Inclusion control method of ultralow temperature steel

A control method and technology for inclusions, which are applied in the field of metallurgy to achieve the effects of prolonging service life, improving impact performance and improving performance qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

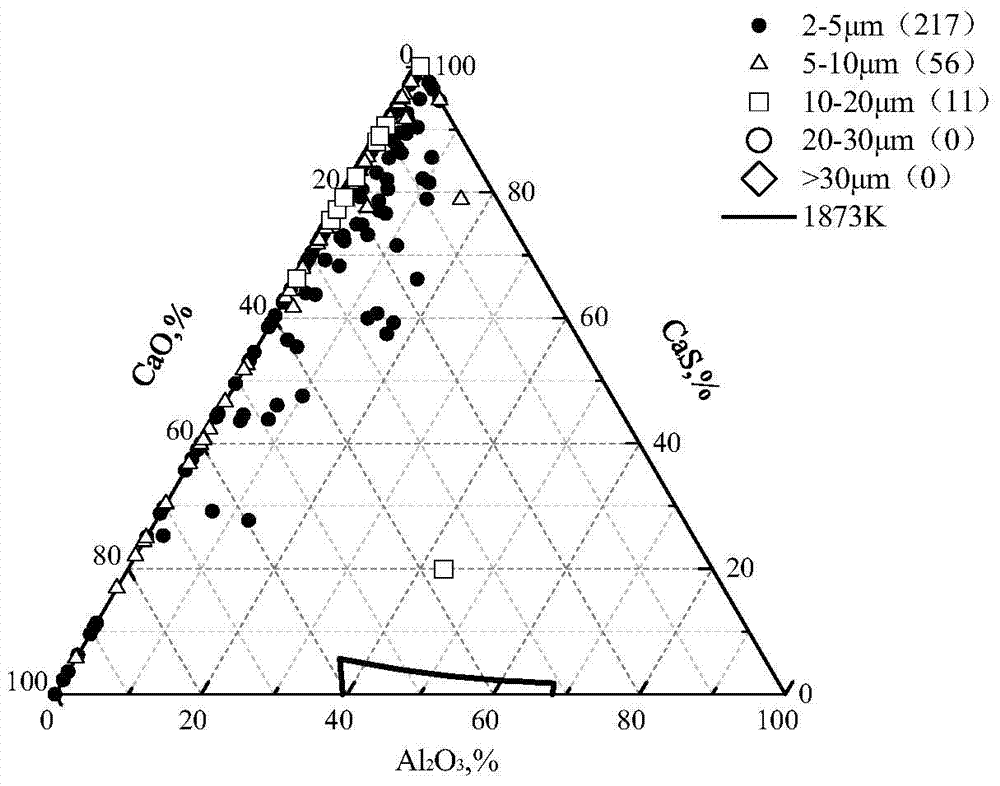

Image

Examples

Embodiment Construction

[0019] This embodiment provides a method for controlling inclusions in steel for ultra-low temperature. Taking 9Ni steel for ultra-low temperature as an example, the main process steps are as follows:

[0020] (1) Converter smelting, using single slag smelting, the temperature at the end of the converter is controlled between 1620 and 1660 °C.

[0021] (2) Deoxidation is carried out after the converter furnace, and a deoxidizer is added to the ladle after the furnace. The deoxidizer uses aluminum blocks of 1.5-1.7kg / ton to create conditions for molten steel refining.

[0022] (3) LF furnace refining. Refining the molten steel in LF furnace, according to the temperature conditions, put the ladle into the LF furnace for heating treatment, the temperature is controlled at 1650°C, transport the ladle to the slag discharge position and lift it, put the steel ladle below it, and start refining for 10-15 minutes The slag-making process is completed within the temperature rise. By...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com