Dyeing and finishing process of recycled high-density nylon cool fabric

A processing technology and recycling technology, which is applied in the field of textile printing and dyeing, can solve the problems of high fiber and fiber arrangement density, easy to produce colored flowers in nylon fabrics, and fast adsorption of acid dyes, so as to eliminate internal stress, improve dyeing rate and Dyeing depth, the effect of reducing the initial dyeing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Fabric gray fabric: recycled high-density nylon fabric made of recycled 20D / 24F nylon filament and low elastic yarn.

[0040] The regenerated nylon used in the fabric comes from waste nylon screens, carpets, etc., which are obtained through depolymerization and repolymerization processes, regenerated granulation, slicing, and spinning.

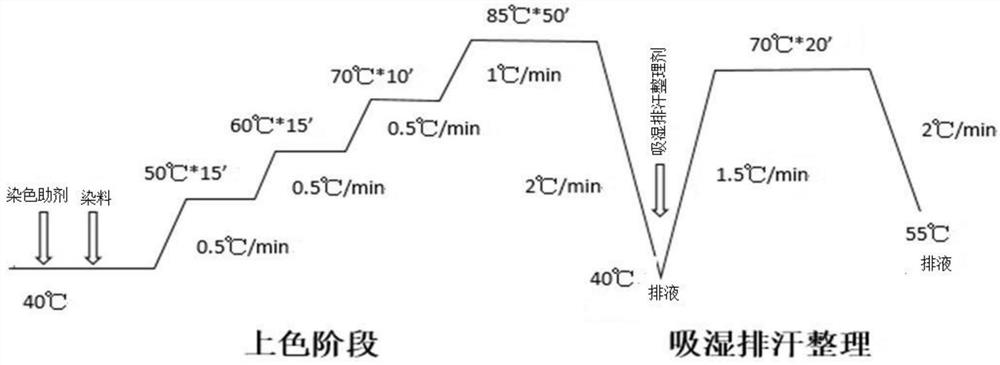

[0041] The dyeing and finishing process of the recycled high-density nylon fabric includes a pretreatment process, a dyeing process and a setting process carried out in sequence.

[0042] (1) Pretreatment process

[0043] The pulp on the recycled high-density nylon gray cloth is mainly chemical pulp such as PVA and PVC; according to the high sizing rate and ultra-high density characteristics of the fabric gray cloth, a pre-treatment process is designed; the pre-treatment process includes the cold pad batch process The flat-width desizing and washing process is divided into two steps and three stages: cold pad batch - low alkali refinin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com