Dyeing method for improving deep dyeing performance of polyamide fiber

A technology of nylon fiber and dyeing method, which is applied in the field of textile printing and dyeing processing, can solve problems such as the influence of nylon fiber application performance, lack of widespread attention, and insufficient dyeing color, so as to improve dyeing depth performance, reduce dyeing cost, and improve physical and mechanical properties. little effect on performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

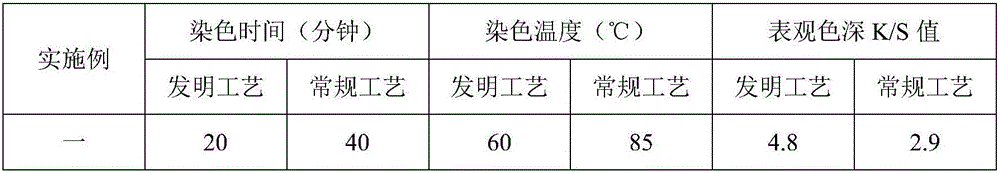

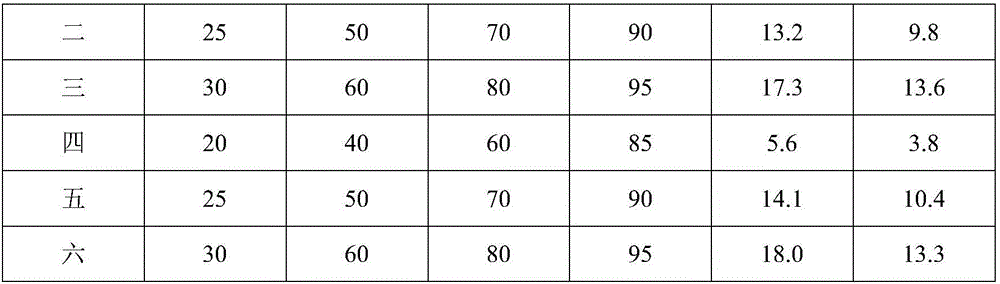

Embodiment 1

[0026] The object to be dyed is nylon 6 fiber, and its mass is 1g. Weigh 0.001g of disperse yellow RGFL, add it to a glass dyeing cup with a volume ratio of 7:3 of ethanol and water to prepare a dyeing solution, and put the nylon 6 fiber in Put it into the dyeing solution, cover the dyeing cup, place the dyeing cup in an ultrasonic generator for dyeing, the dyeing temperature is 60°C, the dyeing time is 20min, and the ultrasonic power is 1200 watts. After the dyeing is completed, the dyed finished product is obtained through soaping, washing and drying.

Embodiment 2

[0028] The object to be dyed is nylon 6 fiber, and its mass is 1g. Weigh 0.05g of disperse yellow RGFL, add it into a glass dyeing cup with a volume ratio of 5:5 of ethanol and water to prepare a dyeing solution, and put the nylon 6 fiber into Put it into the dyeing solution, cover the dyeing cup, place the dyeing cup in an ultrasonic generator for dyeing, the dyeing temperature is 70°C, the dyeing time is 25min, and the ultrasonic power is 1500 watts. After the dyeing is completed, the dyed finished product is obtained through soaping, washing and drying.

Embodiment 3

[0030] The object to be dyed is nylon 6 fiber, its mass is 1g, weigh 0.1g of disperse yellow RGFL, add it into the glass dyeing cup of 50mL ethanol and water mixed solution with a volume ratio of 3:7 to prepare dyeing solution, put nylon 6 fiber Put it into the dyeing solution, cover the dyeing cup, place the dyeing cup in an ultrasonic generator for dyeing, the dyeing temperature is 80°C, the dyeing time is 30min, and the ultrasonic power is 1800 watts. After the dyeing is completed, the dyed finished product is obtained through soaping, washing and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com