Production method for normalizing Q370 qE steel plate for bridge

A production method, q370qe technology, applied in the field of metallurgical technology, can solve the problems of small composition adjustment space, troubles, insufficient strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

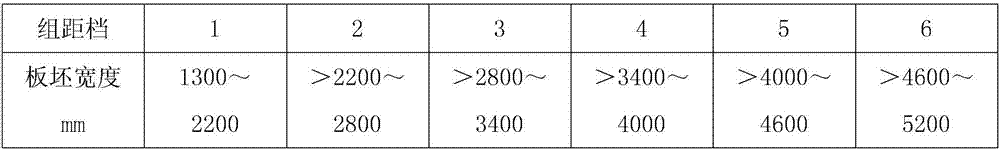

[0015] Embodiment 1: The thickness of the steel plate is 13 mm, and the width is 3000 mm.

[0016] 1. Chemical composition weight percentage: C 0.150%, Si 0.20%, Mn 1.59%, P 0.015%, S0.003%, V 0.045%, Nb 0.02%, Ti 0.010%, Als0.030%, N 0.007%, CEV 0.424.

[0017] 2. Heating and descaling: the slab heating time is 11min / mm, the heating temperature is 1240°C, and the furnace temperature is 1230°C.

[0018] 3. Rolling: The slab rolling temperature is 1050°C, and high-pressure water is used to fully descale during the rolling process. The final rolling temperature of the first stage is 830°C, the rolling start temperature of the second stage is 970°C, and the cumulative reduction rate of the second stage is 58%.

[0019] 4. Heat treatment: normalizing temperature 885°C, total time in the furnace 1.5min / mm, heating rate 1min / mm, air cooling after normalizing.

Embodiment 2

[0020] Embodiment 2: The thickness of the steel plate is 50mm, and the width is 4500mm.

[0021] 1. Chemical composition weight percentage: C 0.160%, Si 0.17%, Mn 1.62%, P 0.012%, S0.004%, V 0.035%, Nb 0.025%, Ti 0.007%, Als0.040%, N 0.010%, CEV 0.412.

[0022] 2. Heating and descaling: the heating time of the slab is 10min / mm, the heating temperature is 1220°C, and the furnace temperature is 1200°C.

[0023] 3. Rolling: The rolling temperature of the slab is 1080°C, and high-pressure water is used to fully remove the scale during the rolling process. The final rolling temperature of the first stage is 850°C, the rolling start temperature of the second stage is 925°C, and the cumulative reduction rate of the second stage is 53%.

[0024] 4. Heat treatment: normalizing temperature 890°C, total time in the furnace 1.3min / mm, heating rate 1min / mm, air cooling after normalizing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com