Preparation method of automotive interior part leftover material molded part

A technology for automotive interior parts and molded products, which is applied in the field of waste recycling and preparation of automotive interior parts, can solve the problems of pollution and high cost, and achieve the effect of simple process, light weight and large loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

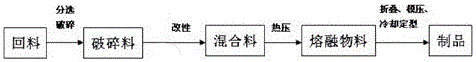

[0037] See Figure 1 to Figure 6 , A method for preparing molded products of automotive interior trim trimmings, comprising:

[0038] (1) Crush the reclaimed leftover materials of automobile interior trim parts to obtain crushed materials;

[0039] (2) The crushed material is heated, melted, and molded, cooled and shaped to obtain a molded product.

[0040] In the step (1), the leftover material of the automobile interior decoration parts is one or two of light-weight GMT and polypropylene hemp felt board.

[0041] In the step (1), the leftover material is thrown into a crusher with a screen mesh diameter of 10mm-40mm for crushing.

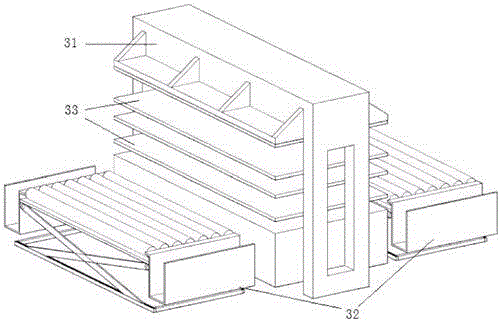

[0042] In the step (2), the temperature of the heating and melting molding is 210-230° C., the mold is put into the heating and melting multilayer molding device, and the molten material is folded and put into the press mold for compression molding.

[0043] The structure of the heating and melting molding die includes a metal sizing frame 10 and a release ...

Embodiment 1

[0047] (1) Put the leftover materials of lightweight GMT automotive interior trim parts into a crusher with a screen with a diameter of less than 20mm to obtain crushed materials with a diameter of less than 10mm.

[0048] (2) Weigh 17.5 kg of crushed material and spread it evenly on the heating and melting molding die (lower plate: 3mm stainless steel plate; lower release cloth: 0.65mm thick Teflon cloth; iron frame: length 1900mm*width 800*height 8mm ; Upper release cloth: 0.65mm thick Teflon cloth), such as Figure 4 with 5 Shown.

[0049] (3) Put the mold into the heating and melting multilayer molding device (such as figure 2 As shown), heat for about 10 minutes to make the material temperature reach 220°C, turn on the heating press, uncover the upper and lower release cloth, remove the mold, fold the heated and melted material around to less than the size of the mold, and then put the material in In the 850*850*20mm mold, a closed mold press is used for compression molding, ...

Embodiment 2

[0052] (1) Put the leftovers of light-weight GMT automotive interior trim parts into a crusher with a screen with a diameter of less than 30mm to obtain crushed materials with a diameter of 20mm.

[0053] (2) Put the leftover material of polypropylene fiber felt car interior trim parts into a crusher with a diameter of less than 30mm to crush the material to obtain a material with a diameter of less than 20mm.

[0054] (3) Weigh 17 kg of the mixed materials and spread them evenly on the heating and melting molding die (12mm thick plywood for the lower plate; lower release cloth: 0.65mm thick Teflon cloth; iron frame: length 1900mm*width 1000mm*height 8.5mm; upper release cloth: 0.65mm thick Teflon cloth).

[0055] (4) Put the mold into the heating and melting multi-layer molding device and heat for 9 minutes to bring the material temperature to 225°C, turn on the heating press, uncover the upper and lower release cloth, remove the mold, and fold the material to be smaller than the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com