Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Improve performance pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for producing thin gauge pipeline steel by using double-stand medium and heavy plate mill

ActiveCN102671941AGuaranteed Dynamic RecrystallizationImprove lateral performanceTemperature control deviceWork treatment devicesMetallurgyLaminar cooling

The invention discloses a process for producing thin gauge pipeline steel by using a double-stand medium and heavy plate mill. A plate blank with the thickness of 180 mm is used for producing the thin gauge pipeline steel with the thickness less than 10 mm. On the basis that the performance of a rolled piece meets requirements, the thin gauge pipeline steel with a good plate shape can be obtained by controlling the tapping temperature of the plate blank, the rough rolling broadening pass pressing rate, the longitudinal rolling pass pressing rate after rough rolling broadening pass, the rough rolling finishing temperature, the thickness of a middle blank, the finish rolling ending pass pressing rate, the finish rolling finishing temperature, the roller gap inclination and sled function in the rolling process, a high pressure water descaling system, the water entry temperature, the re-reddening temperature, and the head and tail shielding and straightening process of a laminar cooling system. The deformation rate is reduced, and the economic benefit is increased.

Owner:NANJING IRON & STEEL CO LTD

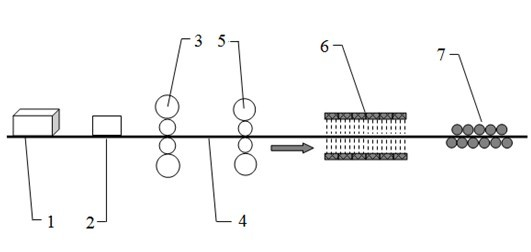

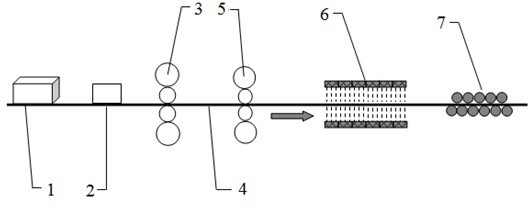

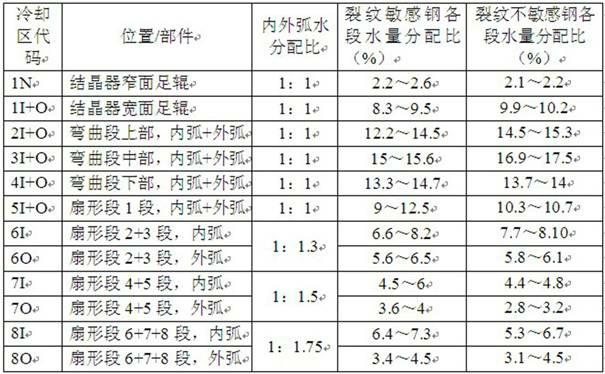

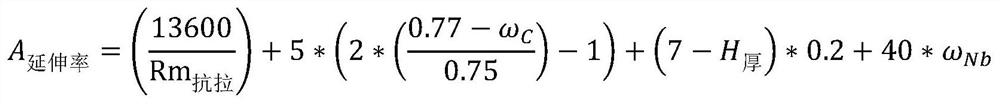

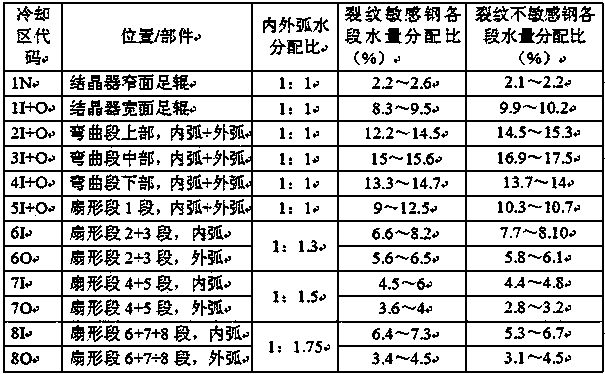

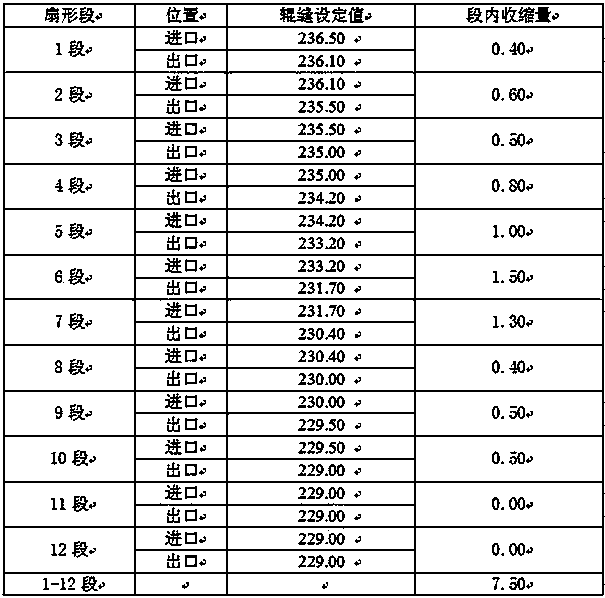

Method for adjusting secondary cooling water amount and roll gap value of double-flow slab casting machine

The invention discloses a method for adjusting the secondary cooling water amount and the roll gap value of a double-flow slab casting machine. In the double-flow slab casting machine, 12 cooling regions are formed for secondary cooling; 10 cooling water meters are provided; five grades, i.e., strong cooling: the secondary cooling water amount is 1.0-1.1 L / kg, medium cooling: the secondary cooling water amount is 0.8-0.9 L / kg, weak cooling: the secondary cooling water amount is 0.7-0.8 L / kg, medium-weak cooling: the secondary cooling water amount is 0.45-0.6 L / kg, and slight cooling: the secondary cooling water amount is 0.4-0.45 L / kg are divided to adapt to the cooling requirements of different types of steel respectively; the roll gap of a secondary cooling region support roll is consistent with the linear shrinkage rule of a casting blank from top to bottom, and decrease continually; and the roll opening between the outlet of a previous fan-shaped section and the inlet of a next fan-shaped section is kept consistent. By adopting the method, the internal cracking rate is lowered, the macrostructure of the casting blank is optimized, and the performance yield of steel is increased.

Owner:ANYANG IRON & STEEL

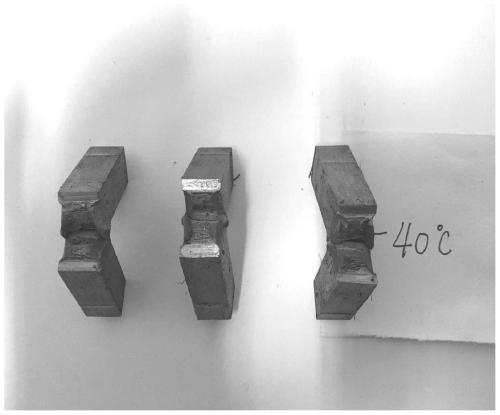

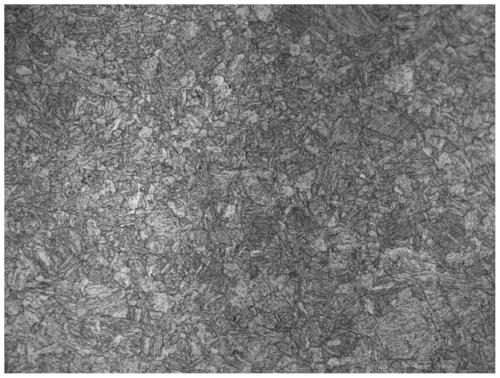

Process for improving rare-earth high-strength steel impact toughness

The invention discloses a process for improving rare-earth high-strength steel impact toughness. The process comprises the following steps of KR desulfurization slagging off, converter smelting, LF refining, RH refining and rare-earth treating, continuous casting, heating, rolling, accelerated cooling and heat treating. According to the process, aiming at the influence on the microstructure of low-alloy high-strength steel in the case that rare-earth exists, a research shows that rare-earth cerium Ce can improve the forms of inclusions and purify grain boundaries, so that the strength of the grain boundaries is improved, the possibility that cracks extend due to the through defects is reduced, and the impact toughness is improved; and addition, the impact toughness can be improved throughrefining austenite grain boundaries, and meanwhile, adding the rare-earth cerium Ce can enable the ductile-brittle transition temperature of the steel to reduce by about 10 DEG C.

Owner:BAOTOU IRON & STEEL GRP

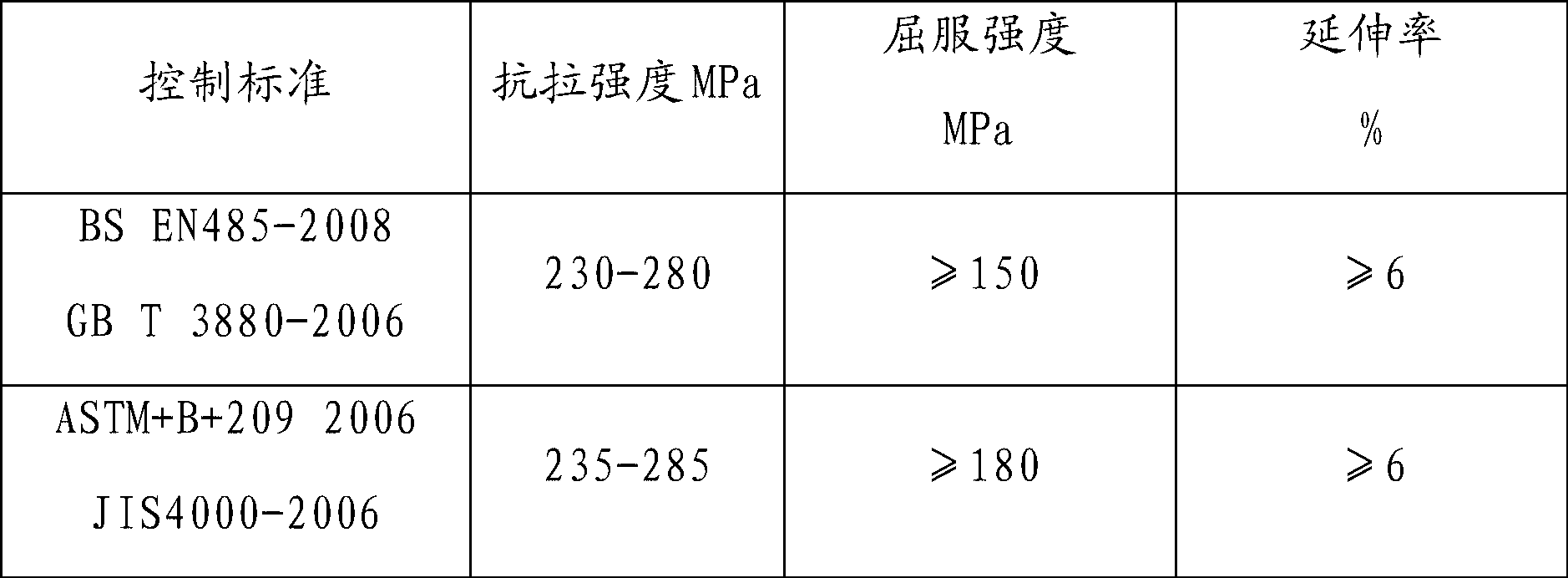

Production method of 5052-H34 aluminum alloy plate strip

The invention discloses a production method of a 5052-H34 aluminum alloy plate strip. The production method mainly comprises the following steps of: fusion casting, saw cutting, plane milling, heating, hot rolling, cold rolling, finished-product annealing and finishing; in the hot rolling step, the hot rolled coil thickness is reserved by 40-60 percent according to the thickness of a finished product, the finish rolling temperature during hot rough rolling is 430-450 DEG C, and the finish rolling temperature during hot finish rolling is 320-350 DEG C; and in the cold rolling step, the finished-product thickness is achieved through 1-pass or 2-pass of cold rolling, and the total working rate is 40-60 percent. According to the invention, with regard to the 5052-H34 product with the finished-product thickness of being more than or equal to 0.8mm, the working procedures of carrying out full annealing and intermediate annealing on a hot-rolled blank can be saved, the production flow can be shortened and the product cost is reduced.

Owner:ALUHOUSE TECHGD CO LTD

SA516Gr70 steel plate meeting high mold welding conditions and production method thereof

The invention discloses a SA516Gr70 steel plate meeting high mold welding conditions and a production method of the SA516Gr70 steel plate meeting the high mold welding conditions. The SA516Gr70 steel plate meeting the high mold welding conditions is composed of the following components including, by weight, 0.18%-0.21% of C, 0.20%-0.40% of Si, 1.10%-1.20% of Mn, not larger than 0.010% of P, not larger than 0.003% of S, 0.020%-1.20% of TAl, 0.015%-0.020% of Nb and the balance Fe and inevitable impurities. The production method comprises the working steps of rolling, water cooling and heat treatment. According to the working step of rolling, the II-type controlled rolling technology is adopted, and rolling is conducted through two stages. The SA516Gr70 steel plate meeting the high mold welding conditions and the production method of the SA516Gr70 steel plate meeting the high mold welding conditions aim to achieve that for different performance requirements and thickness specifications, corresponding internal control components and rolling and heat treatment technologies are determined, the performance yield of the steel plate is improved, the actual performance yield is not higher than 85% at present, and the performance yield is improved to be equal to or higher than 90% through tackling the key problem.

Owner:WUYANG IRON & STEEL

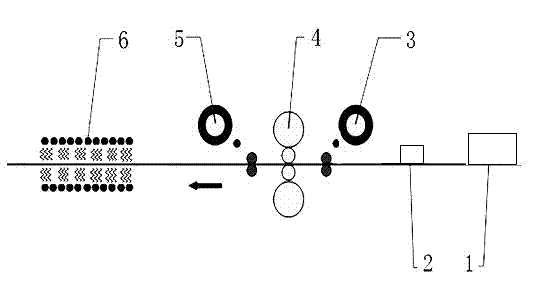

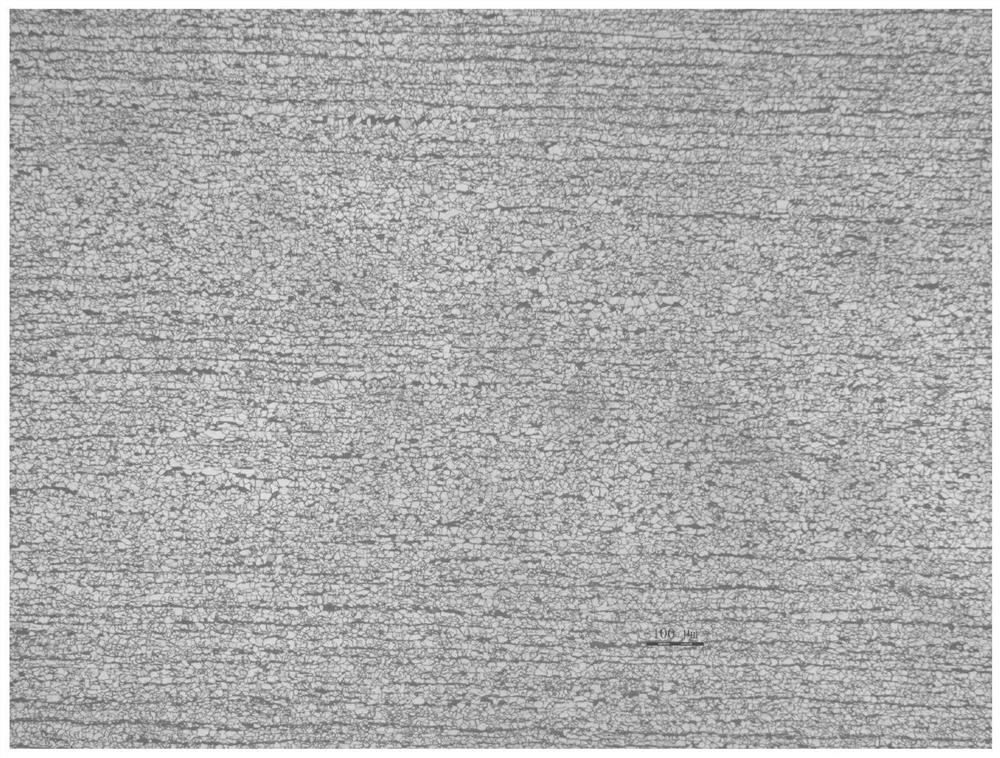

Control process for performances of steel plate during hot rolling and flat rolling process of single-stand steckel mill

ActiveCN102225432AGuaranteed uniform performanceSolve the problem of non-uniform longitudinal performanceTemperature control deviceMetal rolling arrangementsSheet steelStrip mill

The invention discloses a control process for performances of a steel plate during hot rolling and flat rolling process of a single-stand steckel mill, which is characterized in that the steel burning temperature at two ends of a heating furnace is 15-40 DEG C higher than that in the middle, the tail temperature of the billet is 10-25 DEG C higher than that at the head; on the procedure without adoption of the steckel mill for scale removal, an air purging system is started and no accumulated water is left on the surface during the rolling process; after a pyrometer detects that the temperature difference of a rolled piece is larger than 50 DEG C, the mill increases the steel throwing speed by an acceleration smaller than 0.02m / s<2>; after a pyrometer detects that the temperature difference of a rolled piece is larger than 30 DEG C, a laminar flow system automatically closes the last one to three groups of cooling water, so as to improve the temperature rise at the tail of the rolled piece and reduce the temperature rise difference of the rolled piece; and for a wide steel plate, a cooling system adopts edge shielding so as to remove temperature difference between the upper edge and the middle along the width direction. By adopting the process in the invention, the performance uniformity of the steel plate flatly rolled by the single-stand steckel mill can be ensured.

Owner:NANJING IRON & STEEL CO LTD

Method for medium plate of controlled rolling at two stages in non-recrystallization region

InactiveCN101954376AImprove deformationReduce generationTemperature control deviceMetal rolling arrangementsSheet steelHigh pressure water

The invention discloses a method for a medium plate of controlled rolling at two stages in a non-recrystallization region. The method is to perform two-stage rolling in a temperature range of the non-recrystallization region so as to improve the initial rolling temperature of rolling in the non-recrystallization region, and reduce the soaking time of an intermediate billet at high-temperature stage. The method comprises the following steps: the intermediate billet is immediately subject to first high pressure water descaling operation, when the intermediate billet is cooled to the temperature of the non-recrystallization temperature region, and then is subject to the first-stage rolling in the non-recrystallization region; the intermediate billet is subject to swing holding on the front or rear roller bed of a rolling mill; and the intermediate billet is subject to second high pressure water descaling operation after the billet is held to the set temperature, and then is subject to second-stage rolling in the non-recrystallization region to obtain the medium plate in accordance with the requirement. The method has few rolling passes and large total deformation of rolling in the non-recrystallization region, improves the output per hour, can stabilize the low-temperature impact performance of the steel plate, and improves the performance qualification rate.

Owner:NANJING IRON & STEEL CO LTD

Thick X42 pipeline steel and production method thereof

The invention discloses thick X42 pipeline steel and a production method thereof, and particularly relates to thick X42 pipeline steel and a production method thereof which are applied to the field of production of hot-continuous-rolled steel strips. The thick X42 pipeline steel low in production cost comprises, by weight, 0.03%-0.07% of C, 0.10%-0.30% of Si, 0.70%-1.00% of Mn, 0-0.020% of P, 0-0.010% of S, 0.015%-0.030% of Nb, 0.008%-0.019% of Ti, 0.15%-0.30% of Cr, and the balance Fe and inevitable impurities. The invention further provides the production method of the thick X42 pipeline steel. The production method of the thick X42 pipeline steel comprises the following steps of smelting and continuous casting, rough rolling, finish rolling, and double-section cooling. According to the thick X42 pipeline steel and the production method thereof, the production cost is relatively low, and the control difficulty is low.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

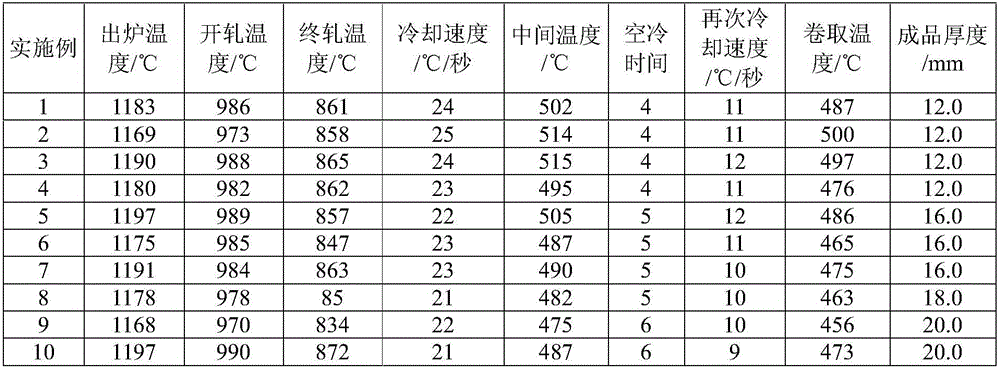

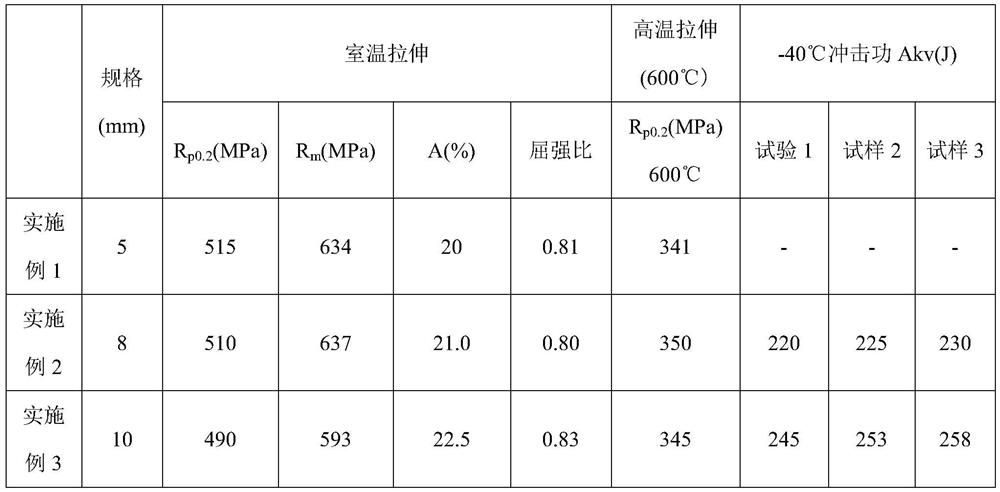

Hot-rolled thin-specification anti-seismic refractory steel plate with yield strength of 460 MPa and preparation method

The invention discloses a hot-rolled thin-specification anti-seismic refractory steel plate with the yield strength of 460 MPa. The steel plate comprises the following raw materials in percentage by mass: 0.03-0.09% of C, 0.10-0.40% of Si, 0.80-1.2% of Mn, less than or equal to 0.015% of P, less than or equal to 0.01% of S, 0.40-0.80% of Cr, 0.15-0.25% of Mo, 0.08-0.12% of Nb, 0.02-0.06% of V, 0.006-0.03% of Ti, 0.01-0.05% of Al, less than or equal to 0.0050% of N and the balance of Fe and inevitable impurity elements. The structure composition of the refractory steel is controlled, the production cost is reduced, the prepared thin-specification refractory steel plate has good room-temperature strength, high elongation, excellent subzero 40 DEG C low-temperature impact toughness and excellent 600 DEG C high-temperature tensile property, the production and manufacturing difficulty of the thin-specification anti-seismic refractory steel is reduced, and the performance qualification rate is increased.

Owner:NANJING IRON & STEEL CO LTD

Thick-specification X65 pipeline steel and production method thereof

The invention discloses thick-specification X65 pipeline steel and a production method thereof, and particularly relates to the thick-specification X65 pipeline steel and the production method thereof in the field of steel band production. The invention provides the thick-specification X65 pipeline steel with the advantages that the process is simple; the qualification rate is high. The weight percentage of chemical ingredients is shown as follows: C accounts for 0.03 to 0.06 percent; Si accounts for 0.10 to 0.30 percent; Mn accounts for 1.40 to 1.60 percent; the content of P is at most 0.020 percent; the content of S is at most 0.010 percent; Nb accounts for 0.030 to 0.039 percent; V accounts for 0.06 to 0.08 percent; Ti accounts for 0.008 to 0.019 percent; Cr accounts for 0.15 to 0.30 percent; the rest is Fe and unavoidable impurities. The invention also provides the production method of the thick-specification X65 pipeline steel with high qualification rate. The method comprises the following steps of melting and coarse milling, fine milling and cooling. The production method has the advantages of low production cost and high production efficiency.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for effectively controlling generation of central cracks in medium-carbon steel plate

The invention discloses a method for effectively controlling generation of central cracks in a medium-carbon steel plate. Molten iron pretreatment, converter tapping pure aluminum block deoxidation, LF (ladle furnace) white slag refinement, RH vacuum treatment and other techniques are mainly utilized to control the molten steel purity and the continuous casting frequency, so that the tundish molten steel superheating temperature is controlled at 5-20 DEG C, the casting blank stacking slow cooling time is controlled to at least 45 hours, and the cooling speed of the rolled steel plate is controlled by an ultra-fast cooling system and a head / tail masking technique, thereby effectively controlling the generation of central cracks in the steel plate. The method improves the internal quality of the steel plate, enhances the performance qualification rate and the flaw detection qualification rate of flaw detection steel, and has favorable economical and social benefits.

Owner:NANJING IRON & STEEL CO LTD

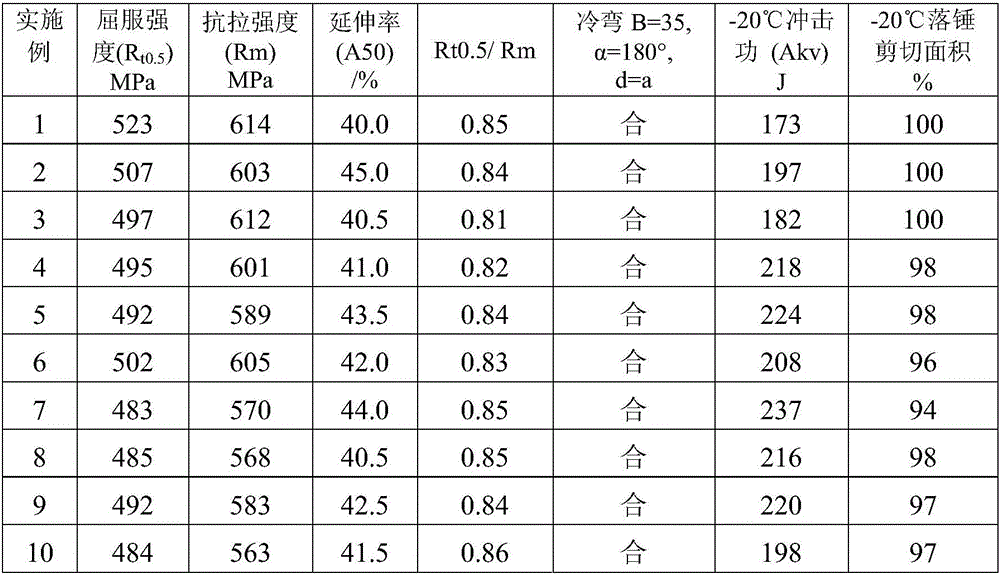

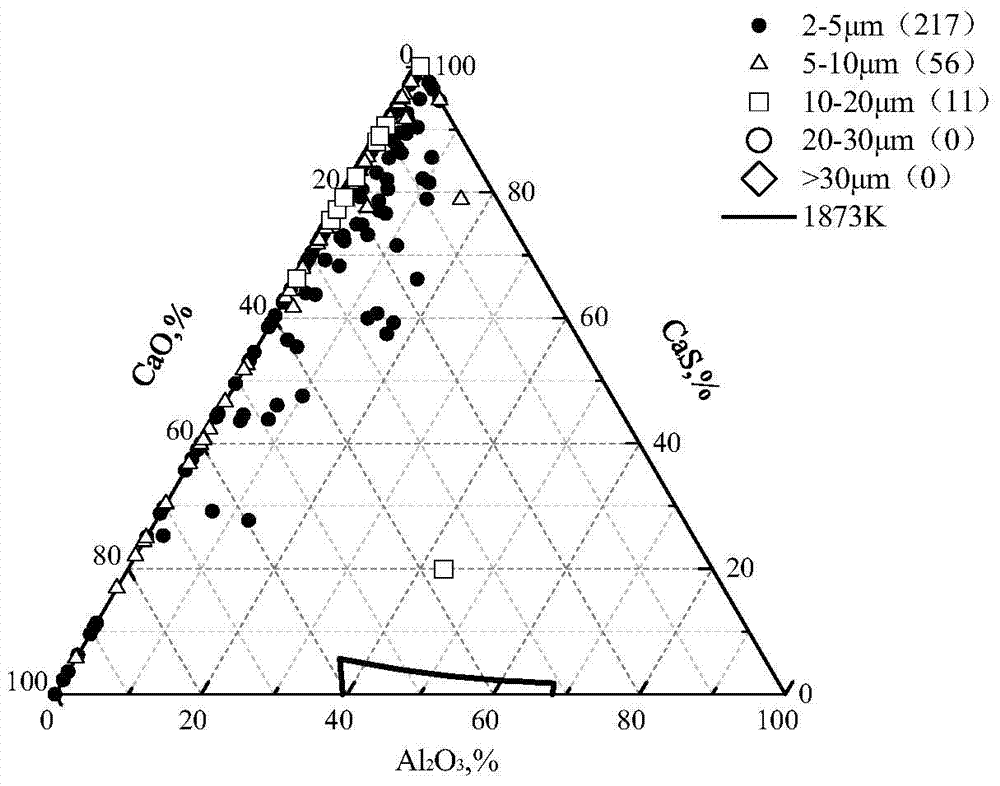

Inclusion control method of ultralow temperature steel

The invention relates to an inclusion control method of ultralow temperature steel, which comprises the steps of firstly performing powerful deoxidation by adopting aluminum blocks of 1.5-1.7kg / ton behind a furnace to create conditions for liquid steel refining; then performing LF furnace refining treatment on the liquid steel and finishing heating up slagging in 10-15 minutes after the refining is started, wherein the top slag alkalinity is controlled within 6-8 and the slag amount is controlled within 14-17kg / ton; the method also comprises a calcium treatment process, in which the feeding amount of calcium is controlled according to S content in the liquid steel, calcium aluminum ratio in the refined slag top slag and yield of Ca, and the calcium sulfur ratio in the liquid steel is controlled within 1.0-1.6, and the calcium aluminum ratio in the refined slag is controlled within 1.5-1.8. By optimizing a calcium treatment process, inclusion types generated by the liquid steel are controlled, enriched inclusions in the liquid steel in the prior art are converted to tiny dispersion, difference between a thermal expansion coefficient of the inclusions and a steel base body is reduced by improving the inclusion types, the influence of the inclusions on the low temperature impact performance of the steel is reduced, so that the impact performance of the ultralow temperature steel is effectively reduced, performance pass rate is improved and the service life is prolonged.

Owner:NANJING IRON & STEEL CO LTD

Anti-seismic fire-resistant steel plate with thickness being 100 mm and yield strength being 460 MPa grade and manufacturing method thereof

InactiveCN112501499AEasy to shapeImprove performanceTemperature control deviceWork cooling devicesNiobiumPhysical chemistry

The invention discloses an anti-seismic fire-resistant steel plate with the thickness being 100mm and the yield strength being the 460MPa grade and a manufacturing method thereof. The anti-seismic fire-resistant steel plate is characterized by comprising, by weight, 0.06-0.12% of C, 0.10-0.50% of Si, 0.90-1.60% of Mn, smaller than 0.015% of P, smaller than 0.01% of S, 0.20%-0.70% of Cr, 0.15-0.22%of Mo, 0.065-0.110% of Nb, 0.015%-0.045% of V, 0.01%-0.04% of Ti, 0.01%-0.04% of Al, smaller than 0.0060% of N and the balance Fe and inevitable impurity elements. The low-molybdenum and high-niobiumcomponent design thought is adopted, the cost of steel is effectively reduced through the low-molybdenum design, and the high-temperature performance is improved through precipitation strengthening of niobium at the high temperature; meanwhile, a certain number of bainite structures are generated by the steel through the means of controlled rolling and controlled cooling, and the high-temperaturestrength of the steel is regulated and controlled through the good high-temperature performance of bainite; and the rolling mode is hot rolling, the production cost is reduced, and great applicationprospects and economic benefits are achieved.

Owner:NANJING IRON & STEEL CO LTD

Magnetic ring production technology

InactiveCN103646771AAchieve removalImprove performance pass rateInductances/transformers/magnets manufactureElectricityElectrical performance

The invention discloses a magnetic ring production technology. The magnetic ring production technology sequentially includes the following steps that (a) raw materials of magnetic rings are proportioned well according to components, and magnetic ring green bodies are made; (b) false burning is performed on the magnetic ring green bodies one time, and the temperature range of false burning is 750-900 DEG C; (c) the magnetic ring green bodies which undergo false burning are placed into grinding clamps and then placed on a grinding machine to be polished; (d) at last, final sintering is performed on the magnetic ring green bodies. Compared with a traditional production process, according to the magnetic ring production technology, burrs of the magnetic rings are removed, peak power utilization can be avoided, the production cost is lowered to a certain extend, the electrical performance qualification rate of the magnetic rings is improved, the final sintering time is shortened, original production processes are optimized and improved, the technology is simple, and operation is easy.

Owner:长兴柏成电子有限公司

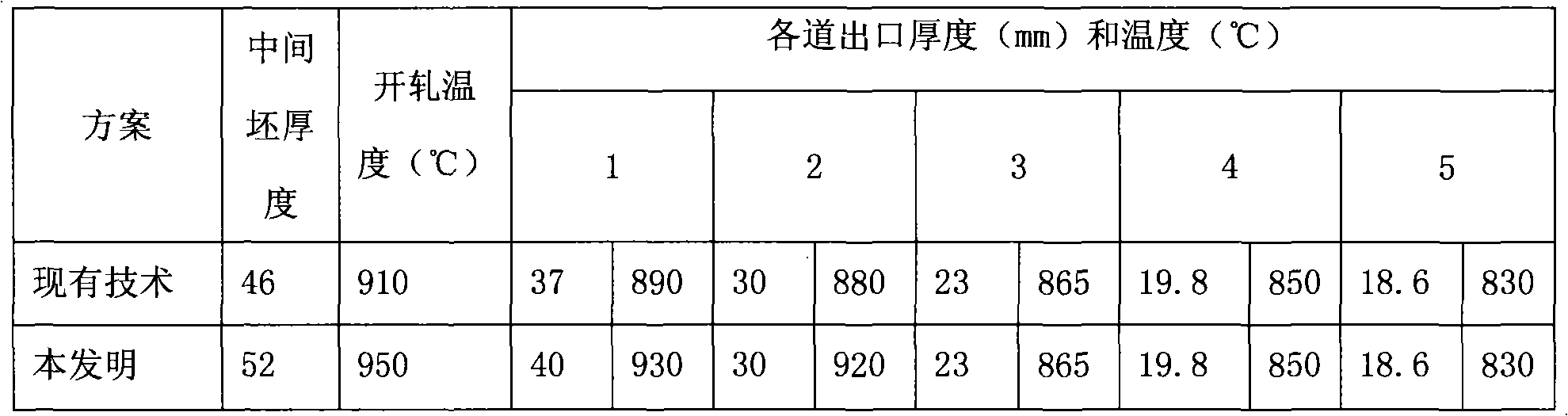

Method for producing thin-specification anti-seismic refractory steel by adopting continuous rolling and rolling heat preservation

InactiveCN112676343APrevent precipitationReduce manufacturing costTemperature control deviceMetal rolling arrangementsAustenite grainHeat conservation

The invention discloses a method for producing thin-specification anti-seismic refractory steel by adopting continuous rolling and rolling heat preservation, and relates to the technical field of steel production. The methodcomprises the following steps: cogging and rolling by adopting a medium-thickness plate rolling mill, rolling an original blank into an intermediate blank with the thickness of 110-130 mm, naturally cooling, returning the intermediate blank to a furnace, heating the intermediate blank to 1220-1260 DEG C, and controlling the austenitizing temperature. The temperature is higher than the full solid solution temperature of microalloy elements Nb and V but lower than the TiN redissolution temperature, the effect of inhibiting austenite grain growth of solid solution TiN is fully utilized, a fine and uniform original austenite structure is obtained, and the good plate shape and excellent comprehensive performance are achieved.

Owner:NANJING IRON & STEEL CO LTD

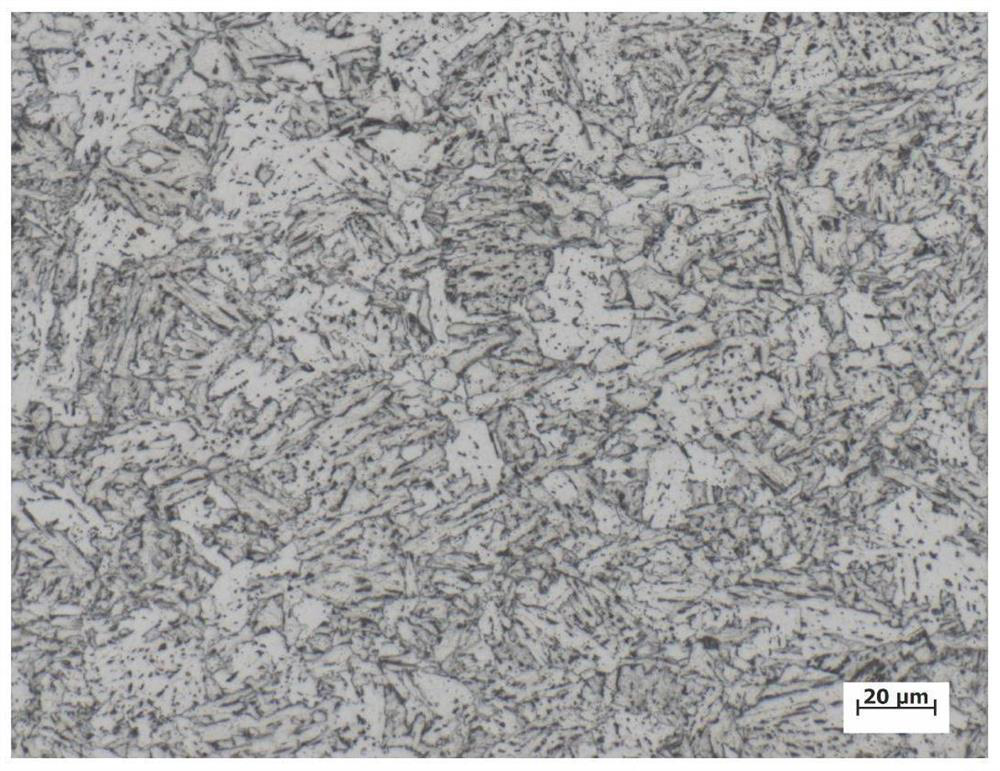

Method capable of reducing thickness of decarburized layer of hot-rolled heavy rail steel

The invention discloses a method capable of reducing the thickness of a decarburized layer of hot-rolled heavy rail steel. The method is characterized in that a heavy rail casting blank is manufactured into the heavy rail steel through heating and rolling; the weight percentage of Cr in the heavy rail casting blank is 0.1-0.14%; and in the heating procedure, during rolling-delay heat preservation, the temperature of a heating zone is controlled at 1230 DEG C and below, and the temperature of a soaking zone is controlled at 1250 DEG C and below. By optimizing the alloying components of the heavy rail casting blank and the rolling-delay heat preservation rule, the yield of the decarburized layer can be raised to above 96%, the method has the advantages of simple technology, high operability and significant effect, and the problem that the thickness of the decarburized layer exceeds the standard due to the fact that the rolling-delay time of the heavy rail casting blank is too long can be solved effectively. With the adoption of the method, the production efficiency is improved, the yield of the rolled steel is raised substantially, the heavy rail performance yield is raised, and thus the reduction of the cost is realized.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Extra-thick anti-seismic fire-resistant steel plate with yield strength of 390MPa and manufacturing method thereof

The invention discloses an extra-thick anti-seismic fire-resistant steel plate with yield strength of 390MPa and a manufacturing method thereof. The steel plate adopts a low-molybdenum and niobium-vanadium-added component design thought, the cost of steel is effectively reduced through the low-molybdenum design, the high-temperature performance is improved through synergistic precipitation strengthening of niobium and vanadium at high temperature, meanwhile, a certain amount of bainite structures are generated by the steel through controlled rolling and controlled cooling means, the high-temperature strength of the steel is regulated and controlled through the good high-temperature performance of bainite, the rolling mode is hot mechanical rolling, the production cost is reduced, compared with existing refractory steel for high-rise buildings, the steel is more economical and practical, meanwhile, the anti-seismic fire-resistant steel plate with the thickness of 100mm has important significance on development of super high-rise and large-span green steel structure buildings, and no related patent and report special for the hot-rolled extra-thick fire-resistant steel exists at present, so that the anti-seismic fire-resistant steel plate has great application prospects and economic benefits.

Owner:NANJING IRON & STEEL CO LTD

Hot continuous rolled strip steel coiling dual detection method

InactiveCN106513445AEliminate detection inaccuraciesRealize automatic controlMeasuring devicesMetal rolling arrangementsAutomatic controlLaminar cooling

The invention discloses a hot continuous rolled strip steel coiling dual detection method and belongs to the field of automatic control over the coiling temperature of hot continuous rolled strip steel. The method is characterized in that two temperature detectors are arranged at an outlet of laminar cooling equipment and located between the laminar cooling equipment and a coiling machine, wherein the two temperature detectors meet the following conditions that (1) the distance between the detectors and a rolling center line in the horizontal direction is no larger than 4 meters, (2) the distance between the detectors and the rolling center line in the vertical height direction is no larger than 3 meters, and (3) the two temperature detectors have different detection angles, with the horizontal line as a reference, the detection angle of one temperature detector is 35-45 degrees, the detection angle of the other temperature detector is 35-40 degrees, and two temperature detection values T1 and T2 are input into a first-stage controller simultaneously. The situation that strip steel temperature detection is affected when water exists on the strip steel locally is eliminated, stability of control over strip steel coiling temperature is achieved, the product performance and the qualified rate are improved, and good benefits are gained.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Heat treatment method of extra-thick, extra-wide and extra-long chromium-molybdenum steel plate

ActiveCN111394546AExtended swing timeSolve the problem of low performance pass rateFurnace typesHeat treatment process controlFurnace temperatureHeat conservation

The invention belongs to the technical field of metallurgy, and discloses a heat treatment method of an extra-thick, extra-wide and extra-long chromium-molybdenum steel plate. The heat treatment method comprises a heating procedure and a water cooling procedure, and is characterized in that the steel plate is made of a steel ingot; in the heating procedure, a single steel plate is charged into a furnace, the single steel plate is heated to the heat preservation temperature and subjected to heat preservation, and the furnace temperature is increased by 5-10 DEG C 30-40 minutes before tapping; and in the water cooling procedure, the roller speed is 0.02-0.06 m / s, the quenching water amount is 8400-8550 m<3> / h, the water pressure is 0.75-0.95 MPa, and the low-pressure section swings for 30-35minutes. According to the heat treatment method, the strength surplus, the negative temperature impact toughness and the performance qualification rate of the whole plate in the thickness direction,the width direction, the length direction and the like of the chromium-molybdenum steel plate of the special specification are comprehensively improved, and wide applicability is achieved.

Owner:WUYANG IRON & STEEL

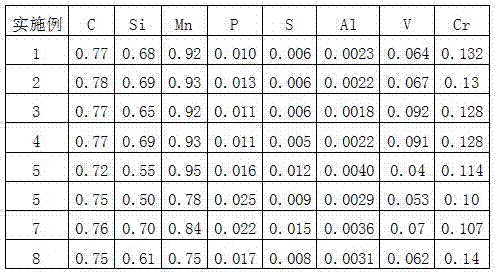

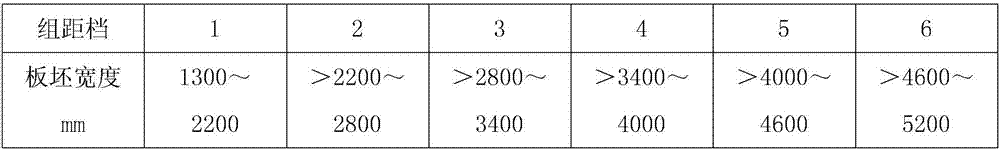

Production method for normalizing Q370 qE steel plate for bridge

InactiveCN107287528AImprove performance pass rateMeet the needs of mass productionReduction ratePerformance index

The invention provides a production method for a normalizing Q370 qE steel plate for a bridge. Chemical components include, by weight percent, 0.130%-0.174% of C, 0.15%-0.25% of Si, 1.5%-1.65% of Mn, smaller than or equal to 0.018% of P, smaller than or equal to 0.005% of S, 0.035%-0.055% of V, 0.01%-0.03% of Nb, 0.005%-0.015% of Ti, 0.015%-0.045% of Als and smaller than or equal to 0.012% of N, and CEV is 0.40-0.43. The slab heating temperature is smaller than or equal to 1,250 DEG C, the rolling starting temperature is larger than or equal to 1,000 DEG C, and the first-stage finish rolling temperature, the second-stage rolling starting temperature and the second-stage accumulated reduction rate are correspondingly selected according to the width and thickness of slabs. After rolling, the heat treatment normalizing temperature is 880+ / -10 DEG C, the total time in a furnace ranges from 1 min / mm to 2 min / mm, the temperature rise rate is 1 min / mm, and air cooling is conducted after normalizing. Various performance indexes of the bridge Q370 qE steel plate produced through the method can reach the standard requirement, the performance qualification rate is increased to 99% from the original 81%, and the requirement of mass production can be completely met.

Owner:ANGANG STEEL CO LTD

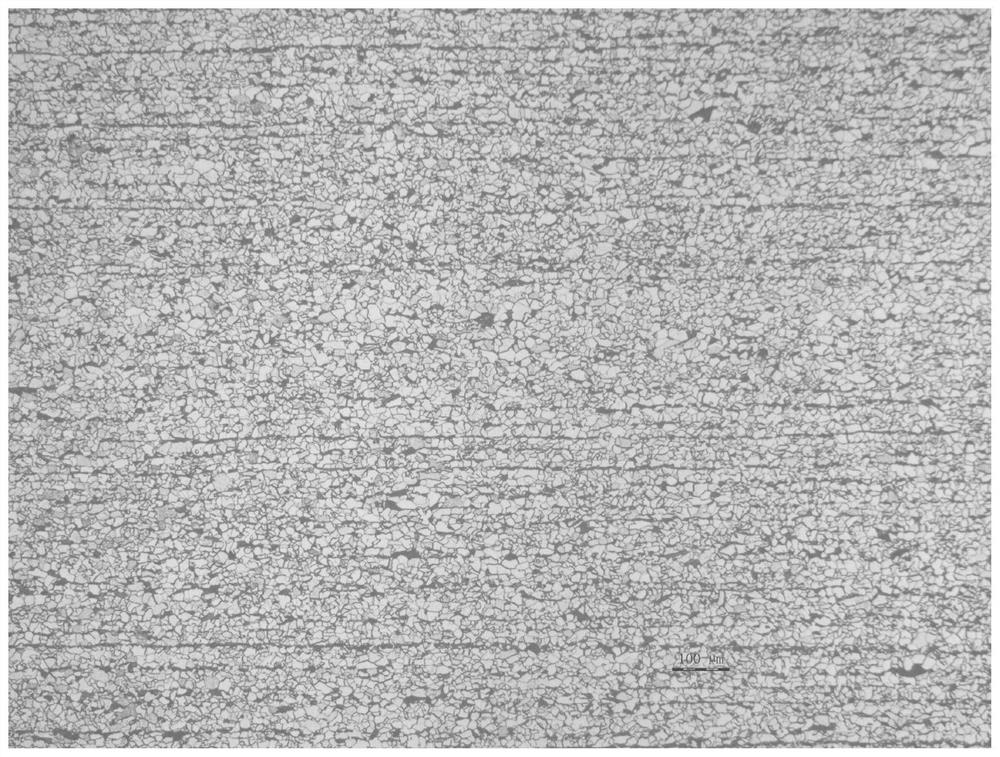

Efficient pipeline steel L245N production process

InactiveCN113652615AHigh strengthHigh hardnessProcess efficiency improvementRare-earth elementProcess engineering

The invention discloses an efficient pipeline steel L245N production process. The component design of the method is more economical and applicable; the rolling method adopts a production mode of normalizing rolling; through high-temperature rolling, a rolled steel plate is at a temperature above the critical temperature Ac3; through a production mode simulating a normalizing heat treatment state, the effects of refining grains and homogenizing the structure are achieved; and by reducing the ferrite content in the hypoeutectoid steel, the pearlite content is increased and refined, so that the strength, hardness and toughness of the steel are improved. The process does not adopt a water cooling process, so that the defect of large head and tail temperature difference caused by the water cooling process is avoided, and the yield is improved while the performance qualification rate is improved. By adding rare earth elements, the grain boundary is improved, and the low-temperature impact toughness of the steel plate is improved.

Owner:BAOTOU IRON & STEEL GRP

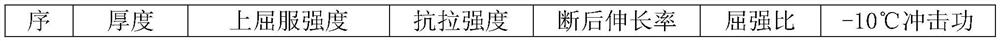

Design method of hot-rolled wide strip steel production process

ActiveCN113094870AFree working timeImprove efficiencyDesign optimisation/simulationSpecial data processing applicationsStatistical analysisProcess engineering

The invention discloses a design method of a hot-rolled wide strip steel production process, which comprises the following steps of: 1) carrying out statistical analysis on production data of a steel plant, and establishing a calculation equation of a corresponding relationship among a component average value of a steel grade, a rolling process parameter and a physical and mechanical property average value; 2) according to the principles that the cost is optimized and the mechanical property meets the requirements, establishing a design model of the steel grade components and the rolling process according to the equation provided in the step 1); and 3) according to the steel grade components calculated by the model, the target set values of the operation process parameters and the operation deviation of operation, determining an actual production process organization for production. The method can reduce the workload of technicians, improve the automation level and reduce the alloy cost.

Owner:SHANDONG IRON & STEEL CO LTD

Anti-seismic steel with ultralow yield point and production method thereof

The invention relates to anti-seismic steel with an ultralow yield point. Ti is added to fix C atoms so as to reduce the hindering effect of the C atoms on dislocation movement; the anti-seismic steel contains the following chemical components in percentage by weight: less than or equal to 0.0015 percent of C, less than or equal to 0.01 percent of Si, less than or equal to 0.05 percent of Mn, less than or equal to 0.03 percent of Ti, less than or equal to 0.01 percent of P, less than or equal to 0.004 percent of S, and the balance of Fe and unavoidable impurities. The anti-seismic steel has the advantages that due to a relaxation process, crystalline grains of ferrite are enlarged, so that the area fraction of the ferrite is increased, and the yield strength is reduced; the performance qualification rate of the anti-seismic steel with the ultralow yield point and the yield strength of 75 to 125 Mpa is greatly improved; according to the statistics, the performance qualification rate within half-a-year production of the type of steel is 85 percent; compared with the conventional method, the production method disclosed by the invention has the advantages that the average qualification rate is increased by 32 percent, and the effect is obvious.

Owner:ANGANG STEEL CO LTD

A Method for Adjusting Secondary Cooling Water Volume and Roll Gap Value of Two-strand Slab Continuous Casting Machine

The invention discloses a method for adjusting the secondary cooling water amount and the roll gap value of a double-flow slab casting machine. In the double-flow slab casting machine, 12 cooling regions are formed for secondary cooling; 10 cooling water meters are provided; five grades, i.e., strong cooling: the secondary cooling water amount is 1.0-1.1 L / kg, medium cooling: the secondary cooling water amount is 0.8-0.9 L / kg, weak cooling: the secondary cooling water amount is 0.7-0.8 L / kg, medium-weak cooling: the secondary cooling water amount is 0.45-0.6 L / kg, and slight cooling: the secondary cooling water amount is 0.4-0.45 L / kg are divided to adapt to the cooling requirements of different types of steel respectively; the roll gap of a secondary cooling region support roll is consistent with the linear shrinkage rule of a casting blank from top to bottom, and decrease continually; and the roll opening between the outlet of a previous fan-shaped section and the inlet of a next fan-shaped section is kept consistent. By adopting the method, the internal cracking rate is lowered, the macrostructure of the casting blank is optimized, and the performance yield of steel is increased.

Owner:ANYANG IRON & STEEL

Heating method of seamless steel pipe

InactiveCN106086372BEliminate unevennessEliminate low performance metricsTemperature control deviceFurnace typesHeating timePerformance index

The invention discloses a heating method of a seamless steel tube. The heating method comprises the temperature schedule, the heating time, the pressure schedule and the atmosphere schedule of an annular heating furnace. According to the heating method, a uniform austenite structure can be formed, oxidation burning losses can be reduced, and the defect that the performance indexes such as yield strength and impact strength are low is fully eliminated.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

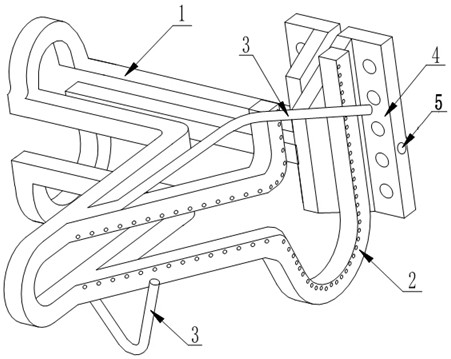

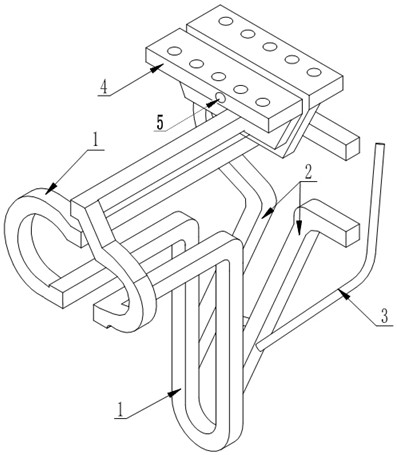

Thermal treatment induction device for T30C-specification ball flat steel and thermal treatment method

ActiveCN112481452AImprove performance pass rateMeet processing needsIncreasing energy efficiencyFurnace typesStructural engineeringThermal treatment

The invention provides a thermal treatment induction device for a T30C-specification ball flat steel and a thermal treatment method. By tempering a quenched sample through a quenching process simulation test, and performing mechanical property detection to confirm reasonability of the thermal treatment induction device and the thermal treatment method, so that a reasonable induction device and a reasonable thermal treatment method are obtained. The induction device is formed by bending a hollow copper tube, and a joint of the induction device and a power supply is equipped with a pedestal madeof a copper plate; a matched induction ring arc-shaped dimension is adopted according to the shape of T30C ball flat steel, so that processing needs of the T30C-specification ball flat steel can be met; in a length direction, a closed loop is formed, a hollow part water receiving tube in the induction device cools, and a spraying tube and a cooling tube can accomplish uniform quenching of a workpiece. The thermal treatment induction device is simple in structure, is convenient in operation, can synchronously quench, and is suitable for being applied as the thermal treatment device and the thermal treatment method. The quenched ball flat steel is high in performance qualification rate.

Owner:中国船舶集团渤海造船有限公司

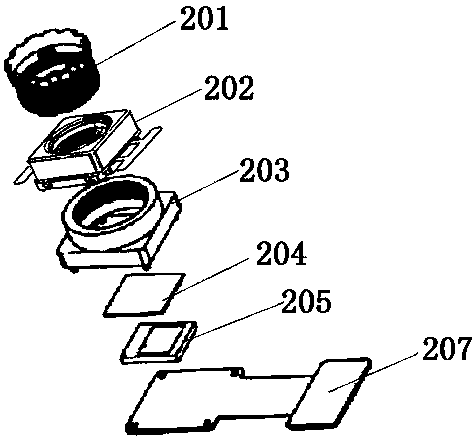

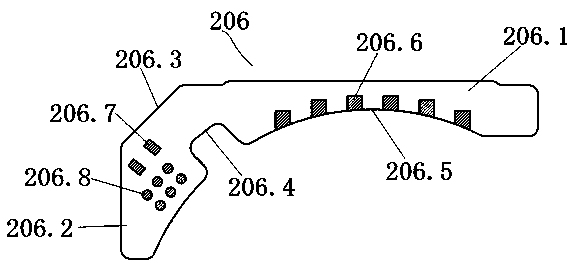

VCM mobile phone camera module

PendingCN110581941AHighly corporatedHigh positioning accuracyTelevision system detailsColor television detailsFlexible circuitsComputer module

The invention relates to a VCM mobile phone camera module. The camera comprises a lens, a voice coil motor, a base, an optical filter, an image sensor, a flexible circuit board, a bottom plate and a connector; the lens is arranged in the voice coil motor; the voice coil motor is arranged on the base; the optical filter and the image sensor are arranged between the base and the flexible circuit board; the flexible circuit board is embedded in the bottom plate; the flexible circuit board comprises a transverse section and a vertical section, a reserved area is arranged on the front face of the transverse section, six preparation bonding pads different in size are arranged in the reserved area and arranged at intervals along the inner edge of the arc-shaped edge, and a groove is formed in theposition, corresponding to the reserved area, of the back face of the transverse section. The VCM mobile phone camera module has the advantages of being high in positioning precision, capable of improving the assembling efficiency and high in performance percent of pass.

Owner:WUXI HAOBANG HIGH TECH CO LTD

Process for producing thin gauge pipeline steel by using double-stand medium and heavy plate mill

ActiveCN102671941BGuaranteed Dynamic RecrystallizationImprove lateral performanceTemperature control deviceWork treatment devicesMetallurgyLaminar cooling

The invention discloses a process for producing thin gauge pipeline steel by using a double-stand medium and heavy plate mill. A plate blank with the thickness of 180 mm is used for producing the thin gauge pipeline steel with the thickness less than 10 mm. On the basis that the performance of a rolled piece meets requirements, the thin gauge pipeline steel with a good plate shape can be obtained by controlling the tapping temperature of the plate blank, the rough rolling broadening pass pressing rate, the longitudinal rolling pass pressing rate after rough rolling broadening pass, the rough rolling finishing temperature, the thickness of a middle blank, the finish rolling ending pass pressing rate, the finish rolling finishing temperature, the roller gap inclination and sled function in the rolling process, a high pressure water descaling system, the water entry temperature, the re-reddening temperature, and the head and tail shielding and straightening process of a laminar cooling system. The deformation rate is reduced, and the economic benefit is increased.

Owner:NANJING IRON & STEEL CO LTD

A method for producing extra-thick steel plates by two-dimensional deformation of continuous casting slabs

The invention provides a method of producing a super-thick steel plate through two-dimensional deformation of a continuous casting billet. In the method, the continuous casting billet being 300 mm in thickness is employed for producing the super-thick steel plate being less than 245 mm in thickness, wherein the total reduction rate in the thickness direction of both forging and rolling is not less than 18.3%. The continuous casting billet is forged through a technology including both the thickness direction and the width direction, wherein the technology includes following steps: (1) forging the continuous casting billet in the width direction; (2) when one-time forging and pressing amount is 90-200 mm, forging the continuous casting billet in the thickness direction with the one-time forging and pressing amount being not less than 35 mm; (3) slowly cooling the forged continuous casting billet; and (4) rolling the forged continuous casting billet at the temperature of 1100-1250 DEG C, wherein the beginning temperature is more than 1050 DEG C, the slowly cooling temperature after rolling is not less than 400 DEG C and the slowly cooling time is not less than 24 h. The method achieves production of the super-thick steel plate being less than 245 mm in thickness at a low compression ratio with the continuous casting billet, so that the range of specification of steel plate production with the continuous casting billet is enlarged. Under a fixed edge cutting amount, the lower limit of width specification of a steel plate finish product can be reduced by 380 mm. The method increases yield of the super-thick steel plate, reduces production cost and can reach more than 90% in defect detection qualified rate.

Owner:ANGANG STEEL CO LTD

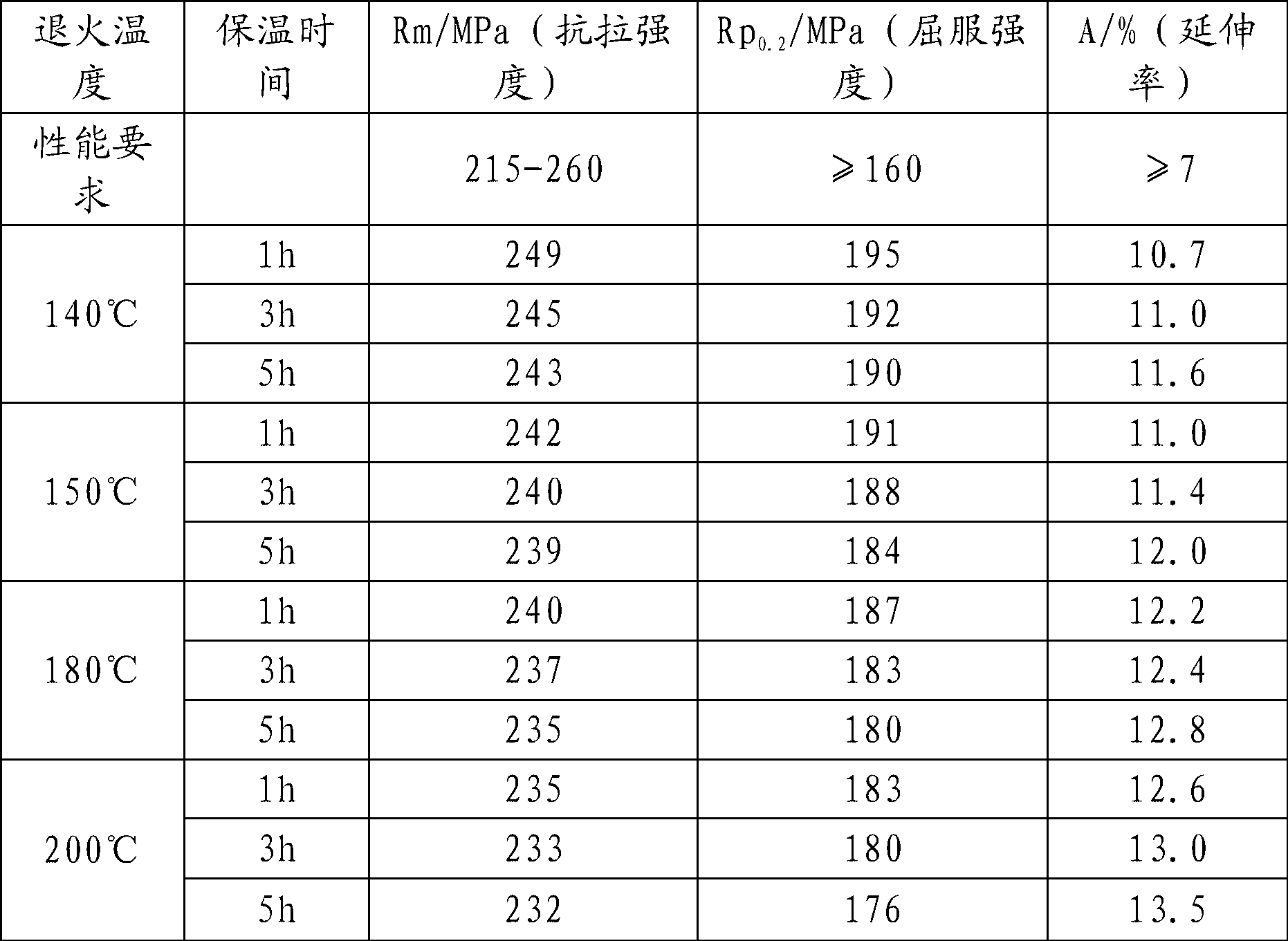

A method for preparing ta2 hot-rolled pure titanium plate based on oxygen equivalent annealing process

ActiveCN110724834BThe mechanical properties are qualifiedUniform tissueProcess efficiency improvementMetal rolling arrangementsAbrasive blastingIngot

A method for preparing TA2 hot-rolled pure titanium plates based on an oxygen equivalent annealing process, the specific steps are as follows: select titanium sponge, titanium dioxide, titanium sheets, titanium chips and titanium tubes, titanium sheets, titanium chips and titanium tubes by shearing, After sorting and pickling treatment, it is mixed with sponge titanium and titanium dioxide, smelted into a slab in an electron beam cooling furnace, and the surface of the slab is milled, partially ground, chamfered and sawed to obtain a TA2 slab. Hot-rolled into titanium coils and cut into flats or sheet-rolled into TA2 plates; then atmospheric annealed in a roller hearth furnace, and then subjected to sandblasting, sandblasting pickling, alkali pickling or shot blasting pickling after being out of the furnace for correction One of them is processed, and the local defects on the surface are repaired to obtain a TA2 titanium plate. The present invention selects the standard of annealing process for slab oxygen equivalent and rolling mode, and then selects annealing temperature, obtains TA2 plates with qualified mechanical properties and uniform structure, improves the pass rate of TA2 titanium plates, and has low production cost and high production efficiency.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com