Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Little impact on physical and mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

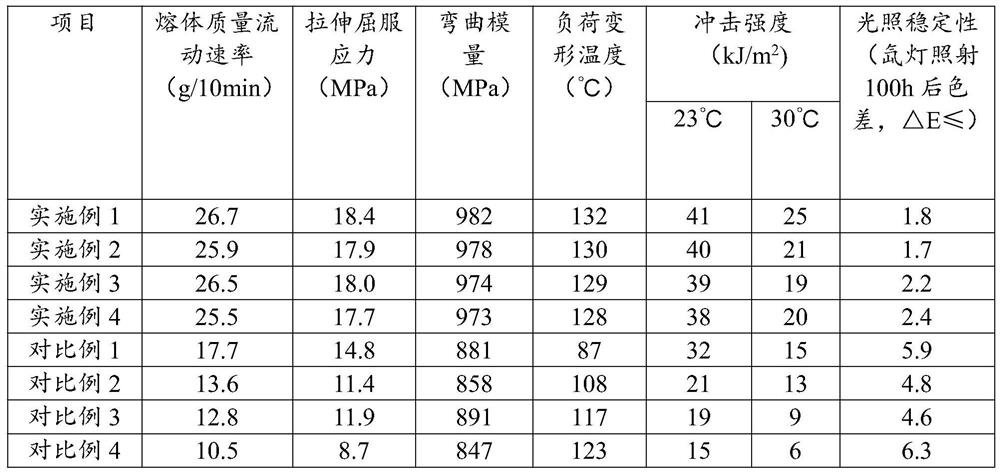

Flame-retardant PPO/PA alloy and preparation thereof

InactiveCN101302336ALittle impact on physical and mechanical propertiesImprove flame retardant performanceMixed materialsAlloy

The invention discloses a flame-retardant PPO / PA alloy and a method for preparing the same. The compositions by weight percentage of the flame-retardant PPO / PA alloy are: 30 to 50 percent of PPO, 10 to 60 percent of PA, 3 to 15 percent of toughener, 5 to 15 percent of composite flame retardant, 3 to 10 percent of compatilizer, and 0.5 to 2 percent of other addition agents. The method for preparing the composite flame-retardant PPO / PA alloy comprises the following steps of: firstly, mixing the materials according to the proportions; then, putting the mixed materials into a plastic double-screw extruder and controlling a temperature between 260 and 320 DEG C for granulation to acquire the composite flame-retardant PPO / PA alloy. The method acquires the flame-retardant PPO / PA alloy with excellent comprehensive property by adopting a composite flame-retardant system. The composite flame-retardant PPO / PA alloy has a simple preparation process.

Owner:ANHUI KEJU NEW MATERIALS

Halogen-free expansion flame retardant and flame-retardant polypropylene composite material

The invention discloses a halogen-free expansive flame retardant and a composite material of flame retardant polypropylene, relating to a composite material of expansive flame retardant and polypropylene, which settles the problem that the prior halogen-free expansive flame retardant is unsuitable for commercial production due to low flame retardant efficiency, large addition quantity, bad thermostability and reduced polymer performance after added, the polypropylene is unsuitable for commercial production, and the application range in the composite material is greatly reduced. The halogen-free expansive flame retardant comprises triazine carbon-formation foaming agent, ammonium polyphosphate and halogen-free flame retardant synergistic agent. The composite material of flame retardant polypropylene comprises thermoplastic resin and halogen-free expansive flame retardant, and processing aid and / or anti-dripping agent as well. The composite material of flame retardant polypropylene has the advantages of high flame retardant efficiency, high oxygen index, non-halogen, low smoke, low mammalian toxicity and excellent processing properties since the halogen-free expansive flame retardant has the advantages of high flame retardant efficiency, less addition quantity, less influence to the physical mechanical property of the composite material, suitability for commercial production and wide application range.

Owner:NORTHEAST FORESTRY UNIVERSITY

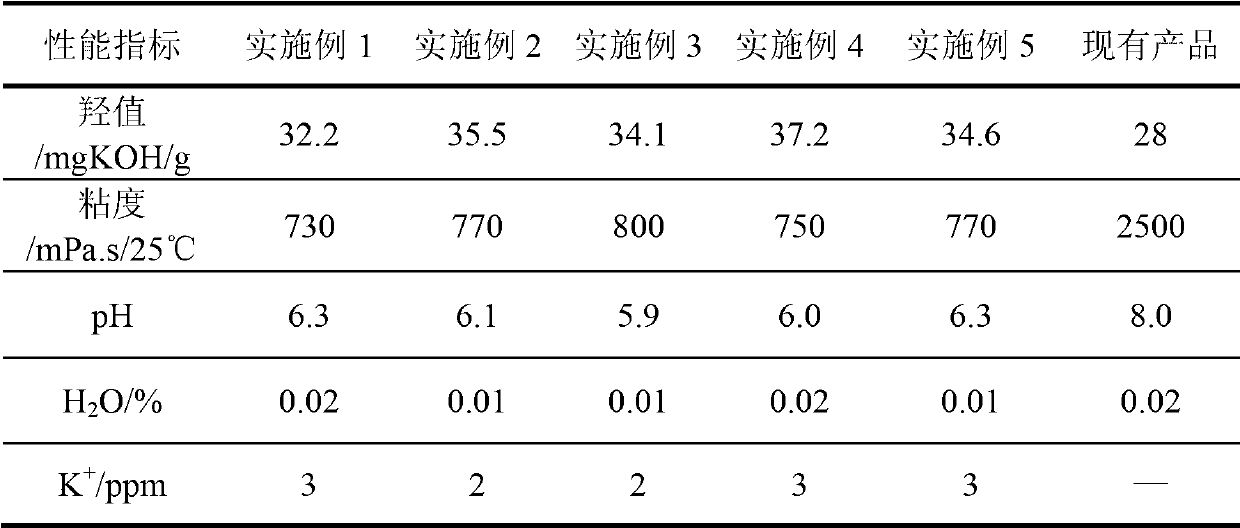

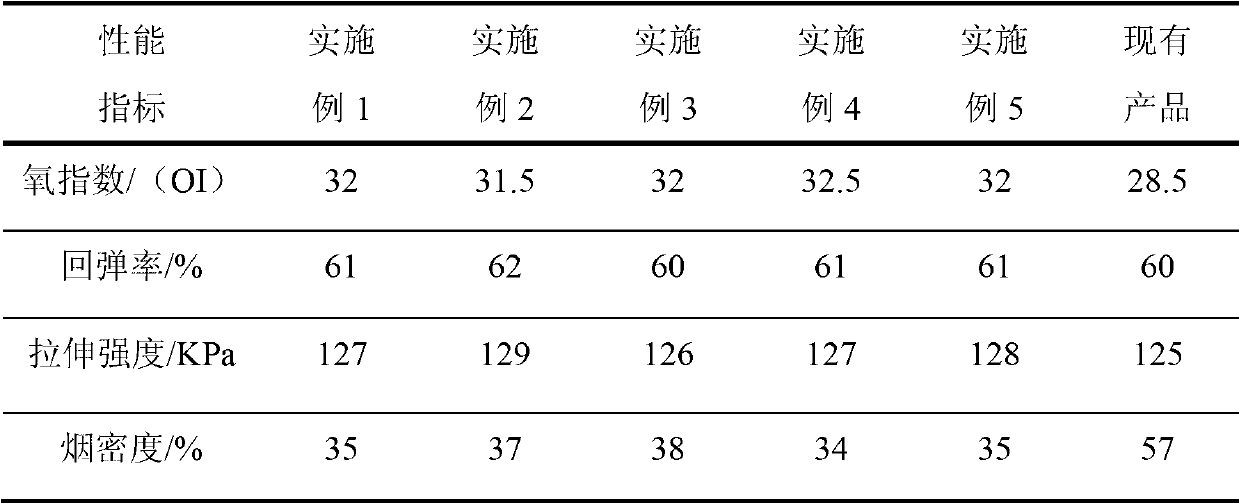

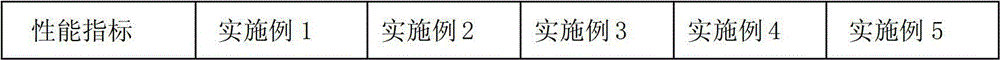

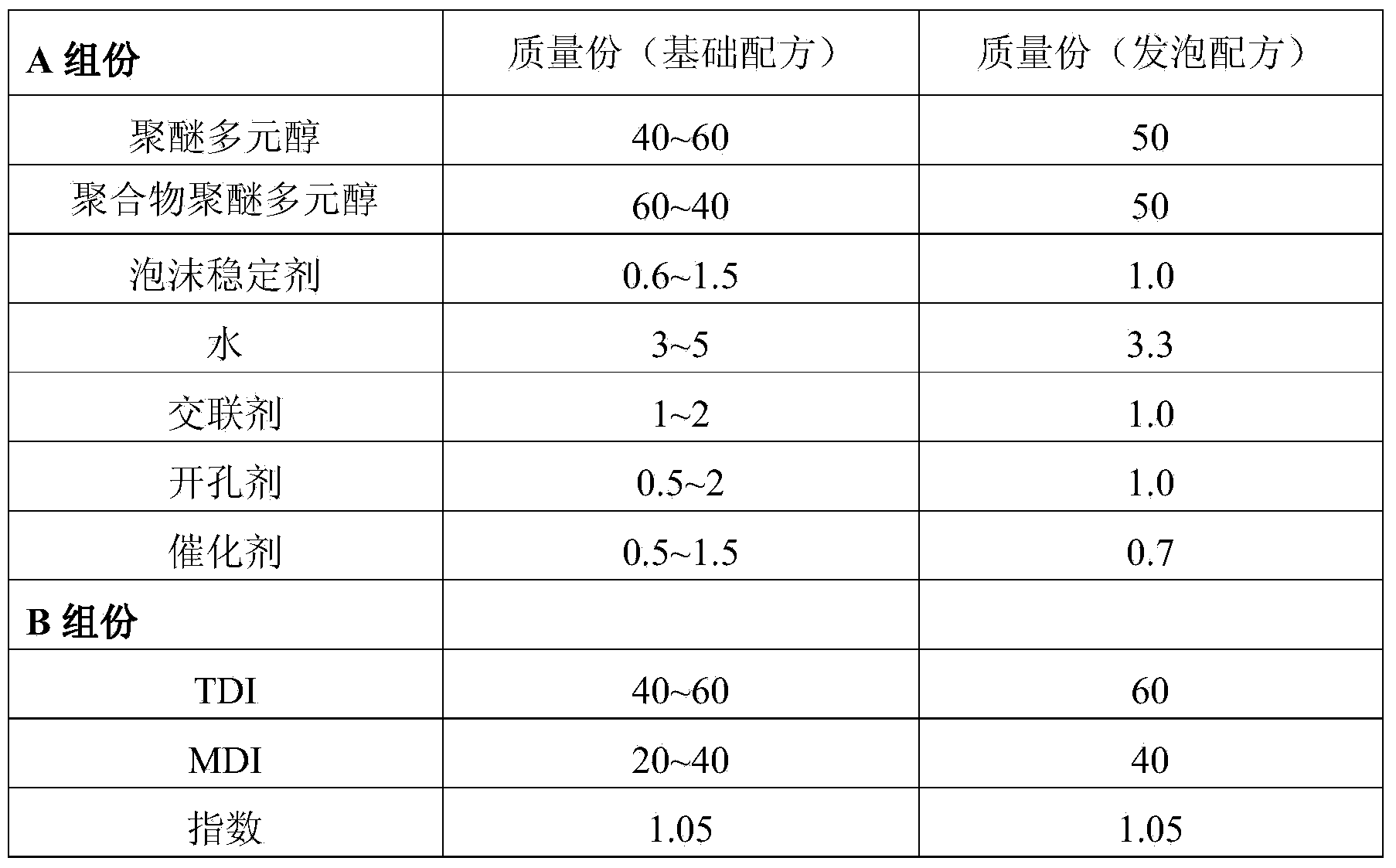

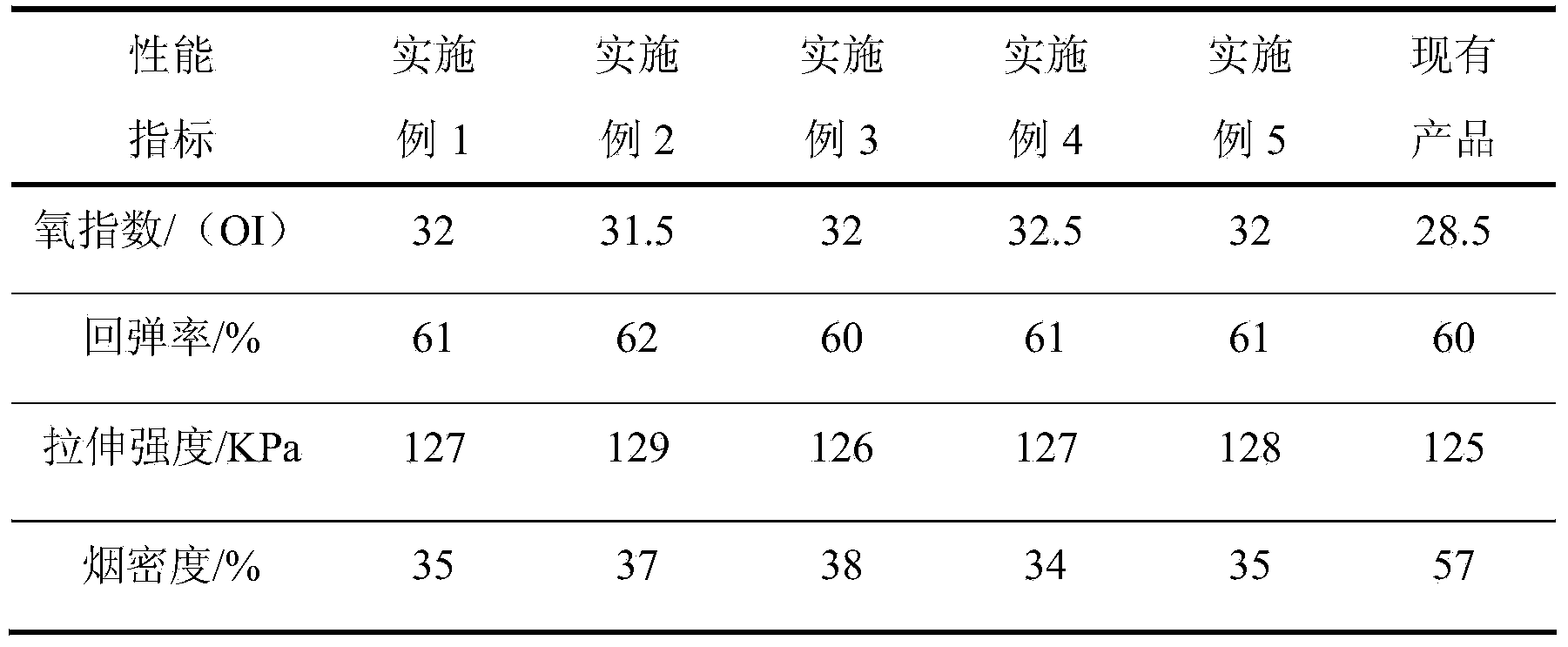

Flame retardant soft foam polyether polyol and synthesis method thereof

ActiveCN102875791AGood durability of flame retardant performanceExcellent physical performance indexHigh oxygenBase metal

The invention relates to a flame retardant soft foam polyether polyol and a synthesis method thereof. The technical scheme is to provide the flame retardant soft foam polyether polyol which is good in flame retardant property, safe and non-toxic, simple in preparation process and low in cost and the synthesis method of the flame retardant soft foam polyether polyol. The synthesis method disclosed by the invention comprises the following steps of enabling melamine-formaldehyde condensation compound to react with amine compounds, polymerizing the reaction product with an acid compound to obtain a polyether initiator, further polymerizing the polyether initiator with oxyalkylene with the action of a base metal catalyst so as to obtain the flame retardant polyether polyol. The flame retardant polyether polyol synthesized by the method has the advantages of light colour, low viscosity and good material flowability, and can be widely used for preparing the flame retardant polyether soft foam. The flame retardant soft polyether foam plastic products foamed and prepared by the flame retardant polyether polyol disclosed by the invention have the characteristics of good flame retardant effect, high oxygen index, good foam uniformity, good size stability and high mechanical strength.

Owner:SHANDONG BLUSR DONGDA CHEM

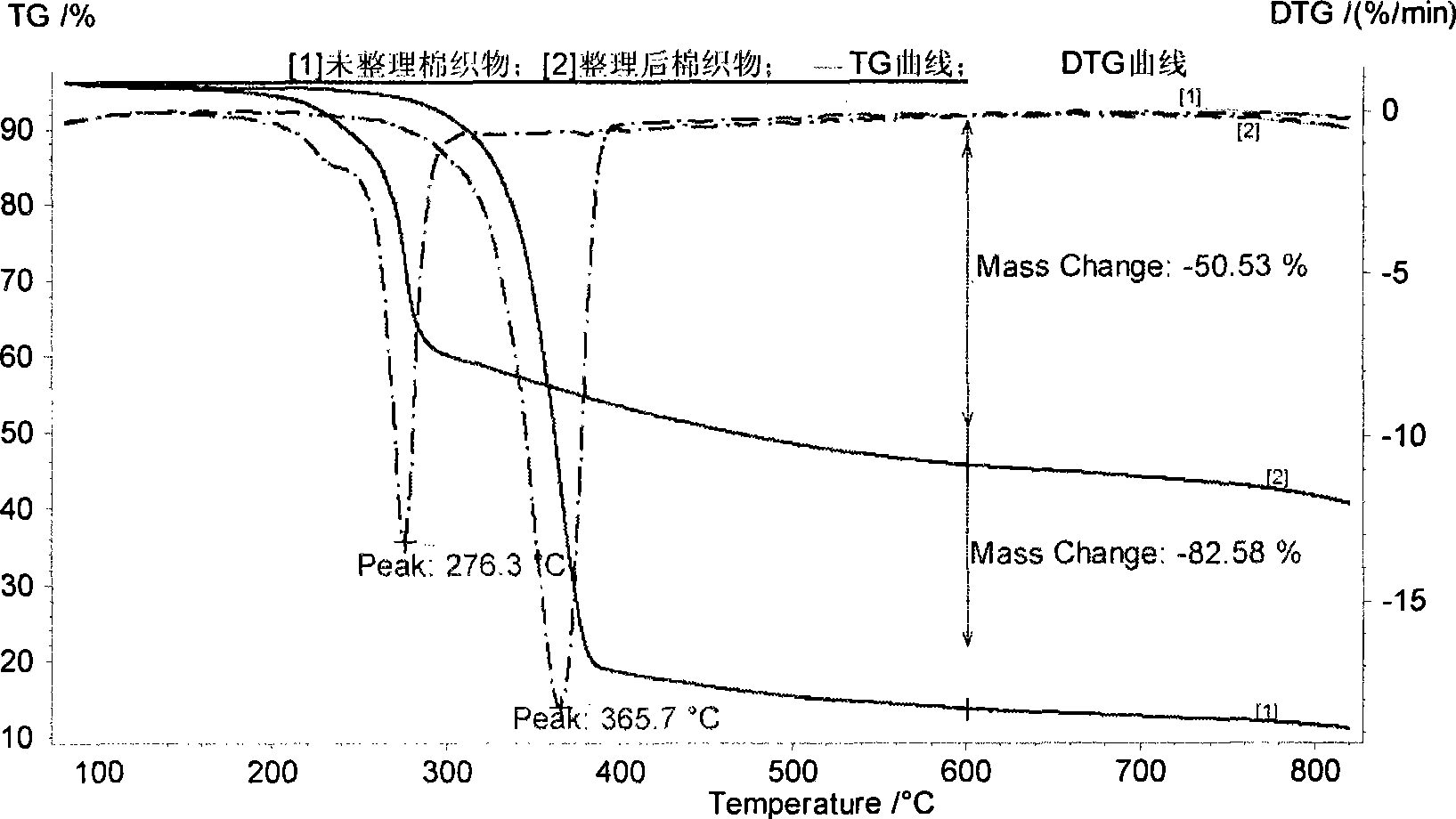

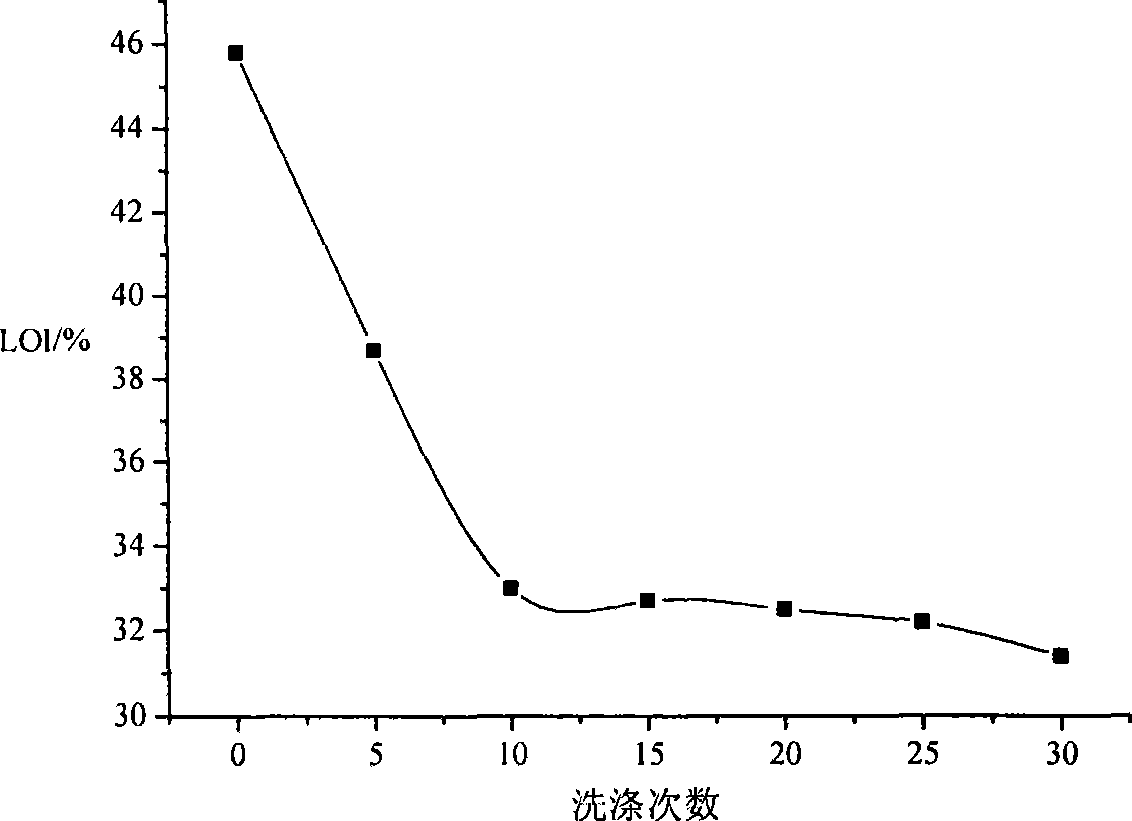

Method for preparing durable flame-proof cotton fabric

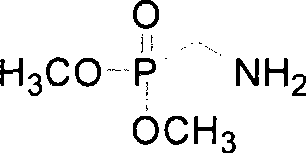

InactiveCN101413214AGood flame retardant effectWide variety of sourcesVegetal fibresChemistrySilane coupling

The invention relates to a method for preparing durable flame retardant cotton fabrics, which comprises the following steps: firstly, preparation of a finishing liquid, namely amino-methylphosphonate DAMP, a silane coupling agent gamma-glycidyl oxyl propyl trimethyl silicane and running water are uniformly mixed, and the pH value of the mixture is adjusted to between 3 and 7 by a finishing liquid pH regulator to obtain the finishing liquid; secondly, flame retardant finishing of the cotton fabrics, namely the cotton fabrics are immersed into the finishing liquid for 20 minutes at a temperature of 40 DEG C, padded until the liquid rate is between 75 and 80 percent, dried for 3 minutes at a temperature of between 80 and 100 DEG C, and roasted for 3 minutes at a temperature of between 150 and 180 DEG C; and thirdly, testing of the flame retardant property and the durability of the cotton fabrics after finishing. The method for preparing the flame retardant cotton fabrics has the advantages that raw materials have wide sources; the prepared cotton fabrics have good durability and flame retardant property; and the method has small influence on physical and mechanical properties of the cotton fabrics.

Owner:DONGHUA UNIV

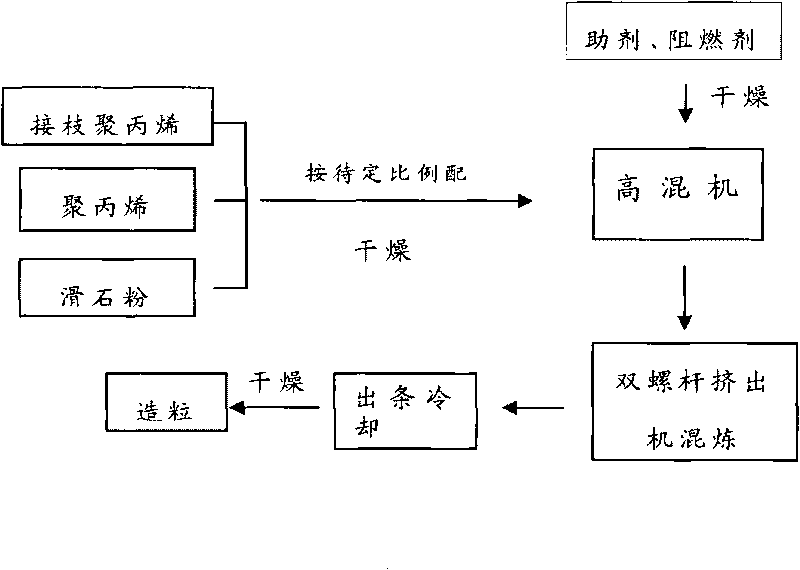

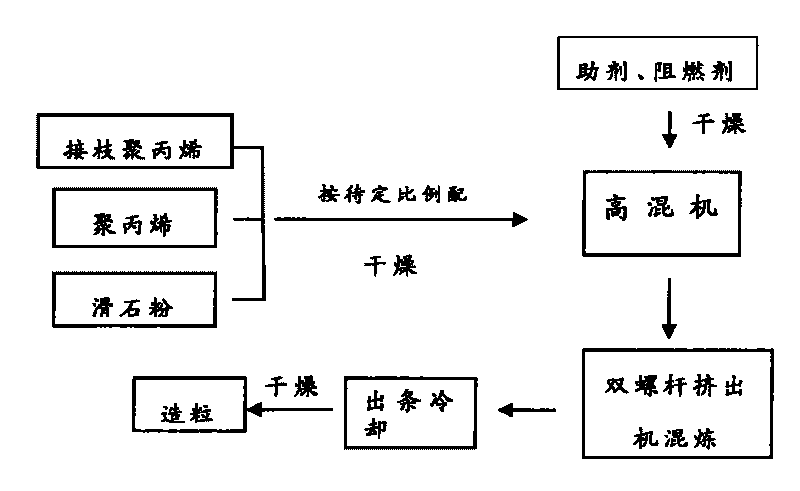

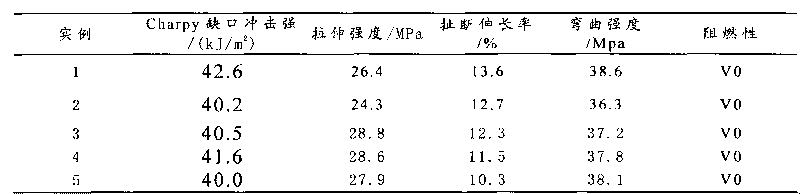

Flame-retardant polypropylene material and preparation method

ActiveCN101735514AHigh flame retardant efficiencyLow flame retardant contentPolymer scienceAntioxidant

The invention provides a flame-retardant polypropylene material and a preparation method, and aims to improve the flame-retardant system and improve the flame retardation of the flame-retardant polypropylene material on the premise of keeping and improving the mechanical property of PP. The invention adopts the technical scheme that the flame-retardant polypropylene material comprises the following components in part by mass: 60 to 70 parts of polypropylene, 0.3 to 0.5 part of antioxidant, 22 to 28 parts of halogen-free intumescent flame retardant, 2 to 6 parts of grafted polypropylene, 0.5 to 0.7 part of lubricant and 12 to 17 parts of filler. Experiments show that the mechanical property of the flame-retardant polypropylene material is improved and the flame retardation is excellent.

Owner:QINGDAO GON TECHNOLOGY CO LTD

Flame retardant adsorption master batch and preparation method thereof

ActiveCN104744840ASolve the difficulty of addingSolving Dispersion ProblemsPolymer sciencePolyolefin

The invention discloses a flame retardant adsorption master batch and a preparation method thereof. The flame retardant adsorption master batch is prepared by mixing and absorbing 1-7 parts of a porous adsorbing material particle and 99-30 parts of a flame retardant additive, wherein the porous adsorbing material particle is a polyolefin open-cell foamed plastic or natural porous material with a partial open-cell structure or sponge or netty microstructure; the average particle size of the porous adsorbing material particle is 1-10 mm, the porosity is at least 30% and the average diameter of the micropore is 50-200 mu m. The porous adsorbing material particle is taken as a storage stack for absorbing a liquid or suspending flame retardant, wherein the maximum concentration is 99%; in the high polymer material machining process, the adding amount of the master batch is few, the operation is convenient and the physical and mechanical properties influence on the resin material is small; the traditional master batch preparation process can be replaced without an expensive device or heating treatment, so that the master batch preparation period and device utilization rate are greatly shortened.

Owner:安徽星贝达新材料科技有限公司

Flame-retardant and wear-proof corrugated case

ActiveCN107034739AEnhanced interfaceImprove compatibilityFlexible coversWrappersVapor phaseFire retardant

The invention discloses a flame-retardant and wear-proof corrugated case. The flame-retardant and wear-proof corrugated case comprises a case body composed of a corrugated paperboard. The paperboard sequentially comprises surface paper, corrugated paper and inner paper from outside to inside, and the surface paper, the corrugated paper and the inner paper are boned through oxidized starch, a vapor phase inhibitor is added into the oxidized starch, the surfaces of the surface paper and the inner paper are coated with a flame-retardant and wear-proof coating, and the coating is prepared from, by weight, 30-40 parts of phenolic resin, 10-15 parts of nanometer Sb2O3-Al(OH)3, 10-20 parts of nanometer wear-proof powder, 1-3 parts of a reactive diluent, 0.5-2 parts of an antifoaming agent, 2-5 parts of a penetrating agent, 0.5-1 part of an antioxidant, 10-20 parts of an organic solvent and 10-20 parts of a curing agent. According to the flame-retardant and wear-proof corrugated case, as cashew-nut-shell-oil-or-tripolycyanamide-modified phenolic resin is applied to the surface of the paper case, the quite-high wear-proof performance and the quite-high mechanical performance are achieved; meanwhile, the wear-proof nanometer powder is added into the coating, the wear-proof capacity of the surface of the paper case is enhanced, and a nanometer aluminum hydroxide is used as a flame retardant to achieve the aim of reducing the using amount and improving the flame-retardant performance.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

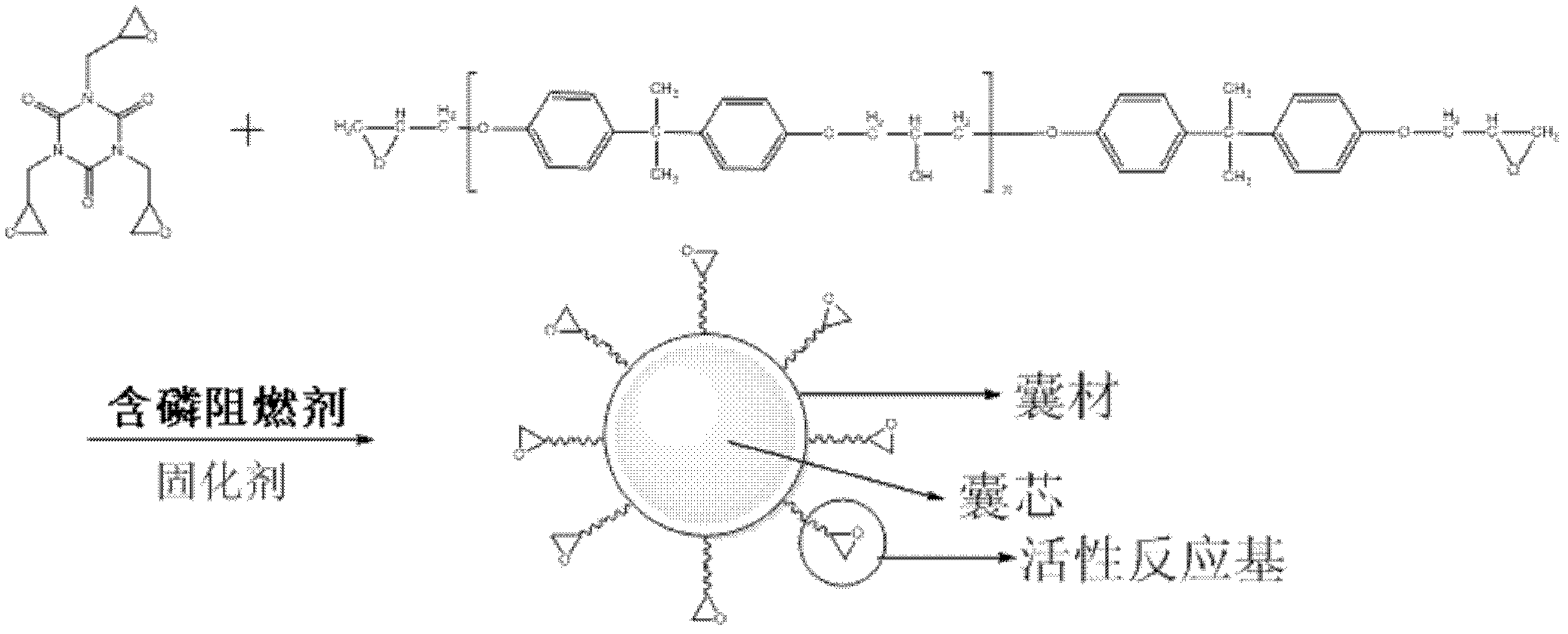

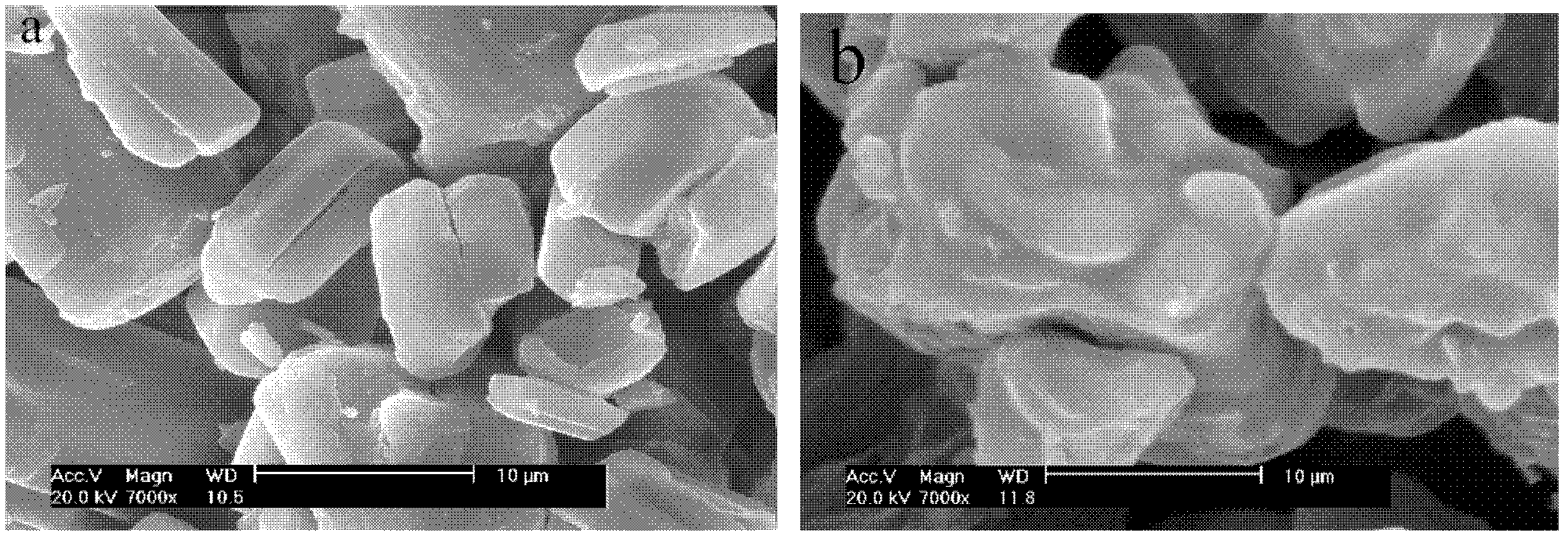

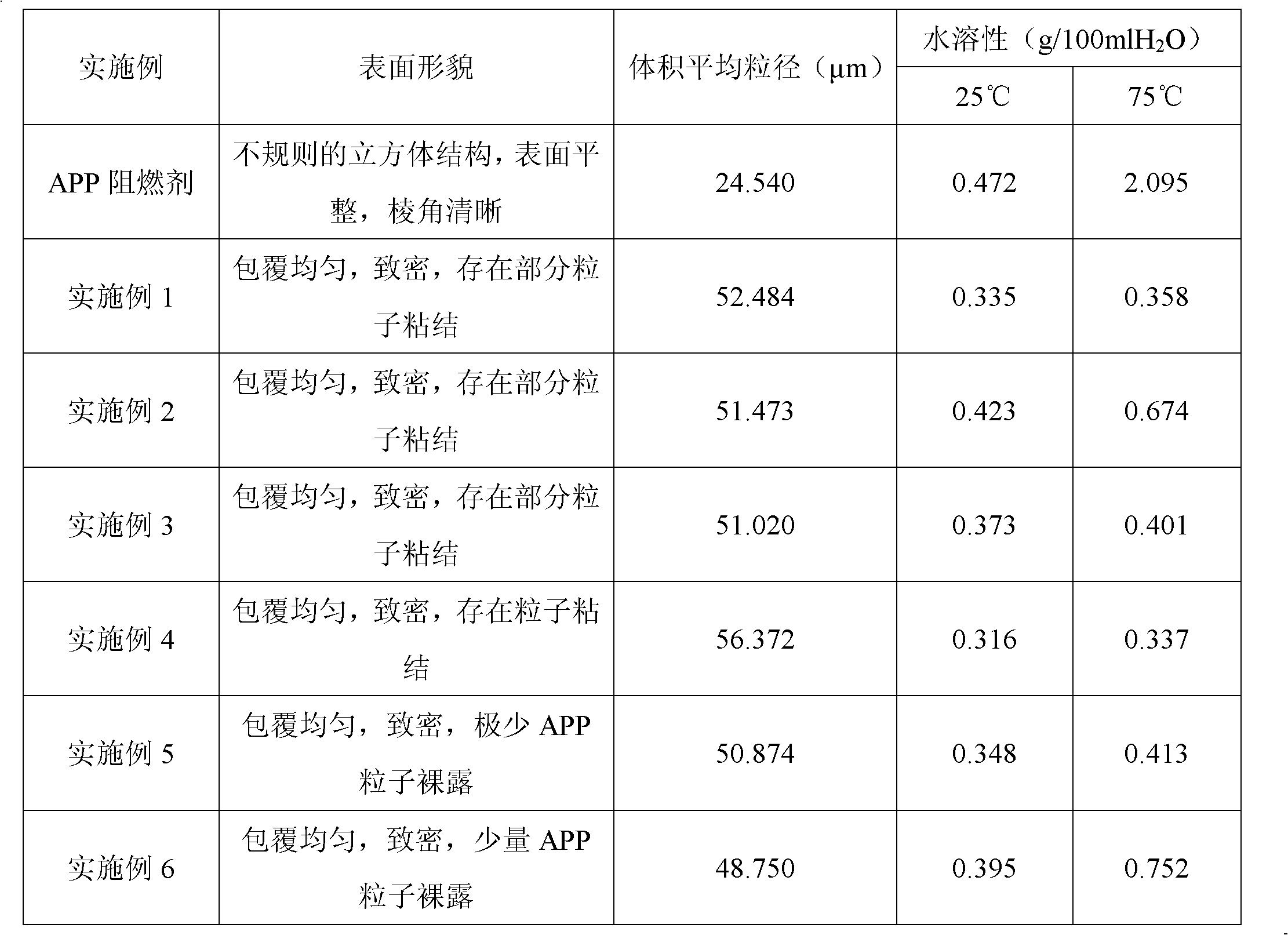

Epoxy resin reaction-type microcapsule fire retardant and preparation method thereof

InactiveCN102585292AImprove temperature and humidity resistanceImprove flame retardant performanceSolubilityEpoxy

The invention belongs to the field of polymer flame retardation and discloses an epoxy resin reaction-type microcapsule fire retardant and a preparation method thereof. The epoxy resin reaction-type microcapsule fire retardant is characterized in that at least one phosphorus-containing fire retardant is utilized as a capsule core; a product of a reaction of at least one curing agent, an epoxy resin and triglycidyl isocyanurate is utilized as a capsule material; a mass ratio of the capsule material to the capsule core is (0.05 to 0.4): 1; and a mass ratio of the epoxy resin to the triglycidyl isocyanurate is (0 to 6): 1. The preparation method provided by the invention comprises the following steps of dispersing the at least one phosphorus-containing fire retardant in at least one solvent,heating, adding a triglycidyl isocyanurate solution and an epoxy resin solution into the heated solution, stirring for a reaction for 10 to 30 minutes, dropwisely adding a curing agent solution into the reaction system, carrying out a reaction process for 1 to 2 hours, heating to a temperature of 70 to 78 DEG C, carrying out a reaction process for 2 to 12 hours, cooling, filtering, washing and drying to obtain the epoxy resin reaction-type microcapsule fire retardant. The epoxy resin reaction-type microcapsule fire retardant has uniform granularity, good liquidity, low water-solubility and good polymer compatibility. Through utilization of the epoxy resin reaction-type microcapsule fire retardant, good flame resistance, good water tolerance and good mechanical properties are obtained.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

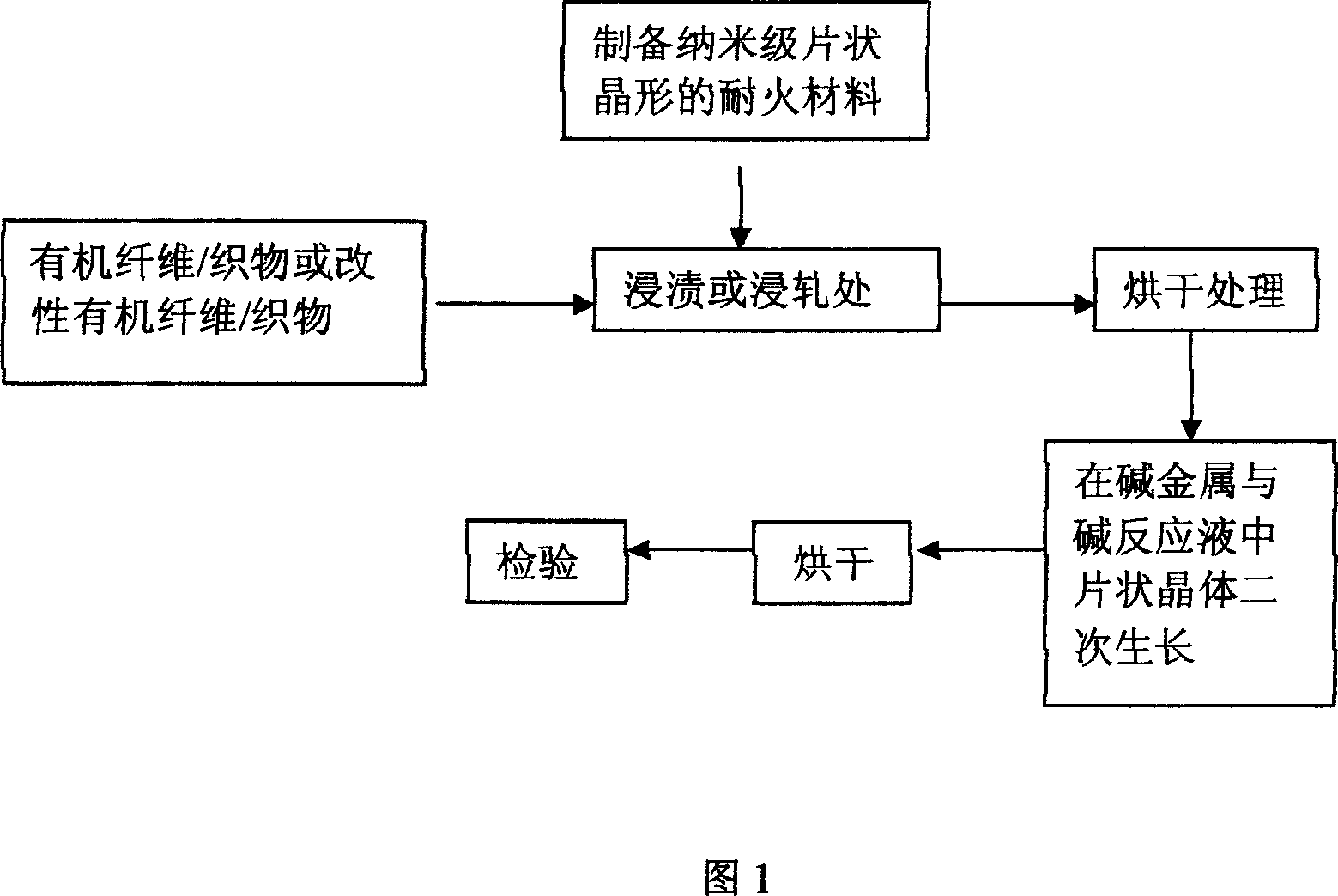

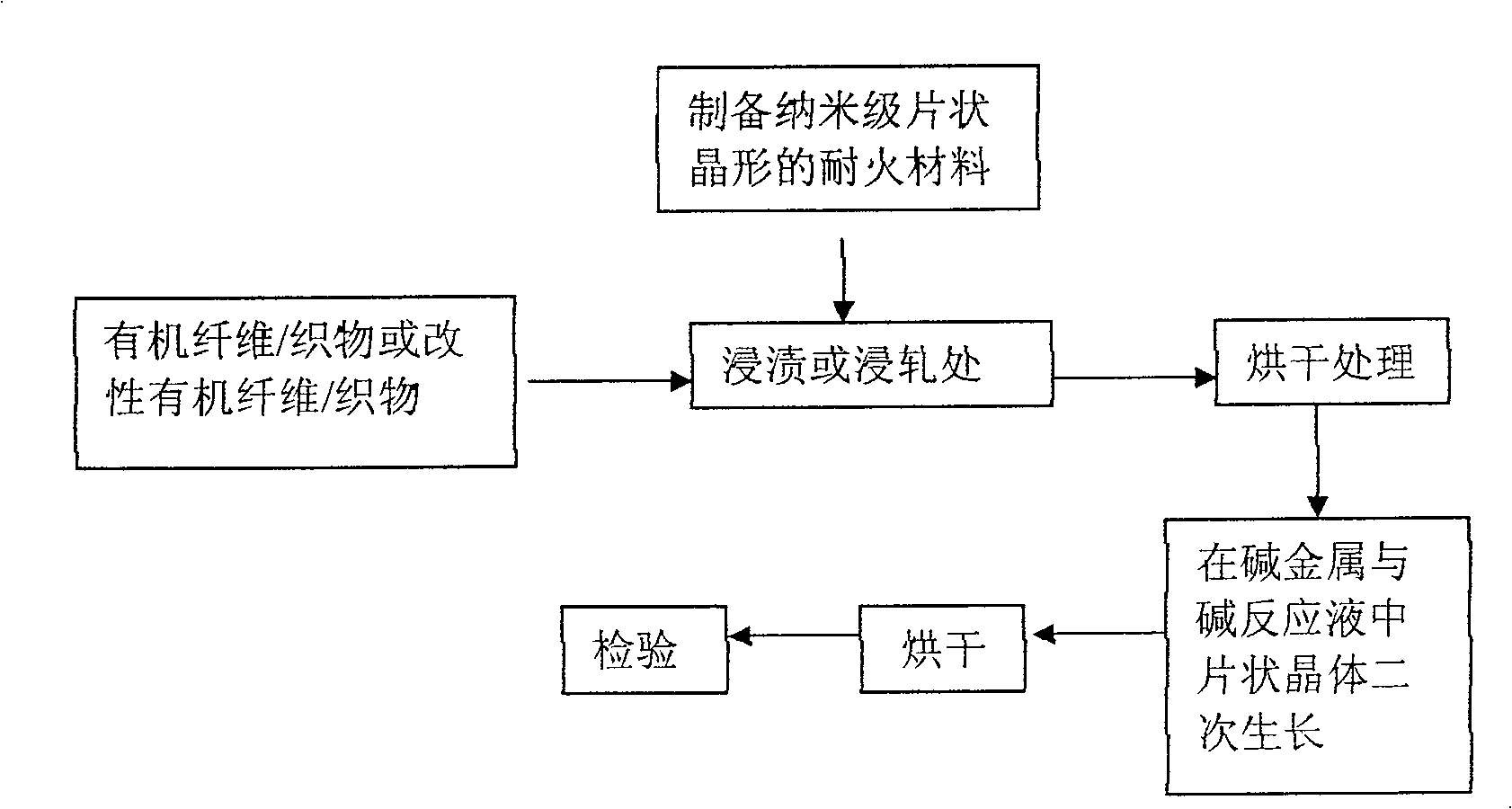

Flame resisting heat insulating conditioning method for orgainic fiber fabric

InactiveCN1932135AAchieve wrappingNo pollution in the processFibre treatmentFiberAgricultural engineering

The present invention discloses a finishing method for raising heat-insulating and flame-proofing performance of organic fibre fabrics. Said method is characterized by forming a continuous protective film made of sheet hydroxide on the surface of organic fibre or fabrics so as to raise flame-proofing and heat-insulating performance of organic fibre fabrics.

Owner:DONGHUA UNIV

Compound type uvioresistant antibacterial agent and preparation method thereof

The invention discloses a compound type uvioresistant antibacterial agent and a preparation method thereof. The preparation method for the compound type uvioresistant antibacterial agent comprises the following steps of: firstly, coarsening talc powder by adopting fluohydric acid; secondly, sensitizing the talc powder after coarsening; and finally, performing silver deposition reaction on the talc powder after sensitizing. Metallic state silver of which the weight is 5 to 10 percent of that of the talc powder and the thickness is 50 to 100 nanometers is deposited and coated on the surface of the talc powder. By using the ultraviolet shielding, absorbing and bacteriostatic functions of nano-state metallic silver, the preparation method prepares the compound type uvioresistant antibacterialagent which simultaneous has uvioresistant and antibacterial functions by depositing the nano silver on the surface of the talc powder. The compound type uvioresistant antibacterial agent has the advantages of simplicity, practicability, high uvioresistant antibacterial efficiency, wide application range, large-scale production and the like. The compound type uvioresistant antibacterial agent provided by the invention can be widely applied to the industries of textiles, plastics, coatings and the like, and has good economical and social benefits.

Owner:ZHEJIANG SCI-TECH UNIV

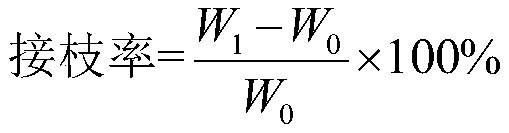

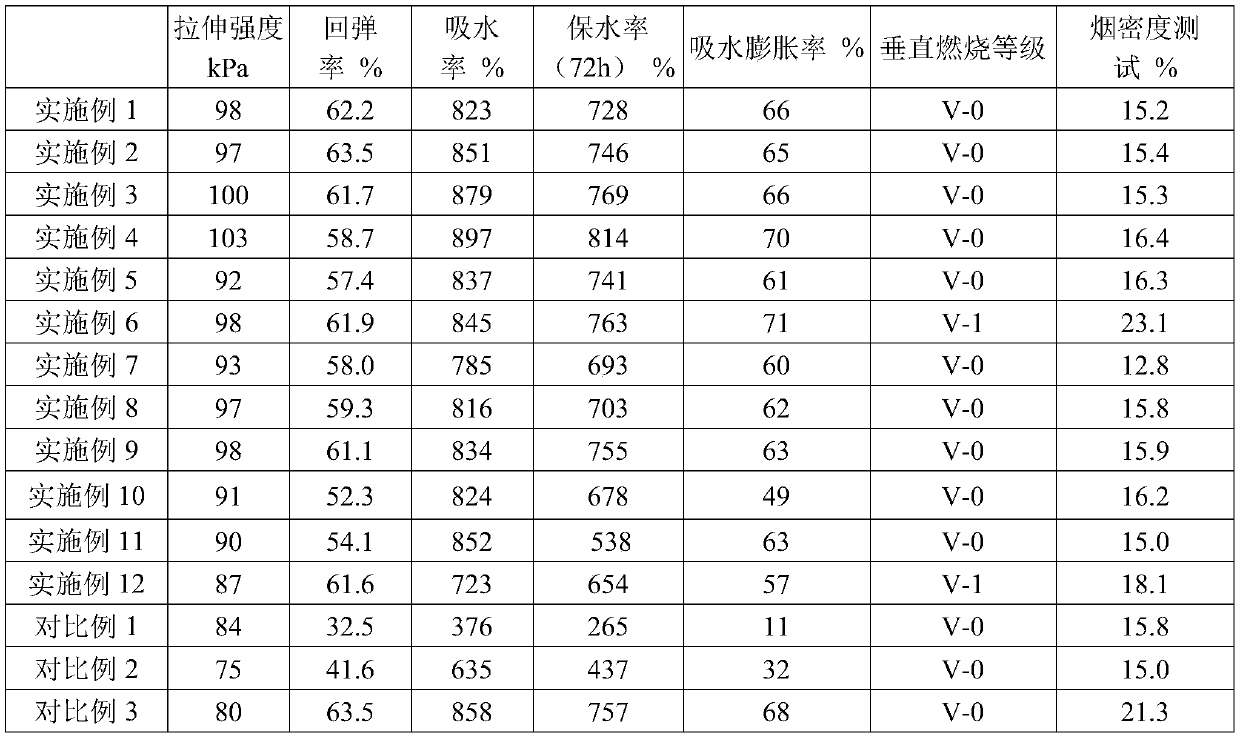

Water-expandable flexible flame-retardant foam plastic and preparation method thereof

The invention relates to water-expandable flexible flame-retardant foam plastic. The water-expandable flexible flame-retardant foam plastic is prepared from the following raw materials in parts by weight: 40-60 parts of a polyester polyol and / or a polyether polyol, 5-10 parts of s graft copolymer of polyvinyl alcohol / an isocyanate group silane coupling agent, 50-90 parts of a polyisocyanate, 1-5 parts of an opening agent, 0.2-3 parts of a foam stabilizer, 5-20 parts of a compound foaming agent, 10-30 parts of a modified flame retardant and 0.2-1 part of a catalyst. The invention simultaneouslyfurther provides a preparation method of the water-expandable flexible flame-retardant foam plastic. According to the prepared water-expandable flexible flame-retardant foam plastic, the graft copolymer of the polyvinyl alcohol / the silane coupling agent is introduced on a polyurethane foam skeleton, unexpectedly it is found that the water absorption capacity and the water retaining capacity of obtained polyurethane foam are enhanced, thus the prepared foam plastic has better water absorption expansion rate and rebound resilience, and the application field of polyester foam is widened; and theflame retardant reacts to a skeleton molecule, intrinsic flame-retardant foam plastic is formed, migration and precipitation of the flame retardant are avoided, so that the flame retardant effect lasts longer, and the effect on the physical and mechanical properties of a material is less.

Owner:中电保力(北京)科技有限公司

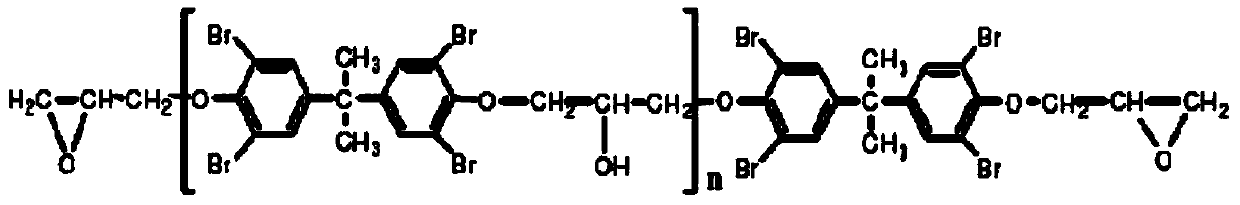

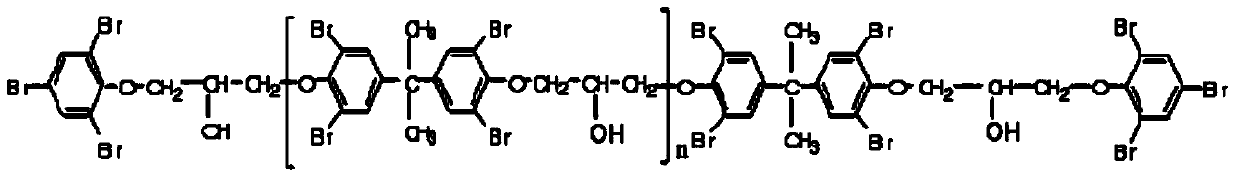

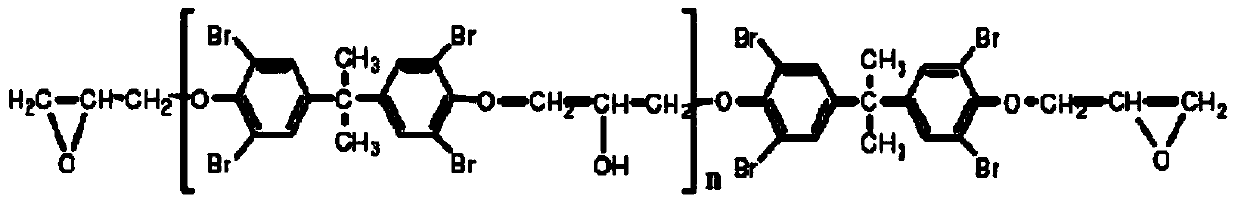

High-polymer bromine flame retardant/nano clay compound flame-retardant ABS (acrylonitrile-butadiene-styrene) resin and preparation method thereof

InactiveCN103992612AHigh flame retardant efficiencyImprove mechanical propertiesPolymer scienceBromine

The invention discloses a high-polymer bromine flame retardant / nano clay compound flame-retardant ABS (acrylonitrile-butadiene-styrene) resin and a preparation method thereof. The material is characterized by comprising the following components in percentage by weight: 52-70% of ABS resin, 20-25% of high-polymer bromine flame retardant, 5-10% of flame-retardant synergistic agent, 1-3% of nano clay and 4-10% of solubilizer. Since the high-polymer bromine flame retardant has favorable compatibility with the ABS resin matrix, the flame-retardancy-modified material has satisfactory melt flow rate and higher flame-retardant efficiency, and the material can be endowed with favorable flame retardancy, high ultraviolet stability, favorable mechanical properties and high heat stability; the flame retardant can not easily migrate, and the processed product can not easily bloom; and thus, the high-polymer bromine flame retardant / nano clay compound flame-retardant ABS resin is especially suitable for home appliances, electronics, automobiles and other industries with various strict performance requirements.

Owner:宁波泛塑新材料科技有限公司

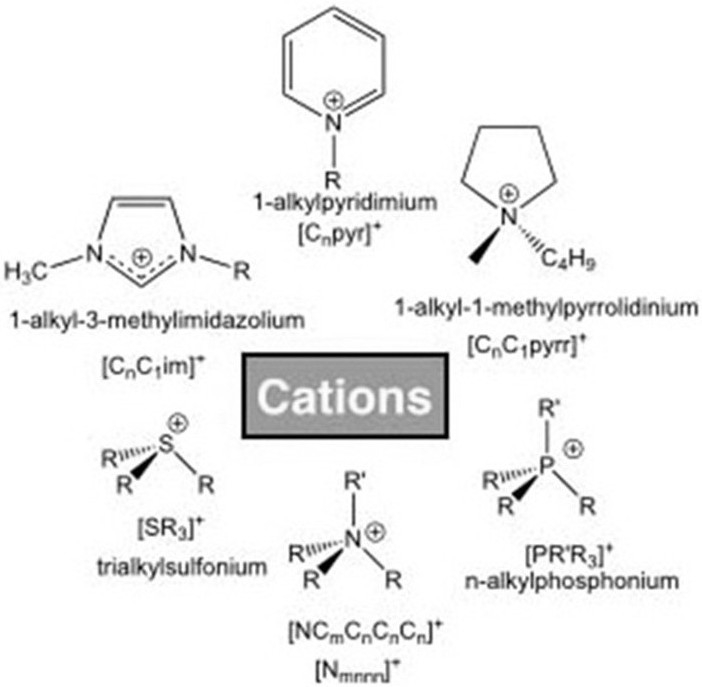

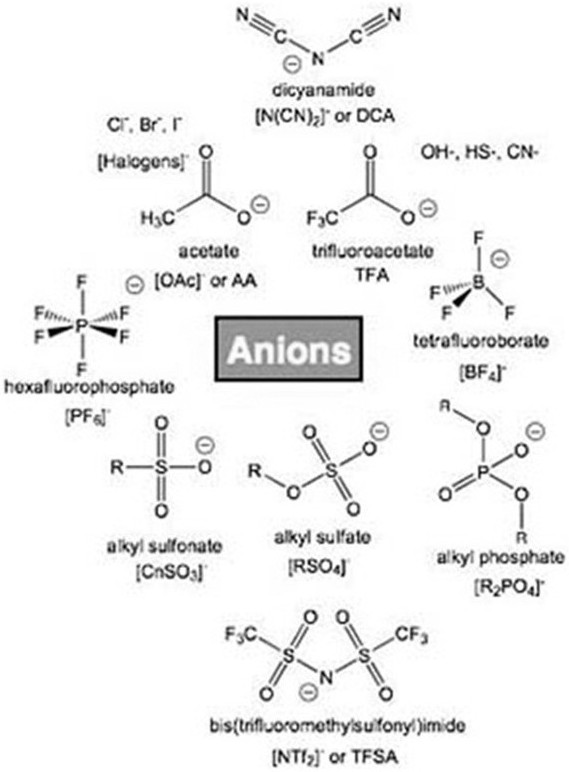

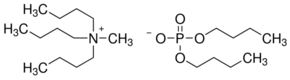

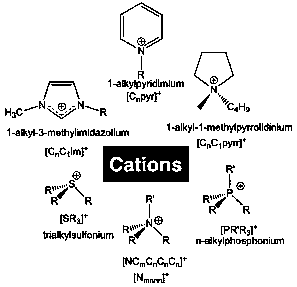

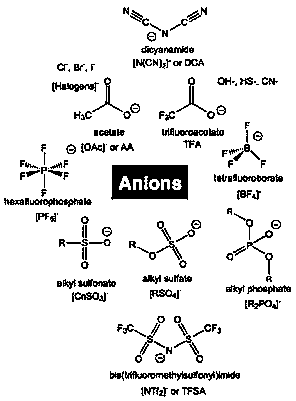

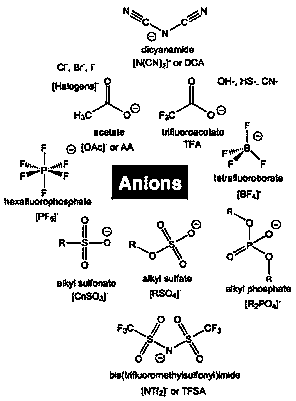

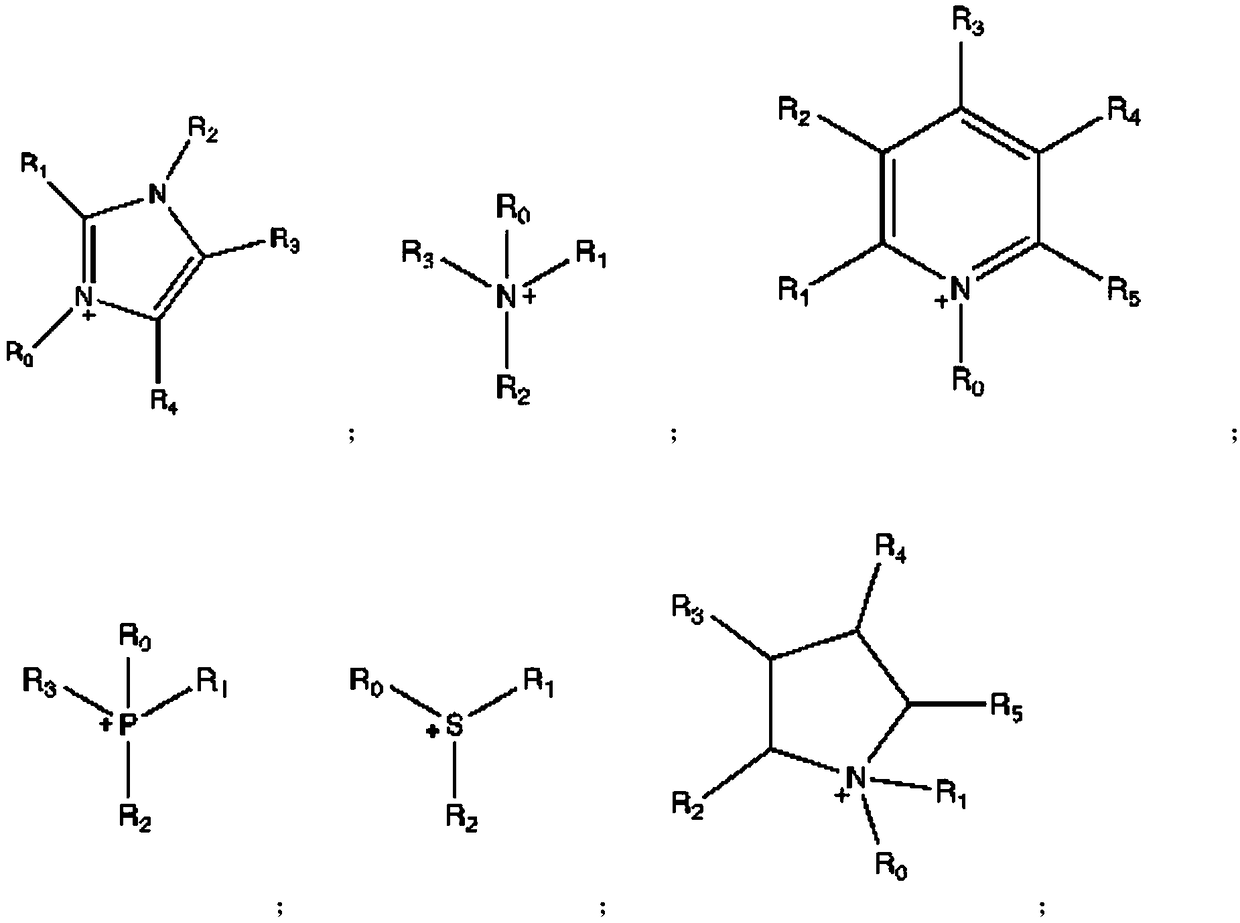

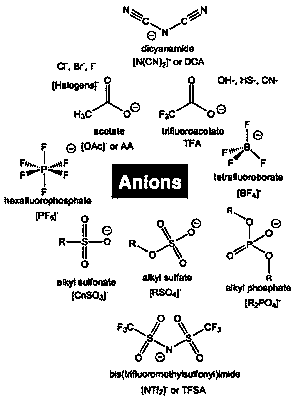

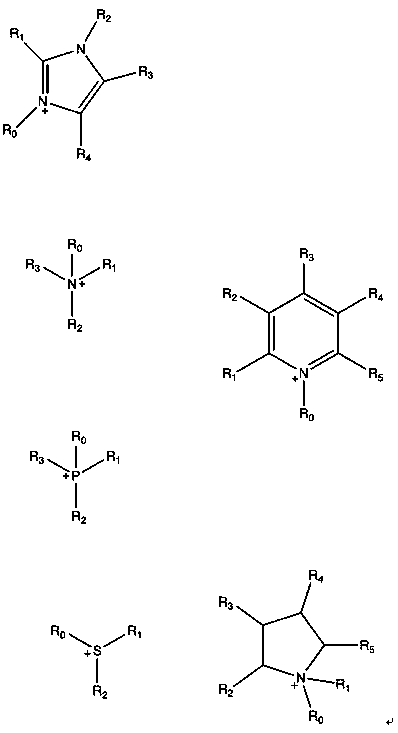

Flame-retardant thermoplastic polyurethane plastic, flame retardant and application

The invention discloses a novel flame-retardant thermoplastic polyurethane plastic (flame-retardant TPU), and components, preparation and application thereof. Specifically, the flame-retardant TPU disclosed by the invention comprises polyether type TPU and polyester type TPU, the TPU flame retardant disclosed by the invention comprises an ionic liquid component, and the ionic liquid can be a single ionic liquid component, can be shared by several ionic liquids, and can also be a mixture of the ionic liquid and a traditional flame retardant. The flame-retardant TPU plastic plate disclosed by the invention can be applied to the fields of automobiles, buildings, national defense, aviation and the like.

Owner:南通诺为新材料科技有限公司

Synthesis method of flexible-foam flame-retardant polyether polyol

The invention relates to a synthesis method of flexible-foam flame-retardant polyether polyol, aiming at providing the synthesis method of the flexible-foam flame-retardant polyether polyol with good flame retardance, safety, no toxicity and low cost. The synthesis method comprises the following steps of: adopting a melamine-formaldehyde condensation compound and a polyol compound as a mixed initiator; firstly under the action of amine, carrying out polymerization with olefin oxide and obtaining high-hydroxyl-value polyether; and then under the action of alkali metal catalyst, adding the olefin oxide again for further polymerization and obtaining the flexible-foam flame-retardant polyether polyol. In the synthesis method, the preparation process is simple, the cost is low and the influence on the physical and mechanical performances is less. The flexible-foam flame-retardant polyether polyol prepared by the method is light in color and low in viscosity and can be widely used for preparing the flame-retardant flexible polyurethane foam. A prepared flame-retardant flexible polyurethane foam plastic product has the advantages of high oxygen index, good flame-retardant effect, high heat resistance, good size stability and high strength.

Owner:SHANDONG BLUSR DONGDA CHEM

Antimony-less environment-friendly novel flame-retardant polyvinyl chloride cable material and preparation method thereof

ActiveCN107474433AGood flame retardant performancePhysical performance balancePlastic/resin/waxes insulatorsAmmonium polyphosphateChemistry

The invention discloses an antimony-less environment-friendly novel flame-retardant polyvinyl chloride cable material and a preparation method thereof. The antimony-less environment-friendly novel flame-retardant polyvinyl chloride cable material is prepared from the following materials in parts by weight: 100 to 150 parts of PVC (polyvinyl chloride) resin, 40 to 50 parts of polyester plasticizer, 4 to 8 parts of compound calcium-zinc stabilizer, 0.5 to 1 part of chemical lubricant, 25 to 40 parts of filler and 3 to 5 parts of components of a formula A. The formula A is prepared from the following materials in parts by weight: 0.6 to 1 part of zinc stannate, 1 to 2 parts of aluminium hydroxide, 0.8 to 1.2 parts of organic phosphorus flame retardant, 0.8 to 1.5 parts of nitrogen series flame retardant, 1 to 1.5 parts of ammonium polyphosphate, 1 to 2 parts of magnesium hydroxide, 0.1 to 0.3 parts of pentaerythritol and 0.1 to 0.3 parts of chemical lubricant. Besides flame-retardant property, the cable material disclosed by the invention also has excellent physical and chemical properties.

Owner:江西省安安科技有限公司

A flame-retardant and wear-resistant corrugated box

ActiveCN107034739BAvoid contactWith quantum size effectFlexible coversWrappersWear resistantPaperboard

The invention discloses a flame-retardant and wear-resistant corrugated box, which comprises a box body composed of corrugated cardboards. The cardboards are surface paper, corrugated paper and inner paper from the outside to the inside, and the three are bonded by oxidized starch, wherein the oxidized starch is added Vapor-phase corrosion inhibitor, and coating fire-resistant wear-resisting paint on surface paper and inner paper surface, this coating is prepared from following raw materials by weight: 30-40 parts of phenolic resin, nanometer Sb2O3-Al (OH) 310-15 parts, 10-20 parts of nano wear-resistant powder, 1-3 parts of reactive diluent, 0.5-2 parts of defoamer, 2-5 parts of penetrating agent, 0.5-1 part of antioxidant, 10-20 parts of organic solvent, 10 parts of curing agent ‑20 servings. In the present invention, the phenolic resin modified by cashew nut shell oil or melamine is applied to the surface of the carton, which has strong wear resistance and mechanical properties. Nano-aluminum hydroxide is used as a flame retardant to reduce the dosage and improve the flame retardancy.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

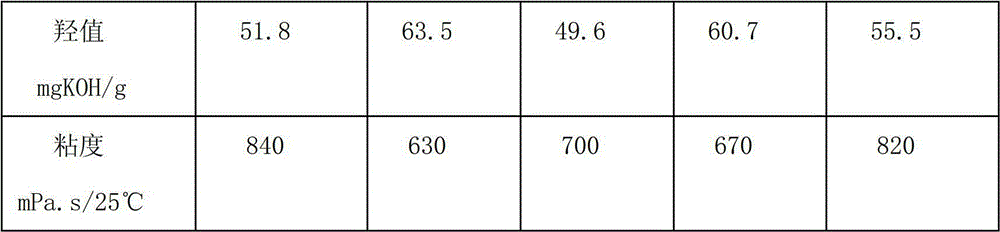

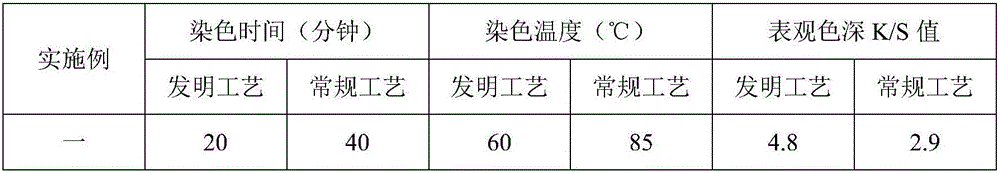

Dyeing method for improving deep dyeing performance of polyamide fiber

ActiveCN106835765AHigh dyeing depthLittle impact on physical and mechanical propertiesDyeing processTextile printerDisperse dye

The invention relates to a dyeing method for improving deep dyeing performance of polyamide fiber, and belongs to the technical field of textile printing and dyeing. The dyeing method comprises the following steps: adding disperse dye into a mixed solution of ethanol and water to obtain a dyeing solution, and dyeing the polyamide fiber in an ultrasonic environment, wherein by virtue of strong penetration of ethanol into the polyamide fiber, a synergistic effect is produced under the auxiliary action of ultrasonic, and a large number of dye molecules are carried into the free volume of the fiber so as to deeply and thoroughly dye the polyamide fiber. By the dyeing method, the dyeing temperature is low, the dyeing time is short, strength damage of the polyamide fiber in the dyeing process is alleviated, and the problem that the dyeing depth is not high when the disperse dye dyes the polyamide fiber is effectively solved; and the dyeing method is simple in process and strong in operability and is an efficient polyamide fiber dyeing method.

Owner:WUHAN TEXTILE UNIV

High-toughness flame-retardant polypropylene material and preparation method thereof

InactiveCN109518293AImprove toughnessStrong adhesionFlame-proof filament manufactureFibre typesPolymer sciencePolypropylene

The invention discloses a high-toughness flame-retardant polypropylene material and a preparation method thereof. The preparation method comprises the following steps of: preparing modified isotacticpolypropylene with good impact toughness, flame retardancy and heat resistance by using isotactic polyethylene fibers, hexahydroxymethylaminotristritrientriene, and temperature-resistant toughening filler, obtaining a compact fiber net with good adhesive force, compatibility, ultraviolet ray resistance and flame retardancy through the melt spinning of the modified isotactic polypropylene, a sisalfiber composite light stabilizer loaded with FeTiO3 / titanium dioxide, and an adhesion promoter, carrying out infiltration and hot pressing on the compact fiber net in an ester-soluble chlorinated polypropylene resin solution, and discharging to obtain the polypropylene material. On the basis of maintaining the good toughness and flame retardance, the dust removal and sterilization efficiency of the obtained polypropylene material is greatly improved; and an automobile lining prepared by the polypropylene material is not easy to crack and wrinkle under the condition of long-term illumination and rain.

Owner:上海阜泰实业有限公司

Flame-retardant polyacrylic acid plastic, and preparation method and application thereof

The invention discloses a flame-retardant polyacrylic acid plastic, and a preparation method, composition and application thereof. Samples prepared in the invention are obviously improved in flame resistance; longer time is needed to ignite the samples; the samples realizes self-extinguishing in the air; and smoke density in resin combustion is obviously reduced. An ionic liquid fire retardant used in the invention can also be used for preparation of a cast plate. Besides conventional acrylic acid monomer, an ionic liquid copolymerization monomer also exists, and the monomer introduces flame-retardant components at the same time. The plastic can be prepared through bulk polymerization or solution polymerization and is eventually applicable to synthetic glass, buildings, advertisements, traffic, medical science and civilian goods, to industrial fields like surface plates and protecting covers of instruments, and to illumination fields like covers for fluorescent lamps, pendent lamps andstreet lamps.

Owner:南通诺为新材料科技有限公司

Tin antimony oxide dispersion liquid for improving fiber conduction performance, preparation method of tin antimony oxide dispersion liquid and preparation method of conductive regeneration cellulose fiber

ActiveCN107815743AGood dispersionImprove bindingArtificial filaments from viscoseConductive polymerSoft water

The invention discloses tin antimony oxide dispersion liquid for improving the fiber conduction performance, a preparation method of the tin antimony oxide dispersion liquid and a preparation method of conductive regeneration cellulose fiber. The dispersion liquid is prepared by mixing ammonium polycarboxylate solution, soft water, ATO powder and sodium hexametaphosphate according to the weight ratio of (4 to 8):(2 to 6):(0.5 to 3):(0.1 to 0.5); the pH value of the dispersion liquid is 8 to 12. The dispersion liquid is added into prepared spinning viscose according to the addition quantity that the ATO powder in the dispersion liquid accounts for 3 to 10 weight percent of the methylcellulose in the spinning viscose; after the uniform mixing, the blending viscose raw liquid is obtained. Theblending viscose raw liquid is subjected to coagulating bath spinning shaping; then, refining and drying are performed to obtain the conduction regenerated cellulose fiber. The tin antimony oxide dispersion liquid is used for modified preparation of the conductive fiber; the addition quantity of the conductive powder is low; the conductive body and the cellulose are tightly combined; falling cannot easily occur in the subsequent use and processing process.

Owner:赛得利(盐城)纤维有限公司

Wet rubbing fastness promoting agent and preparation method thereof

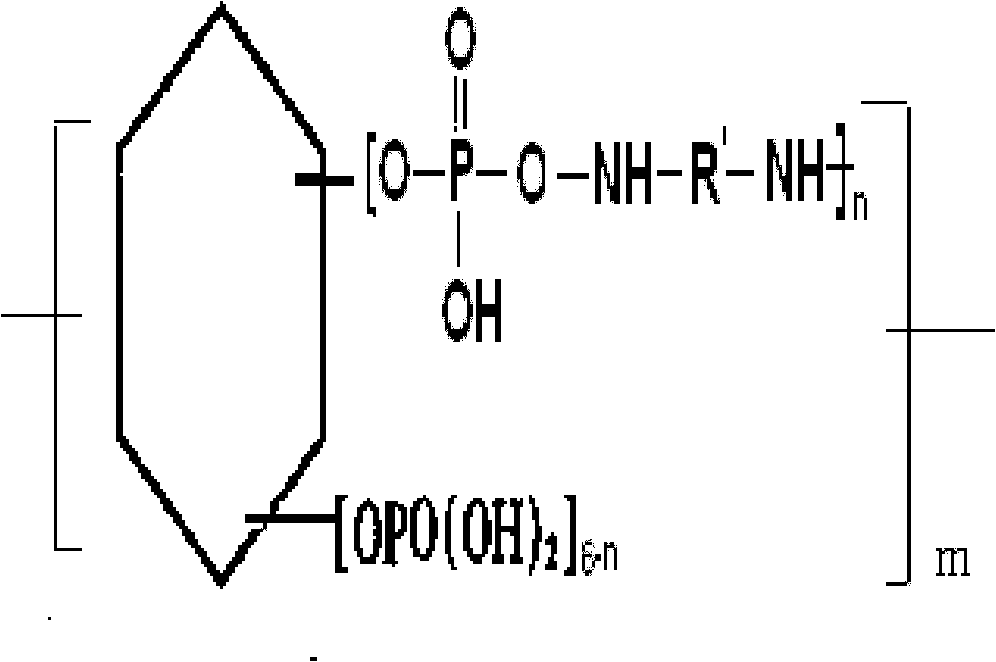

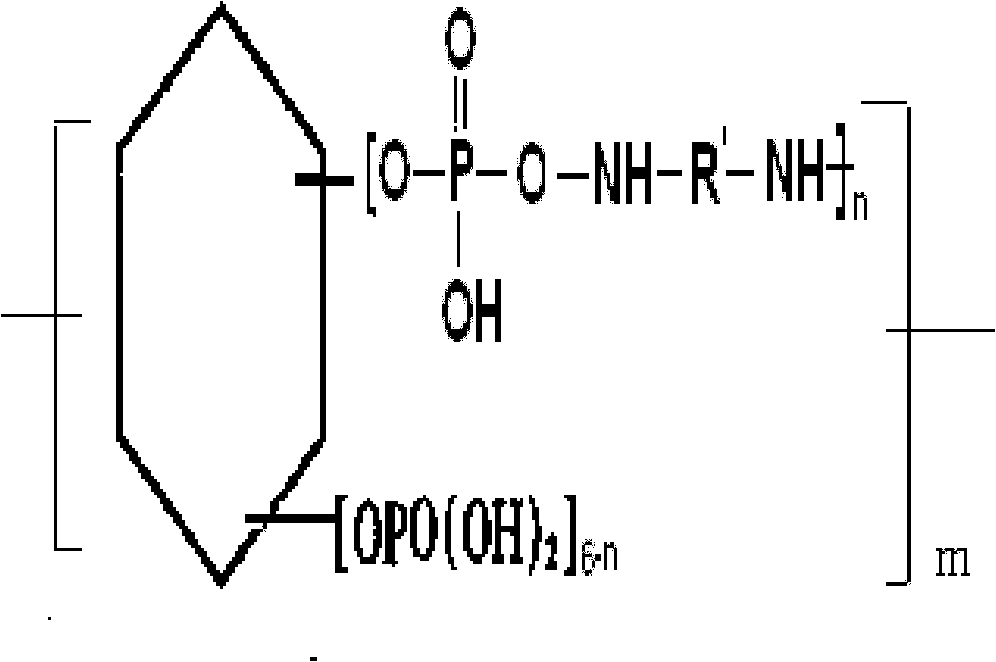

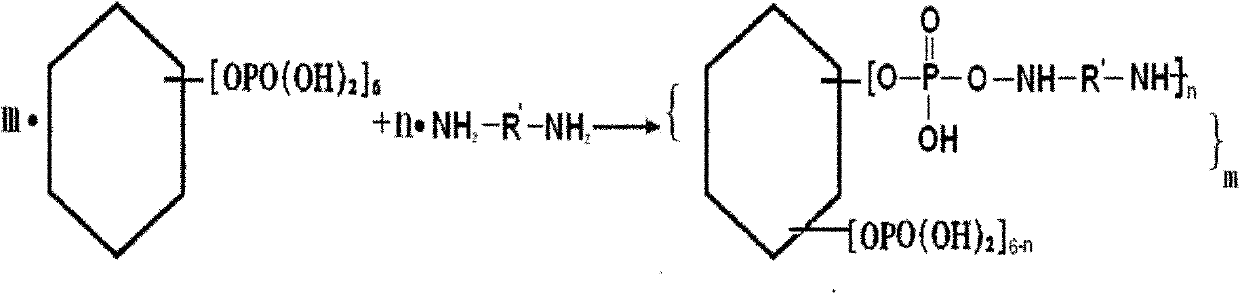

ActiveCN102061637AGood film formingReduce surface friction coefficientDyeing processWater solubleStructural formula

The invention discloses a wet rubbing fastness promoting agent and a preparation method thereof. The promoting agent has a structural formula disclosed in the specification, wherein m is 100-5,000, n is 1-6, and R' is -CH2-CH2-. Compared with the prior art, the promoting agent structure is rich in active groups of phosphamide, and the like, shows weak cation properties and can combine and react with water soluble groups, so that hydrophilic groups of dye are closed so as to form infusible lakes on a fabric; meanwhile, the promoting agent also can react and combine with active groups of fabric macromolecules so as to improve the rubbing fastness; the promoting agent consists of meshed macromolecules, and the film forming property is strong; and after drying treatment, a flexible and tough film can be formed on the surface of the fabric.

Owner:WUHU FUCHUN DYEING & WEAVING

Flame-retardant acrylate plastic, and preparation method and application of casting plate thereof

The invention discloses a flame-retardant acrylate plastic, and a preparation method and application of a casting plate thereof. A flame retardant used in the invention comprises an ionic liquid component which may be a single ionic liquid or a mixture of a plurality of ionic liquids or a mixture of an ionic liquid and a traditional flame retardant. A plastic extruded sheet is prepared from a polyacrylic plastic matrix and the flame retardant through blending via an extruder. The flame retardant can also be mixed with acrylic monomers before polymerization so as to obtain the flame-retardant acrylate plastic casting plate. The flame-retardant acrylate plastic plate disclosed by the invention can be used in the fields of lighting products, automobiles, buildings, advertisements and the like.

Owner:南通诺为新材料科技有限公司

Flame resisting heat insulating conditioning method for orgainic fiber fabric

InactiveCN100412258CAchieve wrappingNo pollution in the processFibre treatmentFiberAgricultural engineering

Owner:DONGHUA UNIV

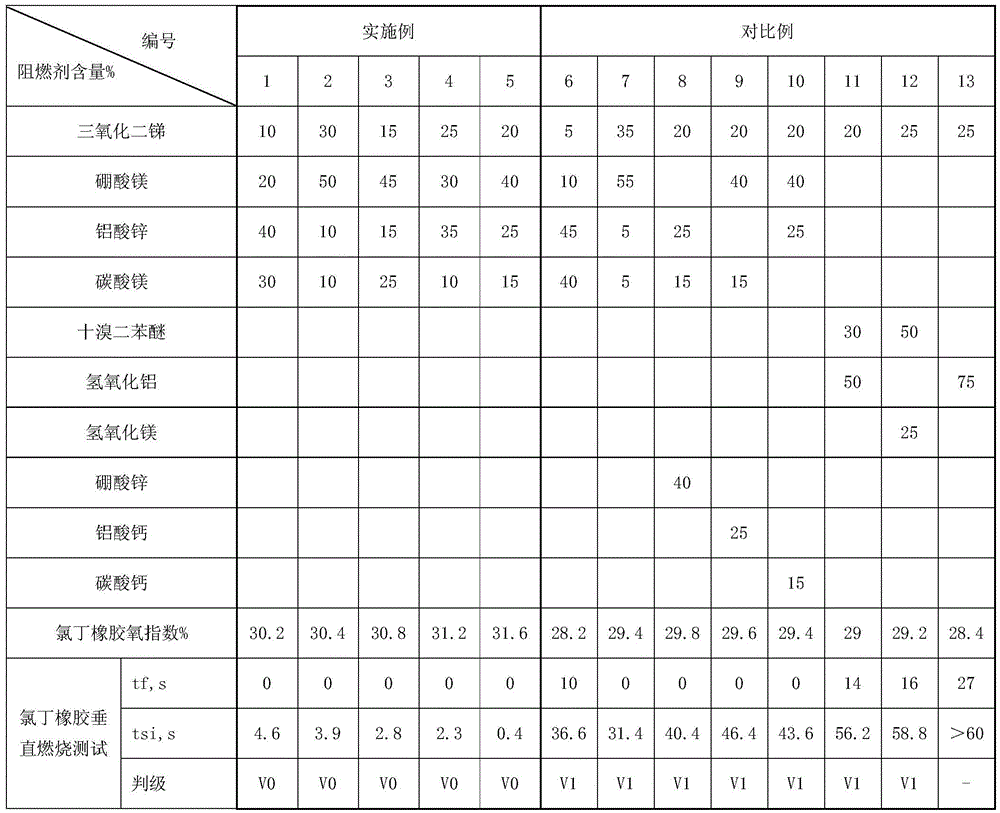

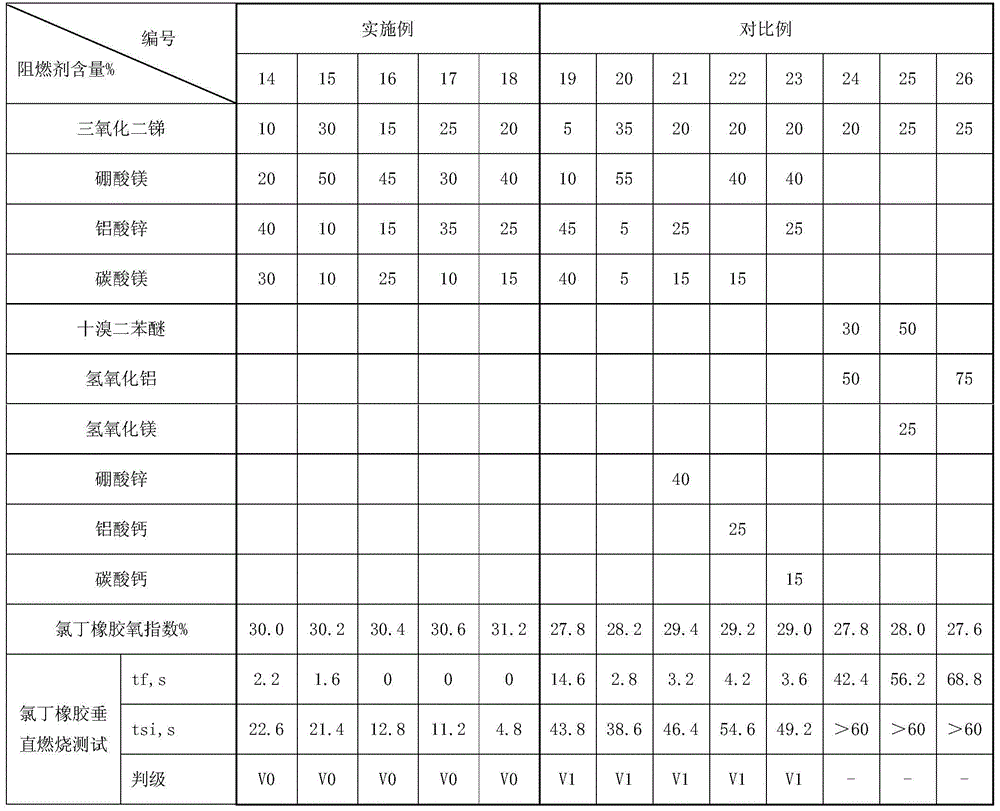

A kind of flame retardant composition for chloroprene rubber and preparation method thereof

The invention provides a flame retardant composition for chloroprene rubber and a preparation method thereof, wherein the flame retardant composition comprises antimony trioxide, magnesium borate, zinc aluminate and magnesium carbonate; in parts by weight, The flame retardant composition comprises 10-30 parts of antimony trioxide, 20-50 parts of magnesium borate, 10-40 parts of zinc aluminate and 10-30 parts of magnesium carbonate. With this flame retardant composition, there is no need to add brominated flame retardants (such as decabromodiphenyl ether, decabromodiphenylethane, etc.), halogenated flame retardants (chlorinated paraffin, chlorine, etc.) to the neoprene rubber. Polyethylene), metal hydroxides and zinc borate and other flame retardants. Moreover, the flame retardant composition has the advantages of less dosage and high flame retardant efficiency.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

Engineering solid tire intermediate rubber with added fly ash

InactiveCN110724314AImprove performanceSolve the problems that easily affect the physical and mechanical properties of rubberRubber materialStearic acid

The invention provides engineering solid tire intermediate rubber with added fly ash. The intermediate rubber comprises, by mass, 90-110 parts of natural rubber, 30-50 parts of super wear-resistant furnace black, 20-35 parts of the fly ash, 5-15 parts of aromatic oil, 1-5 parts of zinc oxide, 1-5 parts of stearic acid, 1-5 parts of sulfur and 1-5 parts of an accelerant. By using the fly ash to replace a part of carbon black to serve as one of the production raw materials of the intermediate rubber, the influence on physical and mechanical properties of the rubber material is small; by introducing the material, cost is lowered, and meanwhile product competitiveness is improved; and moreover, by adding a tackifier, a separant, a fame retardant and an anti-pressure agent, all properties of the intermediate rubber are improved, and the problem that when the carbon black is used as one raw material to produce the solid tire intermediate rubber, the physical and mechanical properties of therubber are prone to being influenced is solved.

Owner:芜湖集拓实心胎有限公司

A kind of high-toughness flame-retardant polypropylene material and preparation method thereof

InactiveCN109518293BImprove toughnessStrong adhesionFlame-proof filament manufactureFibre typesSisal fibrePolypropylene

The invention discloses a high-toughness flame-retardant polypropylene material and a preparation method thereof. The preparation method comprises the following steps of: preparing modified isotacticpolypropylene with good impact toughness, flame retardancy and heat resistance by using isotactic polyethylene fibers, hexahydroxymethylaminotristritrientriene, and temperature-resistant toughening filler, obtaining a compact fiber net with good adhesive force, compatibility, ultraviolet ray resistance and flame retardancy through the melt spinning of the modified isotactic polypropylene, a sisalfiber composite light stabilizer loaded with FeTiO3 / titanium dioxide, and an adhesion promoter, carrying out infiltration and hot pressing on the compact fiber net in an ester-soluble chlorinated polypropylene resin solution, and discharging to obtain the polypropylene material. On the basis of maintaining the good toughness and flame retardance, the dust removal and sterilization efficiency of the obtained polypropylene material is greatly improved; and an automobile lining prepared by the polypropylene material is not easy to crack and wrinkle under the condition of long-term illumination and rain.

Owner:上海阜泰实业有限公司

Compound type uvioresistant antibacterial agent and preparation method thereof

InactiveCN101744003BFunctionalLittle impact on physical and mechanical propertiesBiocideFungicidesSocial benefitsHydrofluoric acid

The invention discloses a compound type uvioresistant antibacterial agent and a preparation method thereof. The preparation method for the compound type uvioresistant antibacterial agent comprises the following steps of: firstly, coarsening talc powder by adopting fluohydric acid; secondly, sensitizing the talc powder after coarsening; and finally, performing silver deposition reaction on the talc powder after sensitizing. Metallic state silver of which the weight is 5 to 10 percent of that of the talc powder and the thickness is 50 to 100 nanometers is deposited and coated on the surface of the talc powder. By using the ultraviolet shielding, absorbing and bacteriostatic functions of nano-state metallic silver, the preparation method prepares the compound type uvioresistant antibacterialagent which simultaneous has uvioresistant and antibacterial functions by depositing the nano silver on the surface of the talc powder. The compound type uvioresistant antibacterial agent has the advantages of simplicity, practicability, high uvioresistant antibacterial efficiency, wide application range, large-scale production and the like. The compound type uvioresistant antibacterial agent provided by the invention can be widely applied to the industries of textiles, plastics, coatings and the like, and has good economical and social benefits.

Owner:ZHEJIANG SCI-TECH UNIV

Flame retardant soft foam polyether polyol and synthesis method thereof

The invention relates to a flame retardant soft foam polyether polyol and a synthesis method thereof. The technical scheme is to provide the flame retardant soft foam polyether polyol which is good in flame retardant property, safe and non-toxic, simple in preparation process and low in cost and the synthesis method of the flame retardant soft foam polyether polyol. The synthesis method disclosed by the invention comprises the following steps of enabling melamine-formaldehyde condensation compound to react with amine compounds, polymerizing the reaction product with an acid compound to obtain a polyether initiator, further polymerizing the polyether initiator with oxyalkylene with the action of a base metal catalyst so as to obtain the flame retardant polyether polyol. The flame retardant polyether polyol synthesized by the method has the advantages of light colour, low viscosity and good material flowability, and can be widely used for preparing the flame retardant polyether soft foam. The flame retardant soft polyether foam plastic products foamed and prepared by the flame retardant polyether polyol disclosed by the invention have the characteristics of good flame retardant effect, high oxygen index, good foam uniformity, good size stability and high mechanical strength.

Owner:SHANDONG BLUSR DONGDA CHEM

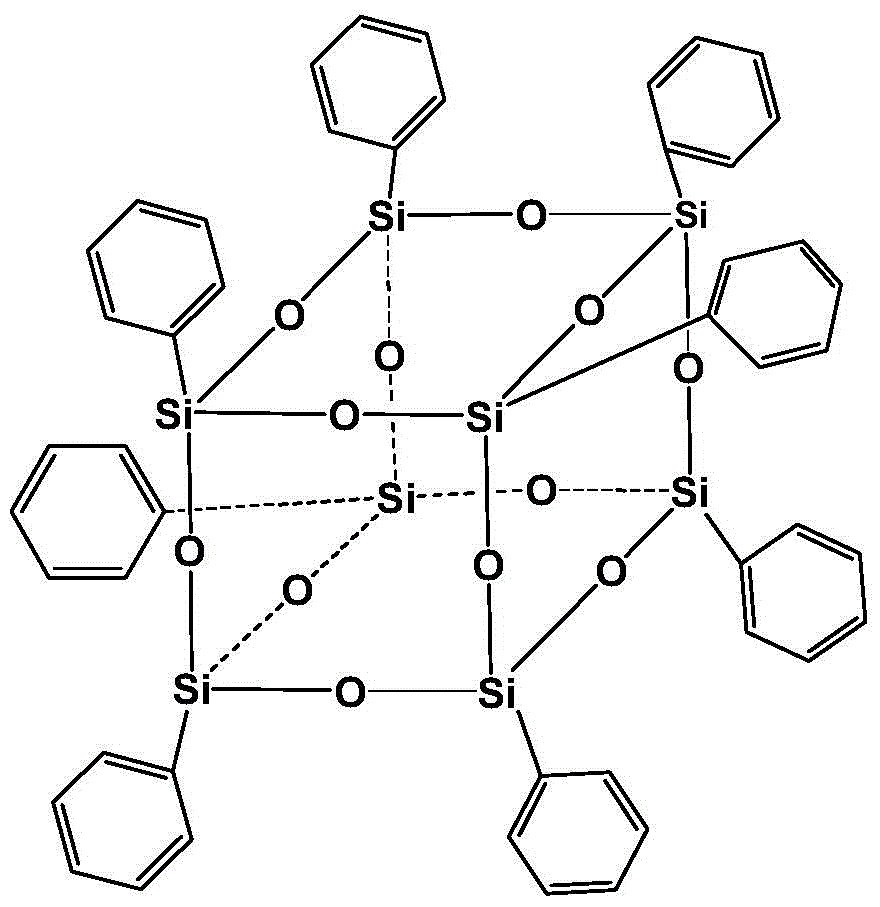

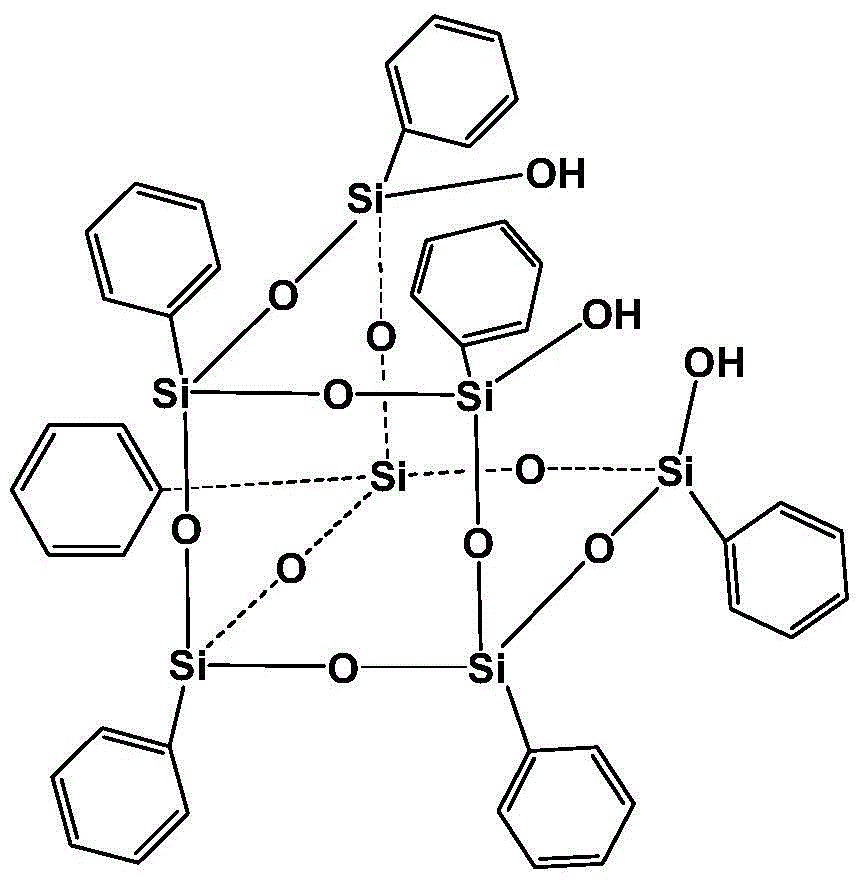

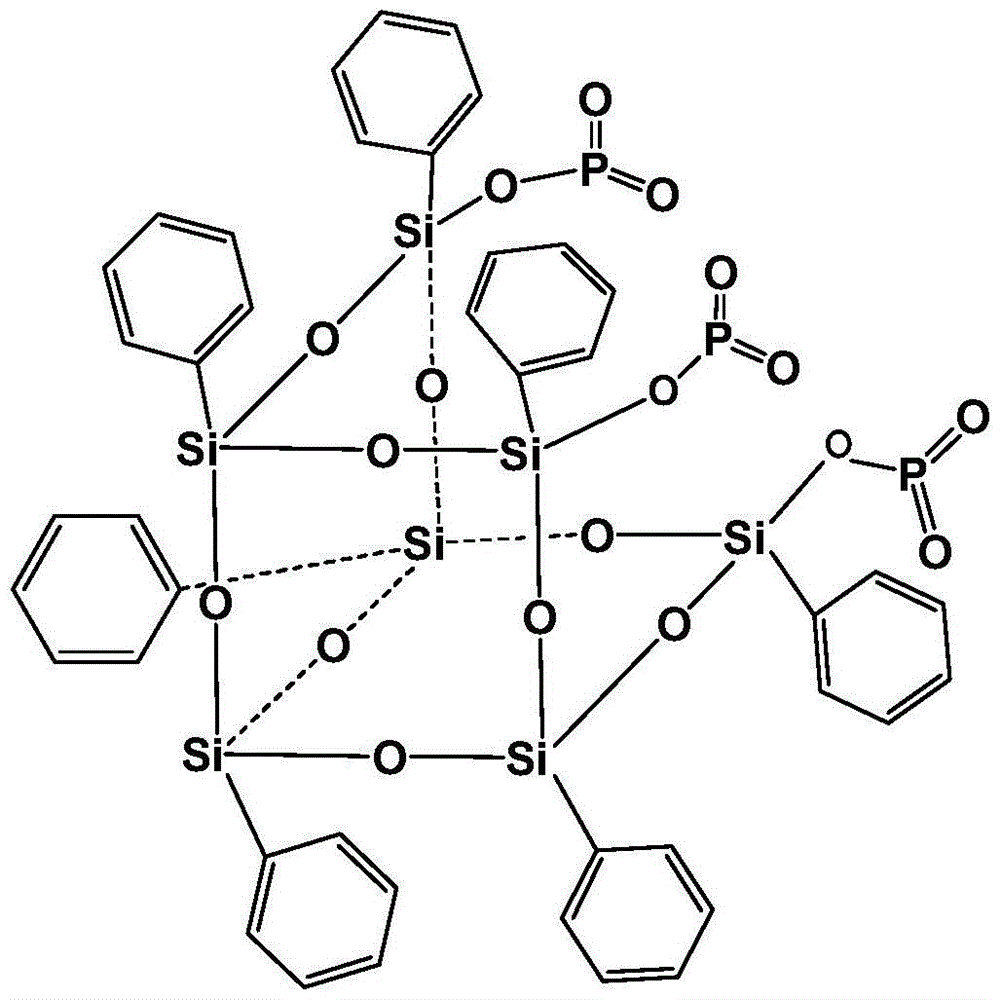

A kind of phosphorus-silicon composite flame retardant and its preparation method and application

ActiveCN104448830BExcellent heat insulation and smoke suppressionEasy to processGroup 5/15 element organic compoundsPolymer scienceThermal insulation

The invention discloses a phosphorus-silicon composite flame retardant as well as a preparation method and application thereof. The phosphorus-silicon composite flame retardant is a cage-like tetraphenyl trisilicate phosphorus silsesquioxane shown in the description, and the flame retardant is prepared according to the following steps: firstly hydrolyzing POSS to chipping POSS under the action of an organic alkali, and then carrying out reaction of the chipping POSS with metaphosphoric acid. Experiments show that the phosphorus-silicon composite flame retardant provided by the invention gives full play to the advantages of a silicon flame retardant and a phosphorus flame retardant, compensates defects of the silicon flame retardant and the phosphorus flame retardant, has significant synergistic flame retardance and complementarity, and excellent thermal insulation, smoke suppression and oxygen supply cutoff functions, also has the functions of protecting the environment, safety and preventing molten drop, can be directly used for preparing silicone rubber, can not only improve the flame retardance of the silicone rubber, but also perfect the thermal insulation, smoke suppression and mechanical properties of the silicone rubber, and the phosphorus-silicon composite flame retardant has the advantages of being low in preparation and application costs, easy to realize large-scale industrialized production, and the like.

Owner:SHANGHAI UNIV OF ENG SCI

High performance flame-retardant polycarbonate alloy, flame retardant, compatibilizer and application

InactiveCN110387116AGood flame retardant effectReduce plasticizing side effectsPolycarbonateChemistry

The invention discloses novel flame-retardant polycarbonate alloy plastic and preparation and application thereof. In the novel flame-retardant polycarbonate alloy plastic, ionic liquid is used as a flame retardant and a compatibilizer. The ionic liquid can be a single ionic liquid component, or can be multiple shared ionic liquid, or can be ionic liquid mixed with a conventional flame retardant or a conventional compatibilizer. The polycarbonate alloy plastic is prepared from PC / ABS, PC / PS, PC / PBT, PC / PET, PC / ASA and the like. A flame-retardant polycarbonate alloy plastic plate disclosed canbe used in the fields of automobiles, electronics, precision instruments, construction, office equipment, household appliances, packaging materials and the like.

Owner:南通诺为新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com