Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Little change in intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of manufacturing an ion-exchanged glass article

ActiveUS20130061636A1Maintain stable propertiesLittle change in intensityBase layer manufactureMolten saltIon exchange

An ion-exchanged glass article manufacturing method includes an ion-exchange step of bringing a glass article with a composition containing Li into contact with a molten salt dissolved solution containing an alkali metal element having an ionic radius larger than an ionic radius of the Li contained in the glass article, thereby ion-exchanging the Li in the glass article with the alkali metal element in the molten salt dissolved solution. At least one kind of additive selected from the group consisting of NaF, KF, K3AlF6, Na2CO3, NaHCO3, K2CO3, KHCO3, Na2SO4, K2SO4, KAl(SO4)2, Na3PO4, and K3PO4 is added to the molten salt dissolved solution so that the ion-exchange step is carried out while the additive is in a solid state.

Owner:HOYA CORP

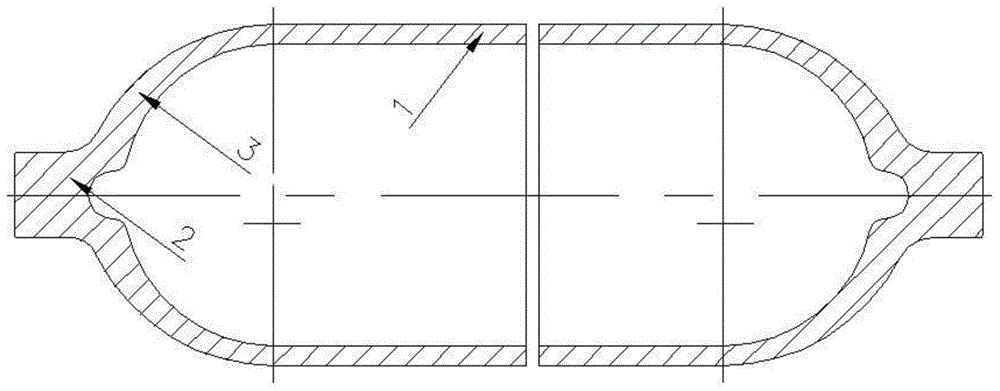

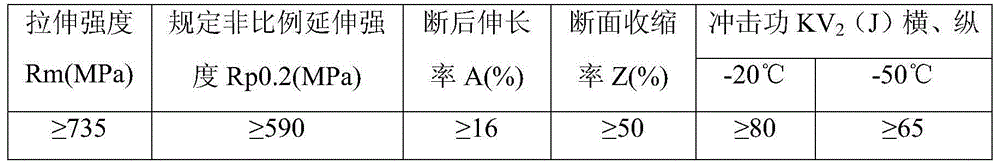

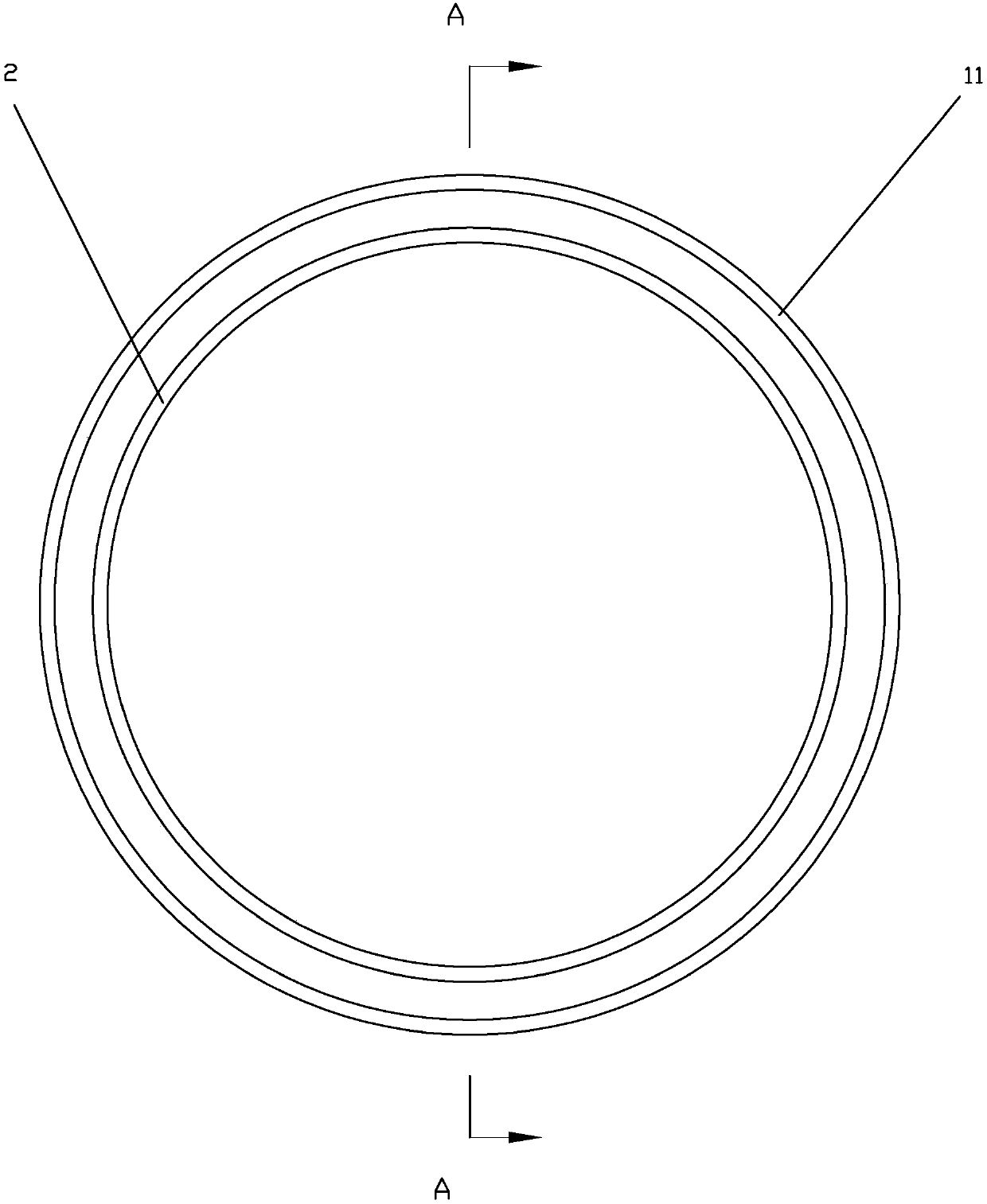

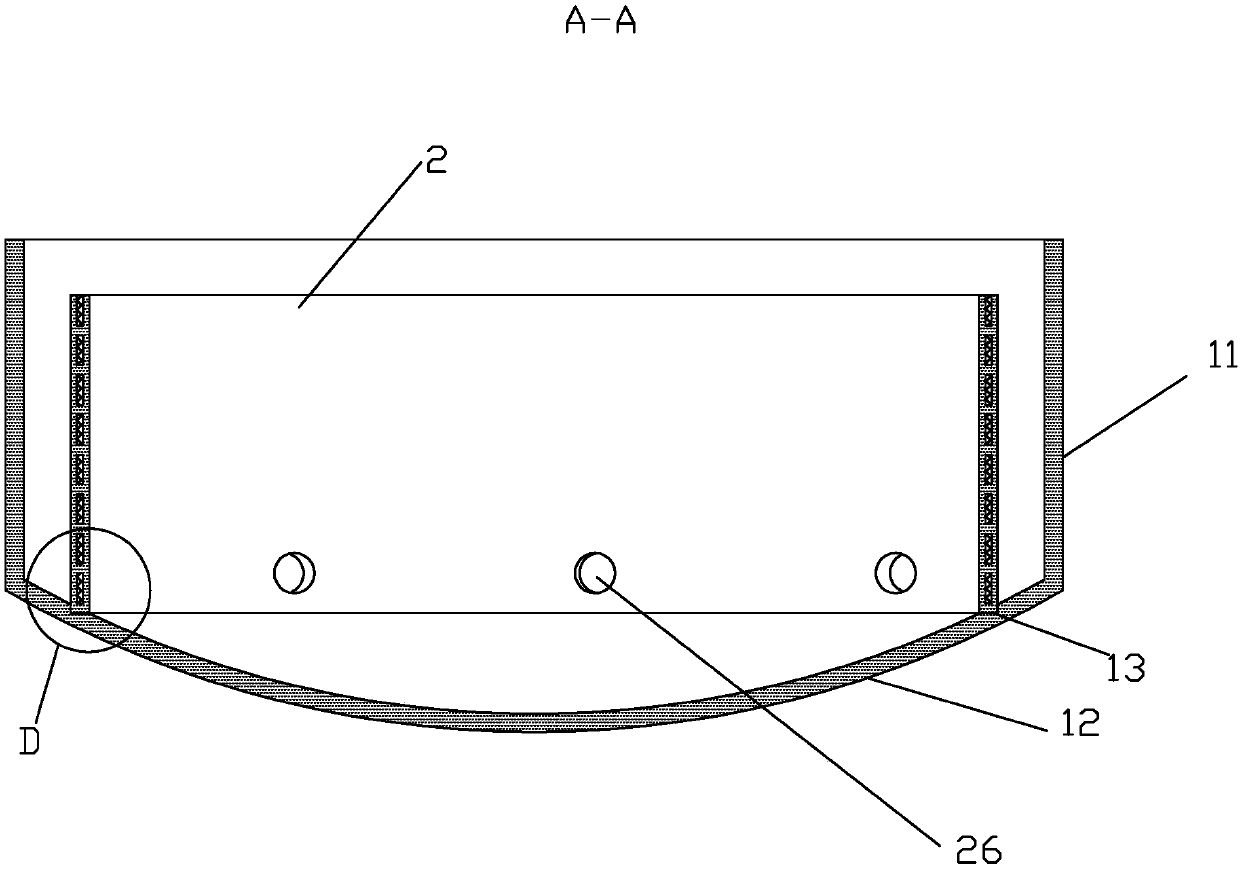

High-pressure seamless 10CrNi3MoV steel cylinder and manufacturing process thereof

ActiveCN104451419AImprove toughnessAvoid brittlenessFurnace typesHeat treatment furnacesHigh probabilityHigh pressure

The invention belongs to the field of machinery manufacturing, particularly relates to a high-pressure seamless 10CrNi3MoV steel cylinder and a manufacturing process thereof, and aims to solve the technical problems of difficulty in manufacturing process determination, poor low-temperature toughness of materials, high probability of deformation and cracking and the like of the current welded type high-pressure seamless 10CrNi3MoV steel cylinder. The scheme is that the high-pressure seamless 10CrNi3MoV steel cylinder adopting seamless 10CrNi3MoV steel pipes as raw materials is provided. The invention further provides a manufacturing process of the high-pressure seamless 10CrNi3MoV steel cylinder. A cylinder body and a seal head of the high-pressure seamless 10CrNi3MoV steel cylinder are seamlessly connected, so that the welding defect is overcome, and meanwhile, with the adoption of the manufacturing process, the low-temperature toughness of steel is further improved.

Owner:CHENGDU GREAT HIGH PRESSURE VESSEL

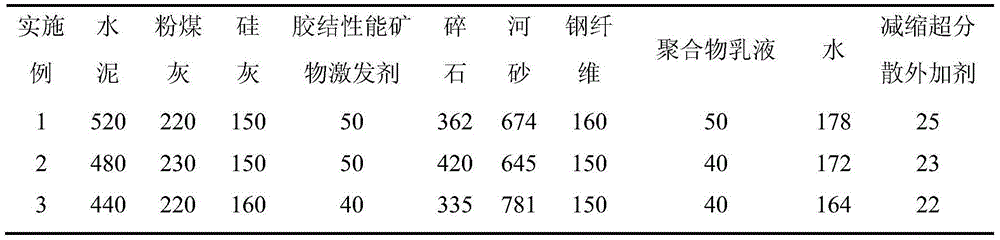

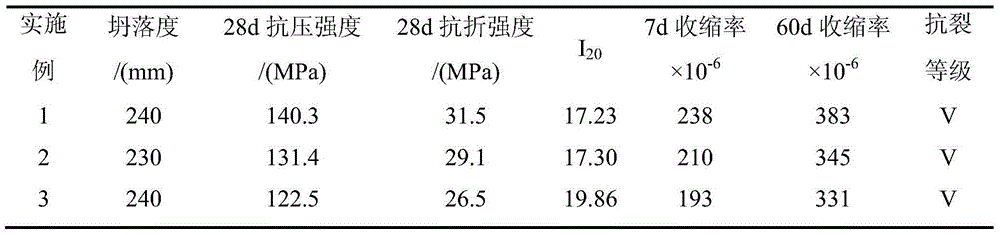

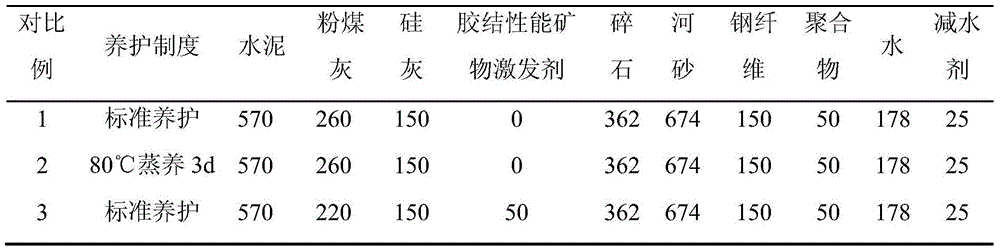

Anti-cracking steam-curing-free ultra-high-strength high-toughness concrete and preparation method thereof

The invention discloses anti-cracking steam-curing-free ultra-high-strength high-toughness concrete. The anti-cracking steam-curing-free ultra-high-strength high-toughness concrete is prepared from cement, fly ash, silica fume, a mineral activator with cementing property, gravel, river sand, steel fibers, a polymer emulsion, water and a shrinkage-reducing super-dispersing admixture, wherein the mineral activator with cementing property comprises waste prefabricated concrete set cement crystal seeds and desulfurized gypsum. By using the mineral activator with cementing property in the concrete, high-temperature steam curing and pressurized steam curing systems adopted in the ordinary ultra-high-performance concrete are eliminated; and the shrinkage-reducing super-dispersing admixture having the functions of super-dispersing cement, reducing shrinkage, decreasing viscosity and the like is adopted to enable the hydration activity of cement to give a full play so that the strength of the concretes has no obvious change after cement usage is decreased by about 10%; and meanwhile, the mineral activator and the admixture can effectively suppress the shrinkage of concrete. The concrete prepared by the preparation method is higher in strength, toughness and shrinkage resistance, low in cost and simple in preparation method and has important practical application value.

Owner:WUHAN UNIV OF TECH

Method of manufacturing an ion-exchanged glass article

ActiveUS8919150B2Long lastingMaintain stable propertiesMagnetic materials for record carriersRecord information storageMolten saltIon exchange

Owner:HOYA CORP

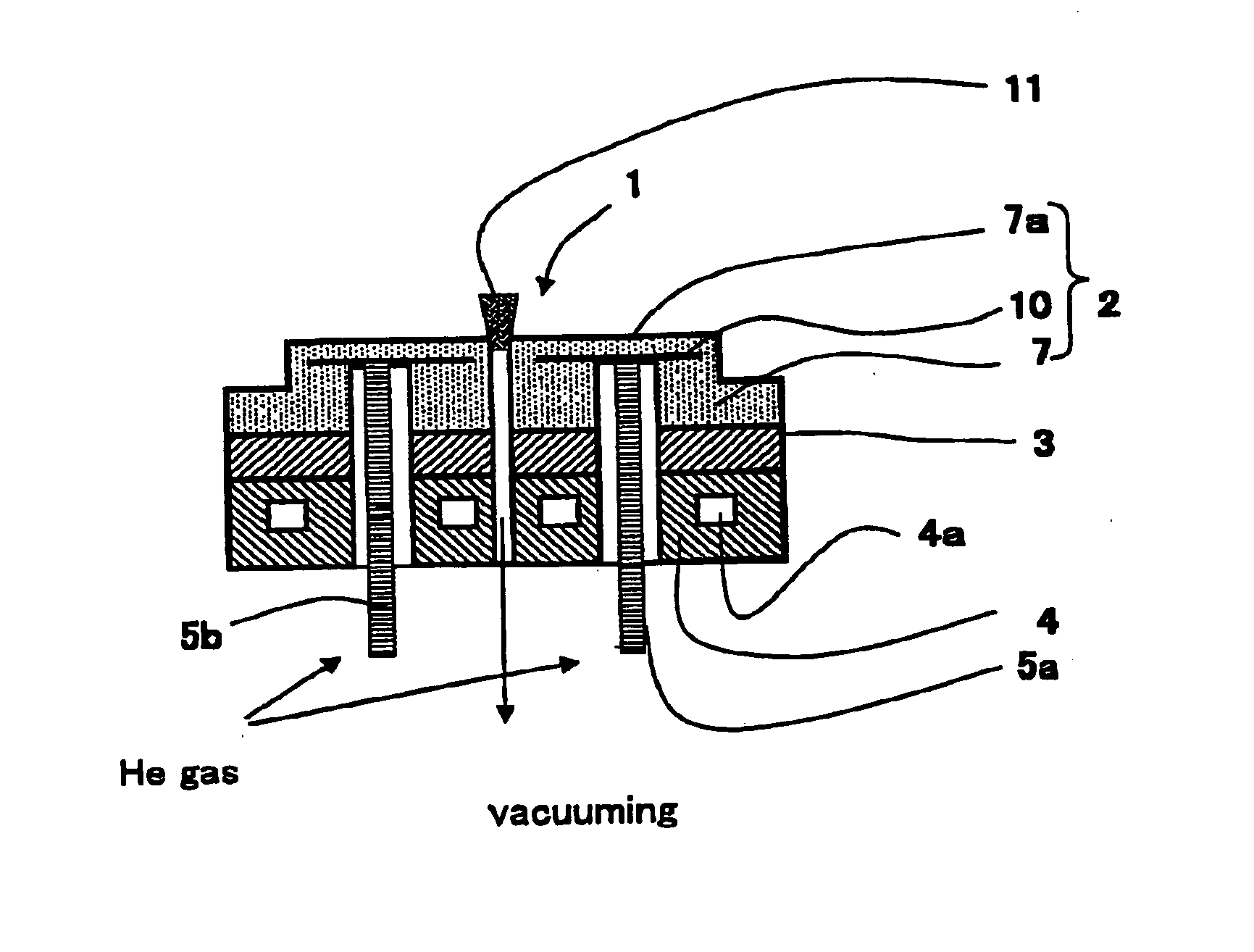

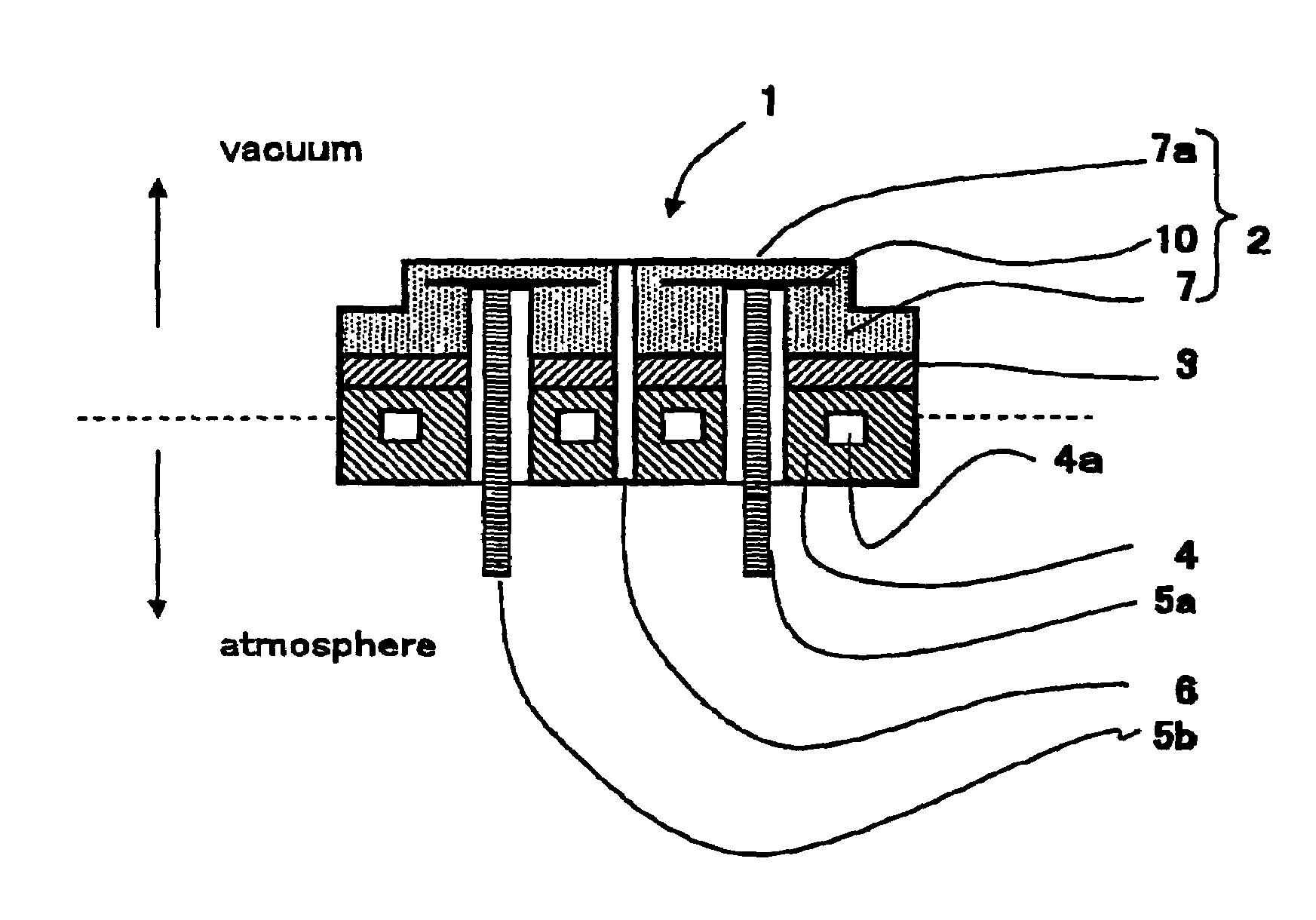

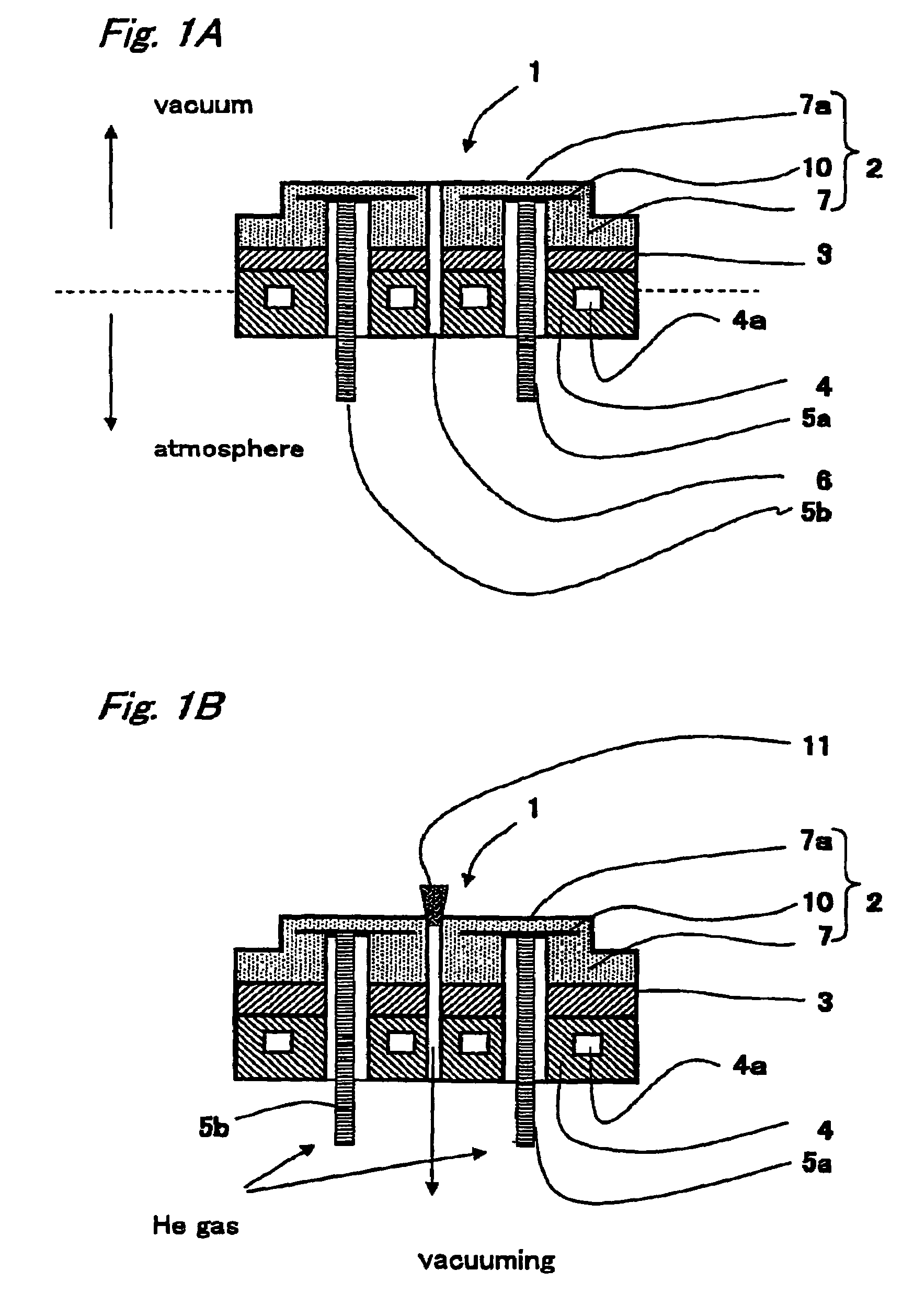

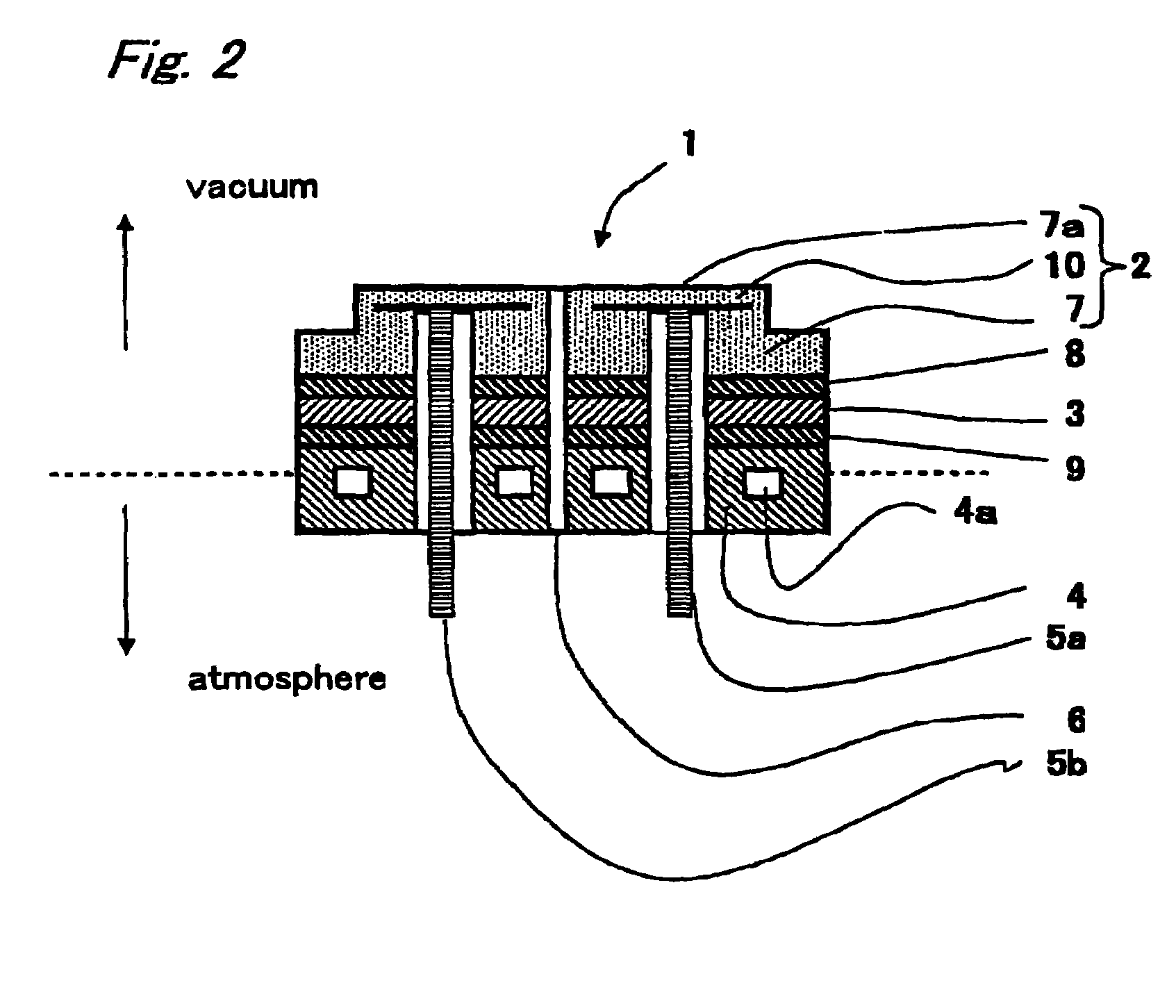

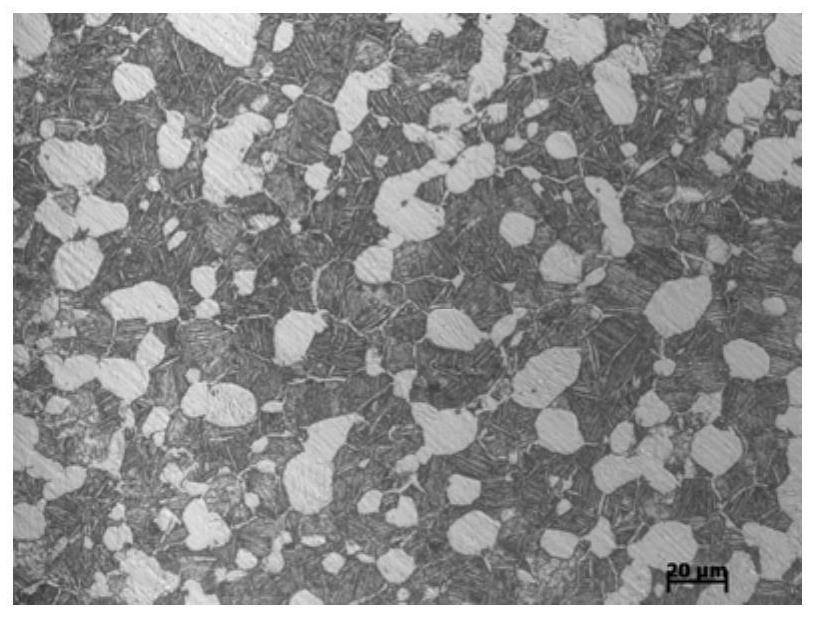

Composite material, wafer holding member and method for manufacturing the same

InactiveUS20050101082A1Improve thermal conductivityLittle change in intensityLiquid surface applicatorsSolid-state devicesThermal expansionAir tightness

A composite material according to the present invention, is composed of SiC, SiO2, at least one out of Al and Si, with He leak rate of 1.3×10−10 Pa·m3 / sec or below, thereby providing a composite material, which has a higher vacuum air-tightness, an excellent thermal conductivity, an adjustable coefficient of thermal expansion, small variation in strength and higher reliability, and a method for manufacturing the composite material, and a wafer holding member including the composite material.

Owner:KYOCERA CORP

Full-biodegradable plastic mulching film, preparation method and application thereof

InactiveCN112980153AAffect mechanical strengthIncrease the range that can be addedClimate change adaptationPlant protective coveringsButanedioic acidPlastic mulch

The invention provides a full-biodegradable plastic mulching film, a preparation method and application thereof. The full-biodegradable plastic mulching film comprises the following components in parts by weight: 100 parts of a full-biodegradable resin, 10-30 parts of an auxiliary agent, 10-60 parts of modified starch and 10-100 parts of modified calcium carbonate, wherein the full-biodegradable resin is prepared from one or more of poly (butylene succinate) (PBS), polylactic acid (PLA), polyhydroxyalkanoate (PHA), poly (butylene adipate-butylene terephthalate) (PBAT) and polypropylene carbonate (PPC). According to the biodegradable mulching film, the contradiction that crops need longer service life of the mulching film and lower thickness of the mulching film and the requirement on the lowest thickness of a polyethylene plastic mulching film can be solved, and the technical scheme of the biodegradable mulching film also has the effects of slow degradation in the early stage, strong protection capability and accelerated degradation in the later stage, so that the influence of the biodegradable mulching film on the planting of succeeding crops is reduced.

Owner:北京惠林苑生物科技有限公司 +1

Method for preparing phenolic resin pre-condensation polymer cross-linking agent

ActiveCN101735421ANo toxicityNo irritationDrilling compositionHexamethylenetetramineHydroquinone Compound

The invention provides a method for preparing phenolic resin pre-condensation polymer cross-linking agent, which takes phenol, hydroquinone, methanol, urotropine, 40% of sodium hydroxide solution and water as raw materials and comprises the following steps: introducing cooling water into a reaction kettle; adding 10-15% of phenol, 15-10% of hydroquinone and 5-10% of sodium hydroxide solution withmass concentration of 40%; starting a stirrer, opening a cooling water valve, adjusting the cooling temperature to be not higher than 50 DEG C; adding 5-10% of urotropine when the cooling temperatureis controlled below 40 DEG C, dissolving, adding 65-55% of methanol slowly when the temperature is controlled to be not higher than 50 DEG C; stirring and reacting for 20-30min after all the raw materials are added, discharging when the fact that the temperature rises without any fallout trend is observed to obtain the phenolic resin pre-condensation polymer cross-linking agent which has the advantages of simple use, low toxicity, environment protection, adjustable gelation time and temperature of jelly thereby, and good temperature tolerance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

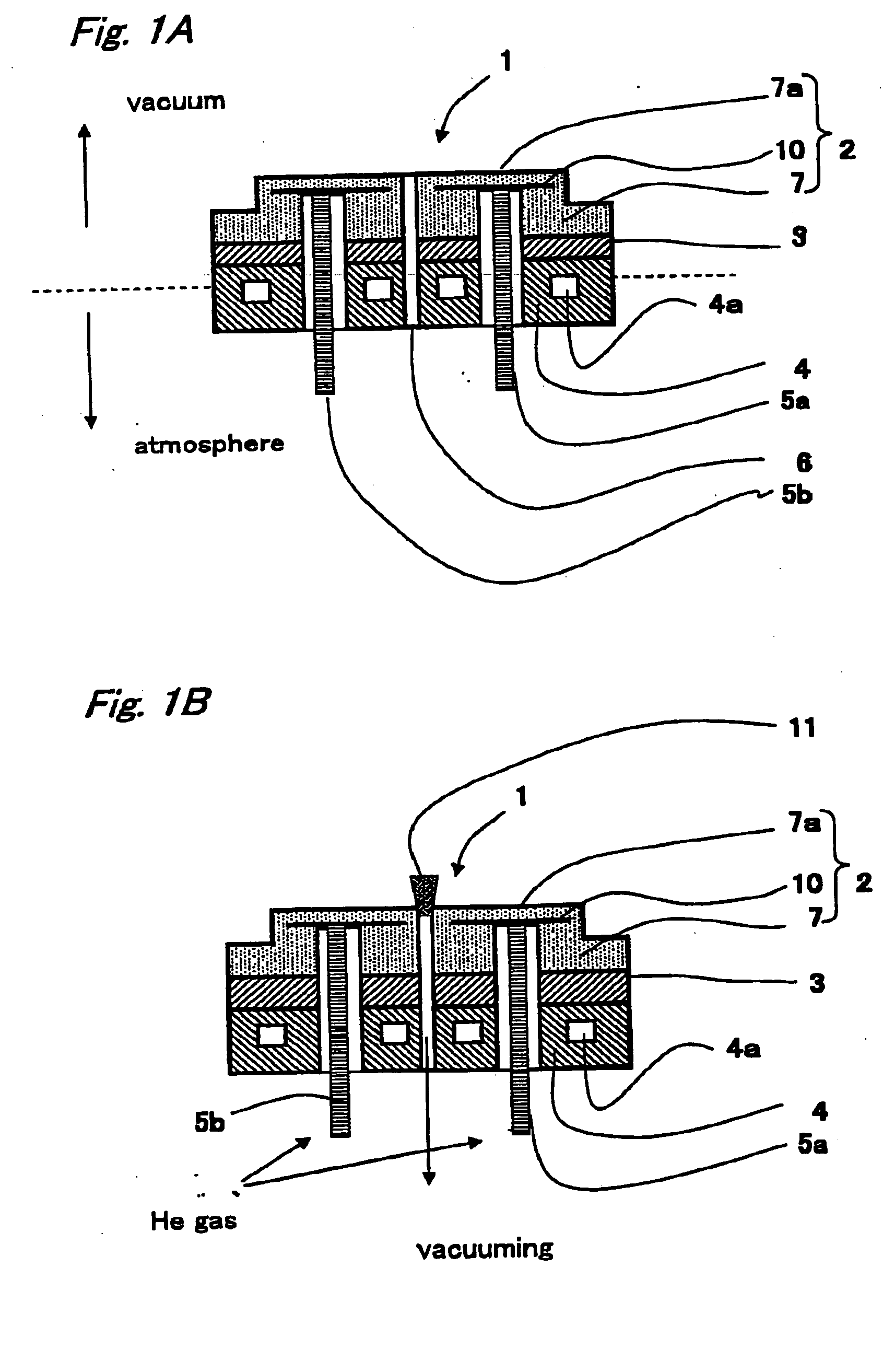

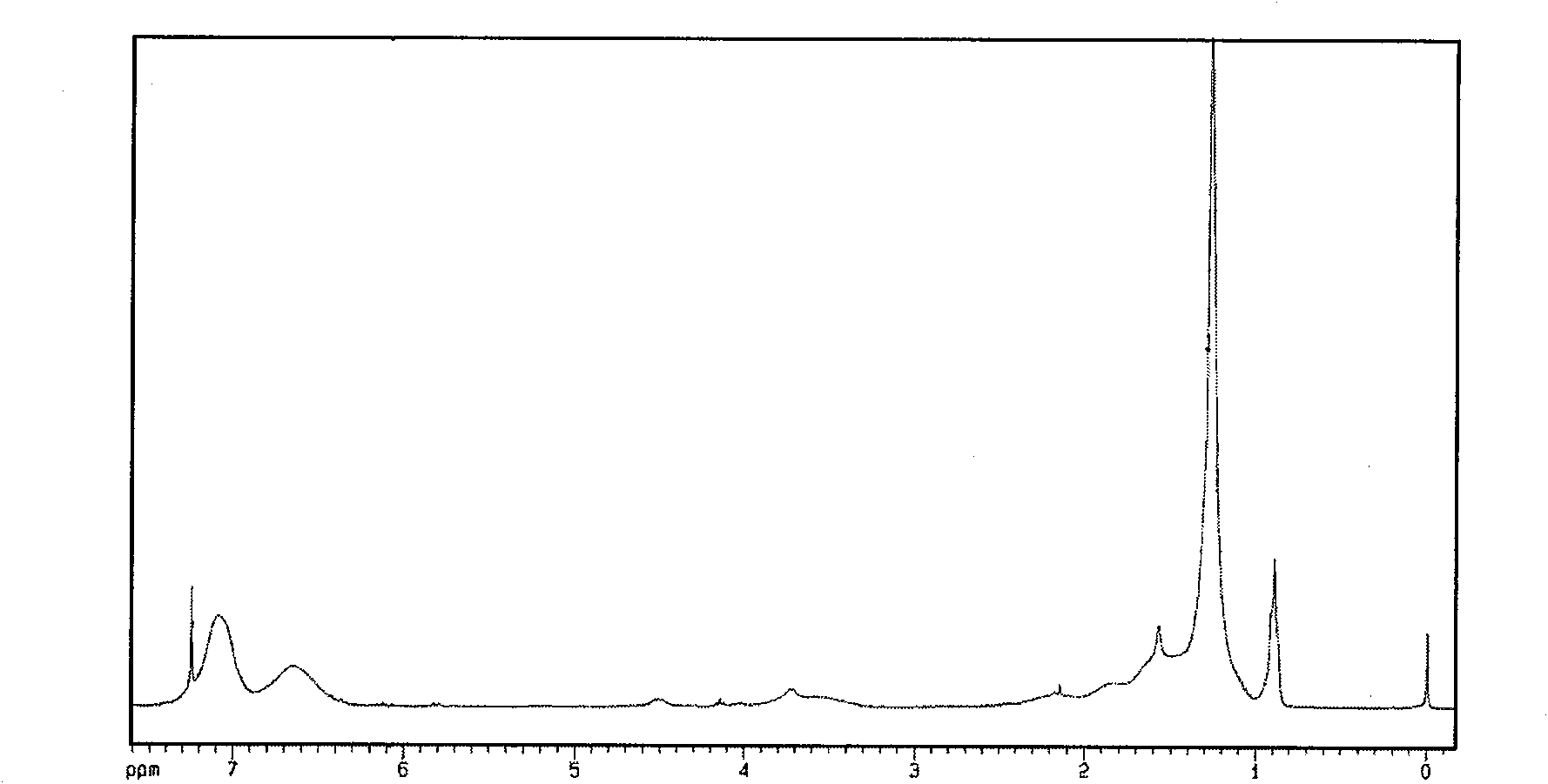

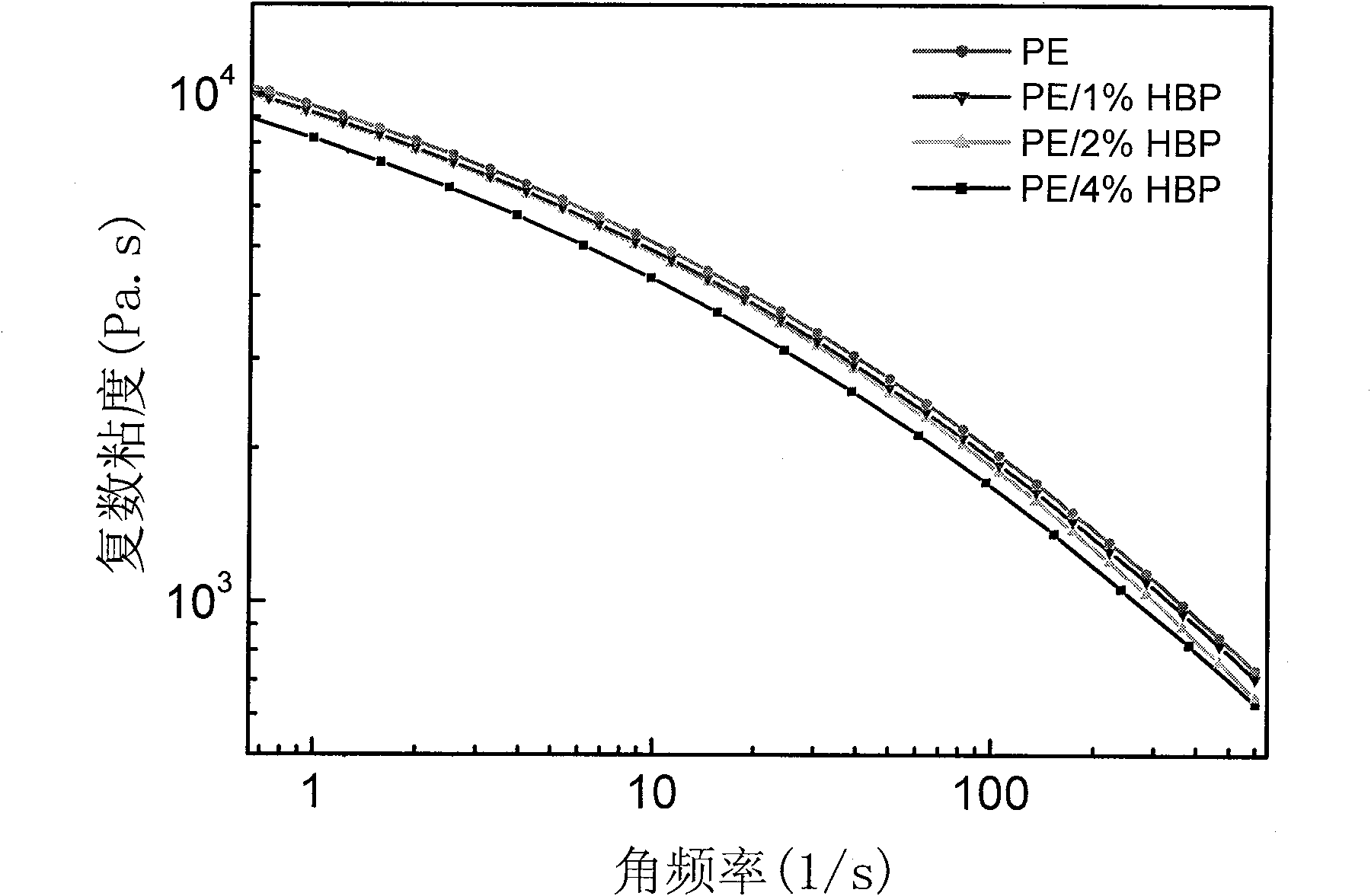

Ultra-branched polymer used as polythene processing auxiliary agent and synthetic method

This invention relates to a hyperbranched polymer used as polythene processing assistant and its synthesis method, specifically the Polymer composed of higher alcohol of acrylic ester and styrene and the method of atom transfer radical polymerization. The invention synthesizes the hyperbranched polymer firstly through the following formula (weight): p-CMS 1, styrene 6.84~13.68, acrylic dodecyl alcohol ester 7.88~23.64, Bpy 0.21~ 0.63, CuCl 0.065~0.196. The above components conduct evacuation, filling argon or nitrogen for more than five times, closing tightly, and response under magnetic stirring for four to twelve hours and 100~130deg.C. The product is dissolved in acetone, filtered in alumina column, precipitated in ethanol, and dried in vacuum for a few hours under 25~40deg.C to obtain the hyperbranched polymers. The melt viscosity of this invention decreases significantly corresponding to pure HDPE, and its strength change is very small showed by the tensile performance test.

Owner:溧阳常大技术转移中心有限公司

Analysis of influences of thermal force and freeze-thaw weathering on tunnel

InactiveCN102031973ALittle change in intensityReduce intensityWeather/light/corrosion resistanceUnderground chambersFreeze thawingThermal force

The invention relates to analysis of influences of thermal force and freeze-thaw weathering on a tunnel. The analysis comprises plateau temperature analysis, concrete intensity monitoring, stress section monitoring and frozen-heave force analysis and is characterized in that: during the analysis of the influences of thermal force and freeze-thaw weathering on the tunnel, an external heating and heat preserving measure and an external heating, temperature raising, covering and moisture preserving measure are taken so as to analyze weathering caused by frozen-heave force. Major factors which cause frost heave damage to the tunnel can be determined, frozen earth is protected, water content of a new frozen earth layer is lowered, freezing of leakage water is avoided, tunnel design and construction technology for the Qilian Mountain is promoted effectively, curing cost is lowered and the service life of the tunnel is prolonged.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD

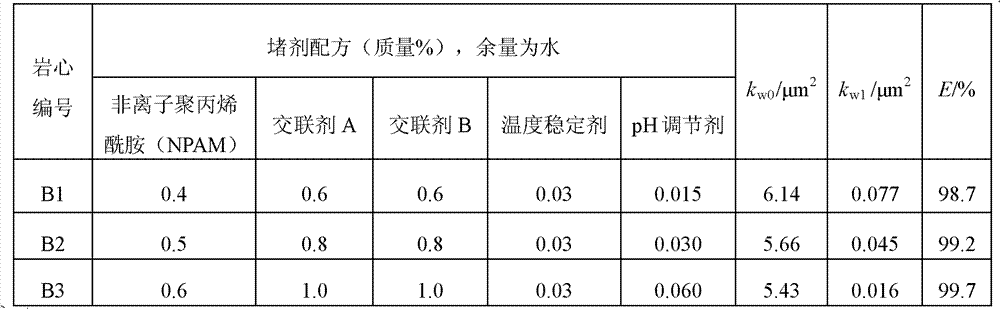

Gel plugging agent for deep profile control of higher temperature oil reservoir and preparation method of gel plugging agent

ActiveCN102807849BImprove heterogeneityExpand the affected volumeDrilling compositionSodium bicarbonateCross-link

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Composite material, wafer holding member and method for manufacturing the same

InactiveUS7381673B2Higher vacuum gas-tightnessImprove thermal conductivityLiquid surface applicatorsSolid-state devicesThermal expansionUltimate tensile strength

A composite material according to the present invention, is composed of SiC, SiO2, at least one out of Al and Si, with He leak rate of 1.3×10−10 Pa·m3 / sec or below, thereby providing a composite material, which has a higher vacuum air-tightness, an excellent thermal conductivity, an adjustable coefficient of thermal expansion, small variation in strength and higher reliability, and a method for manufacturing the composite material, and a wafer holding member including the composite material.

Owner:KYOCERA CORP

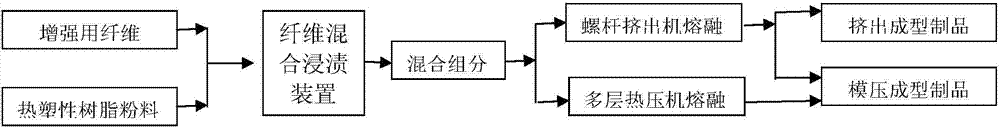

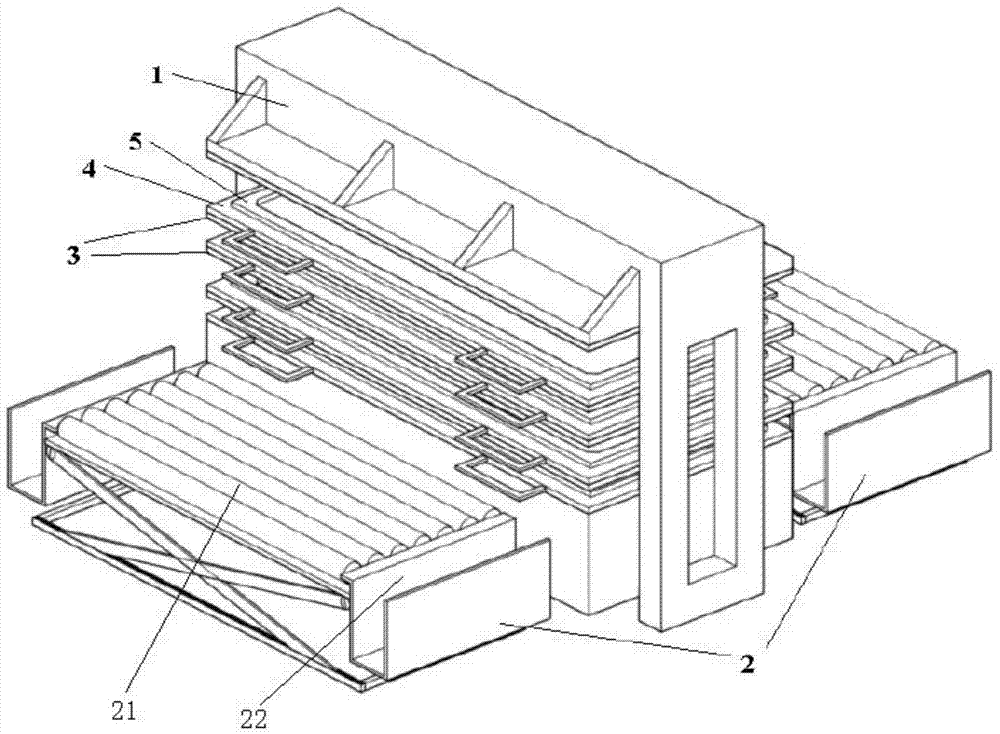

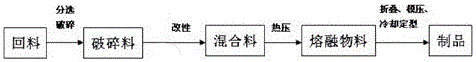

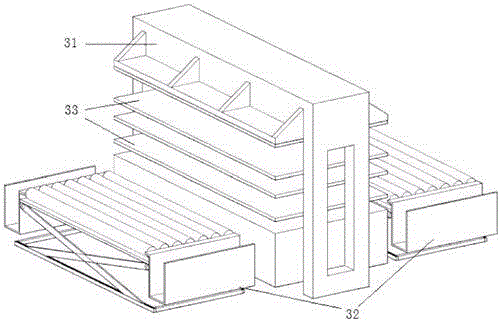

Preparation method of fiber-reinforced thermoplastic product

The invention relates to a preparation method of a fiber-reinforced thermoplastic product. The preparation method comprises the following steps: (1) thermoplastic resin powder and reinforced fibers are mixed by a mixed dipping device; and (2) the mixture is molten through hot pressing or extrusion, and is pressed and cooled to obtain a molded product. The preparation method uses the reinforced fibers and recovered wastes, so that the raw materials are environment-friendly and low in cost, and no secondary pollution is generated; and the molded product is light in mass and high in strength, can be recycled, has wide purposes in industry, and has higher economic and social values.

Owner:NINGBO HUAYE MATERIAL TECH

Pretreatment method used before processing fast growing wood surface concave-convex textures

InactiveCN102785274ANo reduction in strengthLittle change in intensityWood impregnation detailsSolid woodPaulownia

The invention relates to a pretreatment method used before processing fast growing wood surface concave-convex textures, wherein a purpose of the present invention is to overcome serious influence on strength and stiffness of fast growing wood due to traditional wood pretreatment chemical reagents such as strong acids and strong bases. The present invention provides a scheme for carrying out a softening pretreatment on Chinese redwood, paulownia, and pinus massoniana lamb by using a NH3.H2O solution separately providing an effect, wherein the Chinese redwood is treated for 2 hours at a temperature of 10 DEG C by using a 3% NH3.H2O solution, the paulownia is treated for 2 hours at a temperature of 30 DEG C by using a 2% NH3.H2O solution, and the pinus massoniana lamb is treated for 2 hours at a temperature of 30 DEG C by using a 2% NH3.H2O solution. The pretreatment method of the present invention has the following advantages that: strength of fast growing wood pretreated by the pretreatment process of the present invention is not significantly reduced; with processing, decorative solid wood boards with a large breadth and natural texture concave-convex effects are obtained; the product can be widely used in interior decorations and furniture manufacturing decorations; a new approach is developed for application of fast growing wood in engineering and industrial wood fields; no secondary pollution is generated, cost is low, and the processing method is easy to popularize.

Owner:NANJING FORESTRY UNIV

Seamless steel pipe alloy steel with moisture and seawater corrosion resistance and steel pipe working process

InactiveCN1580309AImprove mechanical propertiesLittle change in intensityMetal rolling arrangementsSteel tubeSeawater

This invention is technics about a special kind of alloy steel and its tube machining. The chemical components of the alloy steel are C0.06-0.10, Si0.20-0.50, Mn0.30-0.60, Cr0.80-1.20, Al0.40-0.80, Mo0.25-0.35, S<=0.015, P<=0.025, and Fe is the rest. The technics successfully solve the moist and seawater erode problems which the regular seamless steel used in heat exchanger can't deal with and prolong the equipment life-span, meanwhile it reduces manufacturing cost and saves alloy resources.

Owner:TIANCHANG CITY SEAMLESS STEEL PIPE FACTORY ANHUI TIANDA ENTERPRISE GROUP

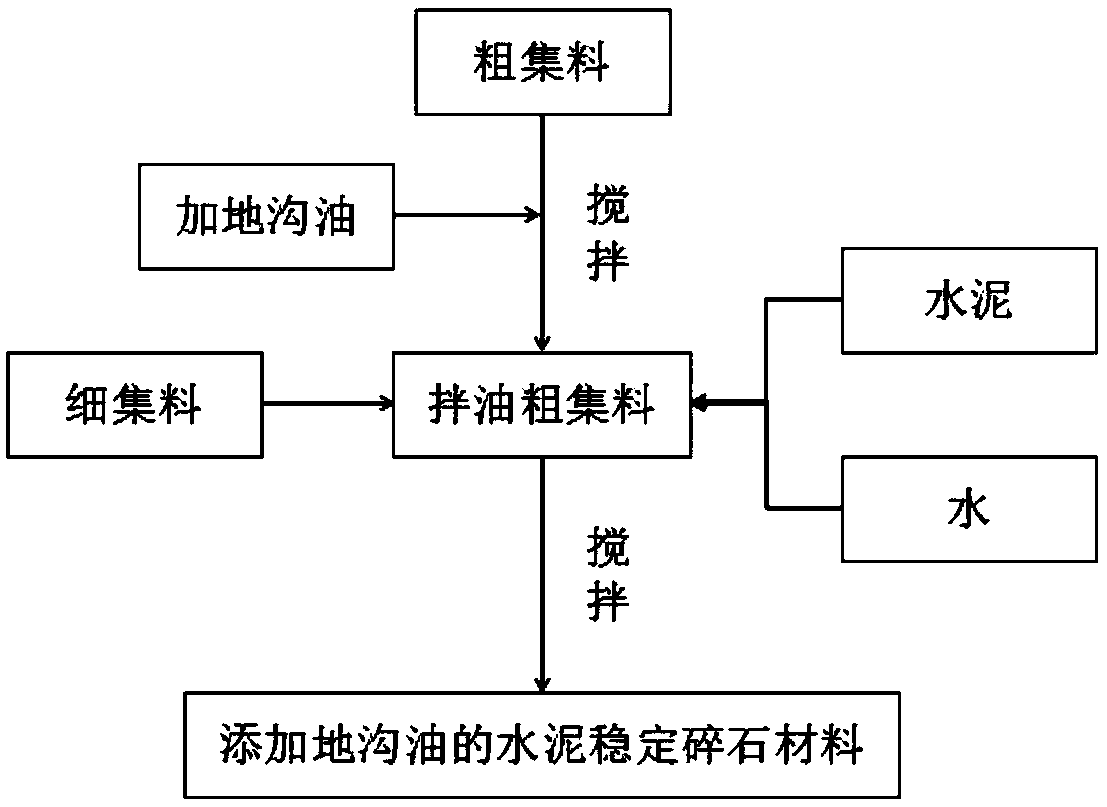

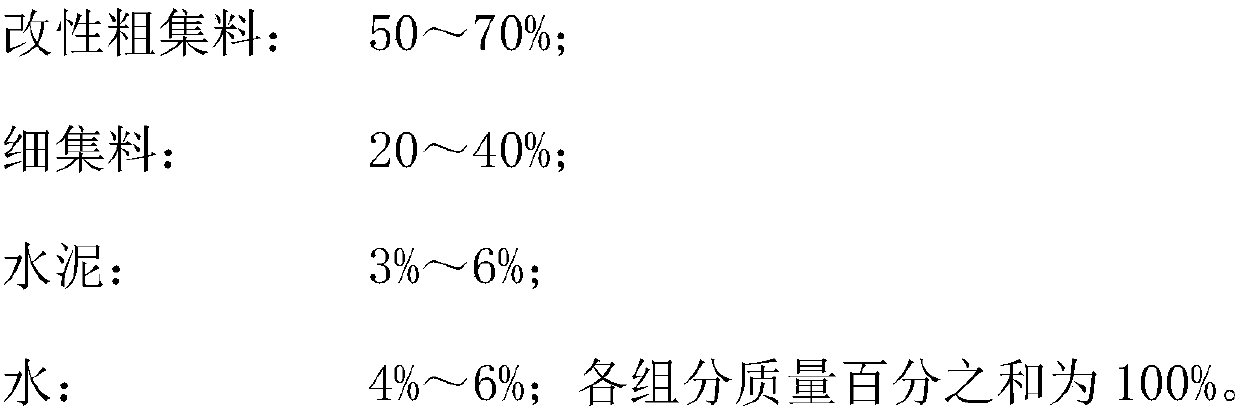

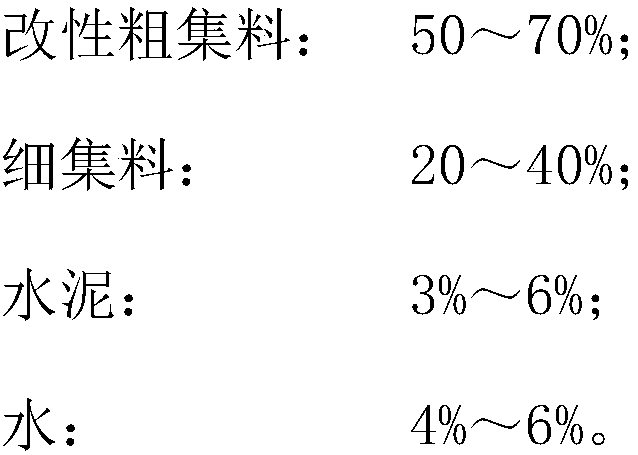

Cement stabilized macadam material added with illegal cooking oil and preparation method

The invention discloses a cement stabilized macadam material added with illegal cooking oil and a preparation method. The material is prepared from the following ingredients in mass percent: 50 to 70%of modified coarse aggregate, 20 to 40% of fine aggregate, 3 to 6% of cement and 4 to 6% of water, wherein the mass percent sum of all the ingredients is 100%, the modified coarse aggregate is prepared by evenly stirring coarse aggregate and pretreated illegal cooking oil, and the mass percent of the pretreated illegal cooking oil in the coarse aggregate is 0.8 to 1.3%. The preparation method comprises the steps: evenly stirring the illegal cooking oil and the coarse aggregate, then adding the fine aggregate, the cement and the water to be stirred and evenly mixing to obtain the cement stabilized macadam material. Compared with a structural layer of a general semi-rigid base material of the same grade, strength of a structural layer of the cement stabilized macadam material added with theillegal cooking oil disclosed by the invention is slightly reduced, rigidity is remarkably reduced, base cracking and reflection crack generation are effectively reduced, and pavement performance isgood.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Steel tube with low temperature resistance and high strength and production method thereof

InactiveCN101709433AImprove performanceLow tensile strengthTemperature control deviceWeather resistanceHeating time

The invention discloses a steel tube with low temperature resistance and high strength and a production method thereof. The steel tube comprises the following alloy components in percentage by weight: C, 0.16-0.20; Si 0.40-0.50; Mn, 1.40-1.60; V, 0.02-0.15; Nb, 0.02-0.06; Ti, 0.02-0.025; Cr, not more than 0.20; Ni, not more than 0.20; P, not more than 0.025; S, not more than 0.015; Mo, not more than 0.10; and the balance of Fe. The components are used as raw materials and subject to steel bloom, perforation, tube rolling and hot sizing to obtain sulphur-resistant oil well pipes, wherein the heating temperature in the perforation working procedure is 1,100-1,300 DEG C and the heating time is 55 minutes; and in the hot sizing working procedure, steel tubes the steel outlet temperature of which is above 800 DEG C are ensured to be subject to air cooling. The invention solves the problems that No. 20 seamless steel tubes have low strength and 16Mn No.20 seamless steel tubes have low low-temperature and poor weather resistance.

Owner:崔永贵

Rolling and hot melting process of producing integral plastic draining belt for reinforcing soft foundation

The rolling and hot melting process of producing integral plastic draining belt for reinforcing soft foundation includes the following steps: extruding stoved and mixed core material in an extruder to form plate; rolling and setting the plate in a core plate rolling and setting apparatus to form draining channel filter element with toothed ribs; combining the core plate and filtering cloth in a drawing apparatus; hot melting to compound the core plate and filtering cloth in a hot rolling apparatus to form one integral; cutting into required width and marking length size in a cutting and printing apparatus; and winding onto roll. The present invention has high integral structure strength, environment friendship, high acid and alkali corrosion resistance, excellent long term work state and other advantages.

Owner:HOHAI UNIV

High-strength semi-trailer shaft tube and production method thereof

The invention discloses a high-strength semi-trailer shaft tube and a production method thereof. The alloy components of a steel tube contain 0.23 to 0.25 wt% of C, 0.15 to 0.30 wt% of Si, 1.30 to 1.45 wt% of Mnl, no more than 0.030 wt% of P, no more than 0.035 wt% of S, no more than 0.01 wt% of Al, no more than 0.025 wt% of Cu, not more than 0.25 wt% of Ni, no more than 0.25 wt% of Cr, no more than 0.15 wt% of Mo and the balance of ferrum. A sulfur-resistant oil well tube is obtained after billet fabrication, perforation, tube rolling and hot coining are performed on the components as raw materials, wherein the heating temperature is from 1100 to 1300DEG C and the heating time is 55 minutes in the process of perforation; the air cooling is ensured at the tapping temperature higher than 900DEG C after coining in the coining process. The invention overcomes the defect that the strength and toughness of a trailer shaft tube made of 45# and 20Mn2 steel can not meet the requirements.

Owner:崔永贵

Preparation method of automotive interior part leftover material molded part

InactiveCN106079163AWide range of usesSimple processPlastic recyclingMechanical material recoveryPollutionMaterials science

The invention relates to a preparation method of an automotive interior part leftover material molded part. The method comprises the following steps: (1) crushing reclaimed automotive interior part leftover materials; and (2) hot-pressing, melting and cooling the crushed materials to obtain the molded product. According to the method, the molded product is prepared from the automotive interior part leftover materials, the raw materials are friendly to environment, low in cost and free of secondary pollution, and the molded product is light in mass and high in strength, can be recycled, and has a wide industrial application range and high economic and social values.

Owner:NINGBO HUAYE MATERIAL TECH

Heat treatment method of TC25 alloy forge piece

InactiveCN112708839AReduce internal stressUniform structure of forgingAlloyUltimate tensile strength

The invention belongs to the technical field of metal heat treatment, and discloses a heat treatment method of a TC25 alloy forge piece. The method comprises the following steps of 1, heating the alloy forge piece to 30-40 DEG C below the beta phase transformation point, keeping the temperature for 1-4 hours, discharging, transferring and dispersing the forge piece within 120 seconds, and carrying out air cooling or air cooling; and 2, heating the alloy forge piece cooled to the room temperature in the step 1 to 540 DEG C, keeping the temperature for 6 h, and performing air cooling. According to the method, by referring to the structure evolution rule of the TC25 alloy in the heat treatment process, the heat treatment systems of different structure states are fully considered, and the original beta grain size and secondary alpha phase sheet layer bundling are adjusted, so that the strength of the forged piece is improved, and the plasticity is improved.

Owner:SHAANXI HONGYUAN AVIATION FORGING

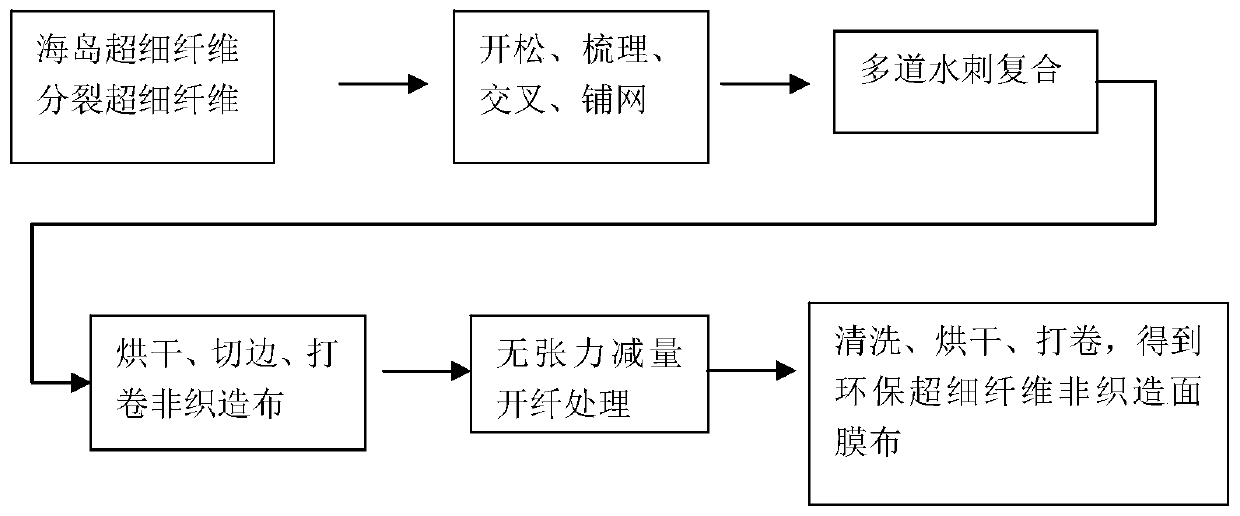

Environmentally-friendly superfine fiber non-woven facial mask cloth and making method thereof

InactiveCN109722791AGood mechanical and physical propertiesSkin-friendlyFibre treatmentNon-woven fabricsEnvironmentally friendlyTextile

The invention relates to the technical field of non-woven clothes, in particular to an environmentally-friendly superfine fiber non-woven facial mask cloth and a making method thereof. Sea-island typeand splitting type super-thin short fibers are mixed according to a proportion, carded and laid into a fiber net with a uniform gram weight, a matched non-woven spunlaced composite strengthening technology is used for forming a composite spunlaced non-woven cloth, and the non-woven cloth is used for making the environmentally-friendly superfine fiber non-woven facial mask cloth according to a tension-free fiber splitting technology. The environmentally-friendly superfine fiber non-woven facial mask cloth has the advantage of being well attached and being skin-friendly.

Owner:杭州海拓皮革有限公司

Ultra-branched polymer used as polythene processing auxiliary agent and synthetic method

ActiveCN100551943CReduce melt viscosityReduce machining torquePolymer scienceAtom-transfer radical-polymerization

The invention relates to a hyperbranched polymer that can be used as a polyethylene processing aid and a synthesis method thereof, in particular to a hyperbranched polymer composed of high-carbon alcohol acrylate and styrene and its use of atom transfer radical polymerization synthetic method. The present invention first synthesizes the hyperbranched polymer (parts by weight) through the following formula: p-chloromethylstyrene 1, styrene 6.84~13.68, lauryl acrylate 7.88~23.64, bipyridine (Bpy) 0.21~0.63, chlorine Cuprous chloride (CuCl) 0.065-0.196, the above components are vacuumized, filled with argon or nitrogen for more than 5 times, sealed and then reacted at 100-130°C for 4-12 hours under magnetic stirring. The product is dissolved in acetone and oxidized Filter through an aluminum column, precipitate in ethanol, and dry under vacuum at 25-40°C for several hours to obtain a hyperbranched polymer. Compared with pure HDPE, the melt viscosity of the present invention is obviously lowered, and the tensile performance test shows that its strength changes little.

Owner:溧阳常大技术转移中心有限公司

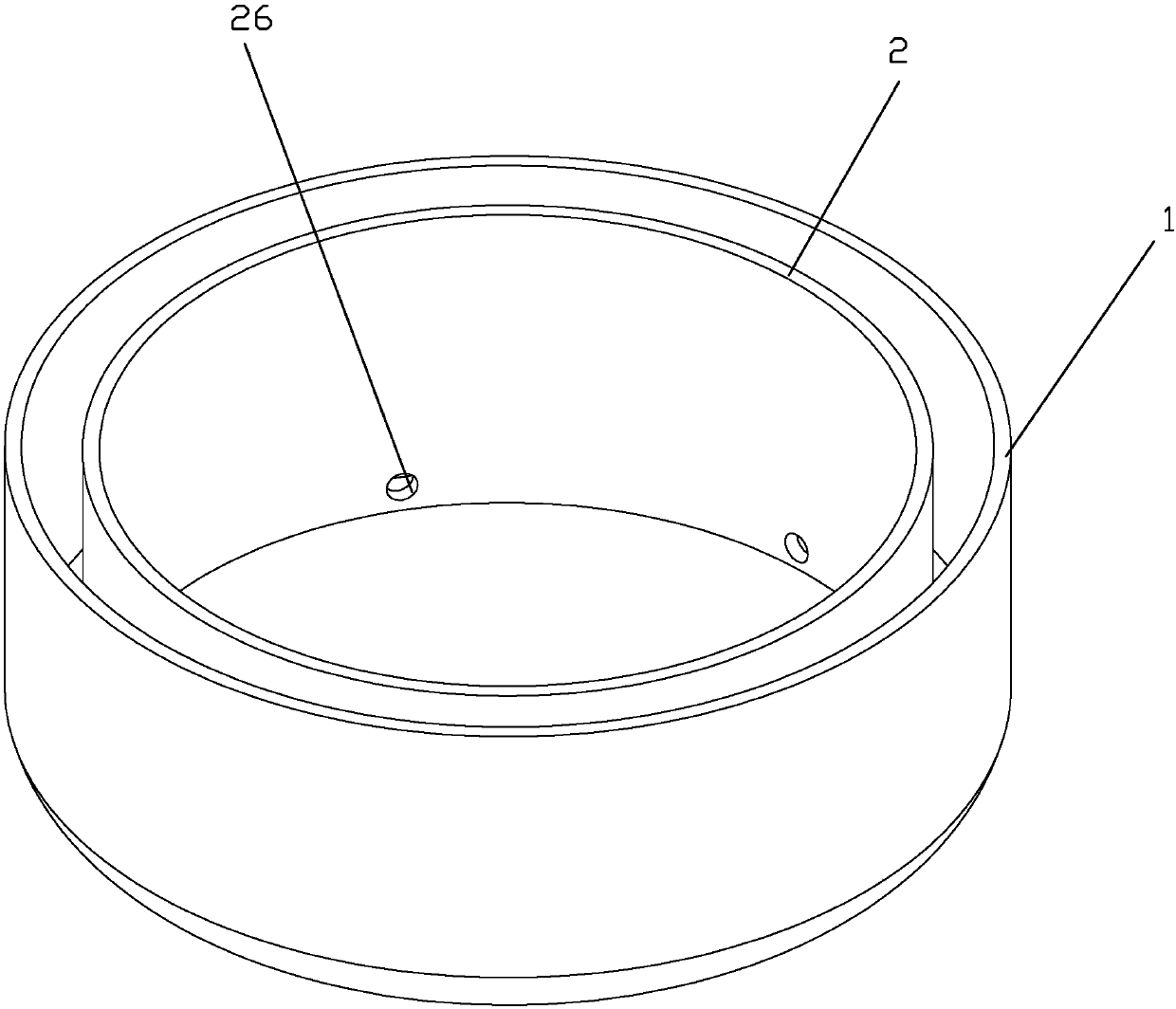

Combined type quartz crucible for monocrystalline silicon growth and preparation method thereof

PendingCN109097824ASave electricity and labor costsIncrease production capacityPolycrystalline material growthBy pulling from meltMonocrystalline siliconFiber

The invention relates to a combined type quartz crucible for the monocrystalline silicon growth and a preparation method thereof. The combined type quartz crucible comprises an outer crucible body ofthe crucible and an inner cylinder body of the crucible, wherein the outer crucible body of the crucible comprises an outer cylinder part and a crucible bottom, and the inner cylinder body of the crucible is composed of a carbon fiber sintering cylinder and a quartz sintering material arranged around the carbon fiber sintering cylinder. The quartz sintering material is an integrated piece formed by sintering quartz powder covering the carbon fiber sintering cylinder. The carbon fiber sintering cylinder is tubular fabric vertically penetrating therethrough and formed by weaving and sintering acarbon fiber. When the quartz crucible is in use, the inner cylinder body of the crucible is arranged in the outer crucible body of the crucible, and the outer crucible body of the crucible is dividedinto inner and outer areas of a crystal growing area and feeding and melting area. The combined type quartz crucible for the monocrystalline silicon growth and the preparation method thereof have theadvantages that the structure is simple, impurities can be separated, it can be achieved that feeding, material melting, crystal growing and impurity separation are carried out simultaneously, and the continuous working time is long under the high-temperature environment.

Owner:常州市永达五金工具厂

Model test foundation soil and preparation method thereof

InactiveCN104215487AShort time spentShorten test timePreparing sample for investigationTested timeEngineering

The invention relates to model test foundation soil and a preparation method thereof, and belongs to the field of building and civil engineering. The model test foundation soil consists of powdered bentonite and glycerinum. The preparation method comprises the following steps of determining a mass ratio of bentonite to glycerinum needed by a model test through vane shear tests, uniformly and adequately mixing the bentonite and the glycerinum by utilizing a kneading civil engineering stirrer according to the acquired mass ratio so as to obtain a mixture, compacting the mixture by utilizing a drop hammer, and enabling the glycerinum to be adequately filled in gaps among bentonite particles. The foundation soil not only has the physical and mechanical properties similar to naturally formed soil, but also relatively stable in character; compared with the naturally formed soil, when the foundation soil achieves the steady non-water-discharging shear strength, the consumed time is relatively short, and the test time is reduced; the foundation soil does not need to be solidified in the test, has no volatility and can be reused, the waste of test materials can be avoided, the strength of the foundation soil before and after the model test is slightly varied, and the problem that the strength is improved due to excessively fast water discharging in the model test process can be avoided. The production process is simple, the simplicity and the easiness in implementation can be achieved, and the applicability is wide.

Owner:TONGJI UNIV

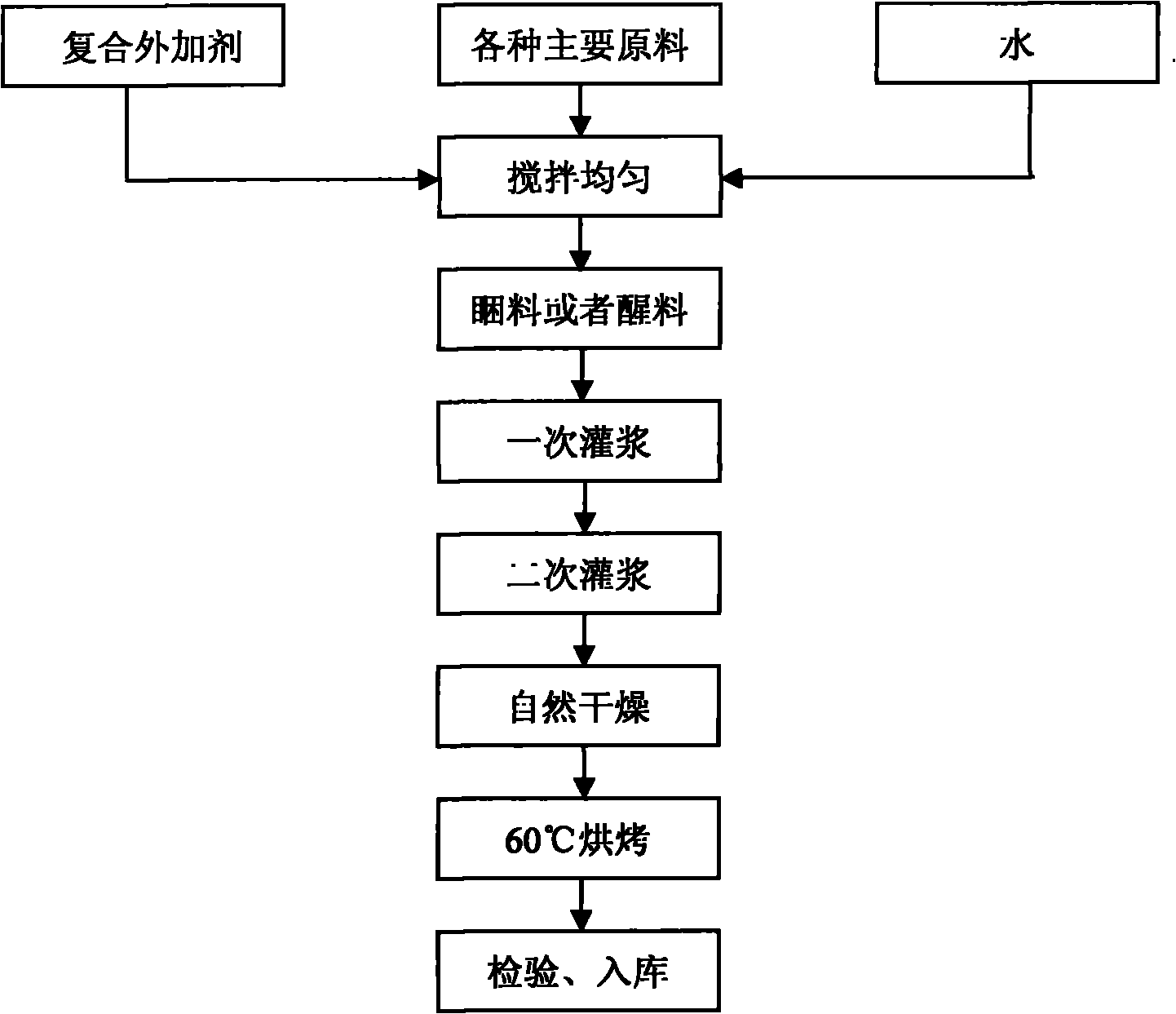

Early-strength quick-drying refractory mud filling material with good insulativity

The invention discloses an early-strength quick-drying refractory mud filling material with a good insulativity. The filling material is prepared through the following steps: adding water in 100 parts of main raw material and 1-10 parts of composite additives, mixing, ageing mixture or fermenting, grouting, naturally drying and baking, wherein the main raw material is a mixture of sintered mullite, quartz sand powder, alumina micropowder and pure calcium aluminate cement; and the composite additives are lignosulfonate, sodium carboxymethylcellulose and one substance or a mixture of two substances selected from subnano alumina micropowder with a grain size of 0.25-0.50 mu m, silicon micropowder with a grain size of 1-2 mu m, sodium tripolyphosphate, sodium hexametaphosphate and sodium polyphosphate. The filling material has good properties such as good early strength, rapid consolidation speed, no moisture regain and good insulativity, dose not corrode metals, can be widely applied to a metallurgy smelting high temperature sensor and a rapid temperature-measuring element to be used as an insulation material.

Owner:马鞍山江润冶金有限责任公司

Novel expansion filling material and preparation method thereof

The invention relates to a novel expansion filling material and a preparation method thereof, and the novel expansion filling material comprises the following main components: a cementing material, mine tailings, an expanding agent and a stabilizer, the novel expansion filling material comprises the following components in percentage by mass: 6.71%-13.65% of slag 325 # cement, 50.09%-54.58% of mine tailings, 26.84%-33.42% of filling water, 6.38%-9.64% of an expanding agent and 2.16%-3.25% of a stabilizer which is preferably methyl cellulose ether, the cementing material is preferably selected from one or more of ordinary Portland cement, Portland slag cement, Portland pozzolana cement, Portland fly ash cement and composite Portland cement. Compared with the prior art, the novel expansion filling material and the preparation method have the beneficial effects that the strength change of the novel expansion filling material is small, the phenomenon of volume instability is avoided after long-term filling, and the novel expansion filling material is used for filling a goaf with the same volume and needs less cementing materials, so that the filling cost is reduced.

Owner:LANZHOU ENG & RES INST OF NONFERROUS METALLURGY

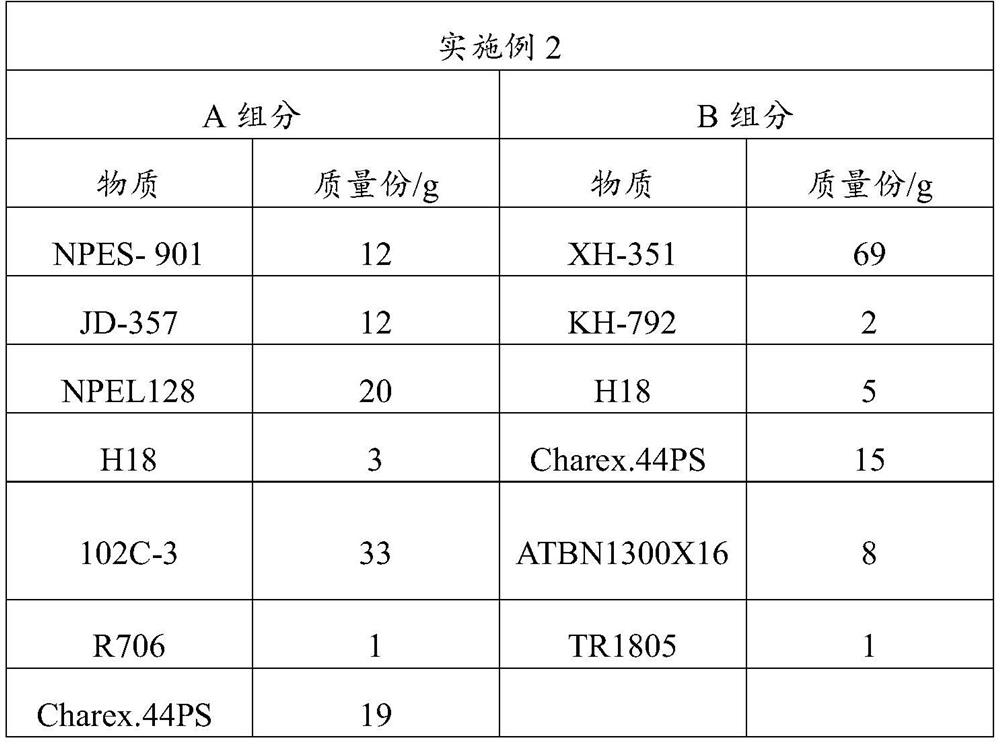

High-toughness bi-component epoxy structural adhesive and preparation method thereof

PendingCN112680156AMeet needsReduce defectsNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive

A high-toughness double-component epoxy structural adhesive comprises a component A and a component B which are mutually independent, the component A comprises 30-70 wt% of epoxy resin, 10-20 wt% of an active diluent, 0-15 wt% of an active toughening agent, 10-30 wt% of a filler and 1-5 wt% of an auxiliary agent, and the component B comprises 60-90 wt% of a curing agent, 3-10 wt% of an active toughening agent, 1-5 wt% of a coupling agent, 1-8 wt% of an auxiliary agent and 10-20 wt% of a filler. The component A and the component B are mixed according to the volume ratio of 1: (0.8-1.2) to obtain the high-toughness double-component epoxy structural adhesive. The component A and the component B of the structural adhesive are long in independent storage period, after the component A and the component B are mixed, the curing rate is low, heat release is stable, volume shrinkage is small, formed colloid defects are few, the epoxy structural adhesive obtained through mixing is quite excellent in toughness, T peel strength, impact peel strength and lap joint shear strength for metal bonding, and after curing, a sea island structure is formed, so that the structural adhesive has excellent impact resistance.

Owner:重庆德天汽车新材料研究院有限公司

A crack-resistant, steam-cured, ultra-high-strength, high-toughness concrete and its preparation method

The invention discloses anti-cracking steam-curing-free ultra-high-strength high-toughness concrete. The anti-cracking steam-curing-free ultra-high-strength high-toughness concrete is prepared from cement, fly ash, silica fume, a mineral activator with cementing property, gravel, river sand, steel fibers, a polymer emulsion, water and a shrinkage-reducing super-dispersing admixture, wherein the mineral activator with cementing property comprises waste prefabricated concrete set cement crystal seeds and desulfurized gypsum. By using the mineral activator with cementing property in the concrete, high-temperature steam curing and pressurized steam curing systems adopted in the ordinary ultra-high-performance concrete are eliminated; and the shrinkage-reducing super-dispersing admixture having the functions of super-dispersing cement, reducing shrinkage, decreasing viscosity and the like is adopted to enable the hydration activity of cement to give a full play so that the strength of the concretes has no obvious change after cement usage is decreased by about 10%; and meanwhile, the mineral activator and the admixture can effectively suppress the shrinkage of concrete. The concrete prepared by the preparation method is higher in strength, toughness and shrinkage resistance, low in cost and simple in preparation method and has important practical application value.

Owner:WUHAN UNIV OF TECH

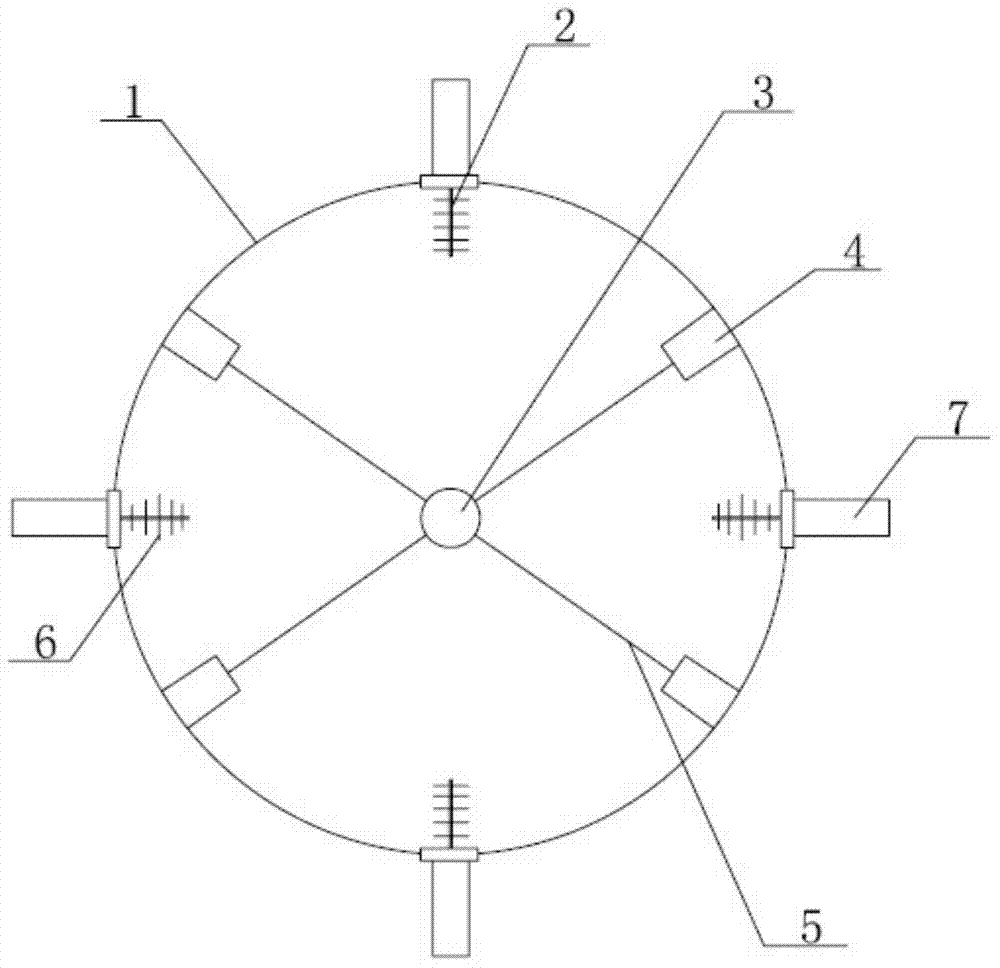

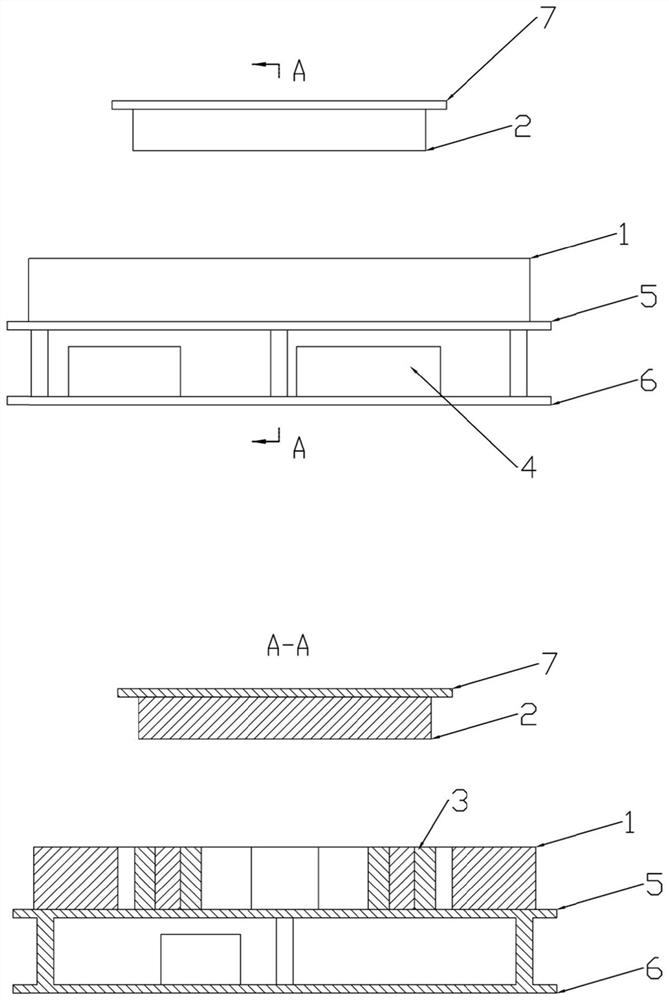

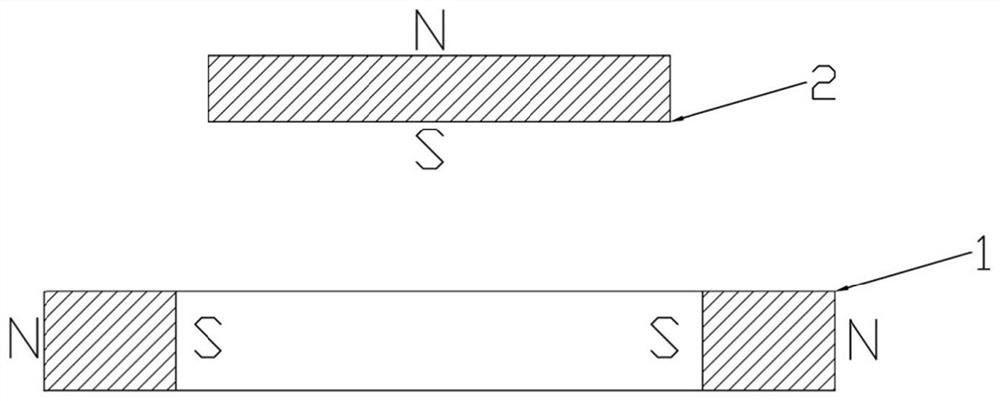

Magnetic suspension device

PendingCN114553056AStrong magnetic repulsionLarge suspension heightMagnetic holding devicesMagnetic polesMagnetic polarity

The invention discloses a magnetic suspension device which comprises a base module, a suspension module and a control module. The base module comprises a first magnet which is magnetized in the radial direction. The suspension module comprises a second magnet which is axially magnetized; the inner side of the first magnet shows a first magnetic polarity, the outer side of the first magnet shows a second magnetic polarity, and the first magnetic polarity is opposite to the second magnetic polarity; the upper surface of the second magnet shows a third magnetic polarity, the lower surface of the second magnet shows a fourth magnetic polarity, and the third magnetic polarity is opposite to the fourth magnetic polarity; the suspension module can suspend above the base module; and the control module is used for keeping the suspension module to suspend stably. The invention has the advantages of strong suspension force, good suspension stability and the like.

Owner:DEEP MAGNETIC TECH SHENZHEN CO LTD

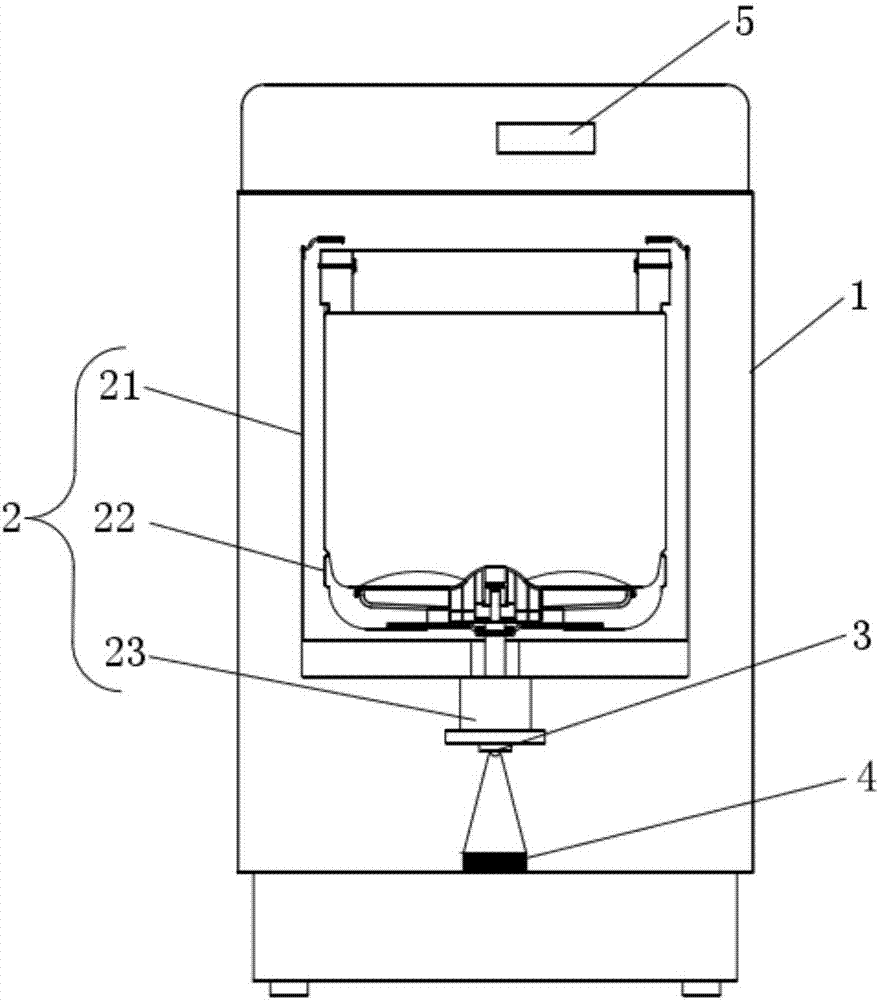

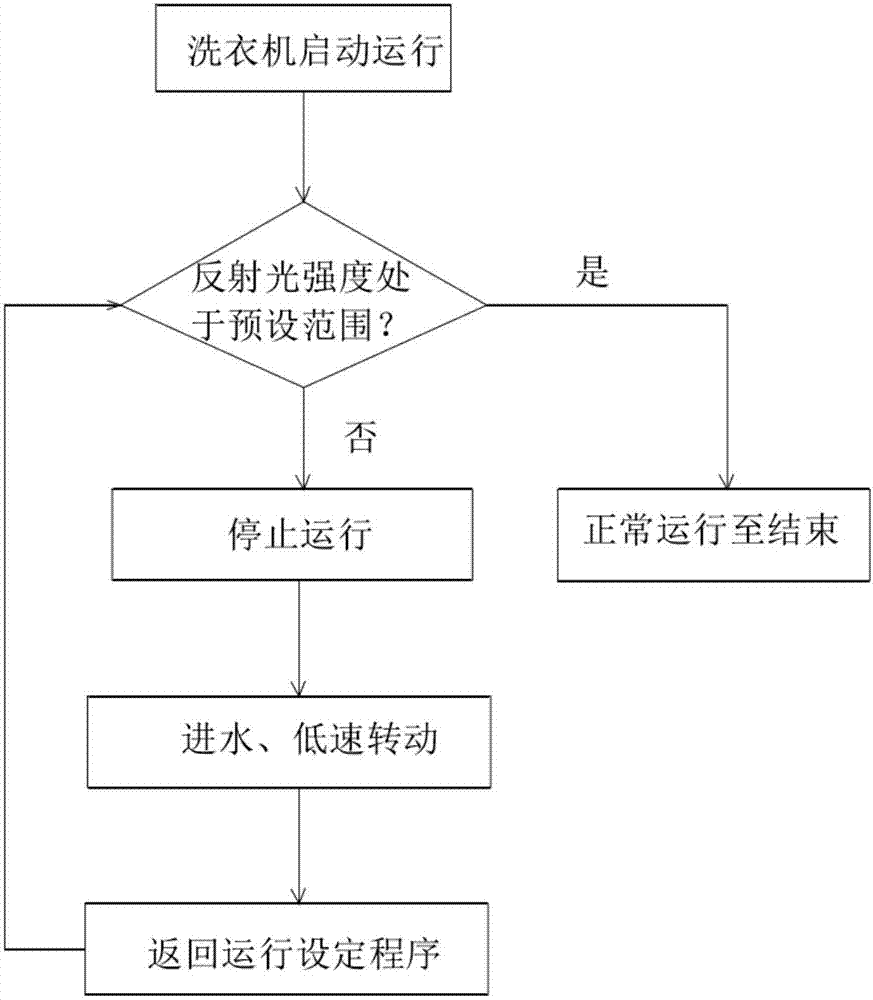

Washing machine and vibration imbalance detecting method thereof

ActiveCN107419479ALittle change in intensityJudgment of vibration imbalanceOther washing machinesTextiles and paperThree-dimensional spaceEngineering

The invention relates to the technical field of washing machines and discloses a washing machine and a vibration imbalance detecting method thereof. The washing machine comprises a box body and a bucket assembly, wherein a light-emitting element is arranged on one of the bottom of the box body and the bottom of the bucket assembly, a reflection element corresponding to the light-emitting element is arranged on the other of the bottom of the box body and the bottom of the bucket assembly, the light-emitting element is used for emitting light at a set angle, and the reflection element is used for reflecting light back to the light-emitting element. The light-emitting element is also connected with a controller, and the controller is used for judging vibration imbalance of the washing machine and controlling the washing machine to stop operating when the strength of the reflected light received by the light-emitting element exceeds a preset range. The space position change between the light-emitting element and the reflection element can be judged by detecting the intensity of the reflected light received by the light-emitting element, accordingly the vibration imbalance situations of the washing machine in all directions in a three-dimensional space are accurately and flexibly detected, detection blind points are effectively decreased, and the damage caused by range-exceeding vibration to the washing machine is avoided.

Owner:NANJING CHUANGWEI HOUSEHOLD ELECTRONICS APPLIANCES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com