber wet-method slag removal device

The invention discloses a mineral compound fiber wet-method slag removal device. The mineral compound fiber wet-method slag removal device comprises an electric melting furnace, the electric melting furnace is connected with a debonding machine, the output end of the debonding machine is connected with softening pools and air floated equipment, wherein the softening pools and the air floated equipment are arranged alternatively, seven softening pools are arranged, and six pieces of air floated equipment are arranged; the softening pool at the most tail end is connected with slag separators, and the two ends of the slag separators are provided with two-phase pulp fluid pumps; two slag separators are arranged to process long fiber and short fiber correspondingly; and the slag separators are then connected with automatic dewatering equipment, fiber dewatering machines, flat belt conveyors, drying machines, cyclone dust collectors and centrifugal fans in sequence. By means of the mineral compound fiber wet-method slag removal device, the problems that existing mineral fiber is poor in tenacity, high in slag ball content, not environmentally friendly, low in production efficiency and not suitable for industrialized production are solved, and no dust is generated in the production process.

Owner:咸阳非金属矿研究设计院有限公司

Method of making mounting mats for mounting pollution control element

InactiveCN104947318AEasy to prepareEasy to manufactureFibre cleaning and opening machine combinationsSilencing apparatusFiberCatalytic transformation

The present invention relates to a method of making mounting mats for use in pollution control device. The method comprises the steps of: (i) supplying inorganic fibers through an inlet of a forming box having an open bottom positioned over a forming wire to form a mat of fibers on the forming wire, the forming box having a plurality of fiber separating rollers provided in at least one row in the housing between the inlet and housing bottom for breaking apart clumps of fibers and an endless belt screen; (ii) capturing clumps of fibers on a lower run of the endless belt beneath fiber separating rollers and above the forming wire; (iii) conveying captured clumps of fibers on the endless belt above fiber separating rollers to enable captured clumps to release from the belt and to contact and be broken apart by the rollers; (iv) transporting the mat of fibers out of the forming box by the forming wire; and (v) compressing the mat of fibers and restraining the mat of fibers in its compressed state thereby obtaining a mounting mat having a desired thickness suitable for mounting a pollution control element in the housing of a catalytic converter.

Owner:3M INNOVATIVE PROPERTIES CO

Novel ultra-filament mineral cotton

The invention discloses a production of centrifugal ultra-filament mineral cotton which is excellent in index and relatively long in cellosilk. The production method comprises the following steps: (1) preparing raw materials, namely fusing 55-65% of blast furnace slag, 12-18% of graystone, 5-7% of coal ash, 2-3% of magnesium oxide, 2% of calcium oxide and 15-20% of wollastonite in percentage by weight into a liquid mixture; and (2) preparing fibers, namely continuously enabling the liquid mixture to flow to a centrifugal roll which rotates at a high speed, coagulating the liquid mixture into filamentous cellosilk under the action of centrifugal throwing and air cooling, and collecting and forming the cellosilk under the blasting action of a blast blower.

Owner:郎溪品旭科技发展有限公司

Environment-friendly rock wool heat-insulation board production process

ActiveCN111892379AHigh compressive strengthReduce foreshadowingGlass making apparatusFiberCupola furnace

The invention discloses an environment-friendly rock wool heat-insulation board production process. According to the invention, raw materials are mixed, crushed and preheated, the temperature in a cupola furnace is kept, and liquid oxygen is added when the raw materials are melted and combusted, so that too high heating temperature is not needed during production, the production requirement is reduced, energy is saved, the proportion is reasonable, and it is ensured that the obtained melted raw material liquid is uniform in component; the melted raw material liquid becomes fibrous through centrifugal fiber forming, and a phenolic resin is sprayed in the centrifugal process, so that the generation of slag balls can be greatly reduced; according to the production process, raw materials are crushed through raw material crushing equipment, a mixture is cut and crushed through a crushing roller rotating at high speed, and powder with small particle size is screened out through a screening plate and discharged, so that the obtained mixed raw material is high in uniformity and good in mixing effect, the difficulty of subsequent heating melting and material fibration processes is reduced,the production temperature of the environment-friendly rock wool heat-insulation board is further easily achieved, and the content of slag balls in the environment-friendly rock wool heat-insulation board is reduced.

Owner:安徽瑞联节能科技股份有限公司

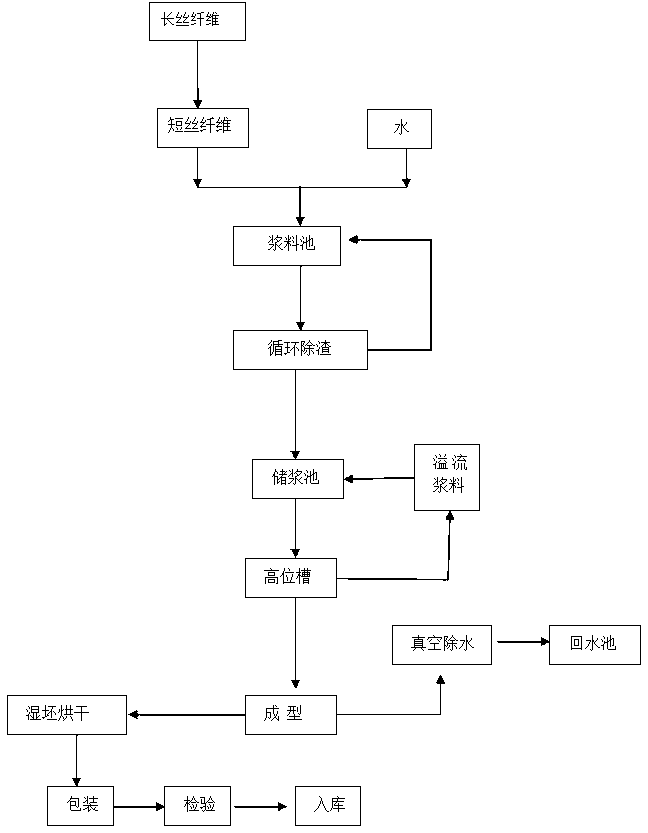

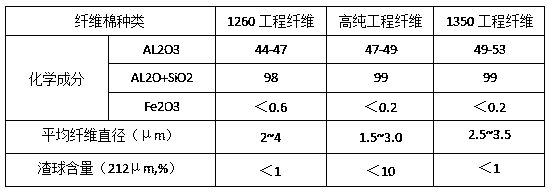

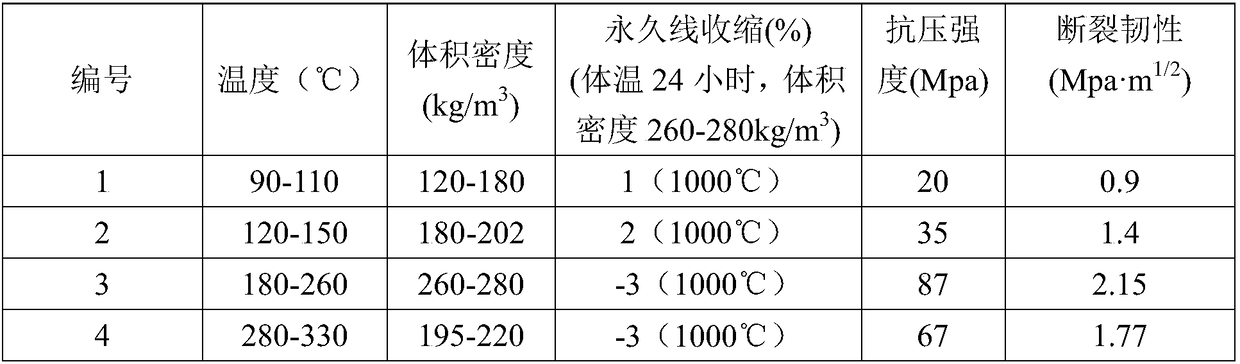

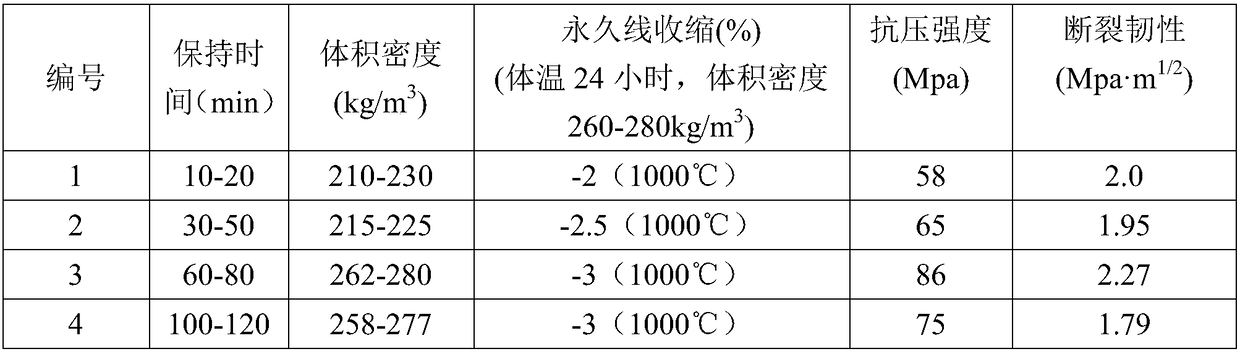

Preparation method of fire-resistant engineering fiber

InactiveCN109763369AGood dispersionThin and uniformDryer sectionSevering to form staple fibresFiberSlag

The invention provides a preparation method of a fire-resistant engineering fiber. The preparation method includes the following steps of (1) short cutting; (2) dispersing; (3) circulation slag removing; (4) molding; and (5) drying. The preparation method of the fire-resistant engineering fiber has the advantages that 1, circulation slag removing is conducted through a slag separator, produced products have the low shot content, and the content of 212 [mu]m shots can reach 1% or below; 2, the fire-resistant fiber subjected to wet slag removal has good dispersibility, and product performance isstable; and 3, the thickness of a fiber wet billet is low and uniform by adopting long mesh molding, in this way, the drying time of hot air is reduced by 30% compared with traditional technologies,and the production efficiency is improved.

Owner:湖北烁砺新材料科技有限公司

Environment-friendly inorganic fiber heat insulation felt and preparation method thereof

InactiveCN108177398AFluffy structureImprove insulation effectLaminationLamination apparatusFiberAdhesive

The invention discloses an environment-friendly inorganic fiber heat insulation felt and a preparation method thereof. The environment-friendly inorganic fiber heat insulation felt comprises a heat insulation inner layer and a heat insulation outer layer, wherein the heat insulation outer layer is formed on the heat insulation inner layer; the heat insulation outer layer is made of an inorganic fiber cloth, and an inorganic fiber heat insulation cotton; the heat insulation inner layer and the heat insulation outer layer are adhered by an adhesive. The preparation method of the environment-friendly inorganic fiber heat insulation felt comprises the following steps of uniformly coating a sodium silicate adhesive onto the surface of the heat insulation outer layer, and covering the heat insulation inner layer at one side, coated with the adhesive, of the heat insulation outer layer; pressing and forming, cooling, and cutting, so as to obtain the environment-friendly inorganic fiber heat insulation felt. The environment-friendly inorganic fiber heat insulation felt has the advantages that the fluffy structure is formed, so that the heat insulation property is better; the thickness is small, the weight is light, the tensile strength is strong in the weft and warp directions, the fireproof property is realized, and the service life is long; the surface is smooth and flat, the easiness in contamination is avoided, the dissolvability is realized, and the pollution to environment is avoided.

Owner:靖宇县金政保温毡有限公司

A kind of production system and production method of microfiber glass wool

ActiveCN110746090BQuality improvementReduce usageGlass furnace apparatusPressure stabilizationAir blower

Owner:内蒙古海晟材料科技有限公司

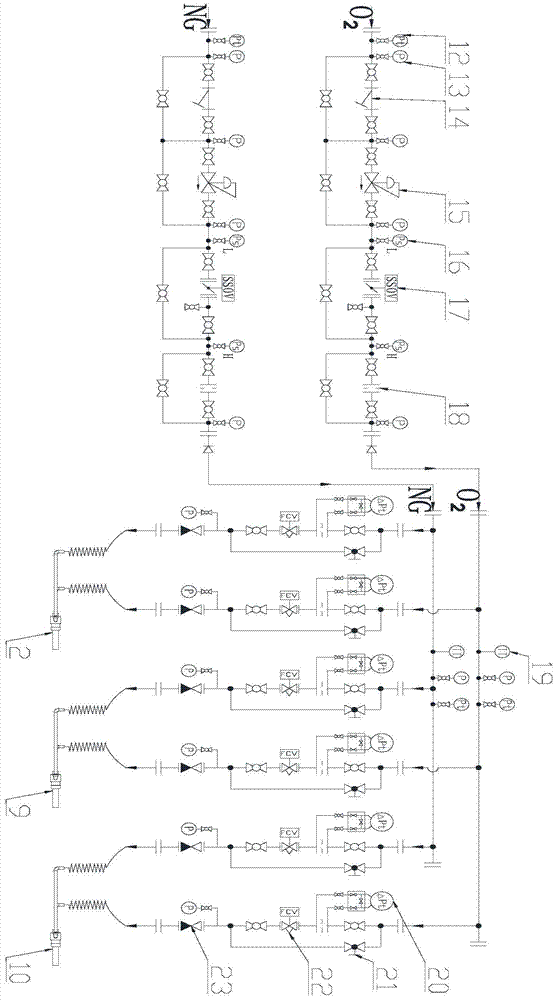

Pure oxygen combustion system for multi-point precise control of rock wool melt temperature

ActiveCN105130166BPrecise control of process temperatureProcess temperature stabilityForehearthsGlass productionFiberCombustion system

The invention discloses a pure oxygen combustion system for rock wool melt temperature multi-point accuracy control, and solves the technical problems that in the conventional rock wool production process, the melting strength of a product is insufficient, the acidity coefficient is high, and the melt is cooled through chute combining. The pure oxygen combustion system is characterized in that natural gas is used as fuel; oxygen is adopted as a combustion-supporting medium; rock wool melt is heated through combustion of pure oxygen combustion guns; the particular positions, acting on the rock wool melt, of the pure oxygen combustion guns are the top part of a siphonal opening, the lower part of a No. 1 movable chute and the lower part of a No. 2 movable chute; the real-time multi-point accuracy control of natural gas or oxygen flow rate is realized through real-time on-line measurement of the multi-point temperatures of the rock wool melt, so that the process temperature needed by the rock wool melt can be accurately controlled. According to the pure oxygen combustion system, stable production of rock wool product with high acidity coefficient can be realized, the fiber forming rate of rock wool melt can be increased, energy consumption in rock wool melt melting process can be effectively lowered, and the shot content of the product can be reduced.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Inorganic fiber using fly ash as main raw material and manufacturing method thereof

ActiveCN103539361BImprove water resistanceIncreased durabilityGlass making apparatusBasaniteThermal insulation

The invention discloses an inorganic fiber with coal ash as a main raw material and a manufacturing method of the inorganic fiber. A residue obtained after the inorganic fiber taking the coal ash as the main raw material is fired at the temperature of 550 DEG C for 30min contains the following components in percentage by weight: 39.0-48.0% of SiO2, 10.0-20.0% of Al2O3, 20.0-28.0% of CaO, 2.5-10.5% of Fe2O3, 3.5-10.5% of MgO, 0.2-2% of Na2O, 0.2-2.0% of K2O and 0.2-2.5% of TiO2. The inorganic fiber disclosed by the invention has favorable water resistance and durability, a relatively high acidity coefficient, relatively low shot content, a relatively small fiber diameter, very high tensile strength and a relatively low heat conductivity coefficient, can be used as a sound absorption material, a thermal insulation material and the like and can be used for completely replacing a rock wool board thermal insulation material made of a basalt fiber in the prior art.

Owner:ZHEJIANG XUANMING NEW MATERIALS +1

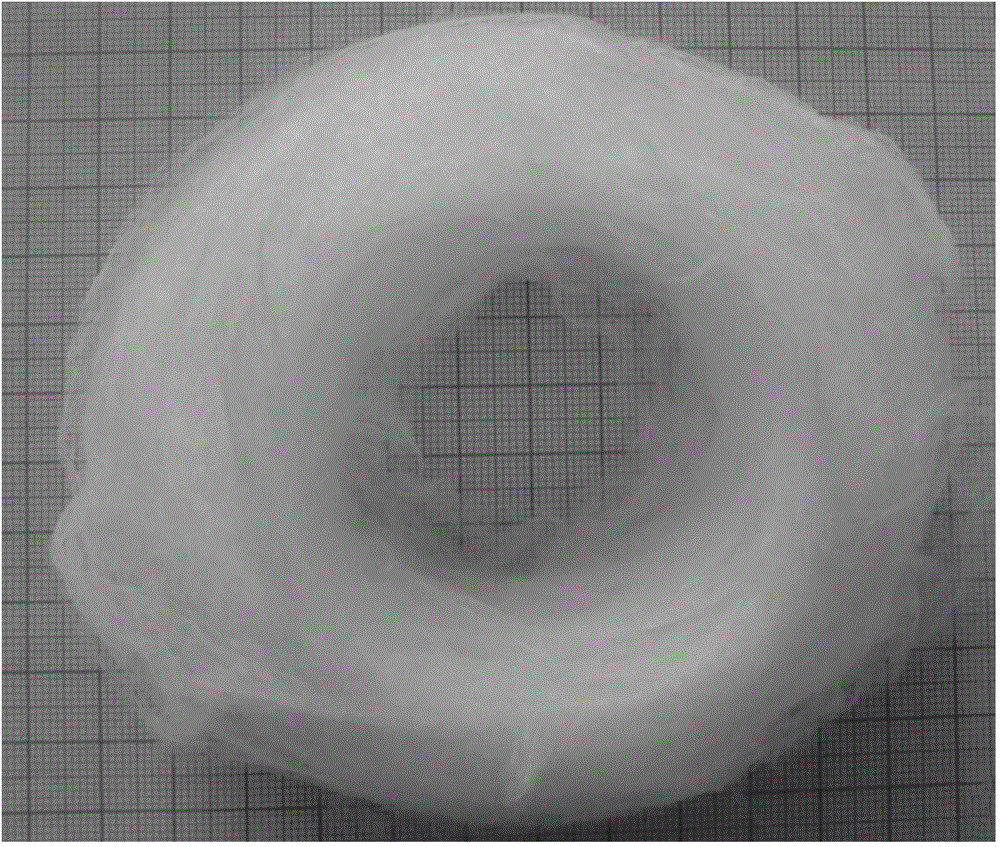

A kind of preparation method of lanthanum zirconate ceramic fiber mat

ActiveCN103643402BReduce the temperatureLarge specific surface areaGlass making apparatusNon-woven fabricsFiberChloride

The invention relates to a preparation method for a lanthanum zirconate ceramic fiber blanket. The method uses lanthanum zirconate as the zirconium source, and lanthanum nitrate and lanthanum chloride and corresponding hydrate thereof as the lanthanum source, prepares precursor sol according to the molar ratio of La<3+>:Zr<4+> = 1:(0.87-1.15), and obtains gelatinous fiber through centrifugal fiber formation technology after aging; the gelatinous fiber is made into a gelatinous fiber blanket through cotton collecting and blanket forming; the La2Xr2O7 ceramic fiber blanket of pyrochlore type is obtained after calcination. The La2Xr2O7 ceramic fiber blanket of pyrochlore type, prepared by the invention, has a flat surface, is low in shot content, good in resilience, has a heat conductivity coefficient of 0.037-0.056W / (m*K), and has an excellent heat-insulating property; the method reduces the calcination temperature, and is simple in structure, controllable in technology, and suitable for large-scale production of the lanthanum zirconate ceramic fiber blanket.

Owner:SHANDONG UNIV

A production process of environmental protection rock wool insulation board

ActiveCN111892379BHigh compressive strengthReduce foreshadowingGlass making apparatusFiberMining engineering

The invention discloses a production process of an environmentally friendly rock wool insulation board. Preheating is carried out after mixing and crushing raw materials, and then the temperature in the cupola is maintained, and liquid oxygen is added when the raw materials are melted and burned, so that the production does not require too high heating temperature , reduces production requirements, saves energy, and has a reasonable ratio to ensure that the obtained molten raw material liquid has a uniform composition. Reduce the generation of slag balls; the production process uses raw material crushing equipment for raw material crushing, cutting and crushing the mixture through high-speed rotating crushing rollers, and screening the powder with small particle size through the sieving plate to discharge, so that the obtained mixed raw materials have high uniformity and mixing The effect is good, which reduces the difficulty of the subsequent heating and melting and material fiberization process, further makes it easy to reach the production temperature of the environmental protection rock wool insulation board, and reduces the content of slag balls in the environmental protection rock wool insulation board.

Owner:安徽瑞联节能科技股份有限公司

A kind of alumina fiber blanket and preparation method thereof

ActiveCN111455554BLow shot contentImprove the protective effectInorganic material artificial filamentsFilament/thread formingFiberAluminium chloride

Owner:山东鲁阳浩特高技术纤维有限公司

Dreg ball free alumina silicate cotton velvet and its uses in brake field

ActiveCN100503492CStable coefficient of frictionImprove heat resistanceGlass making apparatusChemical compositionSlag

The invention relates to a slag-free aluminum silicate cotton wool and its application in the braking field. Contains ordinary type, zirconium-containing type and soluble aluminum silicate fiber lint, the fiber length is 50-300μm±30, the diameter is 2-5μm, the slag content of φ≥0.25mm is 0-8%, and the Mohs hardness is 5-7 , use temperature 1000~1300℃, thermal conductivity W / mk, 500±20℃≤0.153, tensile strength 1000~1600Mpa; chemical composition is Al2O343~55%, SiO245~57%; or Al2O3+SiO2+ZrO298.5~ 99.5%, of which, ZrO2≥15%, impurity balance; or SiO2 52~85%, CaO 5~35%, MgO 1~10%, Al2O30~1%, B2O31~2%; used as fiber reinforcement in the braking field material application.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

A kind of inorganic fiber insulation board and its preparation method and application

ActiveCN111763062BImprove density uniformityImprove thermal insulation performanceGlass making apparatusNon-woven fabricsMetallurgical slagFiber

The invention relates to the technical field of thermal insulation materials, and specifically discloses an inorganic fiber thermal insulation board as well as its preparation method and application. The inorganic fiber insulation board includes the following components: 15-30 parts of metallurgical slag, 20-50 parts of coal gangue, 10-30 parts of elutriated Longyan soil, 30-60 parts of alumina, 30-50 parts of silicon oxide, and talcum powder 5‑10 parts and Fluorite 3‑5 parts. The inorganic fiber insulation board provided by the present invention makes full use of solid waste and realizes the resource utilization of solid waste. At an average temperature of 500°C, the thermal conductivity is 0.03-0.04w / (m.k) (average temperature 500°C), hydrophobic The rate is 99.3% to 99.5%, and the volume water absorption rate is 1.2% to 1.8%. It can be widely used in the insulation of marine cabins, and can achieve good thermal insulation, heat insulation, and moisture-proof effects. The raw materials are cheap and easy to obtain, and have a wide range of applications. Application prospect.

Owner:唐山华纤科技有限公司

A kind of ultra-filament slag cotton

The invention discloses a production method of centrifugal super-filament slag cotton with excellent index and long fiber: (1) raw material preparation: blast furnace slag, basalt, fly ash, magnesium oxide, calcium oxide, silica fume (2) Fiber preparation: The liquid mixture is continuously flowed into the high-speed rotating centrifugal roller, and the liquid mixture is condensed into silky fibers under the action of centrifugal throwing and air cooling. The fiber filaments are collected and formed under the action of the blast, and the (1) raw material components are calculated by weight percentage: 55-65% of blast furnace slag, 12-18% of basalt, 5%-7% of fly ash, 2% of magnesium oxide %‑3%, calcium oxide 2%, wollastonite 15%‑20%.

Owner:郎溪品旭科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com