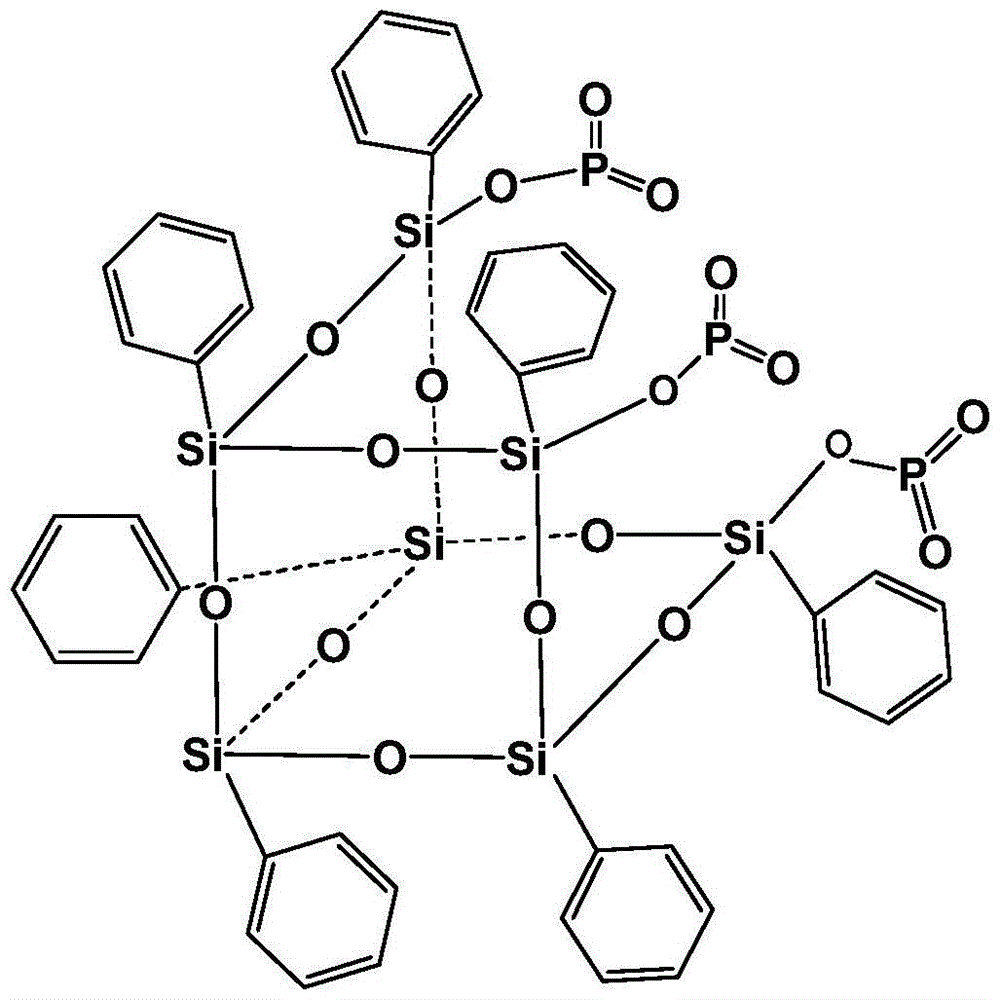

A kind of phosphorus-silicon composite flame retardant and its preparation method and application

A technology of compounding flame retardant and phosphorous silicon, applied in the field of flame retardant materials, can solve the problems of limited application, low thermal stability, foam generation, etc., achieve low preparation and application cost, improve processing performance, prevent melting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

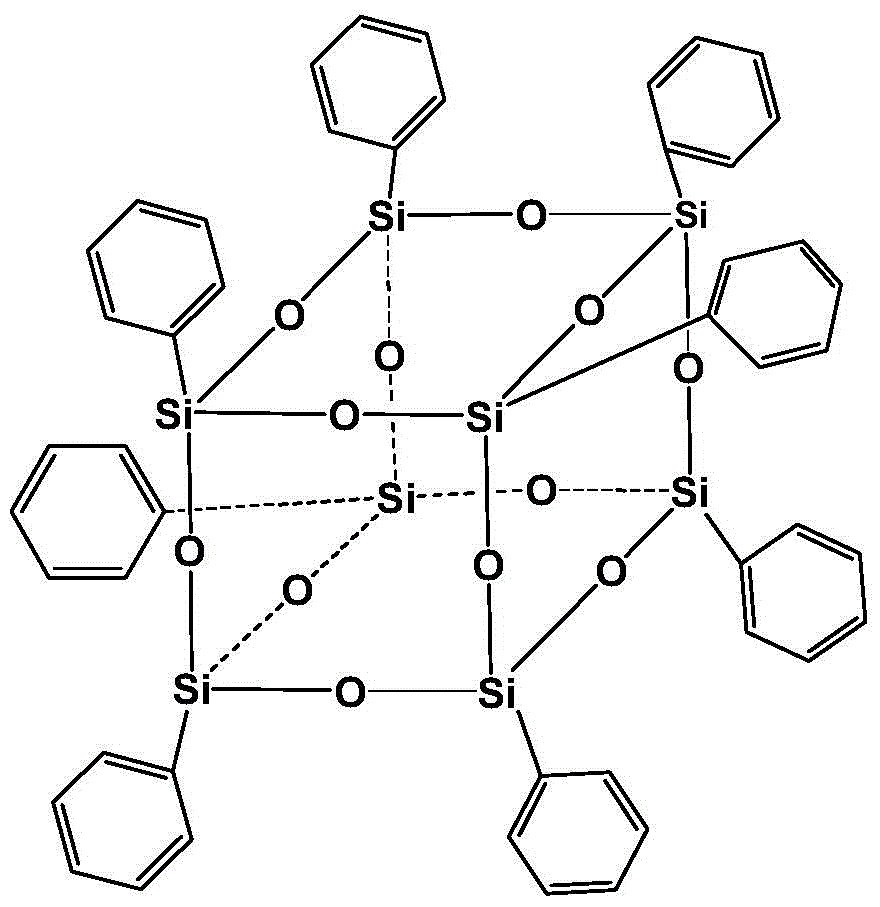

[0038] Add 50g of phenyltrichlorosilane and 250ml of benzene to the round bottom flask successively, slowly add 20mL of water while stirring, and let the system stand for 10 hours after stirring at room temperature for 12 hours; use a separatory funnel to remove the acid layer at the bottom, use distilled water Or wash with an alkaline solvent to make the organic phase neutral; add 8 mL of benzyltrimethylammonium hydroxide methanol solution to the organic phase, stir and reflux for 24 hours; filter and dry to obtain the following figure 1 Caged octaphenylsilsesquioxane (POSS) of the structure shown.

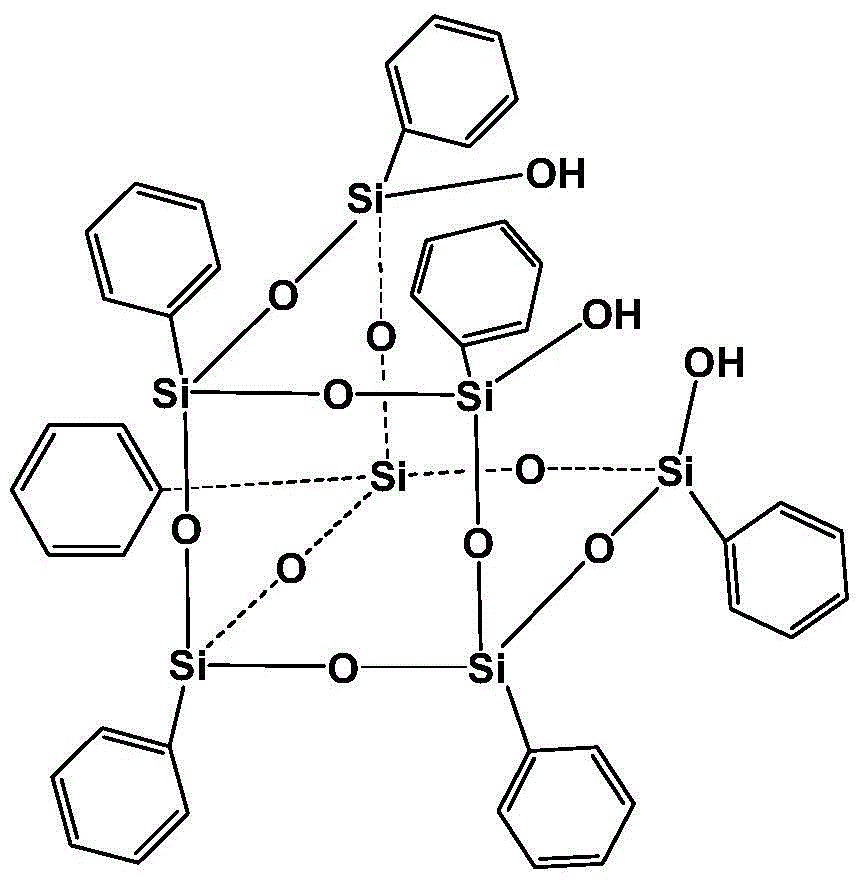

[0039] Take 10g of cage-like octaphenylsilsesquioxane and place it in a round bottom flask, add 100mL of tetrahydrofuran and 4mL of 25vol% aqueous solution of tetramethylammonium hydroxide to it in turn, and reflux for 4 hours; add dilute hydrochloric acid to neutralize the reaction solution to Neutral; concentrated to remove the volatile solvent therein, to obtain a white solid;...

Embodiment 2

[0042] Add 75g of phenyltrichlorosilane and 350ml of benzene to the round bottom flask successively, slowly add 30mL of water while stirring, the system is stirred at room temperature for 16 hours and then stand for 6 hours; use a separatory funnel to remove the acid layer at the bottom, and use distilled water Or wash with an alkaline solvent to make the organic phase neutral; add 10 mL of benzyltrimethylammonium hydroxide methanol solution to the organic phase, stir and reflux for 36 hours; filter and dry to obtain the following figure 1 Caged octaphenylsilsesquioxane (POSS) of the structure shown.

[0043] Take 15g of cage-like octaphenylsilsesquioxane and place it in a round bottom flask, add 200mL of tetrahydrofuran and 6mL of 25vol% tetramethylammonium hydroxide aqueous solution to it successively, and reflux for 5 hours; add dilute hydrochloric acid to neutralize the reaction solution to Neutral; concentrated to remove the volatile solvent therein, to obtain a white sol...

Embodiment 3

[0046] Add 80g of phenyltrichlorosilane and 400ml of benzene in turn to the round bottom flask, slowly add 40mL of water while stirring, the system is stirred at room temperature for 8 hours and then stand for 12 hours; use a separatory funnel to remove the acid layer at the bottom, and use distilled water Or washing with an alkaline solvent to make the organic phase neutral; add 13mL of benzyltrimethylammonium hydroxide methanol solution to the organic phase, stir and reflux for 36 hours; filter and dry to obtain the following figure 1 Caged octaphenylsilsesquioxane (POSS) of the structure shown.

[0047] Take 20g of cage-like octaphenylsilsesquioxane and put it in a round bottom flask, add 250mL of tetrahydrofuran and 8mL of 25vol% tetramethylammonium hydroxide aqueous solution to it successively, and reflux for 6 hours; add dilute hydrochloric acid to neutralize the reaction solution to Neutral; concentrated to remove the volatile solvent therein, to obtain a white solid; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com