Flame-retardant light GMT composite board for interior and exterior ornaments of automobile and preparation method of flame-retardant light GMT composite board

A composite sheet, lightweight technology, used in vehicle parts, applications, household appliances, etc., can solve problems such as little flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

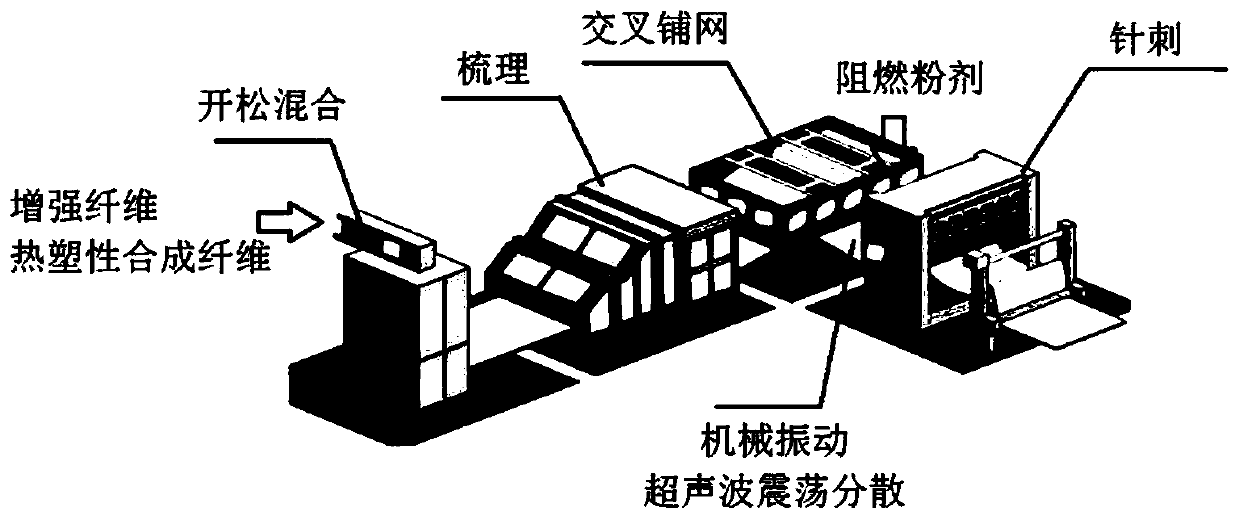

Method used

Image

Examples

Embodiment 1

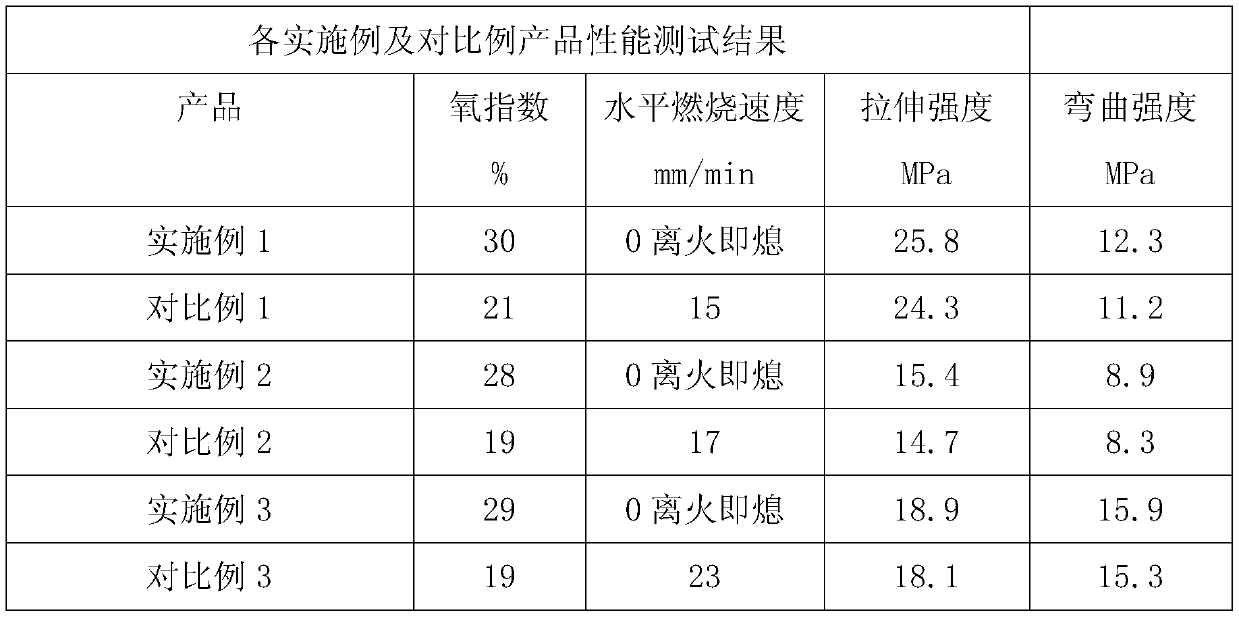

[0028] This embodiment is a kind of flame-retardant light-weight GMT composite sheet material used for preparing the car bottom guard plate, including fiber mat and upper and lower surface layers, the upper surface layer is a non-woven fabric, the lower surface layer is a reinforced composite film, and the fiber mat is made of glass fiber, polyester Composed of propylene fiber and expanded graphite flame retardant powder, glass fiber accounts for 30wt% of the total weight of the fiber mat, expanded graphite accounts for 10wt% of the total weight of the fiber mat, expanded graphite is evenly dispersed in the fiber mat, and the area density of the flame retardant lightweight GMT composite sheet 1600g / m 2 , bulk density is 0.5g / cm 3 .

[0029] After the non-woven cross-lapping process and before the acupuncture process, the expanded graphite flame retardant powder is evenly dispersed on the surface of the fluffy fiber felt by the powdering process, and then the expansion of the ...

Embodiment 2

[0037] This embodiment is a kind of flame-retardant lightweight GMT composite sheet material for preparing the inner lining of the automobile roof, including fiber felt and upper and lower surface layers, the upper surface layer is non-woven fabric, the lower surface layer is polyethylene adhesive film, and the fiber felt is made of basalt Composed of fiber, ES fiber and magnesium hydroxide flame retardant powder, Wuyan fiber accounts for 55wt% of the total weight of the fiber mat, magnesium hydroxide accounts for 20wt% of the total weight of the fiber mat, magnesium hydroxide is evenly dispersed in the fiber mat, and is flame retardant and lightweight The surface density of GMT composite sheet is 1000g / m 2 , bulk density is 0.3g / cm 3 . .

[0038] After the non-woven cross-lapping process and before the acupuncture process, the magnesium hydroxide flame retardant powder is uniformly dispersed on the surface of the fluffy fiber felt by the powdering process, and then the surf...

Embodiment 3

[0046] This embodiment is a kind of flame-retardant lightweight GMT composite board for preparing the car trunk shelf board, including fiber felt and upper and lower surface layers, the upper surface layer is non-woven fabric, the lower surface layer is polypropylene adhesive film, fiber felt Composed of hemp fiber, PET fiber and phosphorus-nitrogen composite intumescent flame retardant powder, hemp fiber accounts for 45wt% of the total weight of the fiber mat, the intumescent flame retardant powder accounts for 30wt% of the total weight of the fiber mat, and the intumescent flame retardant powder is evenly dispersed in the fiber mat Among them, the areal density of the flame-retardant lightweight GMT composite sheet is 2500g / m 2 , bulk density is 0.7g / cm 3 .

[0047] The intumescent flame retardant powder is uniformly dispersed on the surface of the fluffy fiber mat by the powder-sprinkling process after the non-woven cross-lapping process and before the acupuncture process,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com