Flame-retardant thermoplastic polyurethane plastic, flame retardant and application

A flame retardant and plastic technology, applied in the field of new flame retardant TPU plastics, can solve the problems of plastic physical and mechanical properties decline, high cost of flame retardant TPU preparation, limit the use of flame retardant TPU, etc., to achieve small physical properties and good solubility , weaken the effect of plasticizing side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

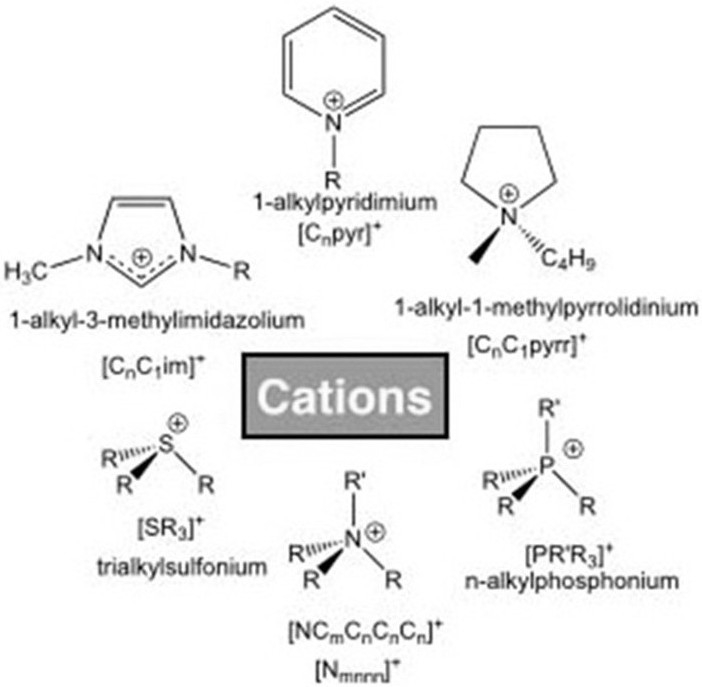

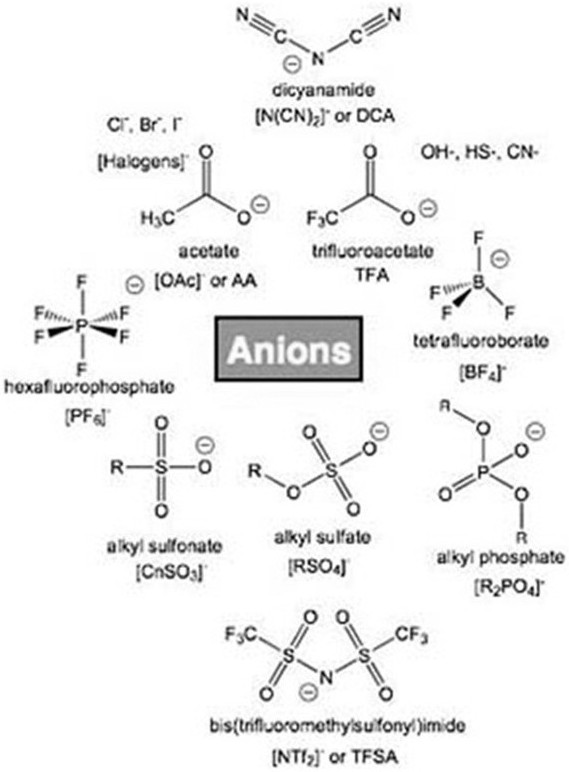

Method used

Image

Examples

Embodiment example 1

[0023]

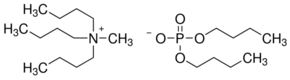

[0024] tributylmethyl ammonium dibutyl phosphate

[0025] 3% tributylmethyl dibutylammonium phosphate and TPU pellets were melt blended with an extruder. The extruder is also equipped with a liquid feeder, and the extrusion temperature is slightly lower than the processing temperature of pure TPU resin. Then the injection molding machine prepared the samples and tested the flame retardancy.

Embodiment example 2

[0027]

[0028] The processing and testing process of the above implementation case 2 is similar to that of case 1 and will not be repeated here. Wherein, the compound is 1-ethyl-3-methylimidazolium diethylphosphate compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com