Dyeing process and application of new polyester imitation suede fabric

A fabric dyeing and imitation suede technology, which is applied in the field of textile printing and dyeing, can solve the problems of level dyeing, poor dyeing fastness, etc., and achieve the effect of improving dyeing depth and level dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0066] As a preferred embodiment of the present invention, described novel polyester imitation suede fabric dyeing process, comprises the following steps:

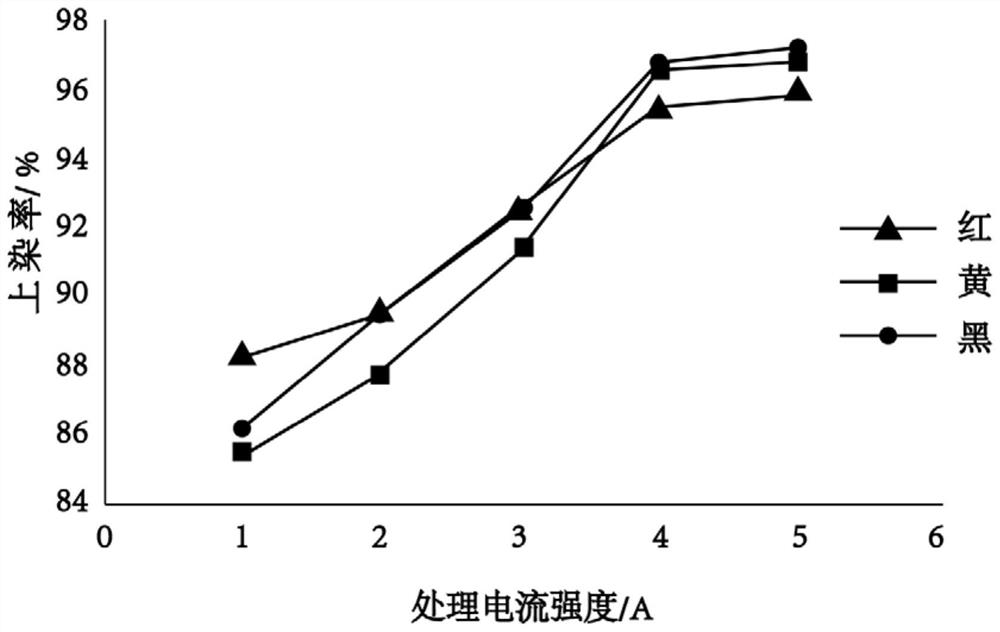

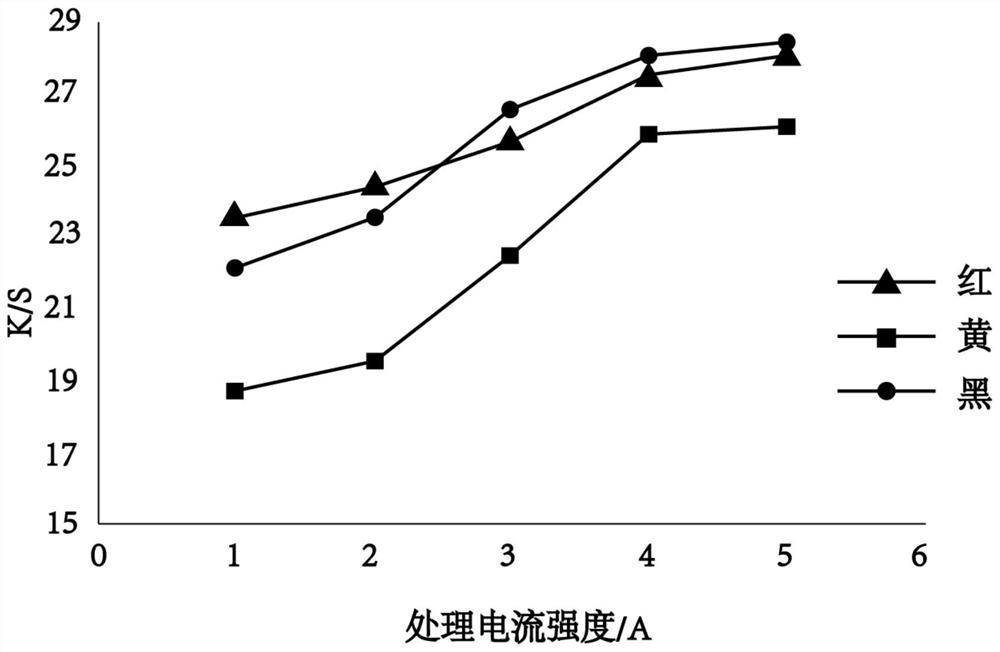

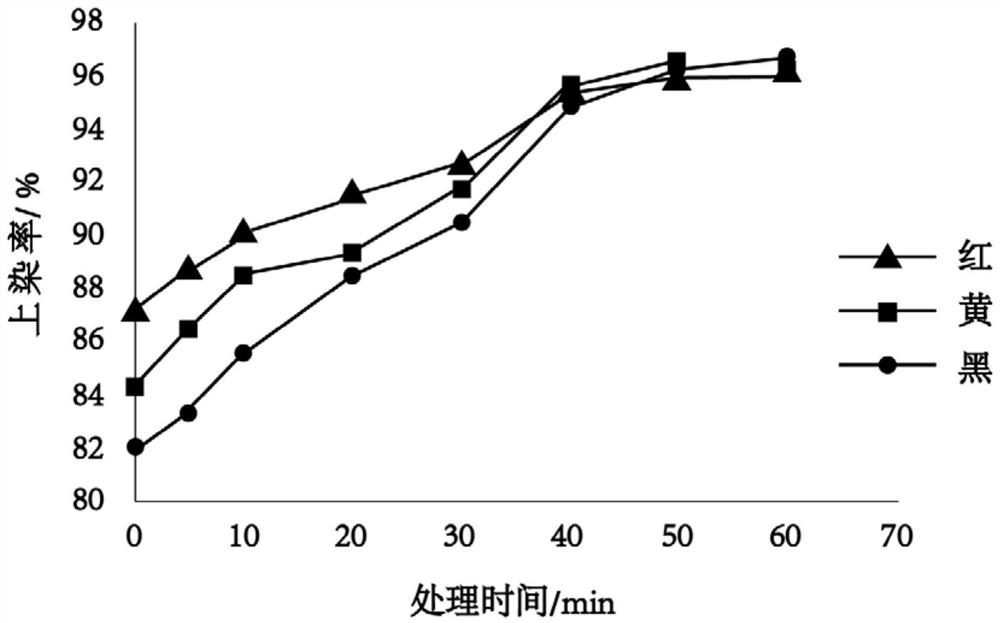

[0067] (a) Pretreat the polyester suede fabric by using double-dielectric barrier subglow discharge plasma treatment equipment; wherein, the treatment current intensity is 1-5A, and the treatment time is 5-60min;

[0068] (b) placing the pretreated polyester suede fabric in a dye bath for dyeing, reduction cleaning, washing, and drying;

[0069] In the dye bath, the dye concentration is 4-10% owf, the bath ratio is 1:(3-100), the concentration of chitosan acetic acid solution is 5-20g / L, and the concentration of polyethylene glycol is 8-12% owf .

[0070] On the basis of ensuring the mechanical properties of the fabric, optimizing the parameters of the double-dielectric barrier sub-glow discharge plasma treatment and improving the processing technology of the ultra-fine polyester suede fabric can reduce the amount of alka...

Embodiment 1

[0075] A kind of novel polyester imitation suede fabric dyeing process that present embodiment provides, comprises the following steps:

[0076] (a) Turn on the power supply of the dual-dielectric barrier sub-glow discharge plasma treatment equipment, preheat for 30 minutes, set the treatment current intensity to 1A, and put a 5cm×25cm polyester suede fabric strip into the built-in cloth of the plasma treatment equipment. Fix it in the gap of the strip, carry out pretreatment, adjust the rotating speed to be 10m / min (the distance of running one circle is 10m), and the processing time is 60min;

[0077] (b) placing the pretreated polyester suede-like fabric in a dye bath for dyeing;

[0078] Concrete, prepare dyeing bath, wherein dyestuff (disperse red EDT-R) concentration is 4% owf, and bath ratio is 1:3, and the concentration of chitosan acetic acid solution is 5g / L (chitosan acetic acid solution passes chitosan Sugar is dissolved in 2% acetic acid and prepared), and the con...

Embodiment 2

[0081] A kind of novel polyester imitation suede fabric dyeing process that present embodiment provides, comprises the following steps:

[0082] (a) Turn on the power supply of the dual-dielectric barrier subglow discharge plasma treatment equipment, preheat for 30 minutes, set the treatment current intensity to 3A, and put a 5cm×25cm polyester suede fabric strip into the built-in cloth of the plasma treatment equipment. Fix in the strip gap, carry out pretreatment, adjust the rotating speed to be 10m / min (the running distance is 10m), and the processing time is 30min;

[0083] (b) placing the pretreated polyester suede-like fabric in a dye bath for dyeing;

[0084]Concrete, prepare dyeing bath, wherein dyestuff (disperse red EDT-R) concentration is 6% owf, bath ratio is 1:30, and the concentration of chitosan acetic acid solution is 10g / L (chitosan acetic acid solution is passed through chitosan Sugar is dissolved in 2% acetic acid and prepared), and the concentration of pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com