Environment-friendly rock wool heat-insulation board production process

A production process and thermal insulation board technology, which is applied in the field of thermal insulation materials, can solve the problems of high production temperature of energy-saving thermal insulation materials, high uniformity of mixed raw materials, and reduction of slag formation, so as to reduce production requirements, reasonable proportioning, and improve water repellency rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

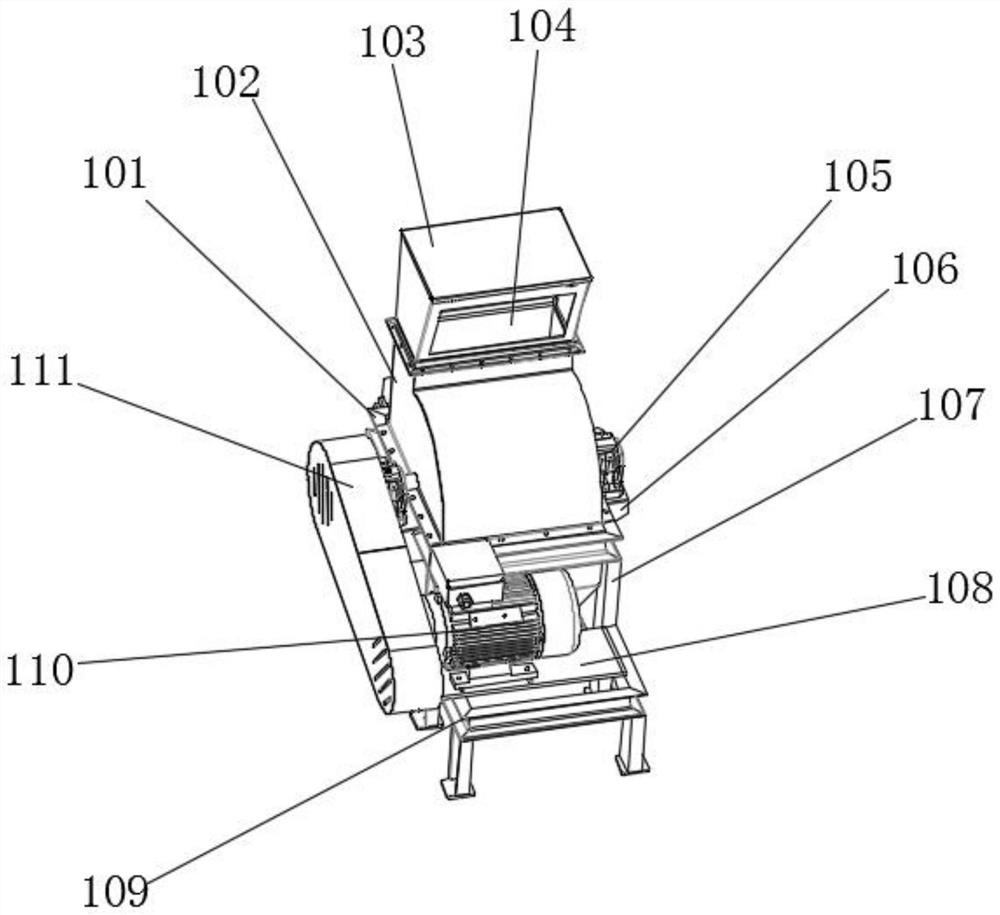

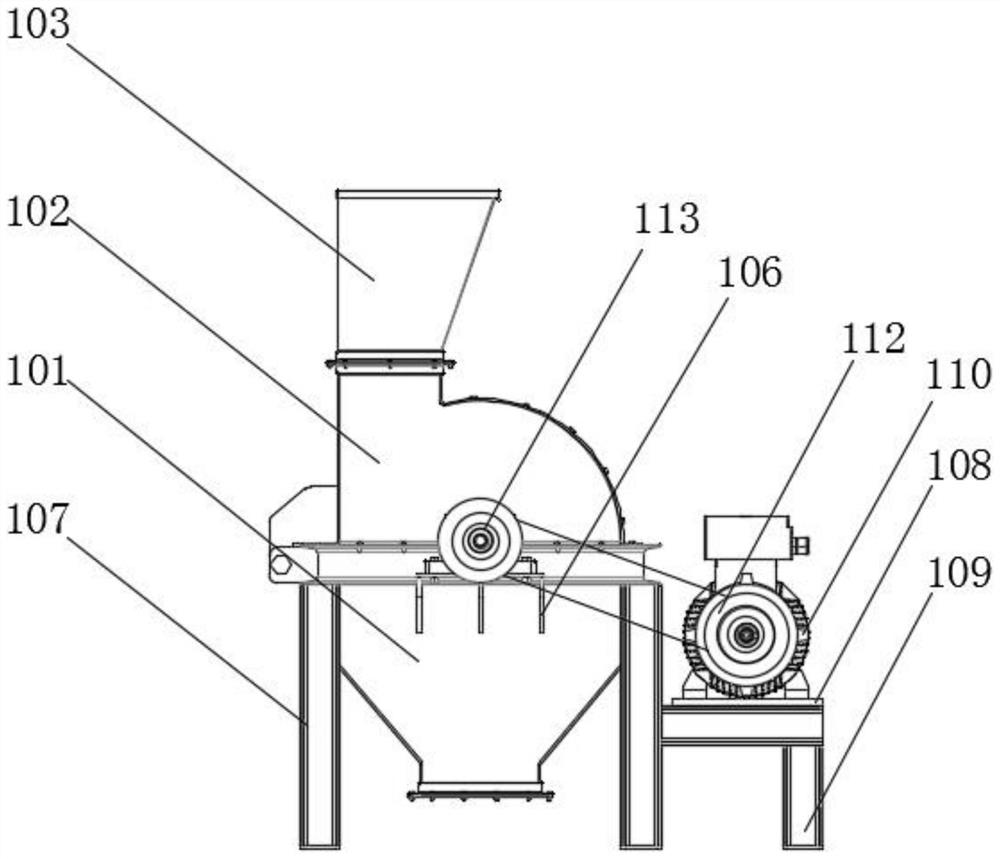

[0034] see Figure 1-6 As shown, the present embodiment is a production process of an environmentally friendly rock wool insulation board, comprising the following steps:

[0035] Step 1, raw material crushing: mix basalt, white rock, slag and coke, put the mixture of basalt, white rock, slag and coke into the feed box 103 from the feeding port 104 of the raw material crushing equipment, and drop it into the crushing bin 102 In the inner cavity, the rotating crushing roller 117 cuts and crushes the basalt, white rock, slag, and coke mixture through several crushing blades 120 to form a mixture powder, and the mixture powder whose particle size is smaller than the sieving hole diameter passes through the sieving plate 116 Discharge from the bottom end of the hopper 101 to obtain mixed raw materials;

[0036] Step 2, heating up and melting: Preheat the mixed raw materials at a temperature of 500°C for 2 hours, then add the mixed raw materials into the cupola after preheating, k...

Embodiment 2

[0046] see Figure 1-6 As shown, the present embodiment is a production process of an environmentally friendly rock wool insulation board, comprising the following steps:

[0047] Step 1, raw material crushing: mix basalt, white rock, slag and coke, put the mixture of basalt, white rock, slag and coke into the feed box 103 from the feeding port 104 of the raw material crushing equipment, and drop it into the crushing bin 102 In the inner cavity, the rotating crushing roller 117 cuts and crushes the basalt, white rock, slag, and coke mixture through several crushing blades 120 to form a mixture powder, and the mixture powder whose particle size is smaller than the sieving hole diameter passes through the sieving plate 116 Discharge from the bottom end of the hopper 101 to obtain mixed raw materials;

[0048] Step 2, heating up and melting: Preheat the mixed raw materials at 500°C for 2 hours, add the mixed raw materials into the cupola after preheating, keep the temperature in...

Embodiment 3

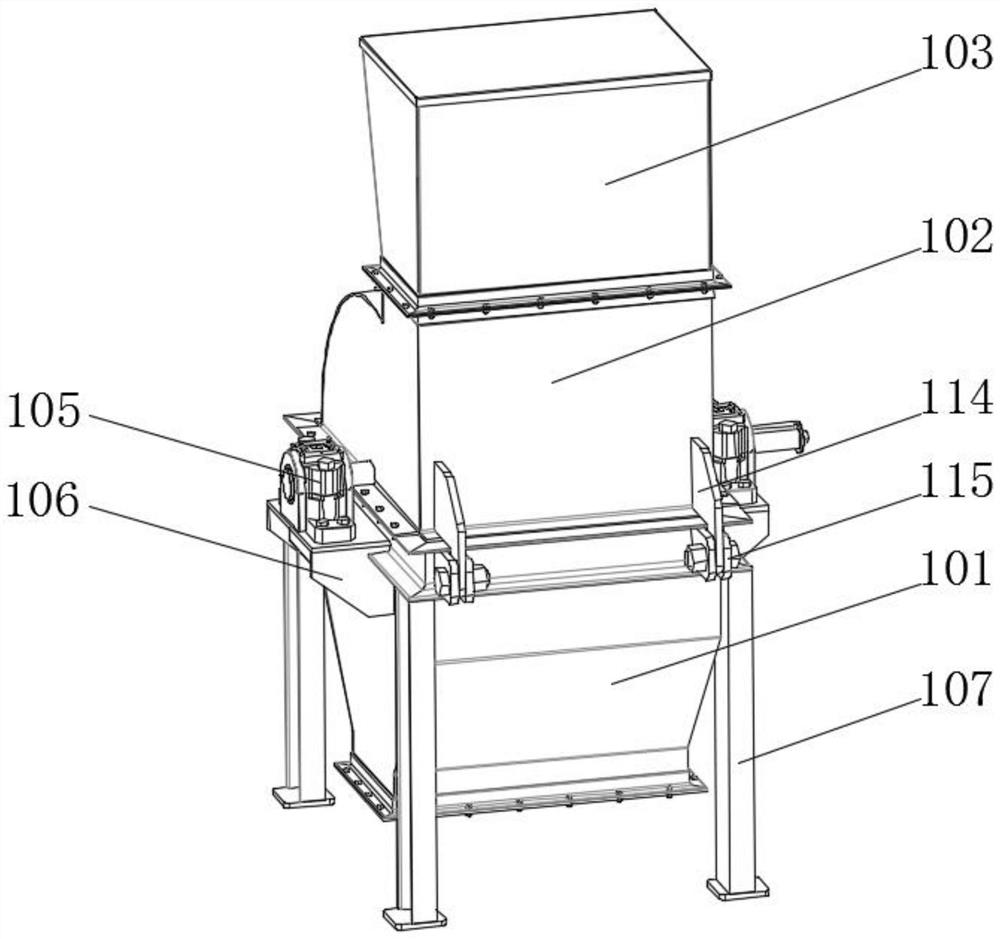

[0058] see Figure 1-6 As shown, the raw material crushing equipment in this embodiment includes a receiving hopper 101, a crushing bin 102, a feed box 103, a first support frame 107, a second support frame 109, a screening plate 116, and a crushing roller 117. A hopper 101 is installed on a support frame 107, a crushing bin 102 is installed on the top of the hopper 101, and a feeding box 103 is installed on the top of the crushing bin 102; Port 104, crushing rollers 117 are arranged in the inner cavity of the crushing bin 102, and a screening plate 116 is installed on the top of the inner cavity of the receiving hopper 101, and several screening holes are opened on the screening plate 116, and the crushing The roller 117 is located in the inner cavity of the screening plate 116, and the two ends of the crushing roller 117 are sleeved with bearing seats 105, and the two bearing seats 105 are installed on the two mounting frames 106 respectively, and the two mounting frames 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Fiber average diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com