Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "High dyeing depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of pure hemp mercerized yarn

InactiveCN102051720AReduce broken endsStrong and goodMercerising of yarns/threads/filamentsSingeingYarnAlkalinity

The invention provides a production method of pure hemp mercerized yarn. By the production method, the mercerized pure hemp yarn has few broken ends, excellent brute force and brightness, the deep dyeing property, level-dyeing property and penetrating property are greatly improved, the handle and smoothness are improved, the difficulty in later processes of dyeing, weaving and after finishing is reduced, and the application performance of the pure hemp yarn is integrally improved. The production method comprises the processes of singeing, reeling, mercerizing, dyeing, squeezing water, drying and rewinding, and is characterized in that the mercerizing process is as follows: yarn is put into a yarn mercerizing machine, wherein the alkalinity of treating fluid is 28-30 baume degrees, the temperature of the treating fluid is 18-22 DEG C, the applied tensile force stretching is 1-3%, the alkali dipping time is 1-3 minutes, the alkali squeezing time is 30 seconds-1 minute, time for washing with hot water is 30-60 seconds at the water temperature of 60-70 DEG C, time for washing with cold water is 30-45 seconds, and the treating time is 5 minutes-5 minutes and 50 seconds.

Owner:WUXI NATURAL GREEN FIBER TECH

Dyeing and finishing technique of cellulose fiber textile

The invention discloses a dyeing and finishing technique of cellulose fiber textile, which sequentially comprises the following steps of: pretreating, dyeing, water washing, neutralizing, soaping and water washing the fiber textile; and the dyeing technique comprises the steps of: under the conditions of 30 DEG C and bath ratio of 1:7-1:15, adding vinyl sulfone type low-temperature dye with the weigh of 2-10% of the textile, and carrying out heat preservation for 10-15min; then, adding anhydrous sodium sulphate and sodium hydroxide which is 1 / 4-1 / 3 of the total weight, and carrying out heat preservation for 10-15min; adding another sodium hydroxide which is 3 / 4-2 / 3 of the total weight, and carrying out heat preservation for 10-15min; and heating to 40 DEG C at the speed of 1 DEG C / min, carrying out heat preservation for 40-60min, and completing the dyeing technique. The dyeing and finishing technique of the cellulose fiber textile has the characteristics of low using quantity of dye, high soaping fastness, low using quantity of alkali color fixing agent, less pollution discharge and reduced cost.

Owner:冯惠英

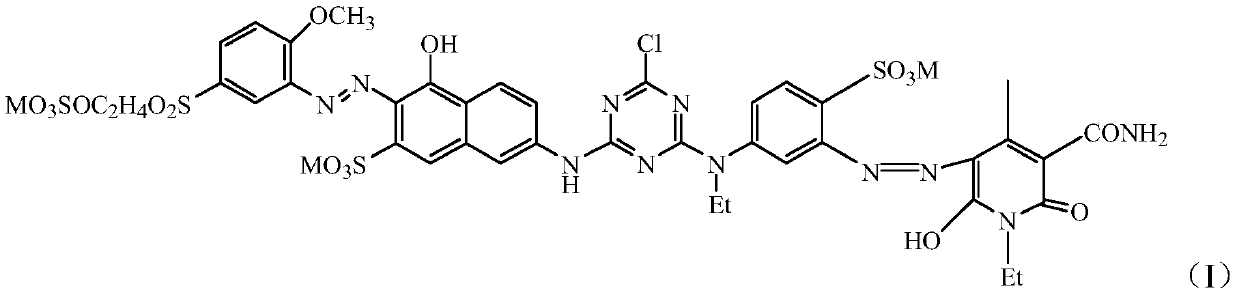

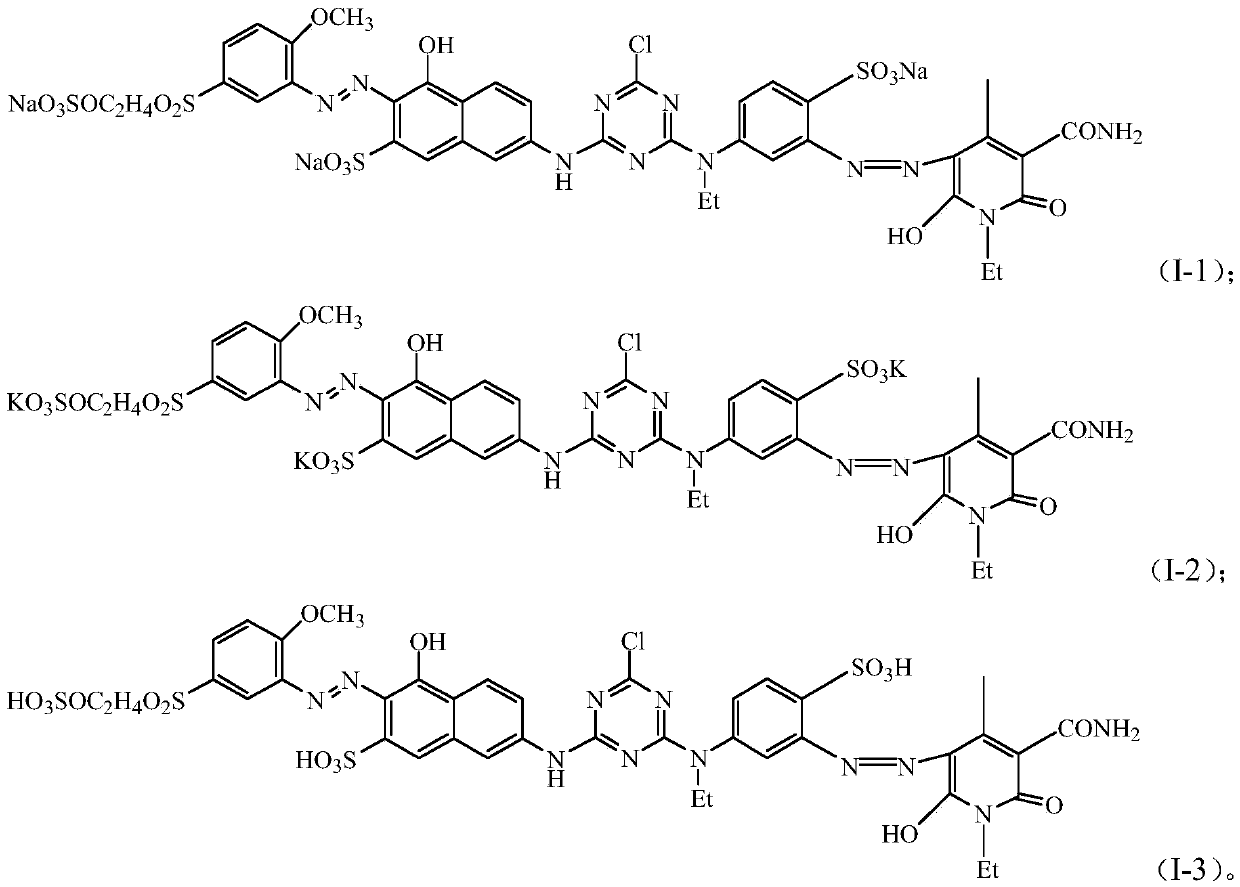

Reactive turquoise blue dye semifinished product, and preparation method and application thereof

InactiveCN104478887AImprove color renderingImprove color fixation rate and dyeing depthOrganic chemistryReactive dyesChemical structureWork in process

The invention relates to a reactive turquoise blue dye semifinished product, and a preparation method and application thereof. The chemical structure general formula is disclosed as Formula (I), wherein 0<x<=2, 0<y<=2, 0<z<=2, and x+y+z=3.5-4; and preferably, 1<=x<=2, 1<y<=2, and 1<z<=2. The molecular formula of the semifinished product contains multiple sulfo-groups and sulfamido groups, and thus, the semifinished product is weakly alkaline on the whole. The phthalocyanine group can be introduced to enhance the color development property. When the reactive turquoise blue dye semifinished product is compounded with another semifinished product B into the dye, the fixation rate and deep dyeing property can be enhanced.

Owner:吴江桃源染料有限公司

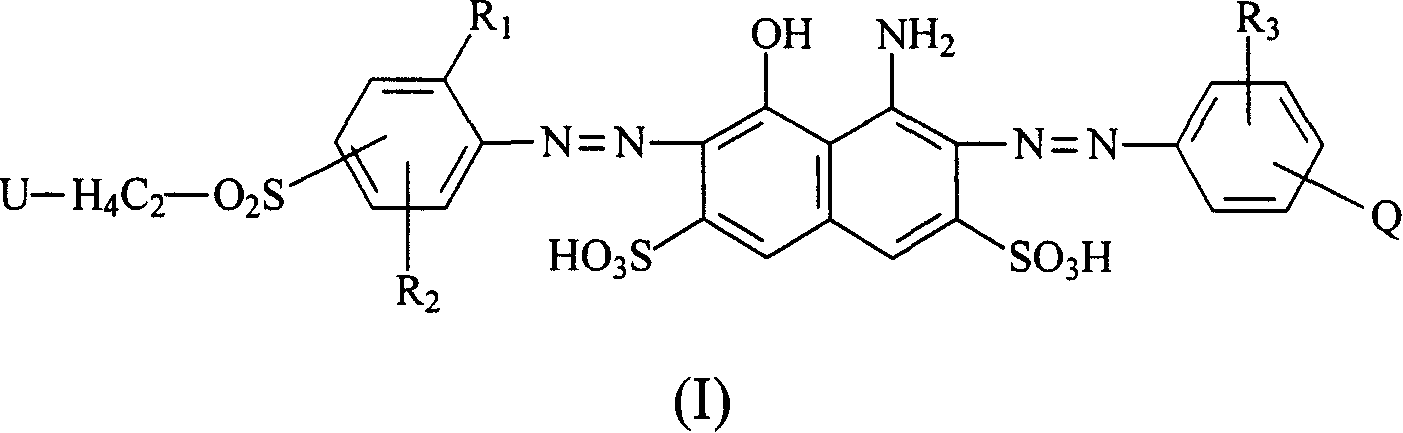

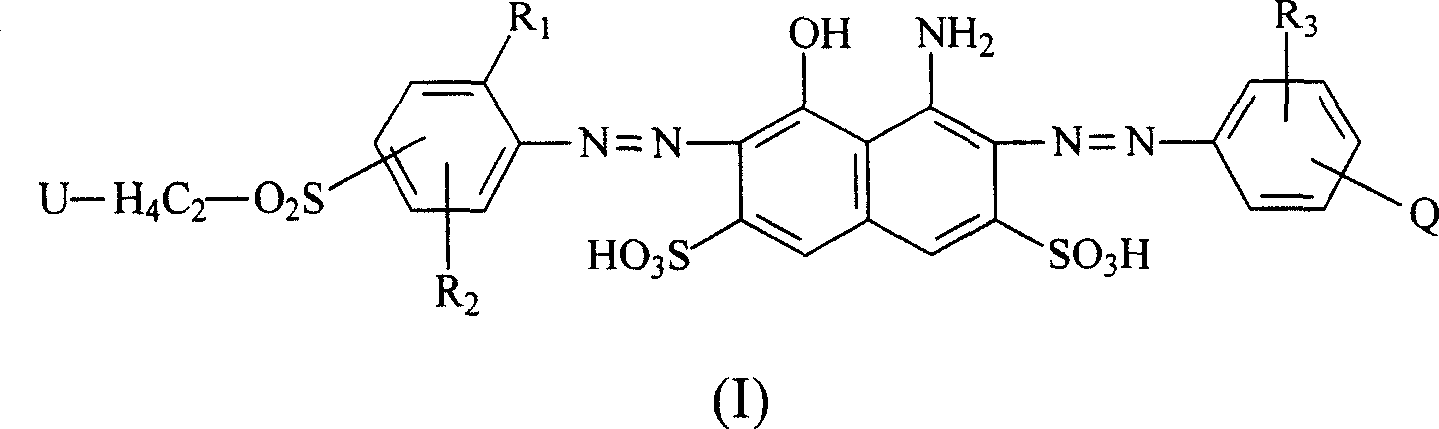

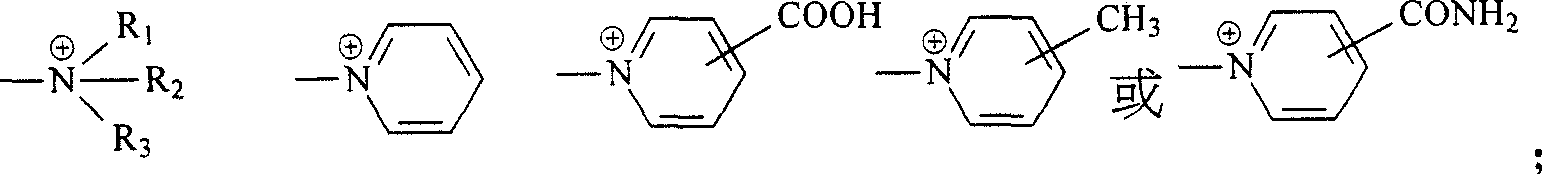

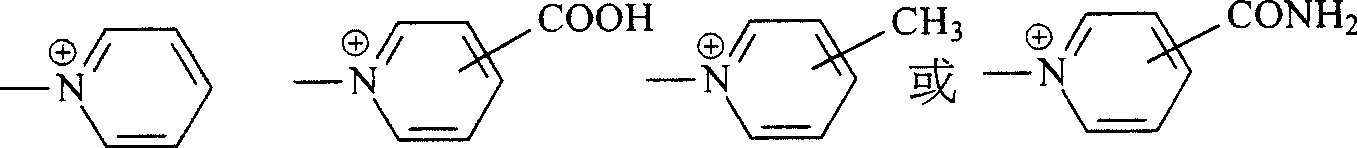

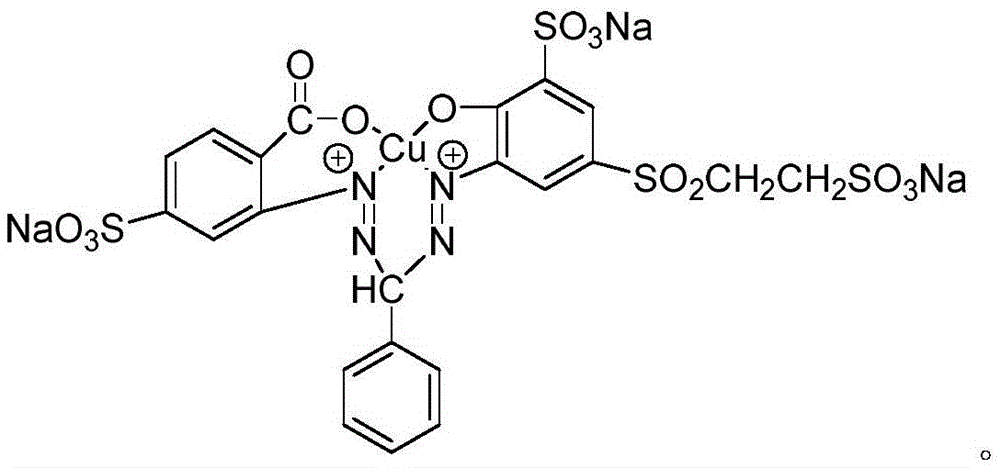

Navy blue quaternary ammonium salt bisazo chemically-reactive dyes

InactiveCN1990605AGreenExcellent color rendering abilityReactive dyesDyeing processCellulose fiberAmmonium

The invention relates to a novel quaternary ammonium saltdisaz navy blue reactive dyestuff. The dyestuff is characterized by high affinity and directness, ability to increase the coloring rate for dying colth, strong chlorine bleaching tolerance and antioxidant bleaching and washing property. It can meet demand of high dying color and high humid strength.

Owner:ETHICAL INT WAREHOUSING TRADING SHANGHAI

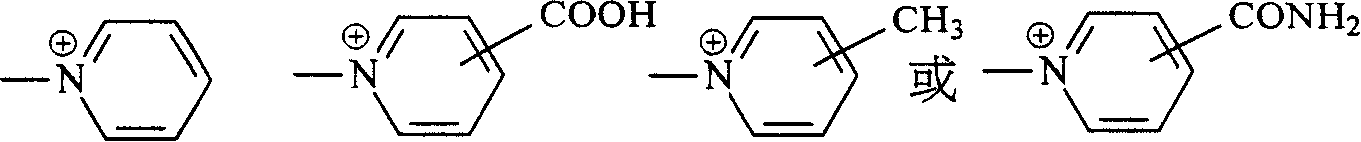

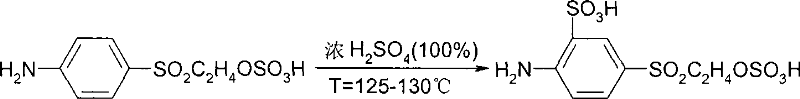

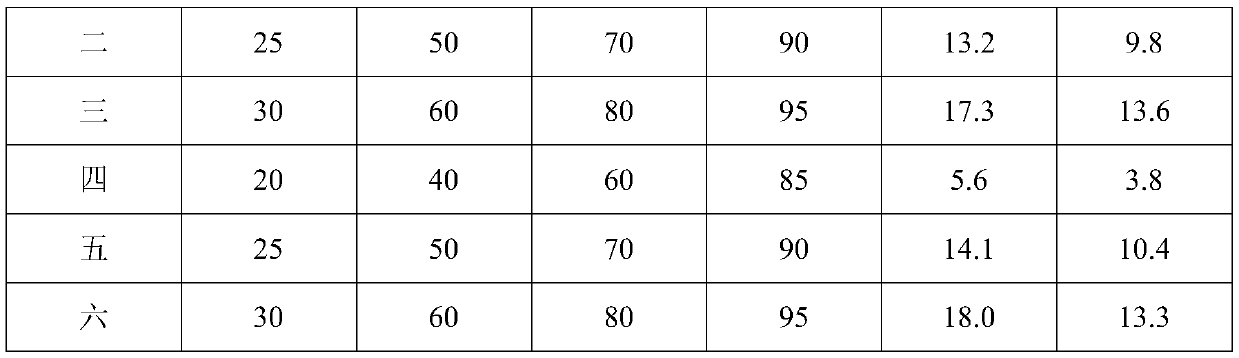

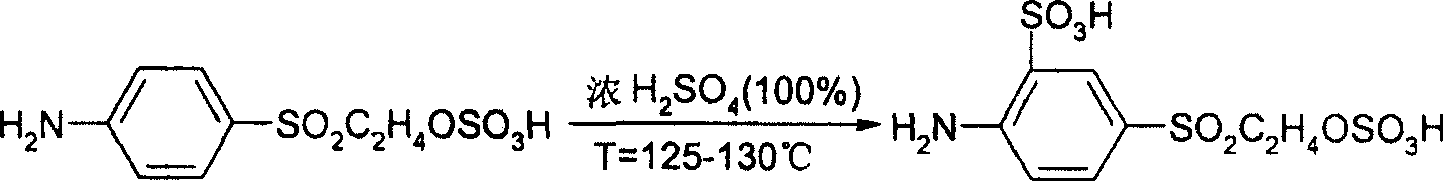

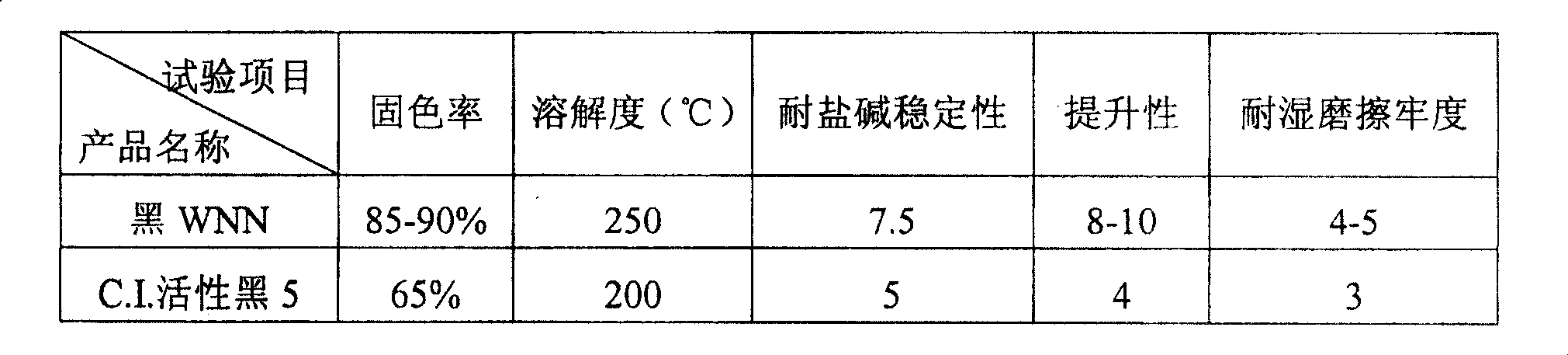

Preparation method of para-(beta-Ethyl Sulfonyl Sulfate) aniline sulfonic acid

InactiveCN101037404AHigh dyeing depthHigh color fixing rateOrganic chemistryOrganic compound preparationSolubilitySulfate

The invention is a producing method of a p-(beta-sulfooxyethylsulfone)phenylamine-o-sulfonic acid, which is characterized in that: having the oil of vitriol (100%) as solvent, p-(beta-sulfooxyethylsulfone)phenylamine as material, dispersing at about 60-90 DEG C, sulfonating at 120-130 DEG C, hydrolyze at 100-110 DEG C, then cooling, acidifying, crystallizing, filtering, drying to get product. The active dye produced by p-(beta-sulfooxyethylsulfone)phenylamine-o-sulfonic acid has a better pile-on property, fixing rate, solubility, alkaline saline resistance, humidity resistance, friction fastness compared the dye produced by p-(beta-sulfooxyethylsulfone)phenylamine.

Owner:HUBEI HUALI DYESTUFF INDAL

Dyeing and finishing process of textile

The invention relates to a dyeing and finishing process of a textile. The dyeing and finishing process of the textile comprises the steps of carrying out pre-treatment, dyeing, washing, neutralizing, soaping and washing on the textile. The dyeing and finishing process of the textile has the beneficial effects that when a low temperature dyeing and finishing process is compared with a middle temperature dyeing and finishing process, in a dyeing step, firstly in dyes of dark series, three primary dark colours are combined, advantages can be shown more obviously for dyeing of black, dark green, dark brown, light army green, dark gray, purplish red and garnet red series, the dyes used in the dyeing and finishing process of the textile has high pile-on property, high absorption rate and good compatibility, compared with middle temperature dyes, dye absorption rate is high, raffinate chromaticity is low, and dosage of low temperature active dyes in coffee, army green and gray dyeing processes is 40-70% that of middle temperature active dyes; production cost of a dyeing and printing enterprise is reduced compared with dark colour series, the problem of high pollution control cost is solved, and treatment cost can be reduced while discharge capacity is reduced for the printing and dyeing industry by adopting the dyeing and finishing process of the textile.

Owner:HUZHOU JINTADI TEXTILE MILL

Dark red reactive dye and preparation method thereof

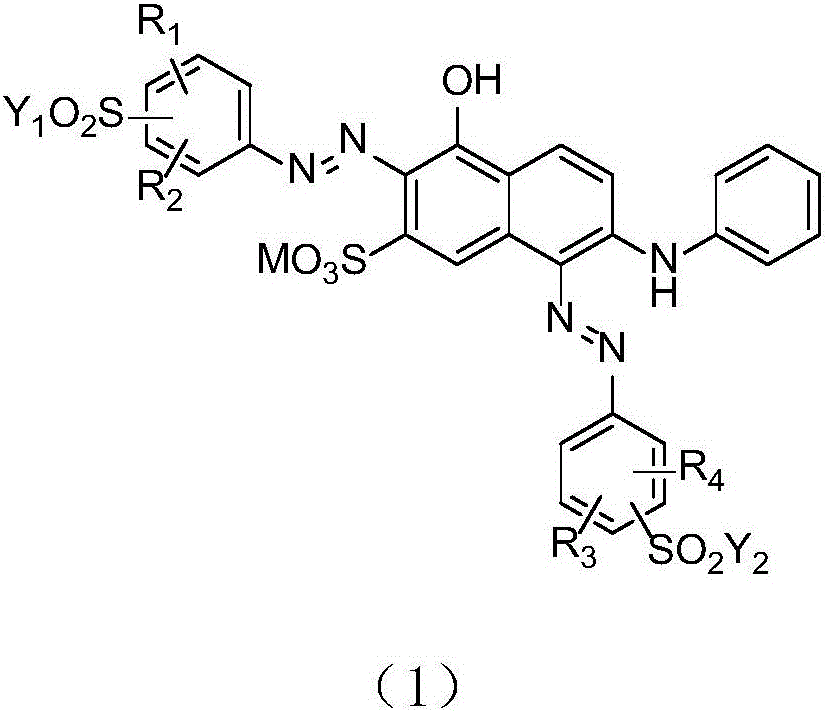

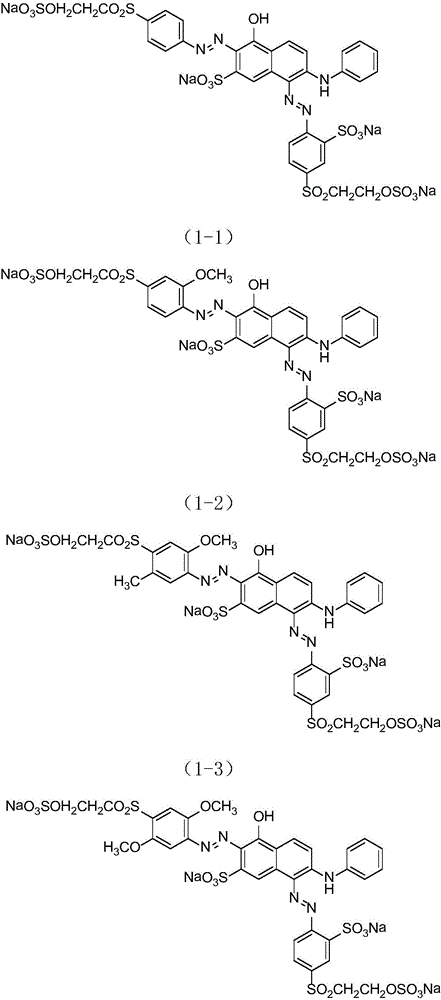

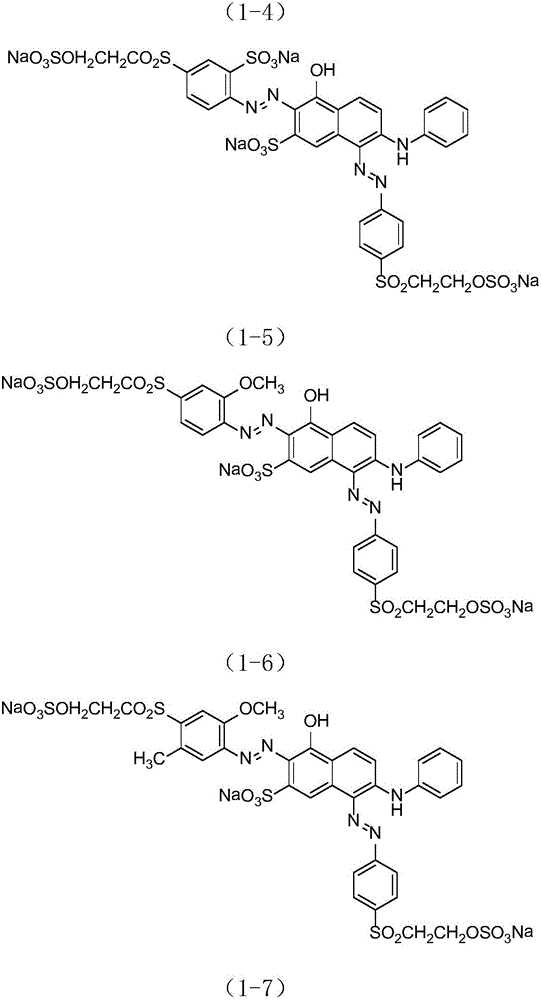

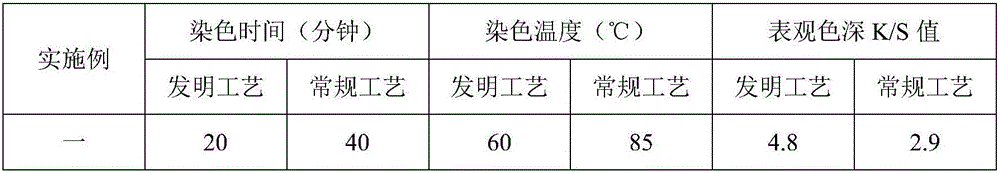

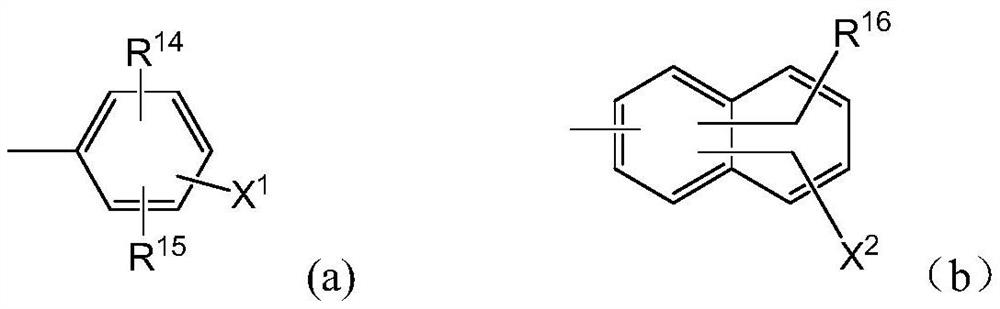

InactiveCN106634045AHigh liftHigh color fixing rateReactive dyesDyeing processHydrogenHeat stability

The invention discloses dark red reactive dye and a preparation method thereof. The dark red reactive dye is one material selected from general formulas of the formula (I) or is a mixture obtained through compounding two or more structures selected from the general formulas of the formula (I) according to any proportion. One material shown by the formula (I) is selected from any one of materials of the following structure general formulas or is a mixture of two or more materials of the structural general formulas, wherein R1, R2, R3 and R4 in the formula (I) respectively and independently represent -H, -CH3, -OCH3 or -SO3M; Y1 and Y2 respectively and independently represent -CH=CH2 or -C2H4OSO3M; M represents hydrogen or alkali metal. The dark red reactive dye has the advantages that the lifting performance is good; the friction firmness, the water washing firmness, the light fastness and the heat stability are high. The formula (I) is shown as the accompanying drawing.

Owner:ZHEJIANG YIDE CHEM

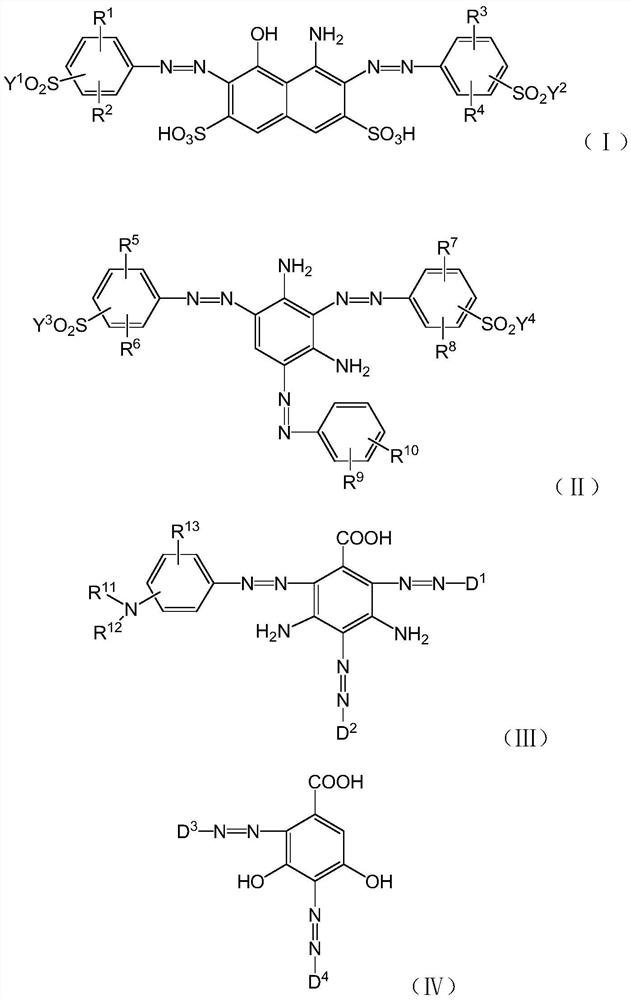

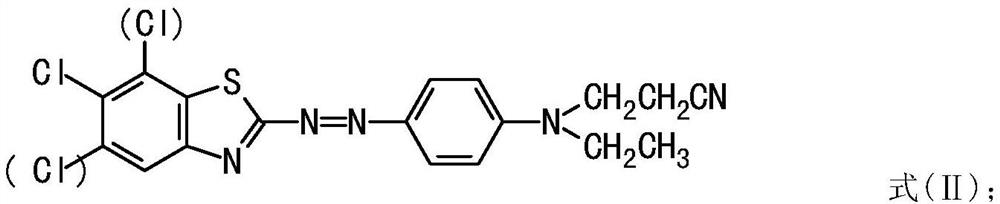

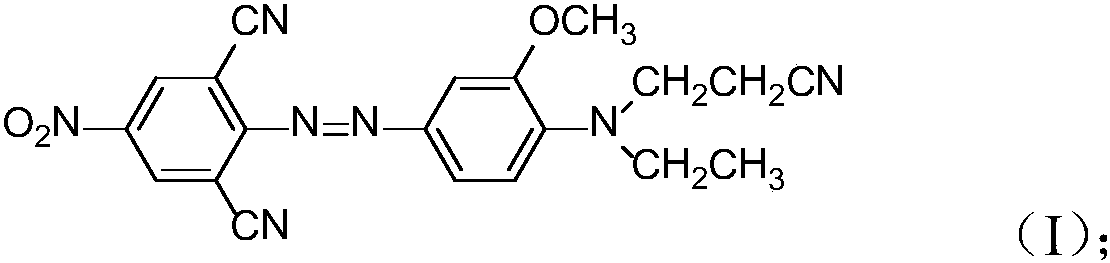

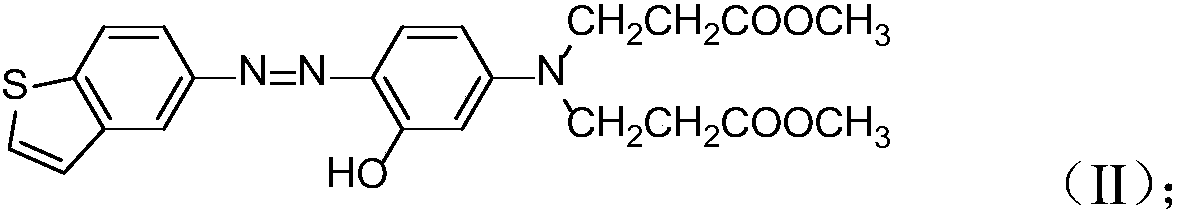

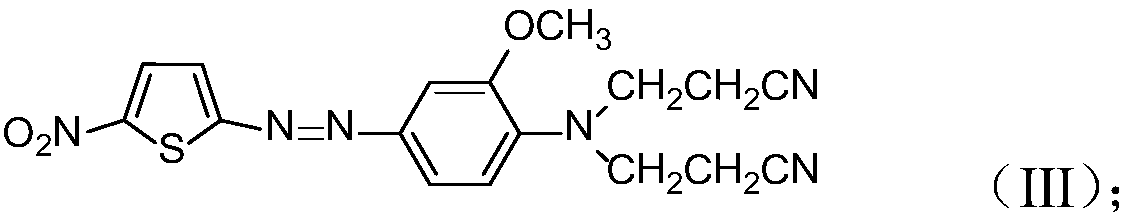

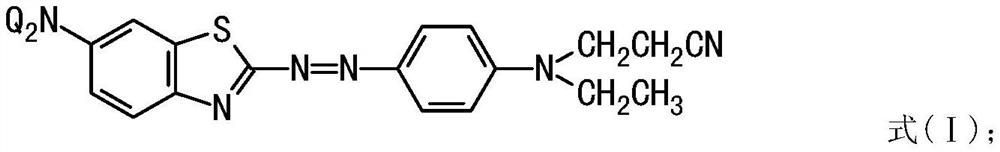

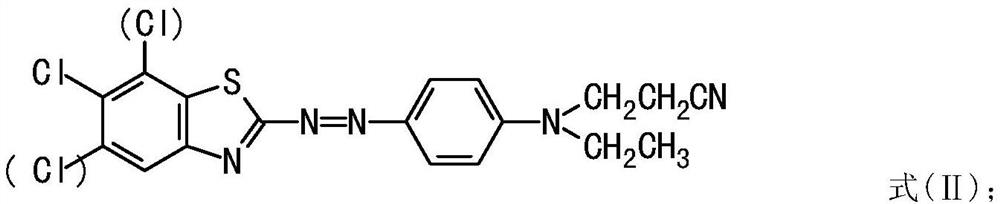

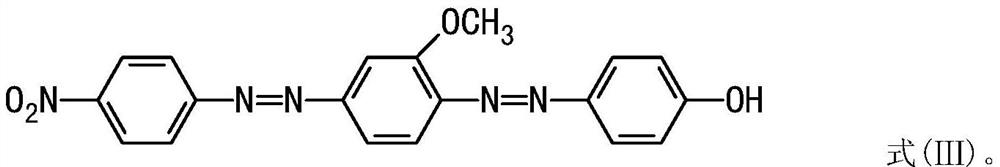

Black dye composition and application of black dye composition in wool dyeing

InactiveCN107936615AGood dyeing rateHigh color fastnessOrganic dyesDyeing processDisperse dyeWool fiber

The invention discloses a black dye composition and application of the black dye composition in wool dyeing. The black dye composition comprises 30-50% of a component A which is shown in a formula (I), 30-50% of a component B which is shown in a formula (II), 1-15% of a component C which is shown in a formula (III), 1-15% of a component D which is shown in a formula (IV) and 1-10% of a component Ewhich is shown in a formula (IV). According to the black dye composition and application of the black dye composition in wool dyeing, the reactive dye (the component E) is mixed with a disperse dye so as to obtain the dye composition which takes the disperse dye as the main component and the reactive dye as the assistant component; and not only can the dye composition have good wet fastness and strong color fastness, but also the binding ability of the dye composition and wool fiber can be enhanced greatly since the component E has a modifying effect on other disperse dye monomers, so that the dye composition has high dye-uptake to the wool fiber.

Owner:卢梅雅

Method for dyeing polyester ultrafine fiber brushed cloth

The invention discloses a method for dyeing polyester ultrafine fiber brushed cloth. The method includes steps of placing the preset polyester ultrafine fiber brushed cloth in dyeing machines; addingsplitting dyeing one-bath dye liquor into the dyeing machines; heating the dye liquor at the speed of 2-3 DEG C / min from the room temperature to the temperature of 60 DEG C; further heating the dye liquor at the speed of 0.5-0.8 DEG C / min from the temperature of 60 DEG C to the temperature of 110 DEG C; soaking the polyester ultrafine fiber brushed cloth in the dye liquor for 10-20 minutes, and then heating the dye liquor at the speed of 0.8-1 DEG C / min until the temperature of the dye liquor reaches 130 DEG C; soaking the polyester ultrafine fiber brushed cloth in the dye liquor for 20-40 minutes, then cooling the dye liquor at the speed of 1.5 DEG C / min until the temperature of the dye liquor reaches 80 DEG C and then draining the liquor; carrying out reduction clearing and acid neutralization on piece goods in environments at the temperatures of 80 DEG C; cooling the piece goods until the temperatures of the piece goods reach the room temperature, and then sequentially dehydrating,setting and drying the piece goods. The method has the advantages of high dyeing efficiency, low dyeing cost and good dyeing effect.

Owner:ZHEJIANG LAIMEI TEXTILE & PRINTING & DYEING SCI TECH

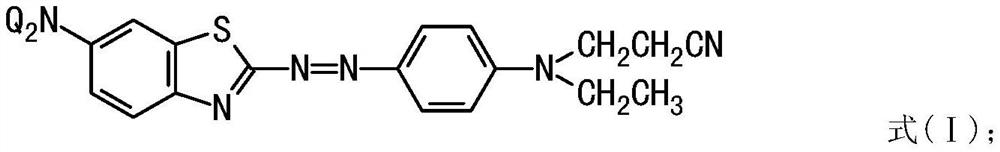

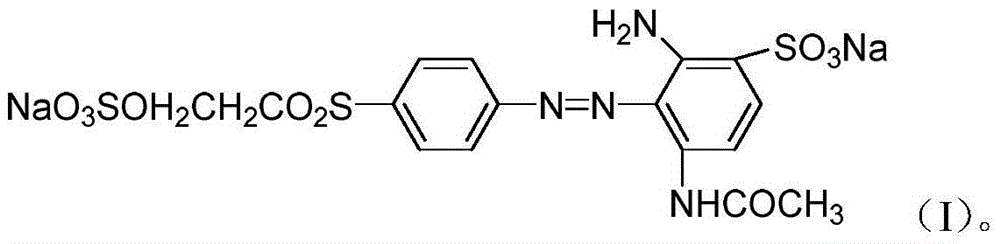

Environment-friendly reactive red disazo dye and preparation method thereof

InactiveCN104479403AWeakly alkalineImprove protectionOrganic chemistryOrganic compound preparationChemical structureBisazomethine dye

The invention relates to an environment-friendly reactive red disazo dye and a preparation method thereof. The chemical structure general formula is disclosed as Formula (I), wherein X is selected from Na, K or Li; R1 is -H, -CH3(CH2)n-1, -CH3(CH2)n-1O, -COOH or -SO3H; R2 is -CH3(CH2)n-1O; R3 is -(CH2)n-; and n is a whole number, and 1<=n<=4. The disazo dye contains hydroxy, amino and sulfo groups, and thus, is weakly alkaline, thereby being beneficial to lowering the strict preparation conditions and further beneficial to the subsequent dyeing technique. The functional groups are combined with the disazo group to enhance the fixation rate and deep dyeing property.

Owner:吴江桃源染料有限公司

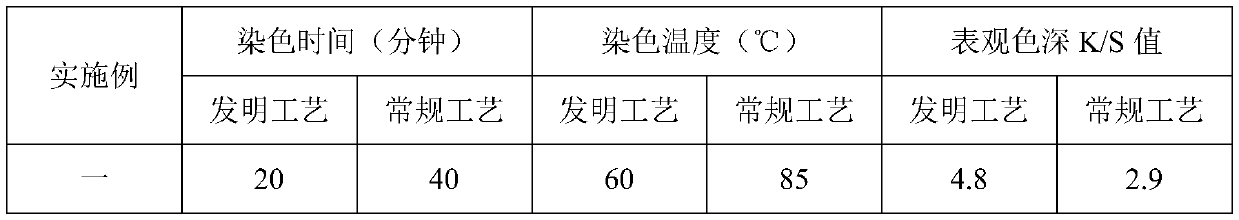

Dyeing method for improving deep dyeing performance of polyamide fiber

ActiveCN106835765AHigh dyeing depthLittle impact on physical and mechanical propertiesDyeing processTextile printerDisperse dye

The invention relates to a dyeing method for improving deep dyeing performance of polyamide fiber, and belongs to the technical field of textile printing and dyeing. The dyeing method comprises the following steps: adding disperse dye into a mixed solution of ethanol and water to obtain a dyeing solution, and dyeing the polyamide fiber in an ultrasonic environment, wherein by virtue of strong penetration of ethanol into the polyamide fiber, a synergistic effect is produced under the auxiliary action of ultrasonic, and a large number of dye molecules are carried into the free volume of the fiber so as to deeply and thoroughly dye the polyamide fiber. By the dyeing method, the dyeing temperature is low, the dyeing time is short, strength damage of the polyamide fiber in the dyeing process is alleviated, and the problem that the dyeing depth is not high when the disperse dye dyes the polyamide fiber is effectively solved; and the dyeing method is simple in process and strong in operability and is an efficient polyamide fiber dyeing method.

Owner:WUHAN TEXTILE UNIV

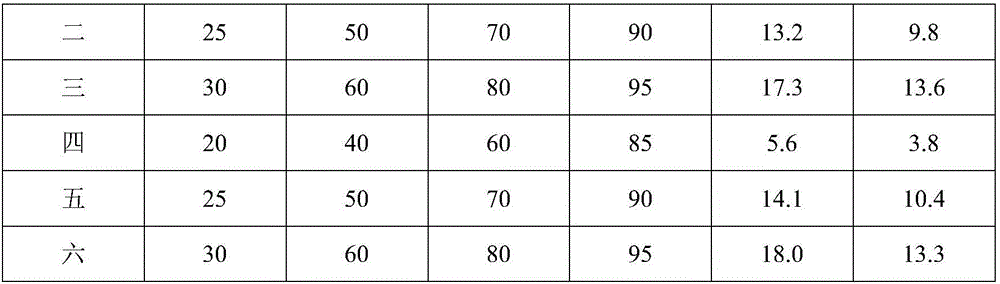

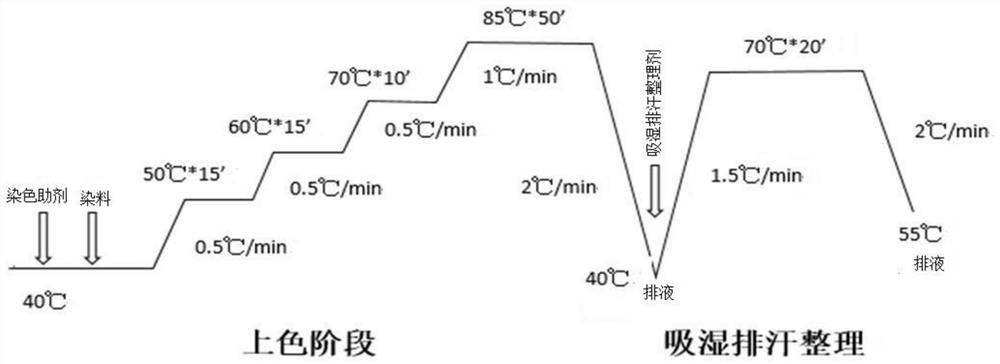

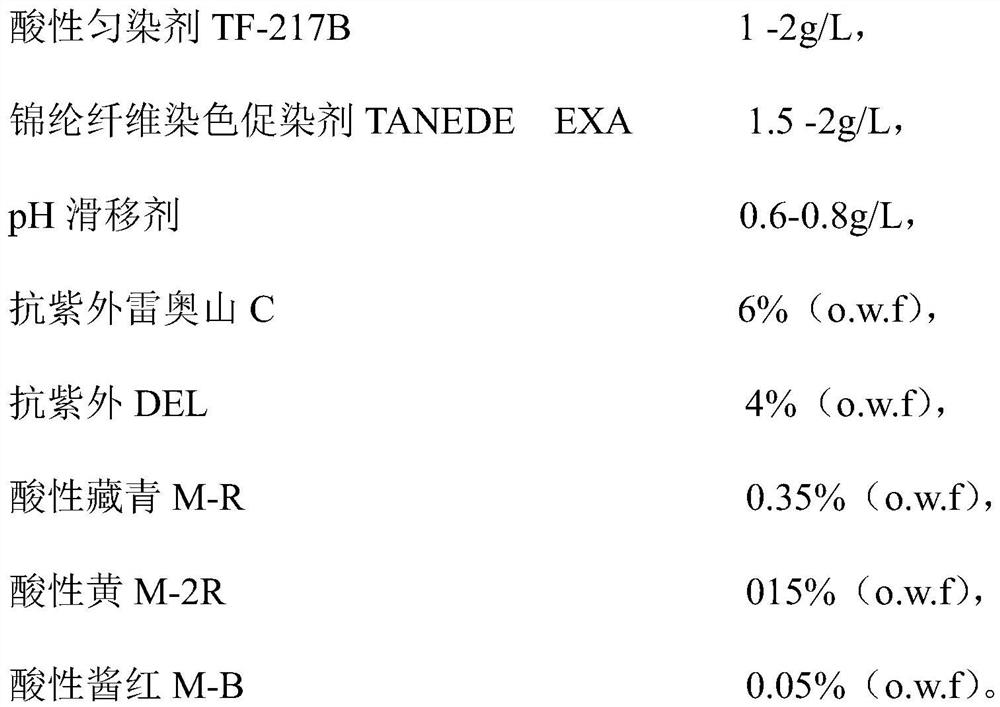

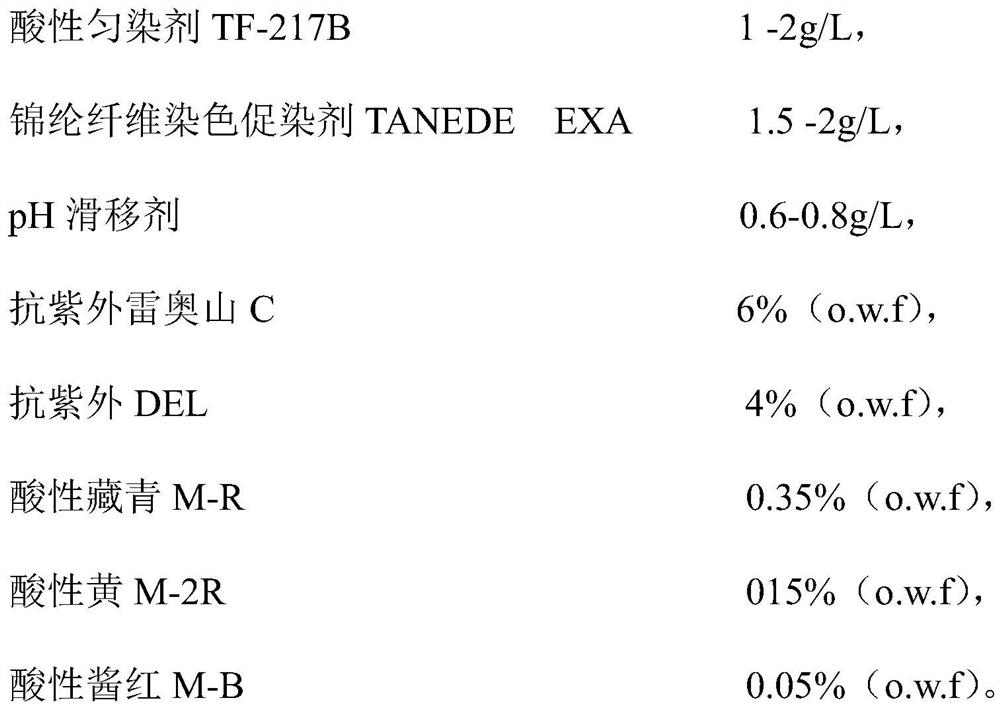

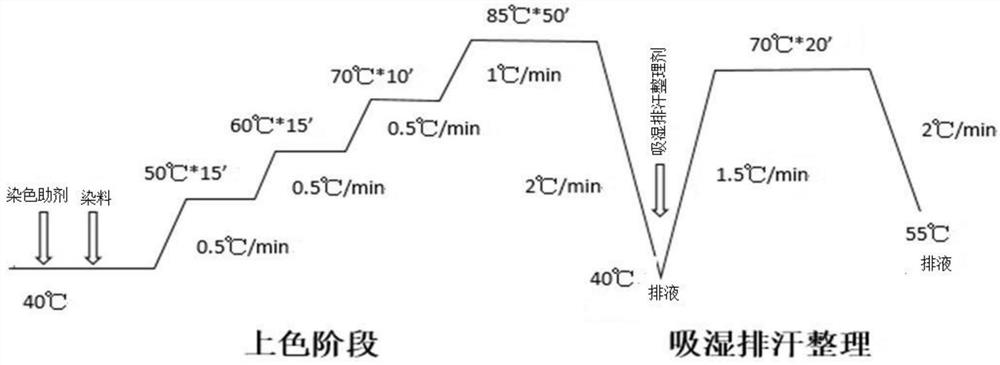

Dyeing process of cyclically regenerated high-density polyamide cool fabric

ActiveCN113322696AImprove dye uptakeHigh dyeing depthTextile/flexible product manufactureDyeing processColour fastnessPolymer science

The invention discloses a dyeing process of a cyclically regenerated high-density polyamide cool fabric. The dyeing process comprises a coloring stage and a moisture-absorbing and sweat-releasing finishing stage; a dyeing agent adopted in the coloring stage comprises a dyeing auxiliary agent and a dye; after the coloring stage is completed, liquid is discharged, and then a moisture-absorbing and sweat-releasing finishing agent is added for moisture-absorbing and sweat-releasing finishing; the dyeing auxiliary agent comprises an acidic leveling agent, a polyamide fiber dyeing accelerating agent, a pH slipping agent, anti-ultraviolet Rayosan C and anti-ultraviolet DEL; and the moisture-absorbing and sweat-releasing finishing agent comprises a moisture-absorbing and sweat-releasing agent and a slipping agent VS. According to the characteristics of the cyclically regenerated high-density polyamide fabric, the color brightness, the color fastness and the hand feeling of the dyed fabric are improved by adopting the proper dyeing auxiliary agent, dye and moisture-absorbing and sweat-releasing finishing agent and designing a reasonable dyeing process curve, and the fabric is endowed with the better anti-ultraviolet effect and moisture-absorbing and sweat-releasing effect.

Owner:SHENGHONG GRP CO LTD

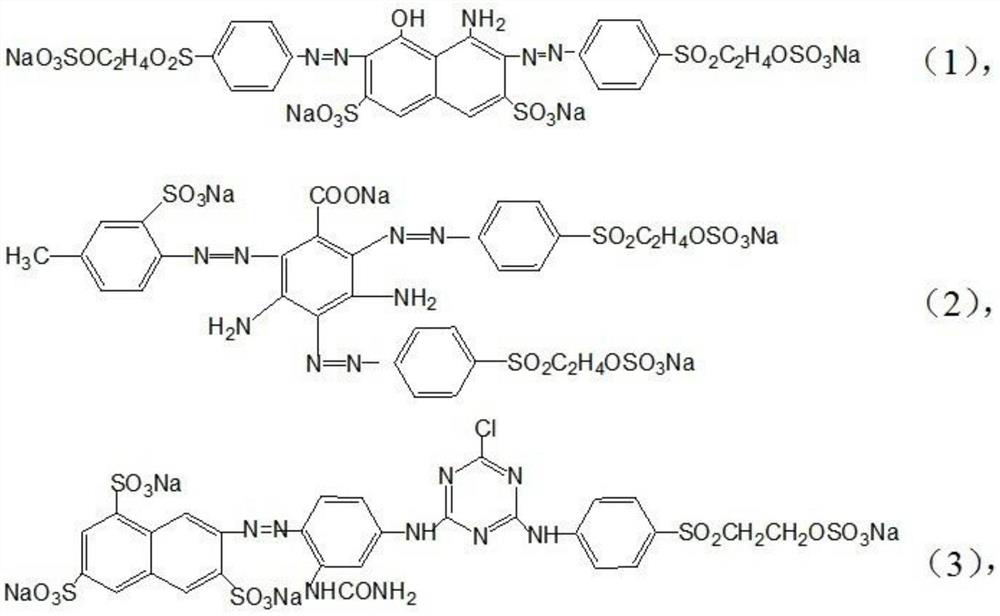

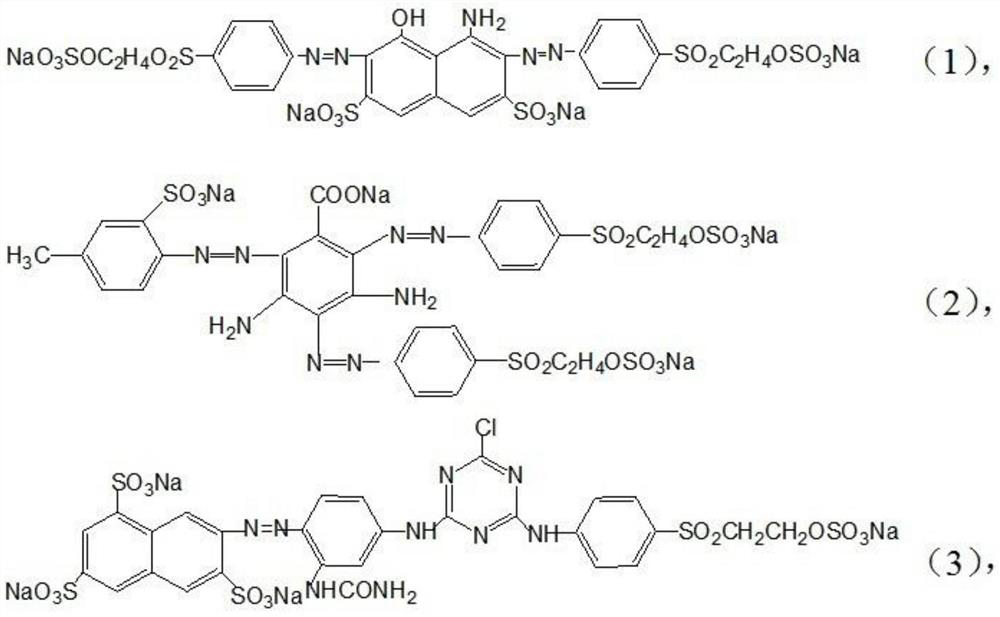

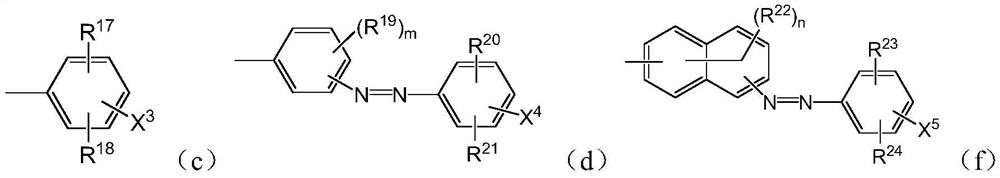

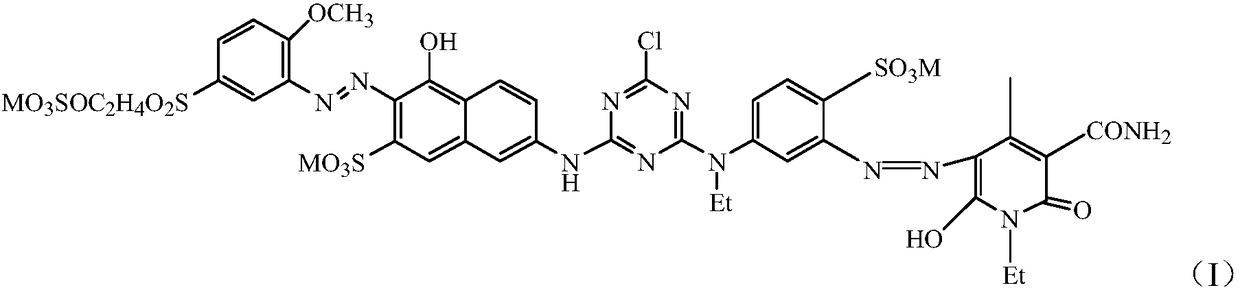

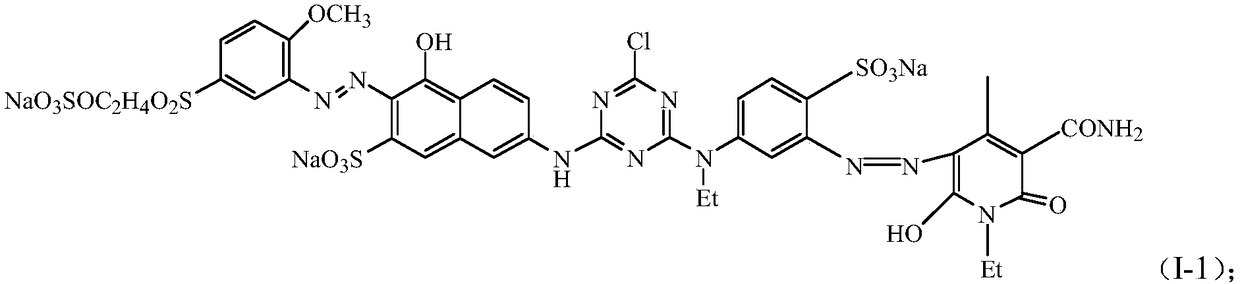

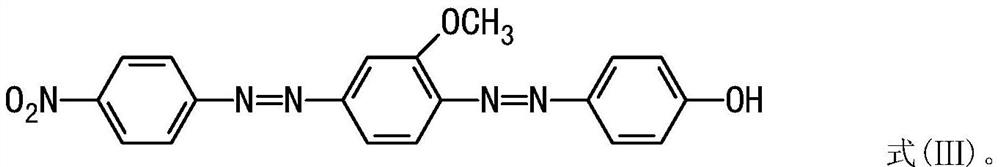

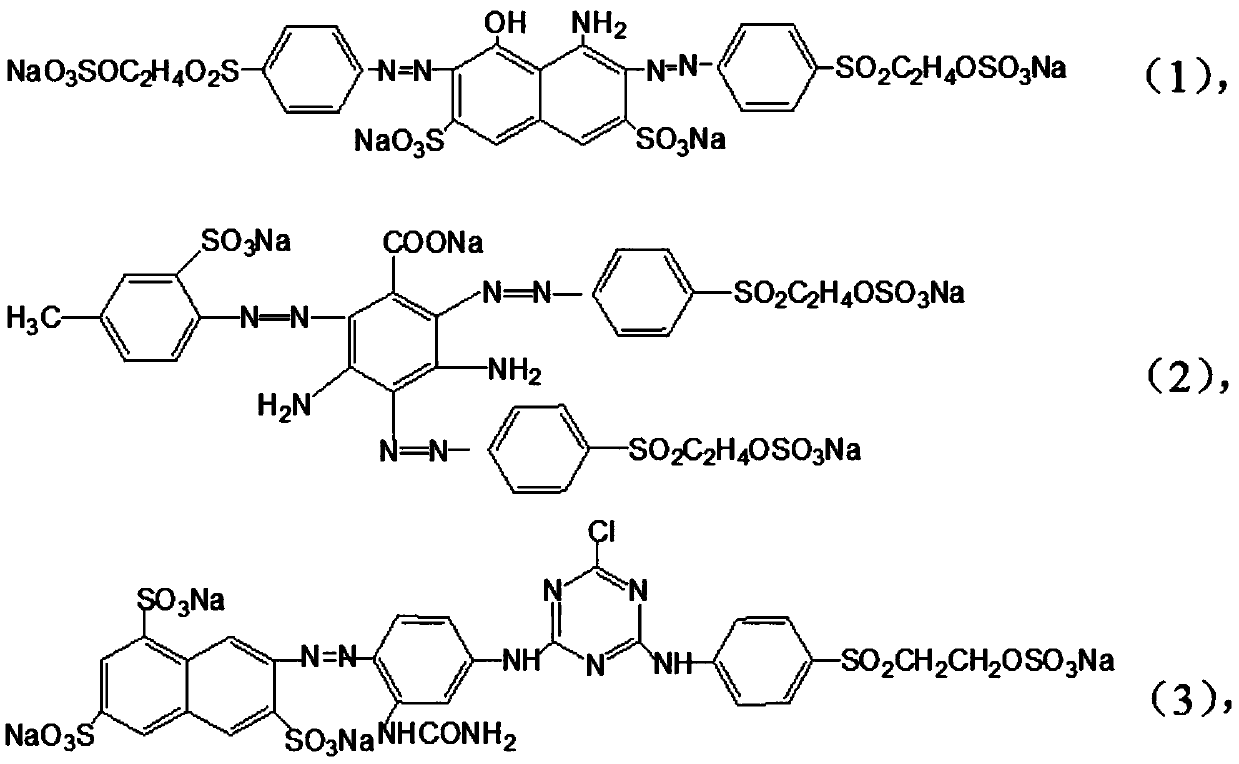

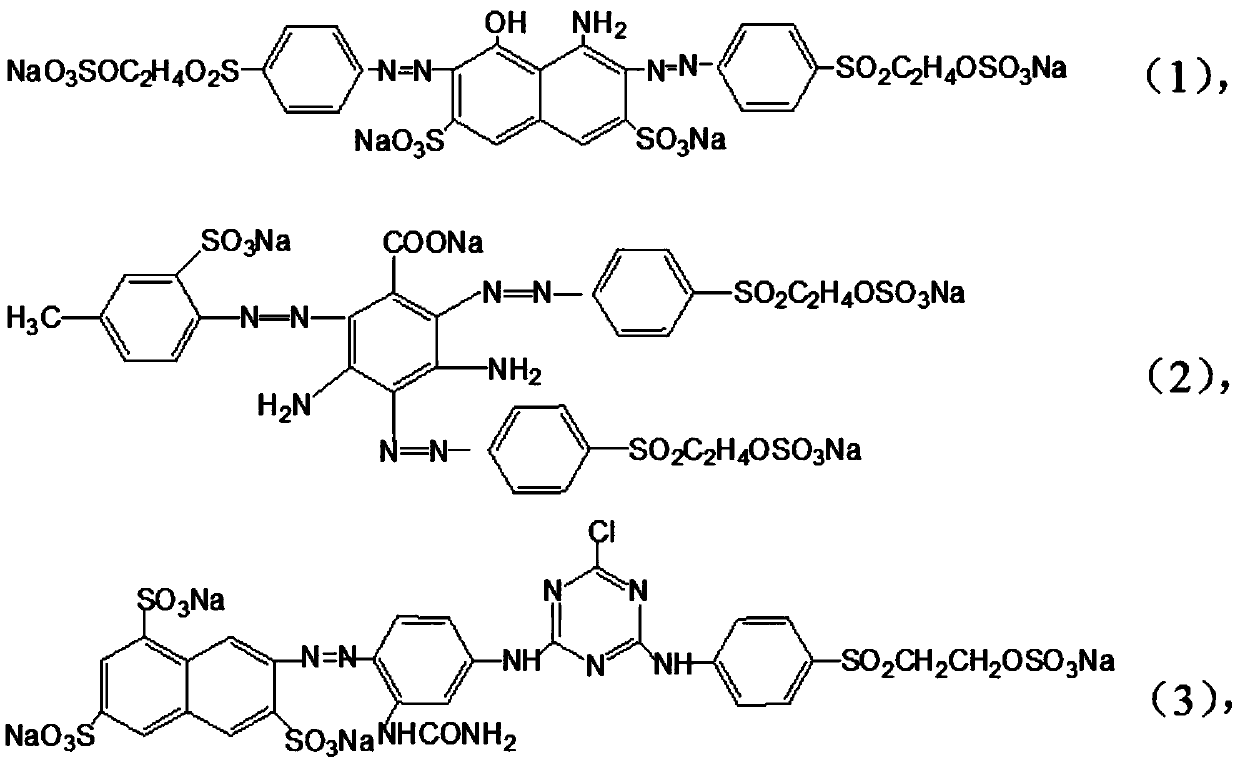

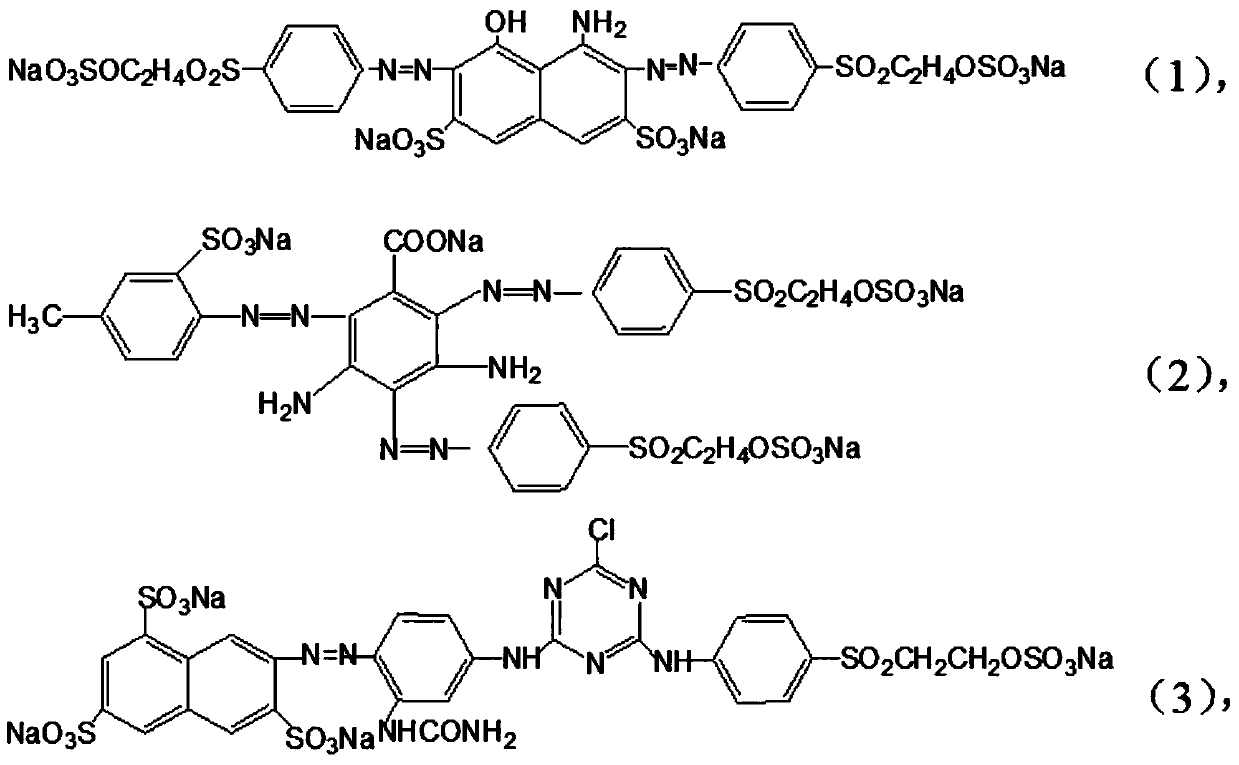

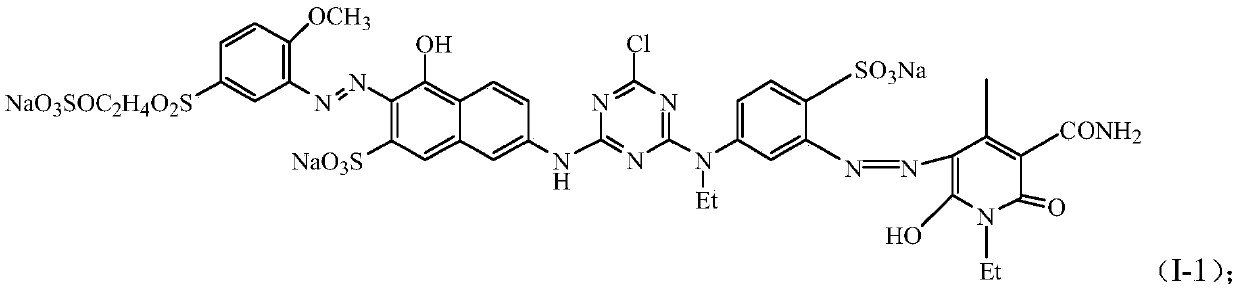

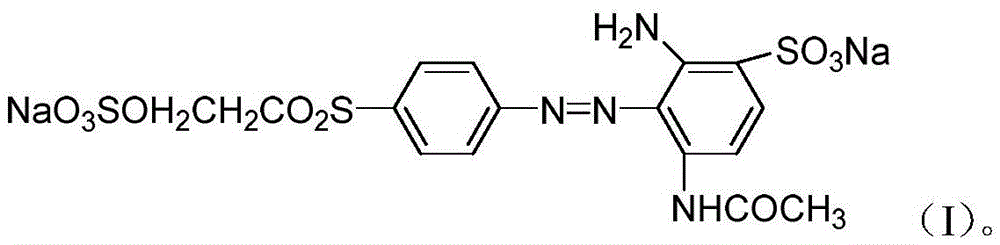

A kind of composite reactive black dye and its application

ActiveCN110305499BHigh dyeing depthGood color fixation rateReactive dyesDyeing processFiberPolymer science

The invention belongs to the technical field of dyes, in particular to a composite reactive black dye, comprising a dye shown in formula (1), a dye shown in formula (2) and a dye shown in formula (3), in parts by weight The proportioning ratio is as follows: 50-100 parts of the dye of the formula (1), 5-45 parts of the dye of the formula (2), and 0-5 parts of the dye of the formula (3). The present invention also provides a black dye composition, including a color-fixing alkali agent, a dyeing accelerator and the above-mentioned composite reactive black dye. The composite reactive black dye provided by the present invention has higher dyeing depth, good color fixation rate and washing performance, and low raw material cost. The compounding of the three dyes of formula (3) makes the dyed fabric have higher level dyeing property, high color fixing rate and high fastness, and achieves unprecedented jet-black fullness and dyeing depth, and increases the washability of the dye It solves the problems of poor washability and serious color sticking of existing reactive black dyes, and is suitable for exhaust dyeing, pad dyeing and resist printing of fiber materials.

Owner:HUBEI HUALI DYESTUFF INDAL

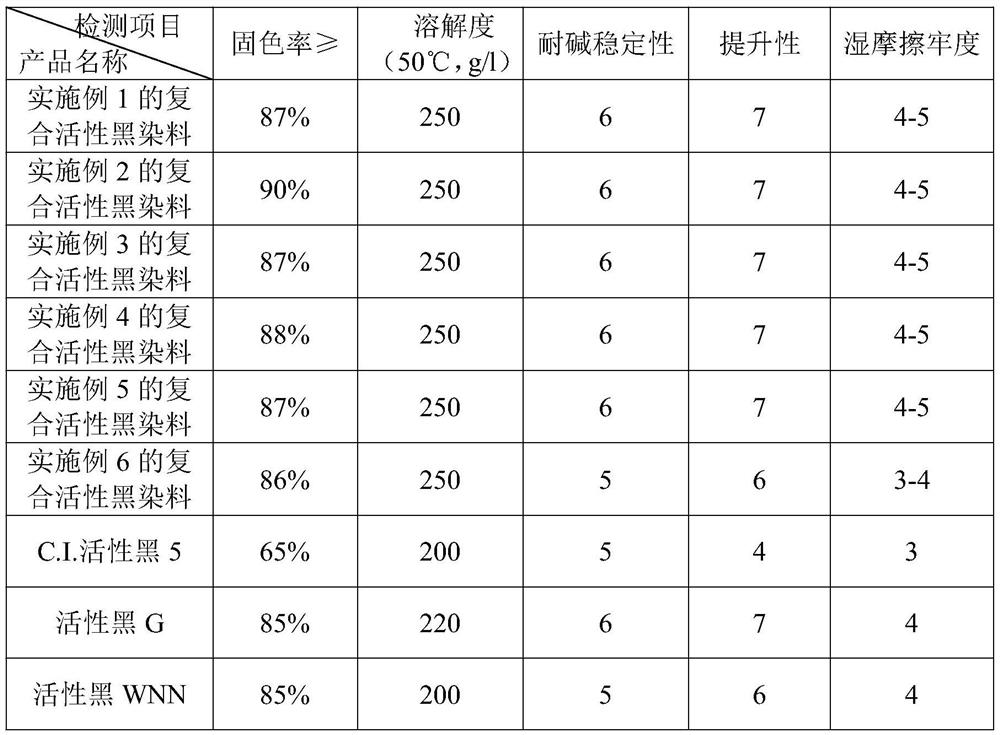

Reactive blue-to-black dye composition and dye product

The invention discloses a reactive blue-to-black dye composition and a dye product. The reactive blue-to-black dye composition comprises a component A, a component B and a component C. The component A is selected from at least one of dye compounds shown in a formula (I) and alkali metal salts thereof, and the component B is selected from at least one of dye compounds shown in a formula (II) and alkali metal salts thereof. And the component C is selected from at least one of dye compounds as shown in formulas (III)-(IV) and alkali metal salts thereof. The invention provides a reactive blue to black dye product which comprises the reactive blue to black dye composition. Compared with conventional reactive black, the reactive blue-to-black dye product disclosed by the invention has the advantages that the strength is higher by 60% or above, the dye is extremely high in deep dyeing property and fixation rate, the use amount of the dye can be greatly reduced, various color fastnesses are excellent, particularly the washing fastness is outstanding, and the reactive blue-to-black dye product is suitable for printing and dyeing nitrogen-containing and / or hydroxyl-containing fiber materials and blended fabrics thereof.

Owner:ZHEJIANG KEYONG CHEM CO LTD +1

Reactive orange dye as well as preparation method and application thereof

ActiveCN108864743AHigh color fixing rateHigh dyeing depthReactive dyesDyeing processReactive orangeSewage

The invention discloses reactive orange dye as well as a preparation method and application thereof. The reactive orange dye has a structural general formula as shown in the description, wherein M represents hydrogen, sodium, potassium or lithium. The preparation method comprises the following steps: completing condensation reaction and diazo-reaction through sub-steps, and then coupling, thus preparing the reactive orange dye. The invention also discloses the application of the reactive orange dye in printing and dyeing. The reactive orange dye disclosed by the invention has higher color fixation rate, deep dyeing property and bright color; meanwhile, the reactive orange dye has low-alkali dyeing property, the sewage emission is greatly reduced, and the requirements on environment protection at present can be particularly met.

Owner:苏州澳缘盛新材料科技有限公司

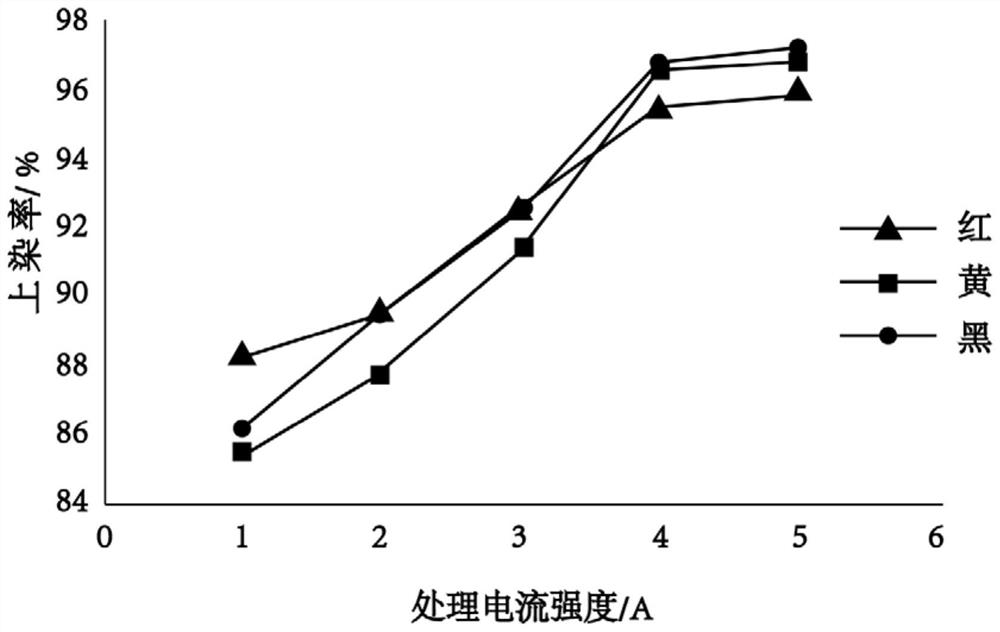

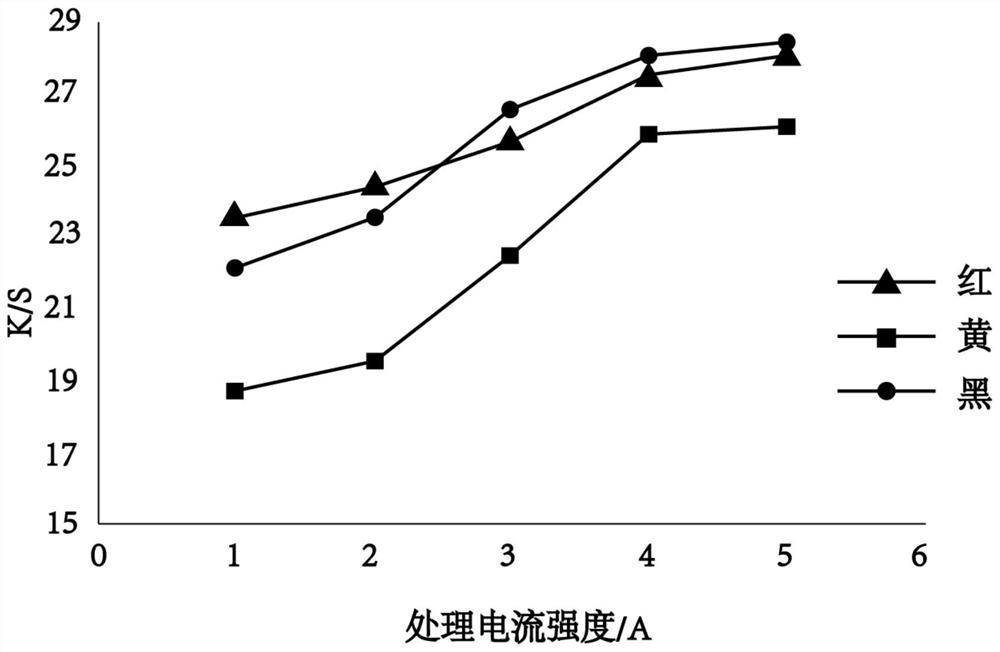

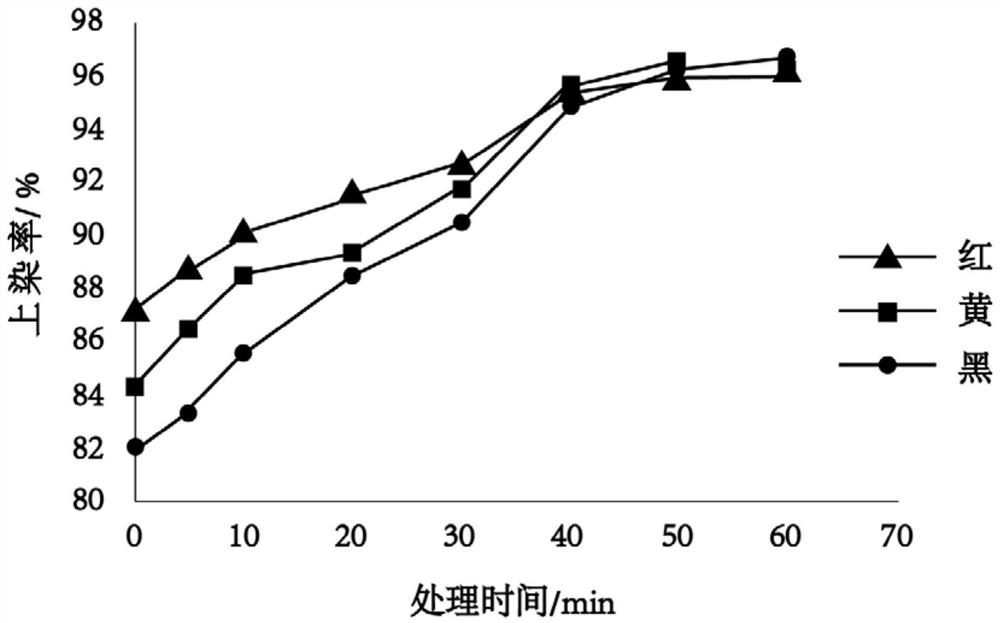

Dyeing process and application of new polyester imitation suede fabric

The invention provides a novel polyester suede fabric dyeing process and an application thereof, and relates to the technical field of textile printing and dyeing. According to the novel polyester suede fabric dyeing process, a polyester suede fabric is pretreated by a subglow discharge plasma treatment technology, and then the polyester suede fabric is subjected to dyeing processing by a method of compounding a non-ionic high-molecular polymer and a cationic high-molecular polymer; the dyeing process can significantly improve the deep dyeing property, levelling property and color fastness ofthe fabric on the basis of no influence, even improving effect, on physical and mechanical properties of the fabric; through detection, the dyeing rate of the polyester suede fabric after the dyeing process treatment can reach 80-98%, and the technical problems of poor levelling property, deep dyeing property and color fastness in the dyeing processing process of a polyester suede fabric are solved. The invention also provides the application of the novel polyester suede fabric dyeing process, and provides the basis for industrialized production of the polyester suede fabric.

Owner:JIAXING UNIV

Dyeing and finishing process of textiles

The invention discloses a dyeing and finishing process of textiles. The dyeing and finishing process is characterized by successively comprising the following steps: preprocessing, dyeing, washing, neutralizing, soap washing and washing textiles. The dyeing process has the advantages that by adopting the low-temperature dyeing and finishing process, compared with the traditional middle-temperature dyeing process, in the dyeing step, firstly in dye of a dark color series, and by virtue of ternary color combination of dark colors, the dyeing for the series of colors such as black, dark green, dark gray and garnet is more advantageous; the dye used by the invention has high deep dyeing performance, high absorption rate and good compatibility; compared with the middle-temperature dye, the absorption rate of the dye is high, and the color of the remaining liquid is light; moreover, the consumption of the low-temperature active dye of the invention in the dyeing process of coffee brown, military green and gray colors is 40 to 70 percent of that of the middle-temperature active dye; compared with the dark color series, the production cost of the printing and dyeing enterprises is decreased, and the problem that the sewage treatment cost is high can be solved; by adopting the dyeing process, the treatment cost of the printing and dyeing industry is decreased, and the sewage discharging amount is reduced.

Owner:NANTONG GUANZHOU INT TRADE CO LTD

Navy blue quaternary ammonium salt bisazo chemically-reactive dyes

InactiveCN100494289CGreenExcellent color rendering abilityReactive dyesDyeing processCellulose fiberAmmonium

The invention relates to a novel quaternary ammonium saltdisaz navy blue reactive dyestuff. The dyestuff is characterized by high affinity and directness, ability to increase the coloring rate for dying colth, strong chlorine bleaching tolerance and antioxidant bleaching and washing property. It can meet demand of high dying color and high humid strength.

Owner:ETHICAL INT WAREHOUSING TRADING SHANGHAI

A kind of red disperse dye composition

ActiveCN112063196BGood alkali resistanceHigh dyeing depthOrganic dyesDyeing processDisperse dyeDark color

The invention discloses a red disperse dye composition, which is characterized by comprising the following components: a dye monomer A with a mass fraction of 60-90%; a dye monomer B with a mass fraction of 8-30%: a mass fraction It is 0.5-10% dye monomer C; wherein: dye monomer A is C.I. disperse red 145, dye monomer B is C.I. disperse red 153, and dye monomer C is C.I. disperse orange 29; the red disperse dye of the present invention, The dye not only has excellent alkali resistance, especially in deep color dyeing, due to the addition of C.I. disperse orange 29, the yellow light will not subside and be reinforced when dyeing dark colors. Under the combined action of yellow light and yellow light, a very deep yellow light-red effect is exhibited. The invention improves the dye depth of the dye and effectively solves the problem of poor color light when the existing red disperse dyes are dyed dark.

Owner:浙江双冠染料有限公司

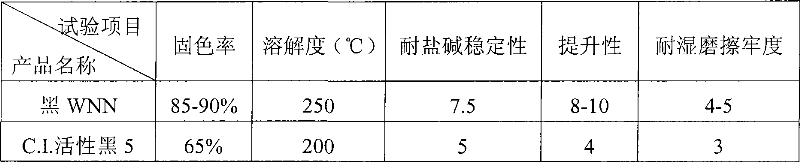

Black reactive dye semi-finished product and preparation method and application thereof

InactiveCN104478770AHas a bisazo structureHigh color fixing rateOrganic chemistryOrganic compound preparationReactive dyeWork in process

The invention relates to a black reactive dye semi-finished product and a preparation method and application thereof. The chemical structural general formula of the semi-finished product is shown in a formula (I), and the structural formula is as shown in the specification, wherein R1 refers to -CH3(CH2)n, -CH3(CH2)n O, -COOX or -SO3X; R2 refers to -H, -CH3(CH2)n, -CH3(CH2)n O, -COOX or -SO3X; R3 refers to -H, -CH3(CH2)n, -CH3(CH2)n O, -COOX or -SO3X; R4 refers to -H, -CH3(CH2)n, -CH3(CH2)n O, -COOX or -SO3X; R5 refers to -(CH2)<n+1>-; and X can be Na, K or Li. On one hand, the black reactive dye semi-finished product has a bisazo structure, and the fixation rate and deep dyeing property of the product can be improved; on the other hand, the black reactive dye semi-finished product comprises multiple sulfonated groups, can achieve the effects similar to a surfactant, is conveniently compound and mixed with other organic matters and is dissolved in water to prepare a dye solution.

Owner:吴江桃源染料有限公司

Production method of pure hemp mercerized yarn

InactiveCN102051720BReduce broken endsStrong and goodMercerising of yarns/threads/filamentsSingeingYarnAlkalinity

The invention provides a production method of pure hemp mercerized yarn. By the production method, the mercerized pure hemp yarn has few broken ends, excellent brute force and brightness, the deep dyeing property, level-dyeing property and penetrating property are greatly improved, the handle and smoothness are improved, the difficulty in later processes of dyeing, weaving and after finishing is reduced, and the application performance of the pure hemp yarn is integrally improved. The production method comprises the processes of singeing, reeling, mercerizing, dyeing, squeezing water, drying and rewinding, and is characterized in that the mercerizing process is as follows: yarn is put into a yarn mercerizing machine, wherein the alkalinity of treating fluid is 28-30 baume degrees, the temperature of the treating fluid is 18-22 DEG C, the applied tensile force stretching is 1-3%, the alkali dipping time is 1-3 minutes, the alkali squeezing time is 30 seconds-1 minute, time for washing with hot water is 30-60 seconds at the water temperature of 60-70 DEG C, time for washing with cold water is 30-45 seconds, and the treating time is 5 minutes-5 minutes and 50 seconds.

Owner:WUXI NATURAL GREEN FIBER TECH

Compound reactive black dye and application thereof

ActiveCN110305499AHigh dyeing depthGood color fixation and washabilityReactive dyesDyeing processDyeingFiber

The invention belongs to the technical field of dyes and particularly relates to a compound reactive black dye. The compound reactive black dye is prepared from, by weight, 50-100 parts of dyes in theformula I, 5-45 parts of dyes in the formula II and 0-5 parts of dyes in the formula III. The invention further provides a black dye compound which comprises a fixing alkali agent, a dye promoting agent and the above compound reactive black dye. The compound reactive black dye has high dyeing depth, good fixation rate and washing property and has low raw material cost; dyed fabric compounded by the Tibetan cyan dyes in the formula I, the orange dyes in the formula II and the yellow dyes in the formula III has high uniformity, high color fixation and high fastness, unprecedented black fullnessand dyeing depth are achieved, the washing property of the dye is increased, and problems of poor washing property of an existing reactive black dye, serious color sticking and the like are solved; the compound reactive black dye is suitable for dyeing, pad dyeing and anti-dyeing printing of fiber materials.

Owner:HUBEI HUALI DYESTUFF INDAL

Dyeing and finishing process of recycled high-density nylon cool fabric

ActiveCN113403837BEliminate internal stressFully release the elasticityLight resistant fibresDry-cleaning apparatus for textilesMoisture permeabilityProcess engineering

The invention discloses a dyeing and finishing process for recycled high-density nylon cool fabrics. The dyeing and finishing process includes a pretreatment process, a dyeing process and a setting process carried out in sequence; the pretreatment process includes a cold pad-batch process and flat-width desizing and water washing process; the dyeing process includes a coloring stage and a moisture-wicking finishing stage; the dyeing agent used in the coloring stage includes dyeing auxiliaries and dyes; after the coloring stage is completed, the liquid is drained, and then moisture-wicking finishing agent is added for moisture-wicking finishing ; Dyeing auxiliaries include acid leveling agent, nylon fiber dyeing accelerator, pH slip agent, anti-ultraviolet Leo Mountain C and anti-ultraviolet DEL; moisture-wicking finishing agents include moisture-wicking agent and slip agent VS. In the present invention, by formulating a suitable pretreatment process, dyeing process and setting process, the fabric has the functions of air permeability, moisture permeability, coolness and ultraviolet resistance, and is soft, ultra-thin, and bright in color under the premise of ensuring the dyeing quality and fabric feel. , fashion light sense and other new features.

Owner:SHENGHONG GRP CO LTD

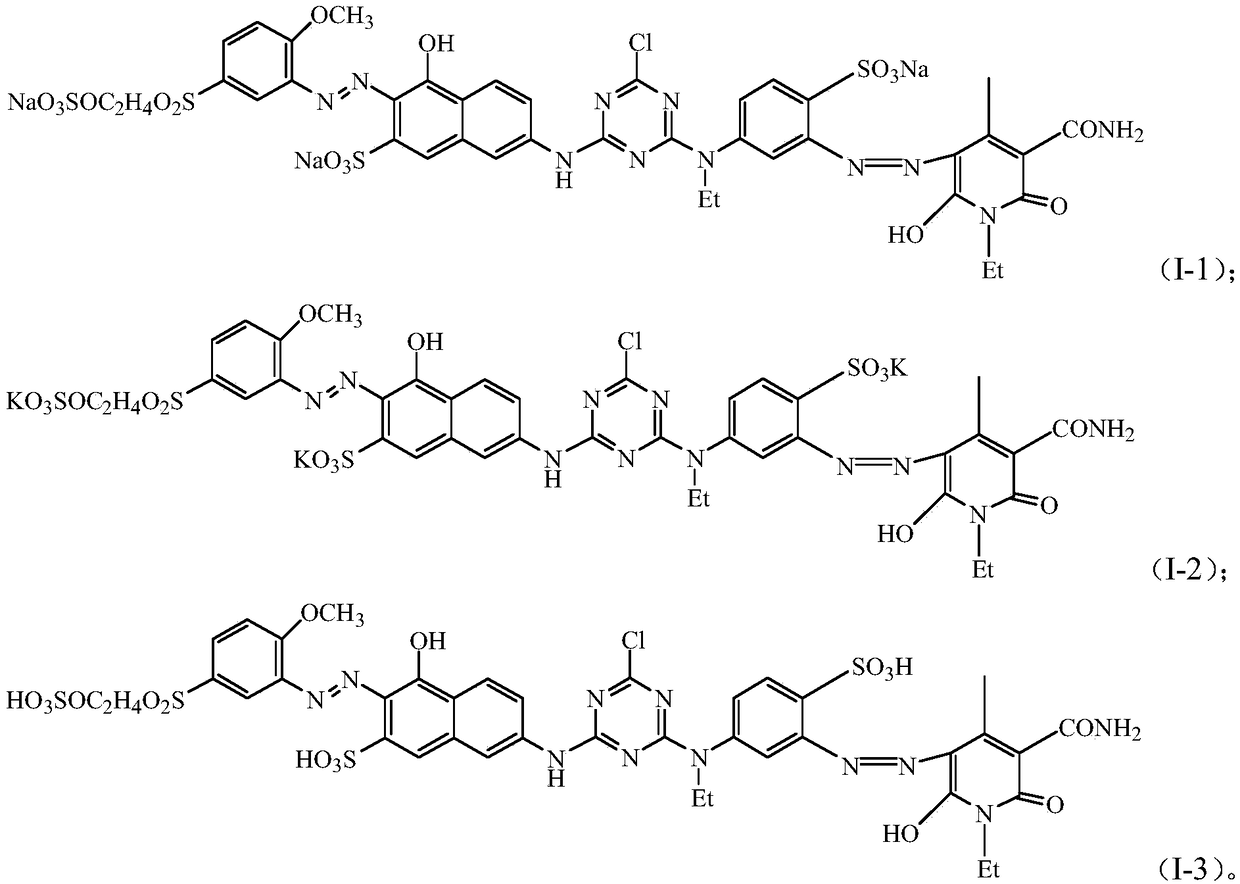

Semi-finished product of deep red dye, preparation method and application thereof

InactiveCN104479402AImprove uniformityHigh color fixing rateReactive dyesChemical structureWork in process

The invention relates to a semi-finished product of deep red dye, a preparation method and an application thereof. The chemical structural formula (I) of the semi-finished product of deep red dye is shown as formula (I) which is as shown in the specification. By introducing two naphthalene rings into the structure, a conjugate large Pi structure is formed by azo group, melamine group, amino group and phenyl group, so that uniformity coefficient of density dispersion of electronic cloud is improved, and thus the color fixation rate and the deep dyeing property of the deep red dye can be improved.

Owner:吴江桃源染料有限公司

A kind of reactive orange dye and its preparation method and application

ActiveCN108864743BHigh color fixing rateHigh dyeing depthReactive dyesDyeing processLithiumReactive orange

Owner:苏州澳缘盛新材料科技有限公司

A blue violet disperse dye composition and applications thereof

InactiveCN108034281AHigh color strengthBright colorOrganic dyesDyeing processDisperse dyePolymer chemistry

A blue violet disperse dye composition and applications thereof are disclosed. The composition includes, by mass, 40-60% of a component A shown as a formula (I), 20-35% of a component B shown as a formula (II), 18-30% of a component C shown as a formula (III) and 2-4% of a component D shown as a formula (IV). The component B and the component C have heterocyclic structures, and the heterocyclic structures are high in coloring intensity so that a dyed product has a bright color and excellent light fastness, sublimation fastness and discharging performance. The component B and the component C are synergistic and compounded to increase the dye uptake rate of the composition. The component D that is reactive dye for wool is mixed and used together with the components A, B and C, can modify disperse dye comprising the components A-B-C, and can greatly enhance bonding capability of the A-B-C and wool fibers, thus further increasing the dye uptake rate of the composition.

Owner:卢梅雅

Red disperse dye composition

ActiveCN112063196AGood effectGood alkali resistanceOrganic dyesDyeing processDisperse dyePolymer science

The invention discloses a red disperse dye composition, which is characterized by being prepared from the following components in percentage by mass: 60-90 percent of a dye monomer A, 8-30 percent ofa dye monomer B, and 0.5-10 percent of a dye monomer C, wherein the dye monomer A is C.I. Disperse red 145, the dye monomer B is C.I. Disperse red 153, and the dye monomer C is C.I. Disperse orange 29. The red disperse dye provided by the invention not only has excellent alkali resistance, but also does not fade and can be reinforced due to the addition of C.I. Disperse orange 29 when deep color dyeing is carried out, and has a very deep yellow light red effect due to the combined action of red, blue and yellow light. According to the invention, the deep dyeing property of the dye is improved,and the problem of poor color light during the deep dyeing of the existing red disperse dye is effectively solved.

Owner:浙江双冠染料有限公司

A dyeing method for improving the dyeing performance of nylon fiber

ActiveCN106835765BHigh dyeing depthLittle impact on physical and mechanical propertiesDyeing processDisperse dyeTextile printer

The invention relates to a dyeing method for improving deep dyeing performance of polyamide fiber, and belongs to the technical field of textile printing and dyeing. The dyeing method comprises the following steps: adding disperse dye into a mixed solution of ethanol and water to obtain a dyeing solution, and dyeing the polyamide fiber in an ultrasonic environment, wherein by virtue of strong penetration of ethanol into the polyamide fiber, a synergistic effect is produced under the auxiliary action of ultrasonic, and a large number of dye molecules are carried into the free volume of the fiber so as to deeply and thoroughly dye the polyamide fiber. By the dyeing method, the dyeing temperature is low, the dyeing time is short, strength damage of the polyamide fiber in the dyeing process is alleviated, and the problem that the dyeing depth is not high when the disperse dye dyes the polyamide fiber is effectively solved; and the dyeing method is simple in process and strong in operability and is an efficient polyamide fiber dyeing method.

Owner:WUHAN TEXTILE UNIV

Preparation method of para-(beta-Ethyl Sulfonyl Sulfate) aniline sulfonic acid

InactiveCN100509775CHigh dyeing depthHigh color fixing rateOrganic chemistryOrganic compound preparationSolubilitySulfate

The present invention is a kind of preparation method of p-(β-sulfate ethyl sulfone) aniline o-sulfonic acid, it is characterized in that: adopt concentrated sulfuric acid (100%) as solvent, p-(β-sulfate ethyl sulfone) aniline As a raw material, it is dispersed at a temperature of 60-90°C, sulfonated at 120-130°C, hydrolyzed at 100-110°C, cooled, acidified, crystallized, filtered, and dried to obtain the product. With the p-(β-sulfate ethyl sulfone) aniline o-sulfonic acid prepared by the inventive method, the reactive dyes made by it are compared with the reactive dyes made from p-(β-sulfate ethyl sulfone) aniline, Its dyeing depth, color fixing rate, solubility, salt and alkali resistance stability, and wet rubbing fastness are all improved, and the washability is better.

Owner:HUBEI HUALI DYESTUFF INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com