Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve daily throughput" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

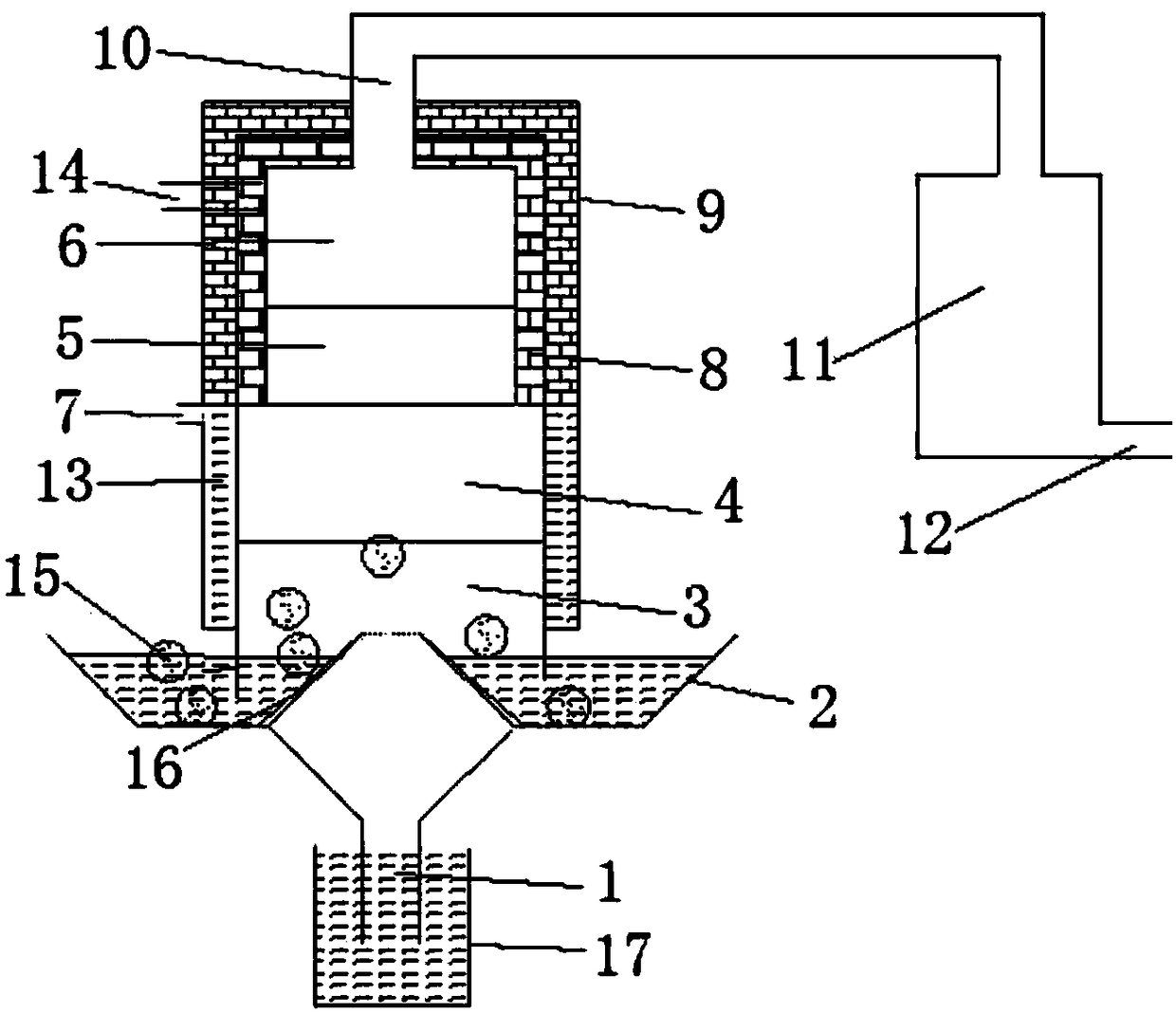

Garbage pyrolysis gasification furnace

ActiveCN105737164AImprove pyrolysis gasification efficiencyReduce generationIncinerator apparatusCombustion chamberInlet channel

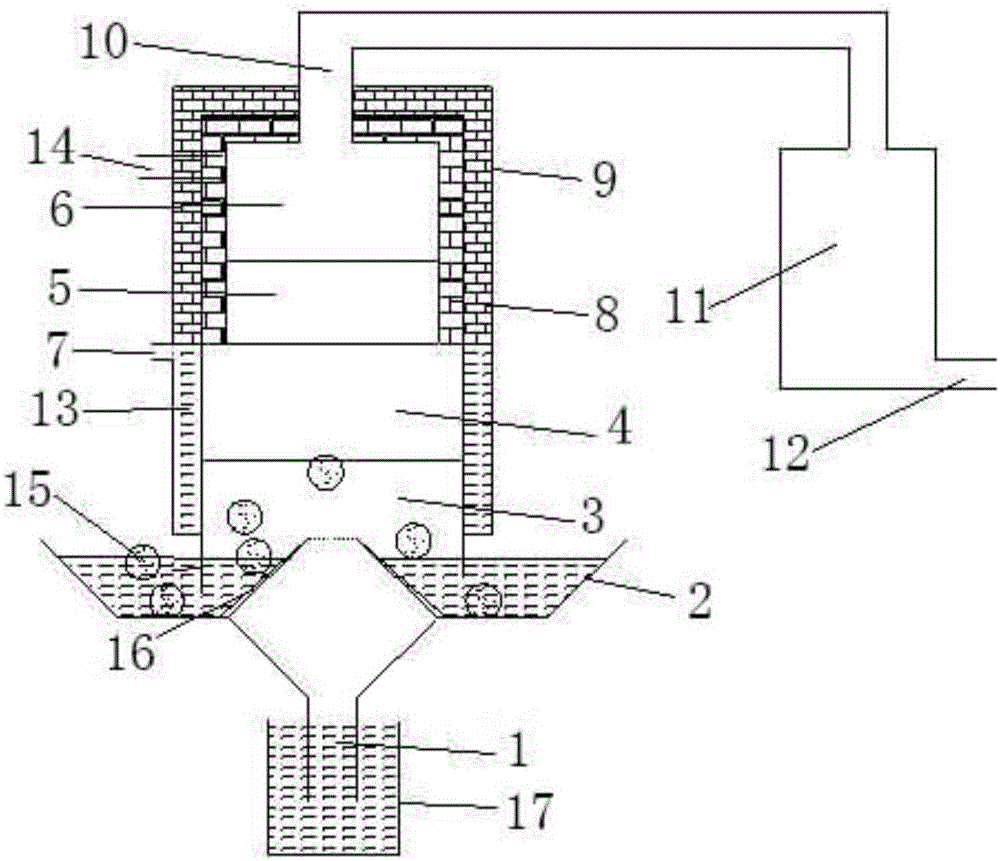

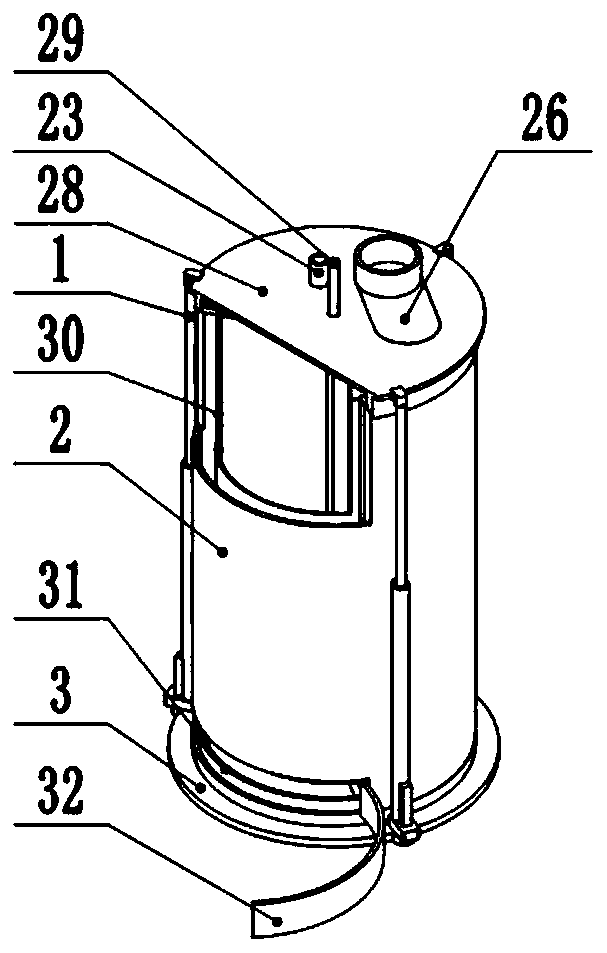

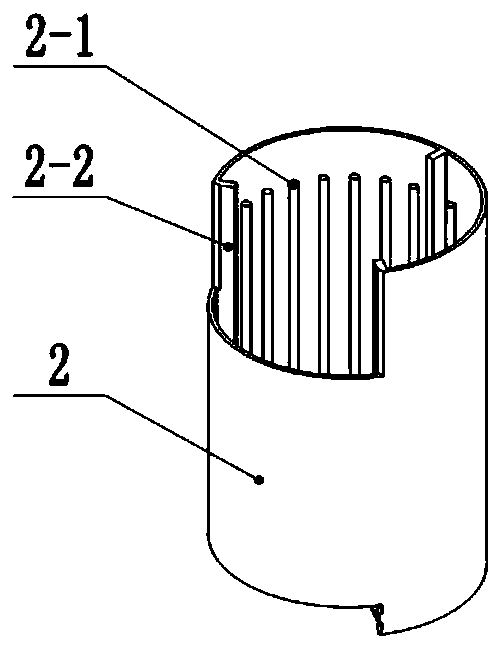

The invention discloses a garbage pyrolysis gasification furnace. A base of a furnace body is arranged in an ash pan. An air and steam inlet channel is formed in the center of the ash pan. An air and steam inlet of the air and steam inlet channel communicates with the interior of the garbage pyrolysis gasification furnace. An air and steam outlet is formed in the top end of the air and steam inlet channel, and the lower end of the air and steam inlet channel is connected with an air blower. A pyrolysis gasification chamber in the garbage pyrolysis gasification furnace is provided with an ash layer, a combustion gasification chamber, a destructive distillation layer and a drying layer from bottom to top. The combustion gasification chamber is provided with an ignition opening. A pyrolysis gasification gas outlet is formed in the drying layer and is connected with a secondary combustion chamber. A feeding opening is formed in the top of the garbage pyrolysis gasification furnace. A scraper is welded to the ash pan, the ash pan is driven by a motor to rotate, ash entering the ash pan is brought out by the scraper, and two rows of small gas holes are formed in the two sides of the scraper. According to the garbage pyrolysis gasification furnace, the optimal efficiency of garbage pyrolysis gasification can be achieved, and the garbage pyrolysis gasification furnace is more economical and environment-friendly.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

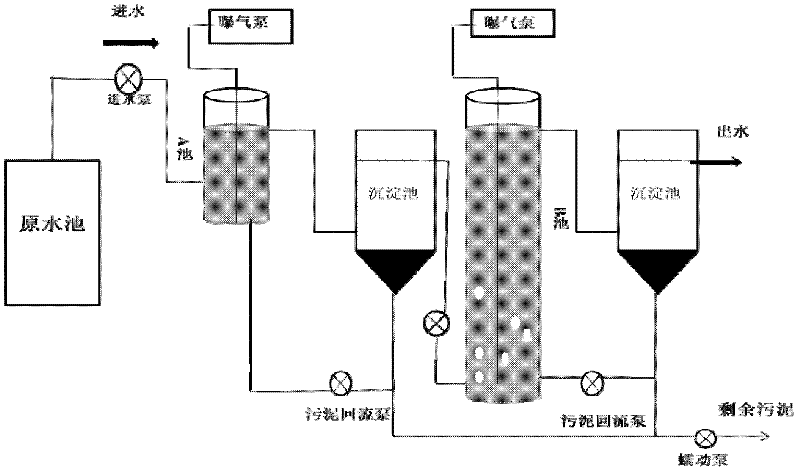

Complex enzyme preparation for sewage treatment and application method thereof

InactiveCN101898830AEasy to handleMonitor effluent qualityTreatment with aerobic and anaerobic processesCelluloseEutrophication

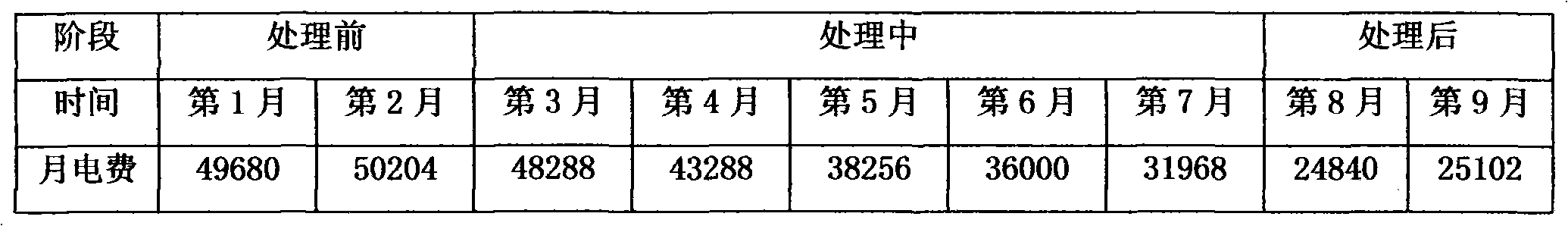

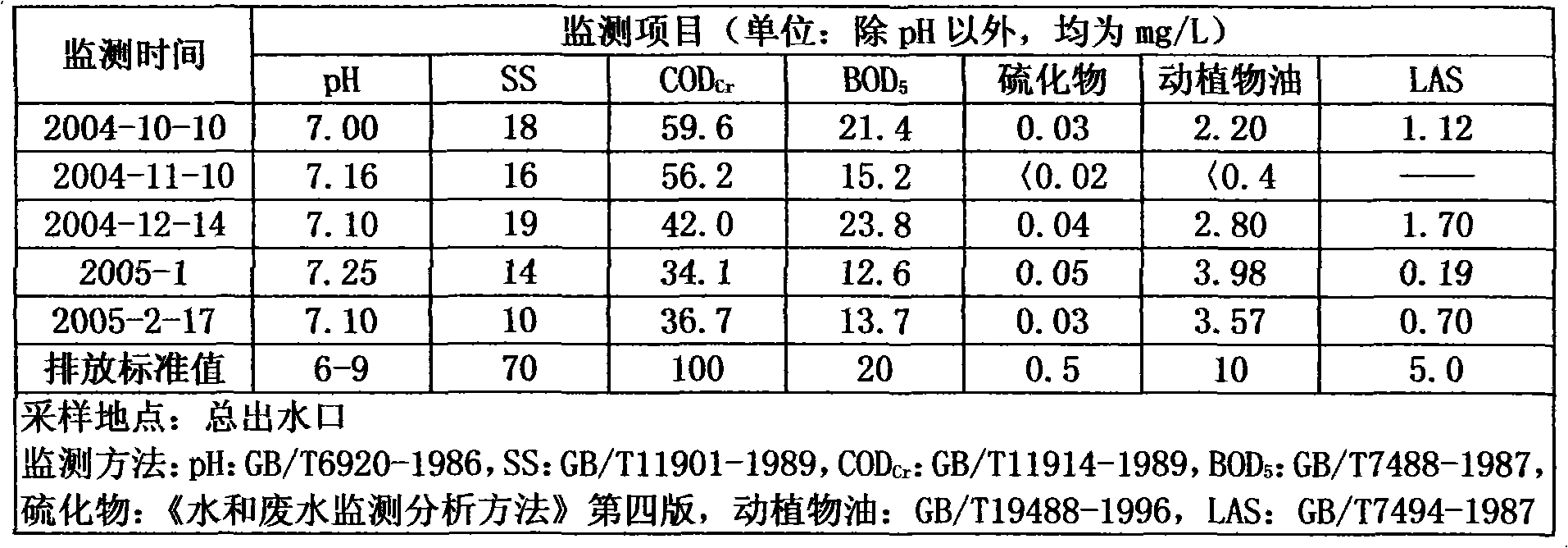

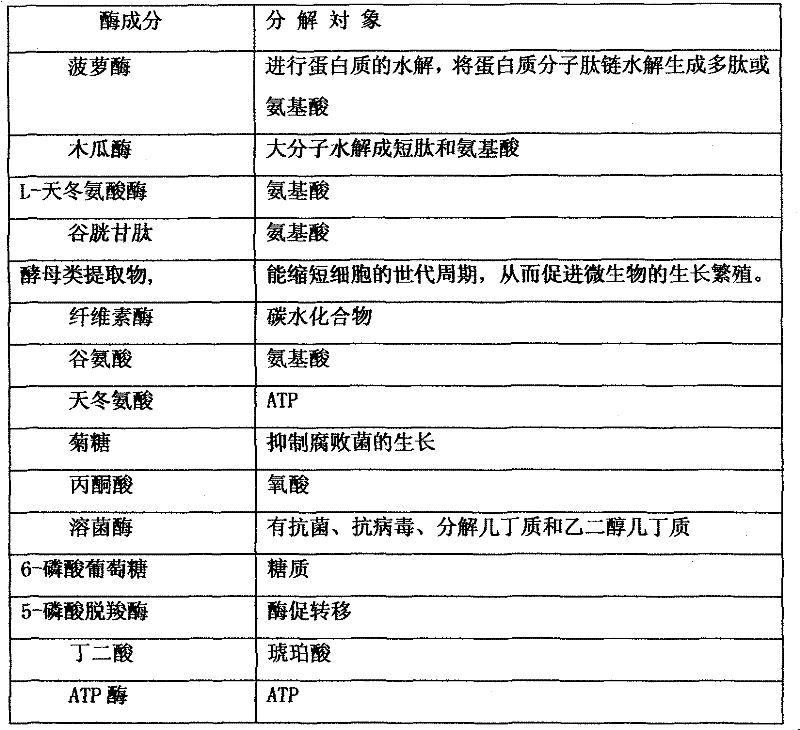

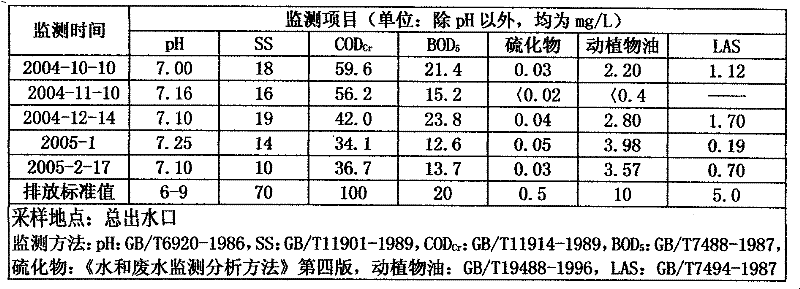

The invention relates to a complex enzyme preparation for sewage treatment. The complex enzyme preparation is compounded by mixing complex enzyme and mineral water, wherein the weight ratio of the complex enzyme to the mineral water is 1:9-50; and the complex enzyme contains the following components in volume content: 50 to 80 mg / L of bromelain, 50 to 80 mg / L of papain, 15 to 30 mg / L of L-aspartase, 15 to 30 mg / L of glutathione, 100 to 150 mg / L of yeast extract and 50 to 80 mg / L of cellulose. The complex enzyme preparation improves the treatment capability of a sewage plant, reduces the running cost, basically achieves zero release of residual organic sludge, prevents environmental secondary pollution of the sewage treatment, improves the self-purification capability of yielding water of the sewage plant, prevents secondary pollution of the yielding water, prevents secondary eutrophication of the yielding water, and radically solves the problem of environmental protection in operation of the sewage treatment plant.

Owner:麦广鸿 +2

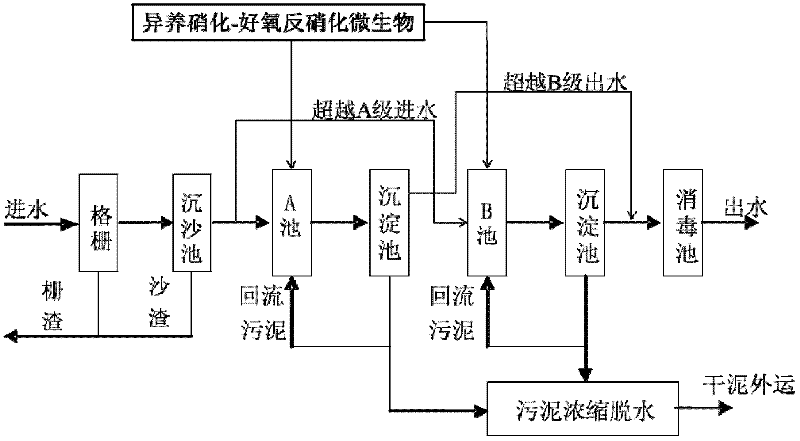

Method for reinforcing adsorption-biodegradation (AB) denitrification technology by use of heterotrophic nitrification-aerobic denitrification bacteria

InactiveCN102241459AEnsuring heterotrophic nitrification-aerobic denitrificationGuaranteed denitrification targetMultistage water/sewage treatmentSustainable biological treatmentProcess systemsActivated sludge

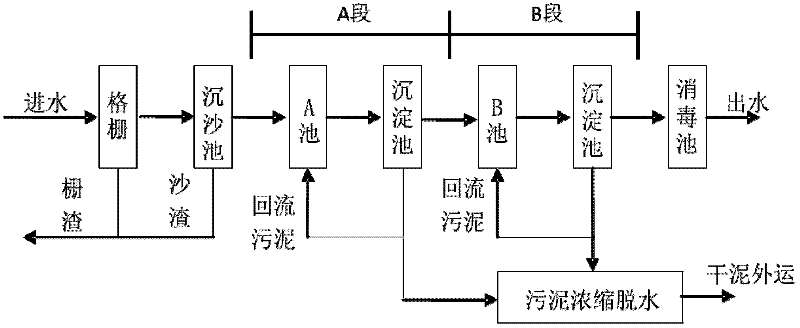

The invention discloses a method for reinforcing an adsorption-biodegradation (AB) denitrification technology by use of heterotrophic nitrification-aerobic denitrification bacteria and belongs to the technical field of water treatment. The method comprises the following specific steps: when the COD (chemical oxygen demand) / N of sewage is more than 8, the sewage passes through a section A and a section B in turn, feeding the effluent of the section A into the section B and inoculating heterotrophic nitrification-aerobic denitrification bacteria into the activated sludge of the section B; and when the COD / N of the sewage is no more than 8, feeding the sewage into the section A and the section B respectively, independently operating the section A and the section B and inoculating the heterotrophic nitrification-aerobic denitrification bacteria into the activated sludge of the section A and the activated sludge of the section B. By adopting the method, the functions of carbon removal and denitrification are realized under the combined action of the section A and the section B in an AB process system and the denitrification effect and efficiency of sewage treatment can be increased.

Owner:PEKING UNIV

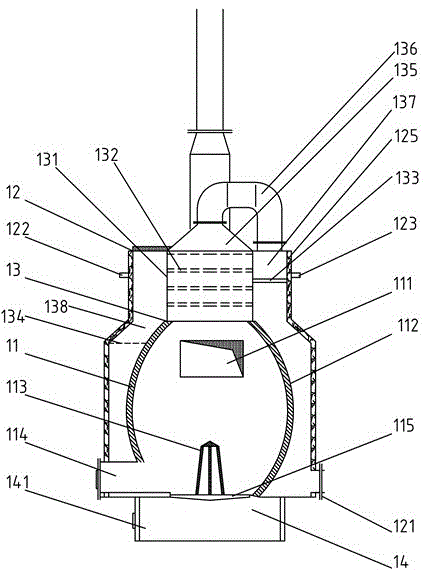

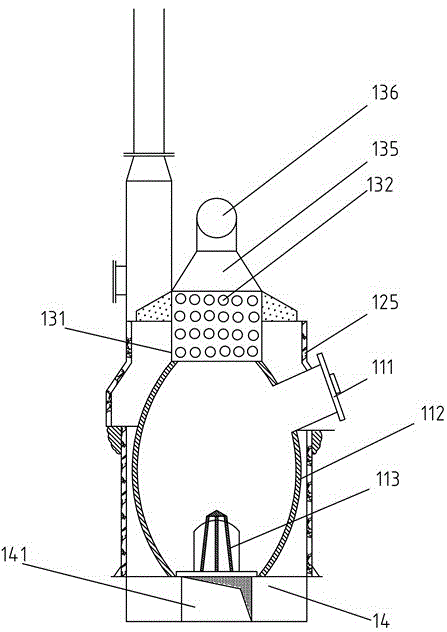

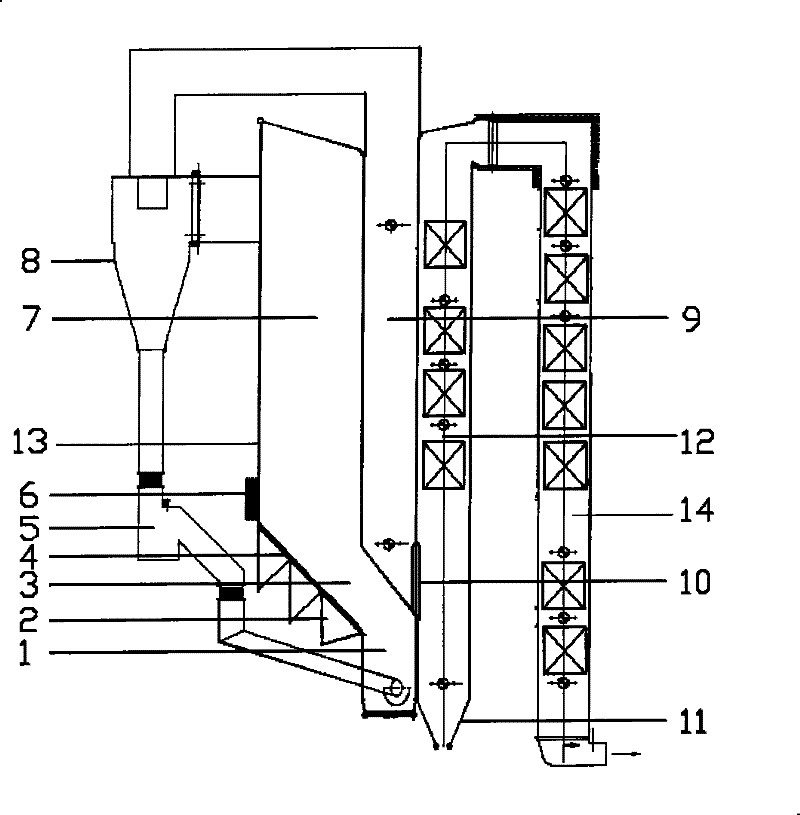

Wind-concentrating type large flow haze-removing air purifying system

InactiveCN104107592AImprove daily throughputGood effectCombination devicesDispersed particle filtrationStreamflowSprayer

The invention relates to a wind-concentrating type large flow haze-removing air purifying system, comprising a tower body and a wind-concentrating cover. A primary filter layer and a secondary absorption layer are arranged in the middle of the tower body; a haze air inlet is arranged at the side wall of the tower body below the filter layer; a clean air outlet is arranged at the top of the tower body; and the clean air outlet at the top of the tower body is communicated to the middle of the wind-concentrating cover. A water storage chamber is arranged at the bottom of the tower body; a submersible pump is arranged in the water storage chamber; a sprayer connected to the submersible pump is disposed between the primary filter layer and the secondary absorption layer. Haze-containing air enters the tower body through the haze air inlet and is purified through the filter layer by removing the haze. According to the invention, the wind-concentrating cover is used to increase air flow rate; filtered clean air in the tower body is pumped out in a self-absorption manner; and the wind-concentrating type large flow haze-removing air purifying system can work in gentle breeze, thereby increasing daily processing capacity of the air. The haze-containing air is subjected to two-stage filtration and water filtration, and thus a haze-removing purifying effect is significant. A power supply is provided to the submersible pump and an axial flow exhaust fan through a wind motor and a solar cell panel, thereby realizing automatic power supply.

Owner:晋中市三元风能除霾发电技术研究所

Method for processing tungsten powder wastes

InactiveCN102912136AHigh recycling valueImprove oxidation efficiencyProcess efficiency improvementTungstateTungsten

The invention discloses a method for processing tungsten powder wastes. The method comprises the steps as follows: oxidizing the tungsten powder wastes to convert tungsten into tungsten oxide; and carrying out reaction between the oxidized tungsten powder wastes and alkali to convert the tungsten oxide into tungstate. According to the method, the tungsten powder wastes can be effectively processed.

Owner:CHONGYI ZHANGYUAN TUNGSTEN

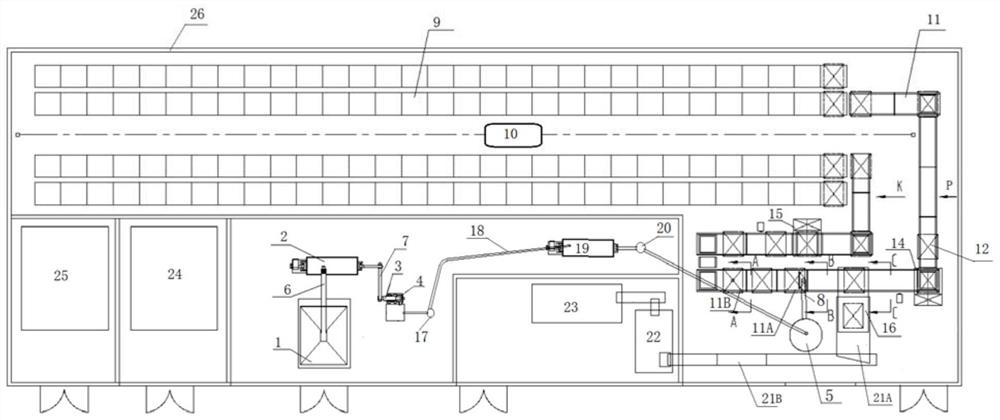

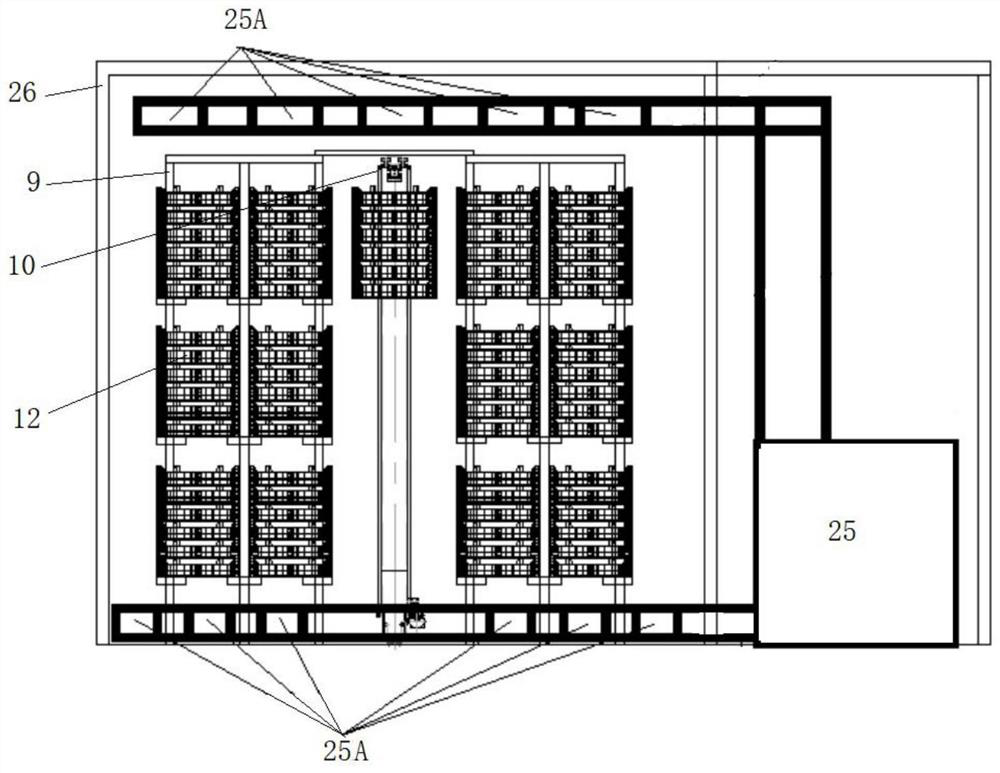

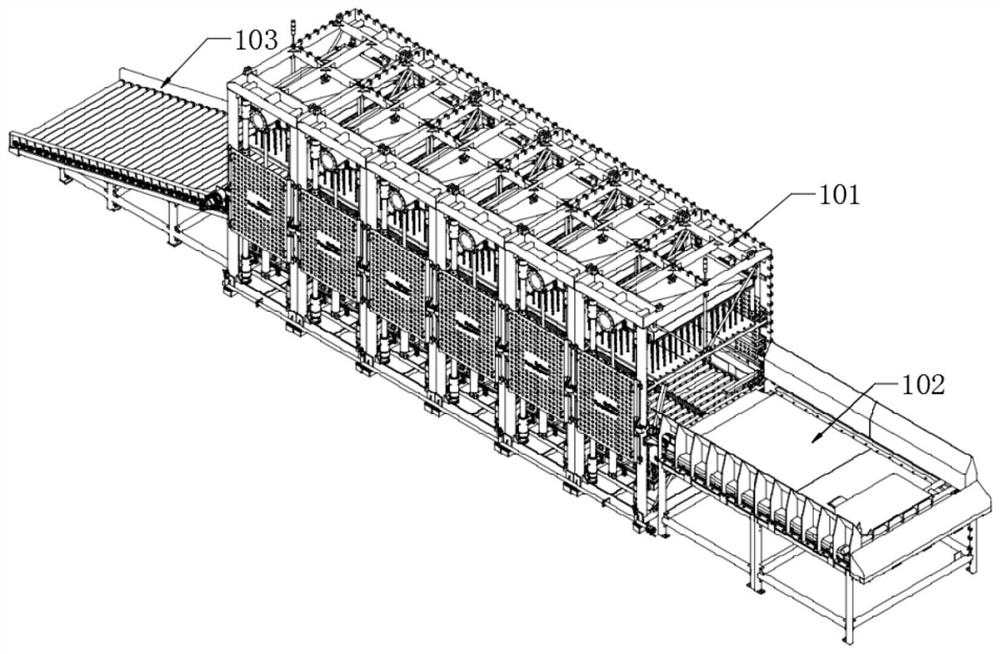

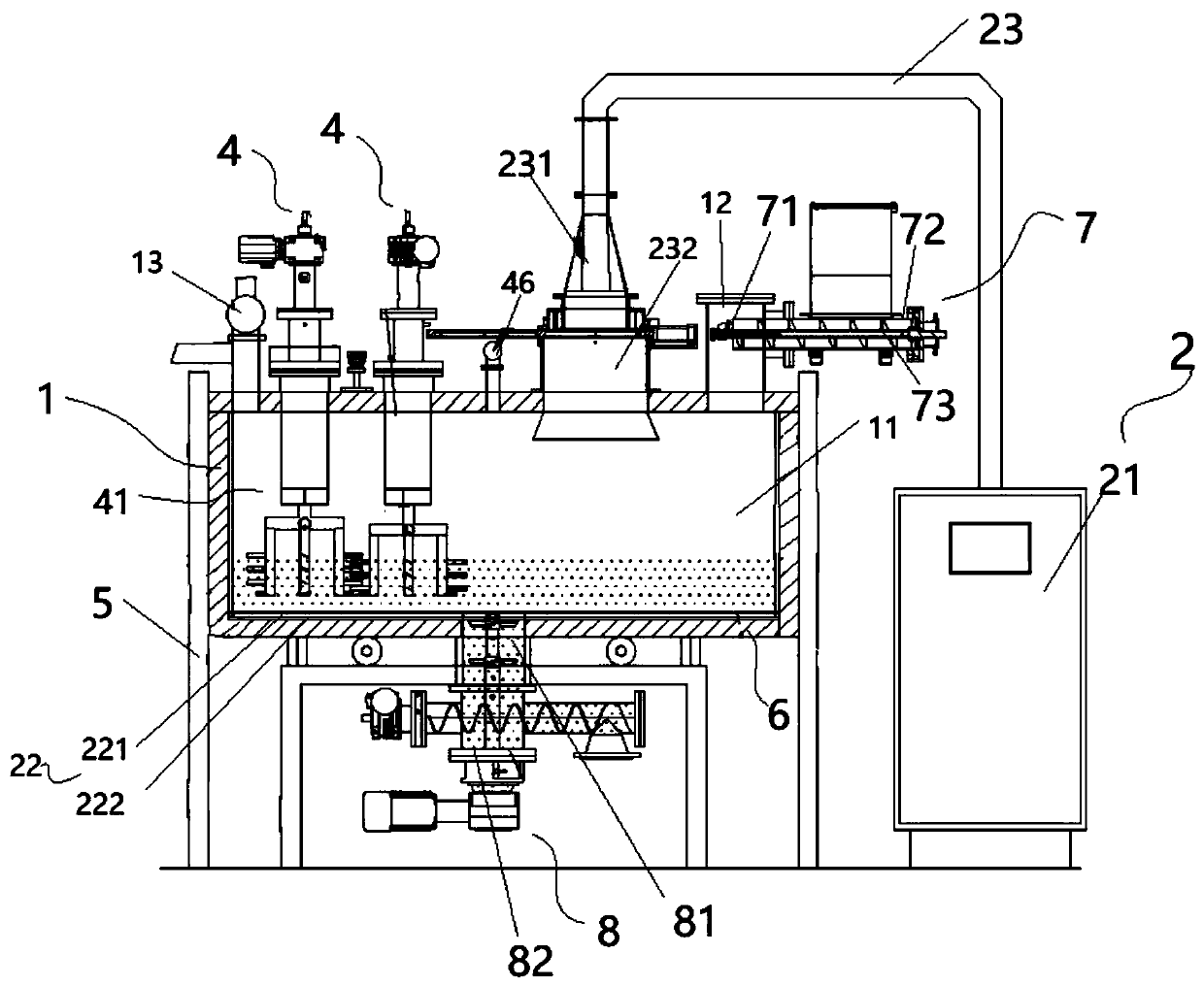

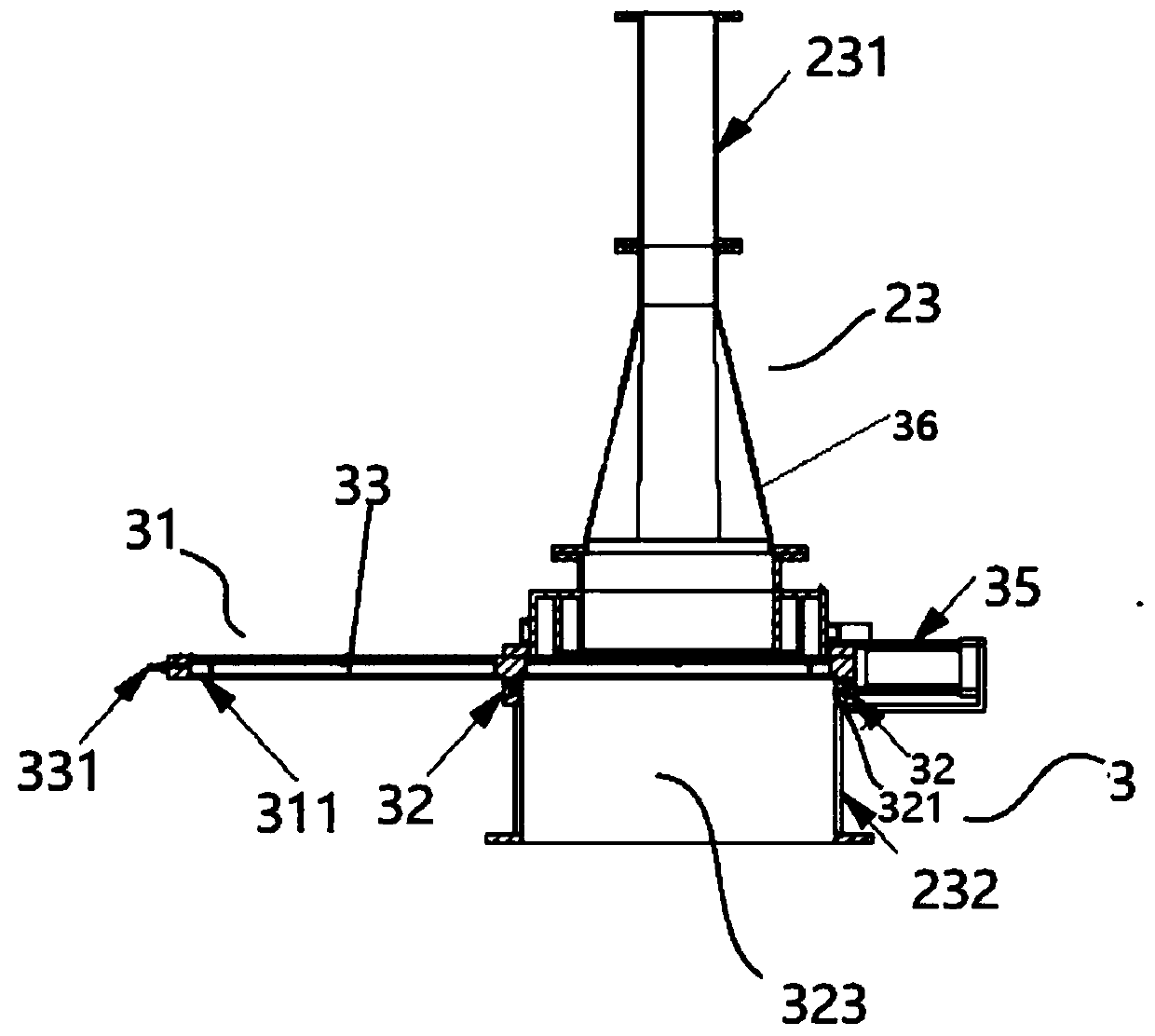

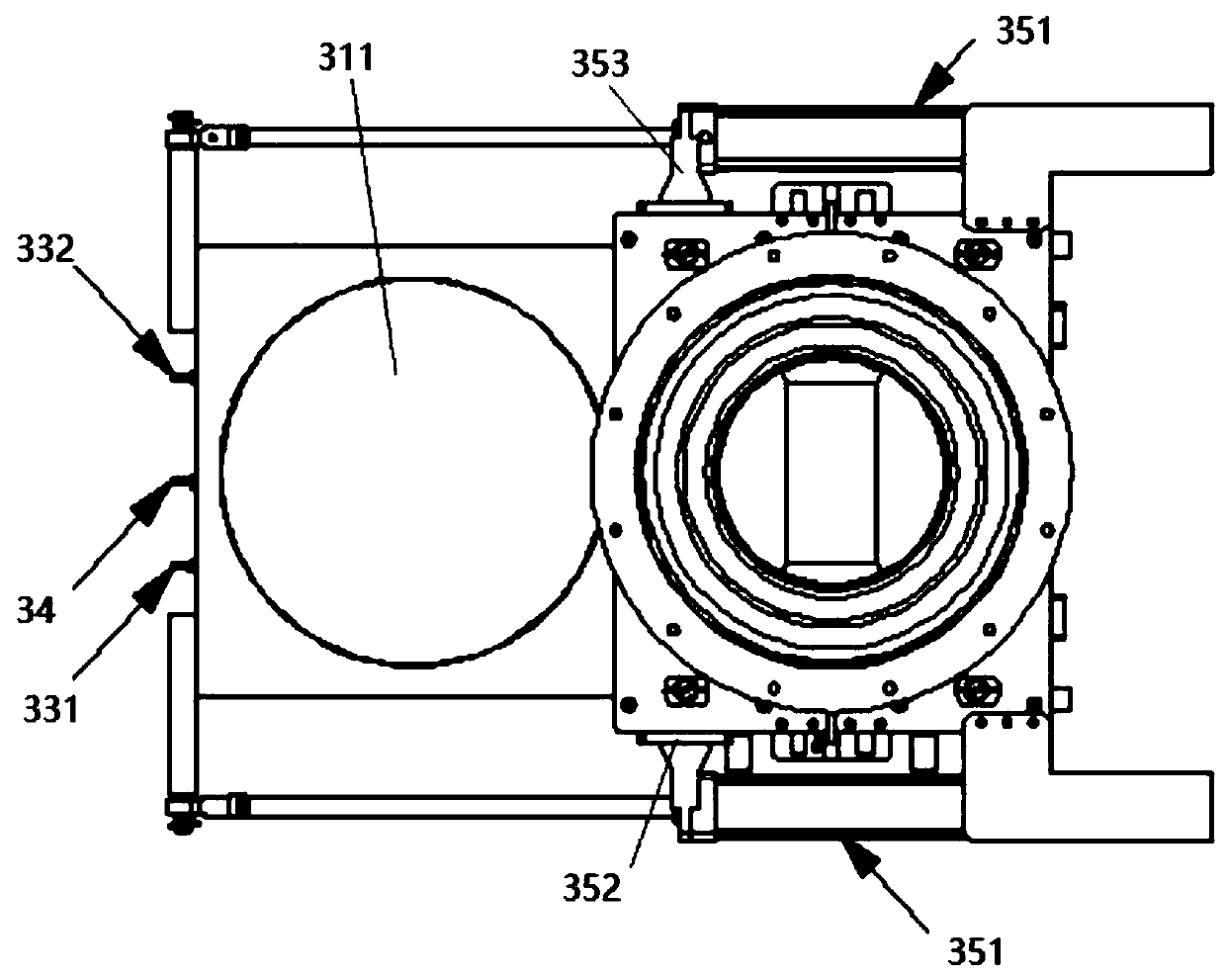

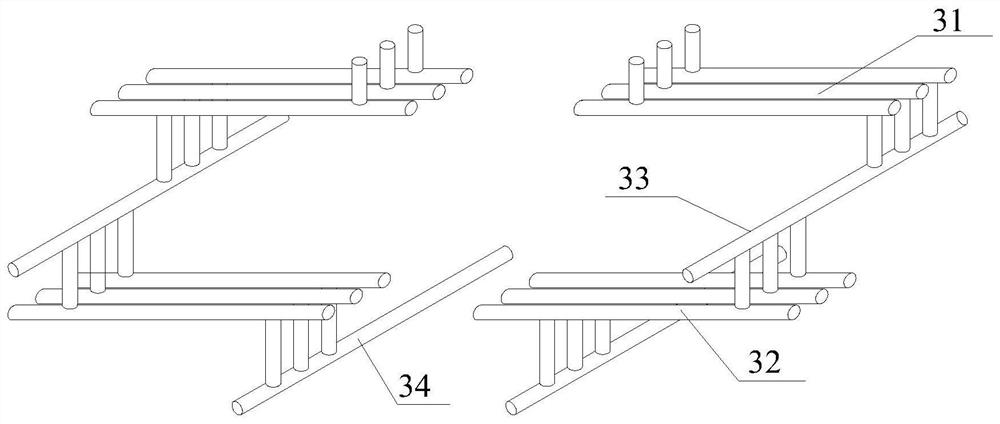

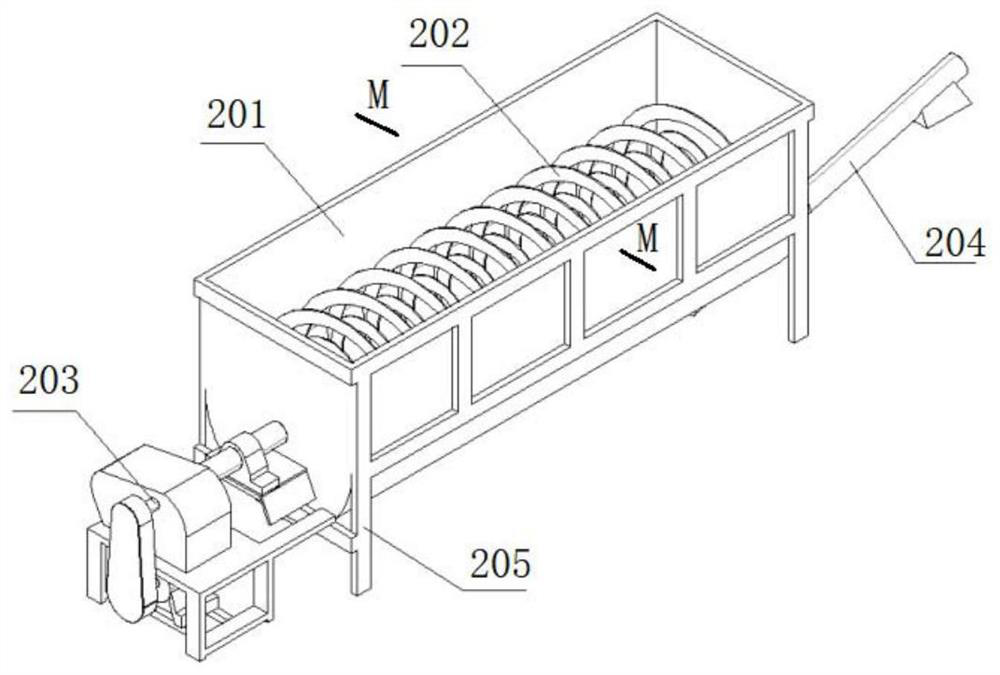

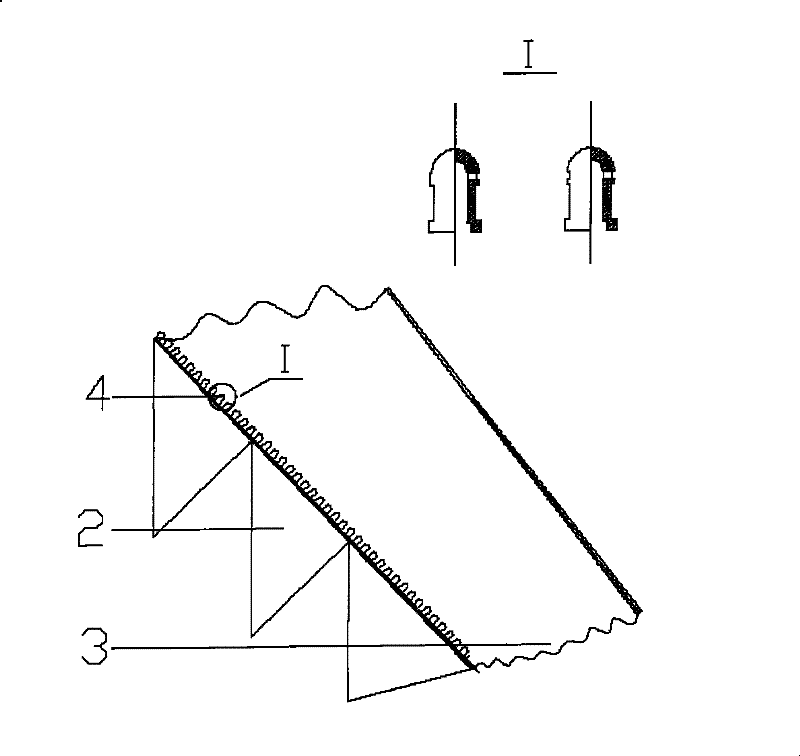

Automatic production system combining livestock and poultry manure treatment and hermetia illucens three-dimensional breeding and method

ActiveCN112772575AImprove daily throughputReduce pollutionAnimal feeding stuffAnimal scienceHermetia

The invention discloses an automatic production system combining livestock and poultry manure treatment and hermetia illucens three-dimensional breeding and a method. The system comprises a livestock and poultry manure treatment system, a vertical warehouse (9) for breeding hermetia illucens, a movable carrying device (10) arranged in the vertical warehouse, a continuous conveying device (11) arranged beside the vertical warehouse, material trays (12) sequentially operating along the continuous conveying device, a bait feeding station (11A) and a larva feeding station (11B), and the bait feeding station (11A) and the larva feeding station (11B) are arranged on the continuous conveying device. By means of the automatic production system and the method, livestock and poultry manure is automatically treated by adopting intelligent system equipment, harmless treatment of the livestock and poultry manure is completed by utilizing digestion of the hermetia illucens, resource utilization and automatic, large-scale and harmless treatment of the livestock and poultry manure are realized, the daily treatment capacity of the livestock and poultry manure is greatly improved, and the environment is improved.

Owner:云南正承融创科技有限公司

Device and method for processing kiln ash generated in cement kiln household garbage co-processing

ActiveCN106396441AImprove daily throughputImprove daily processing efficiencyIncinerator apparatusImpellerLitter

The invention provides a device and method for processing kiln ash generated in cement kiln household garbage co-processing. A raw material vertical mill is connected to a cyclone dust collector and then connected to a big cloth bag dust collector. The bottom of the big cloth bag dust collector is connected to a spiral reamer through a chain conveyor, an elevator, and an ash collecting chamber. The spiral reamer is connected to an impeller feed machine, and the impeller feed machine is connected to a decomposing furnace. According to the method, kitchen garbage and cement raw materials are fed into the raw material vertical mill and grinded, the combustible garbage is fed into the decomposing furnace, after dust absorption, the combustible garbage is delivered to a kiln and burned to obtain clinker; the dust in the high temperature flue gas from the cyclone dust collector is absorbed by the big cloth bag dust collector, and the collected kiln ash is calcined in the decomposing furnace. After improvement, the daily garbage processing amount is increased from 30-50 tons to 200-300 tons, the daily garbage processing efficiency is largely improved, the normal operation of the garbage processing equipment is guaranteed, and the pollution caused by the garbage to the city is reduced.

Owner:葛洲坝洁新(武汉)科技有限公司

Desulfurization wastewater treatment device adopting efficient clarifier

InactiveCN103910445AReduce processing frequencyEasy to handleMultistage water/sewage treatmentCycloneLiquid level measurement

The invention discloses a desulfurization wastewater treatment device adopting an efficient clarifier. The device comprises a wastewater cyclone, the efficient clarifier, an outlet water tank, a drug adding treatment box, a secondary clarifier and an outlet water pump. The wastewater cyclone is communicated with the efficient clarifier through a pipeline, the overflow port of the efficient clarifier is communicated with the outlet water tank through a pipeline, and a liquid level difference exists between the overflow port of the efficient clarifier and the outlet water tank. The outlet water tank is communicated with the drug adding treatment box through a pipeline, which is provided with the outlet water pump. The water outlet of the drug adding treatment box is communicated with the secondary clarifier. A liquid level difference exists between the water outlet of the drug adding treatment box and the secondary clarifier. And the outlet water tank is internally equipped with an outlet water tank liquid level measurement meter. According to the invention, the absorption tower slurry chloride ion concentration is ensured in a scope of design, and long-term, safe and stable operation of the desulfurization system is guaranteed.

Owner:武汉光谷环保科技股份有限公司

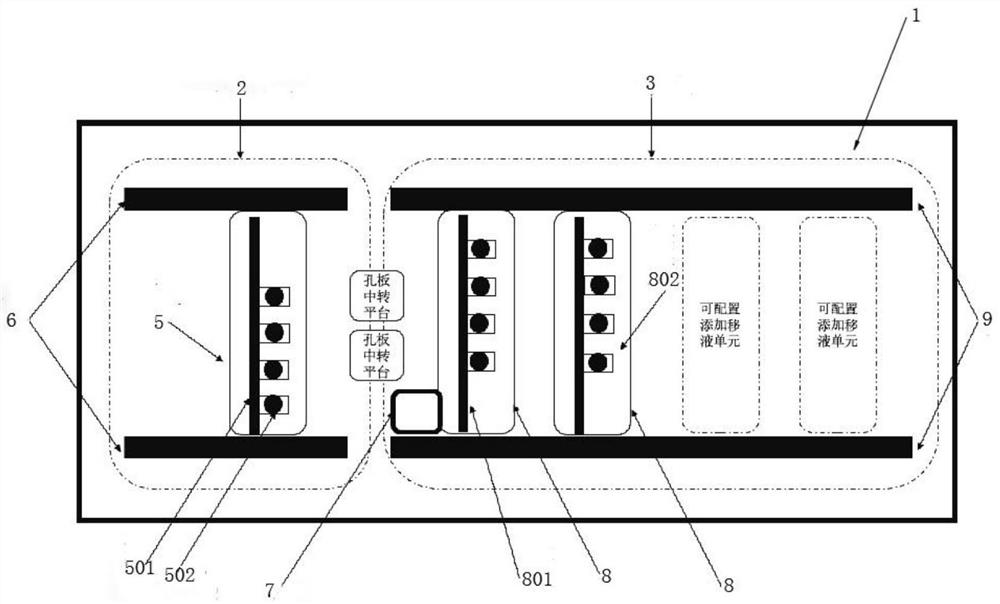

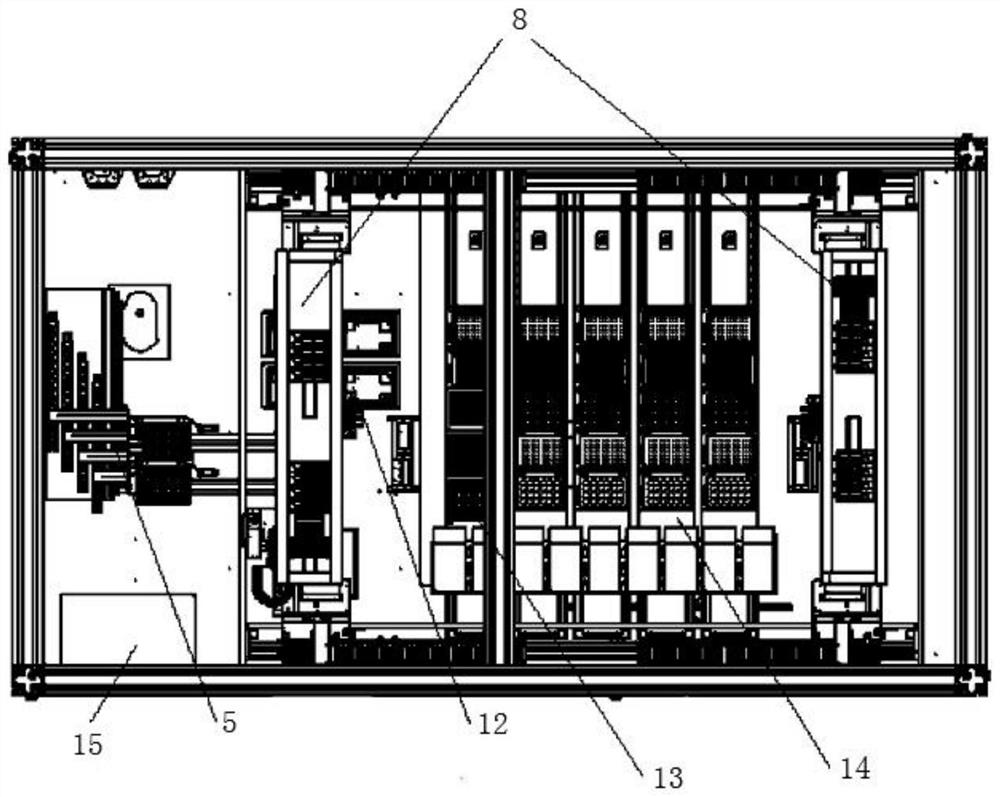

Novel integrated liquid operating system

PendingCN113499813AHigh densityEliminate the risk of contaminationHollow article cleaningBurettes/pipettesElectric machineryProcess engineering

The invention relates to the technical field of biopharmaceutical equipment, in particular to a novel integrated liquid operating system which comprises a workbench, a pump liquid supplementing area, a liquid transferring area and a linear motor gantry main frame; the pump liquid supplementing area comprises a pump liquid supplementing unit, a pump liquid supplementing X-axis linear motor and an orifice plate transfer robot; and theliquid transferring area comprises a liquid transfer unit and a liquid transfer X-axis linear motor. The system of the invention can effectively solve the problems that when a working head of the existing imported equipment 8-channel pipetting liquid workstation is arranged on the same guide rail, although the high efficiency during the pipetting operation of a 96-hole pore plate is ensured, half of channels are idle and hardware waste is caused when a large number of daily consumed materials such as 24-hole plates and 6-hole plates are served, and when a 24-pore plate and a 96-pore plate are used in a mixed mode, most of liquid transfer channels are idle, and existing imported equipment has a huge space for further improving efficiency are solved.

Owner:INNOVEL INTELLIGENT TECH CO LTD +1

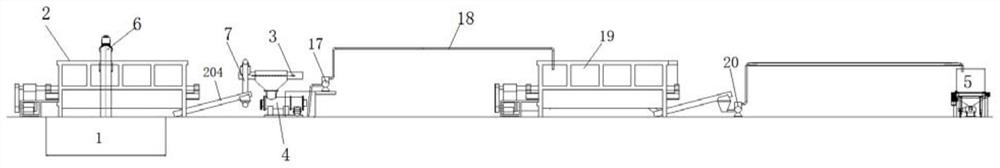

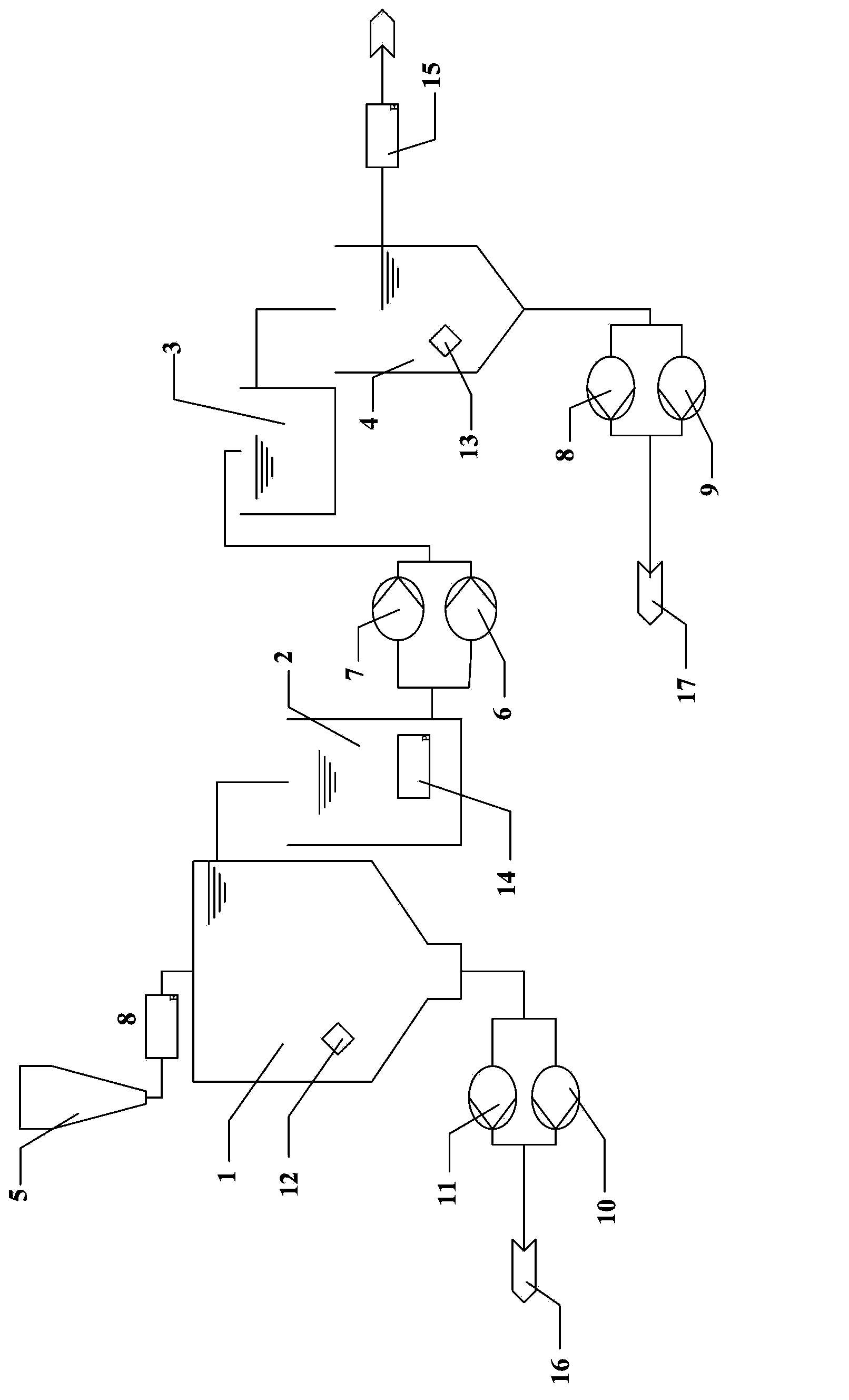

Mobile type rural garbage multi-stage divided chamber pyrolysis water heating system

PendingCN110081430AFast heating rateImprove heating efficiencyDomestic hot-water supply systemSpecial form destructive distillationExhaust gasTar

The invention discloses a mobile type rural garbage multi-stage divided chamber pyrolysis water heating system. The system comprises a feeding mechanism with a breaking device, a rotating type low-temperature pyrolyzing furnace, a high-temperature pyrolysis chamber, a tail gas treatment system and a PLC control device. The tail gas treatment system comprises a cooling chamber, a deacidification chamber, a dust removal chamber, a fan and a boiler, a main water inlet and branch water inlets are formed in the upper portion of the left side of the boiler, a boiler water outlet is formed in the middle of the right side of the boiler, a boiler air inlet is formed in the lower portion of the left side of the boiler, a water outlet of the cooling chamber is connected with the branch water inlets of the boiler through a water conveying pipe, and a tar collecting pipe is arranged in the cooling chamber, and is located below the cooling pipe and communicates with the bottom of the cooling pipe. According to the mobile type rural garbage multi-stage divided chamber pyrolysis water heating system, garbage pyrolysis is used for enabling garbage resource, light reduction and effectiveness to be achieved.

Owner:ZHEJIANG UNIV OF TECH

Method for treating wastewater generated in production of hexabromocyclododecane

ActiveCN102583904AEasy to handleReduce processing costsMultistage water/sewage treatmentNature of treatment waterChemical oxygen demandMagnesium salt

The invention discloses a method for treating wastewater generated in production of hexabromocyclododecane. The method comprises the following steps of: performing metal catalytic reduction on the wastewater by using iron powder and / or aluminum powder and adding inorganic sodium salt and / or inorganic magnesium salt which serves as a catalyst; and performing biochemical treatment. When the wastewater generated in the production of the hexabromocyclododecane, after the wastewater is subjected to the metal catalytic reduction and flocculent precipitation treatment, the biodegradability of the hexabromocyclododecane wastewater is greatly improved, the wastewater treatment effect is improved, the chemical oxygen demand (COD) in the treated wastewater is 80-120mg / L, ammonia nitrogen in the treated wastewater is less than 30mg / L, and the daily treatment capacity of a wastewater biochemical system is improved. A reducing agent has the advantages of readily available raw materials and low price, heavy metal pollution is avoided, and the wastewater treatment cost is reduced.

Owner:山东默锐环境产业股份有限公司

Modularized multifunctional dryer

PendingCN114413606AImprove drying efficiencyReduce excess spaceGrass dryingDrying gas arrangementsAgricultural scienceAgricultural engineering

The invention belongs to the technical field of dryers, and particularly relates to a modularized multifunctional dryer which comprises a dryer body, a feeding device and a discharging device, the dryer body is formed by assembling a plurality of groups of functional modules which are connected in series, and each functional module comprises an upper frame and a lower frame which are fixedly connected together; an upper air outlet mechanism and a lower air outlet mechanism are installed in the upper frame and the lower frame in a sliding mode respectively, and the upper air outlet mechanism and the lower air outlet mechanism are distributed in a mirror image mode. The modular multifunctional drying machine is high in production efficiency and suitable for drying treatment of agricultural and pasture products, the functional modules in the modular multifunctional drying machine comprise a plurality of station drying units and cooling units, continuous drying of forage grass such as alfalfa and grassland grass is achieved, continuous and rapid drying of grains can also be achieved, and the production efficiency is improved. The loss caused by weather influence is reduced, and the daily processing capacity of the dryer is improved, so that the production efficiency is improved.

Owner:厦门奔晨机械科技有限公司

Gathering type large flow haze removal air purification system

InactiveCN104107592BIncrease flow rateImprove daily throughputCombination devicesDispersed particle filtrationWater storageFiltration

The invention relates to a wind-concentrating type large flow haze-removing air purifying system, comprising a tower body and a wind-concentrating cover. A primary filter layer and a secondary absorption layer are arranged in the middle of the tower body; a haze air inlet is arranged at the side wall of the tower body below the filter layer; a clean air outlet is arranged at the top of the tower body; and the clean air outlet at the top of the tower body is communicated to the middle of the wind-concentrating cover. A water storage chamber is arranged at the bottom of the tower body; a submersible pump is arranged in the water storage chamber; a sprayer connected to the submersible pump is disposed between the primary filter layer and the secondary absorption layer. Haze-containing air enters the tower body through the haze air inlet and is purified through the filter layer by removing the haze. According to the invention, the wind-concentrating cover is used to increase air flow rate; filtered clean air in the tower body is pumped out in a self-absorption manner; and the wind-concentrating type large flow haze-removing air purifying system can work in gentle breeze, thereby increasing daily processing capacity of the air. The haze-containing air is subjected to two-stage filtration and water filtration, and thus a haze-removing purifying effect is significant. A power supply is provided to the submersible pump and an axial flow exhaust fan through a wind motor and a solar cell panel, thereby realizing automatic power supply.

Owner:晋中市三元风能除霾发电技术研究所

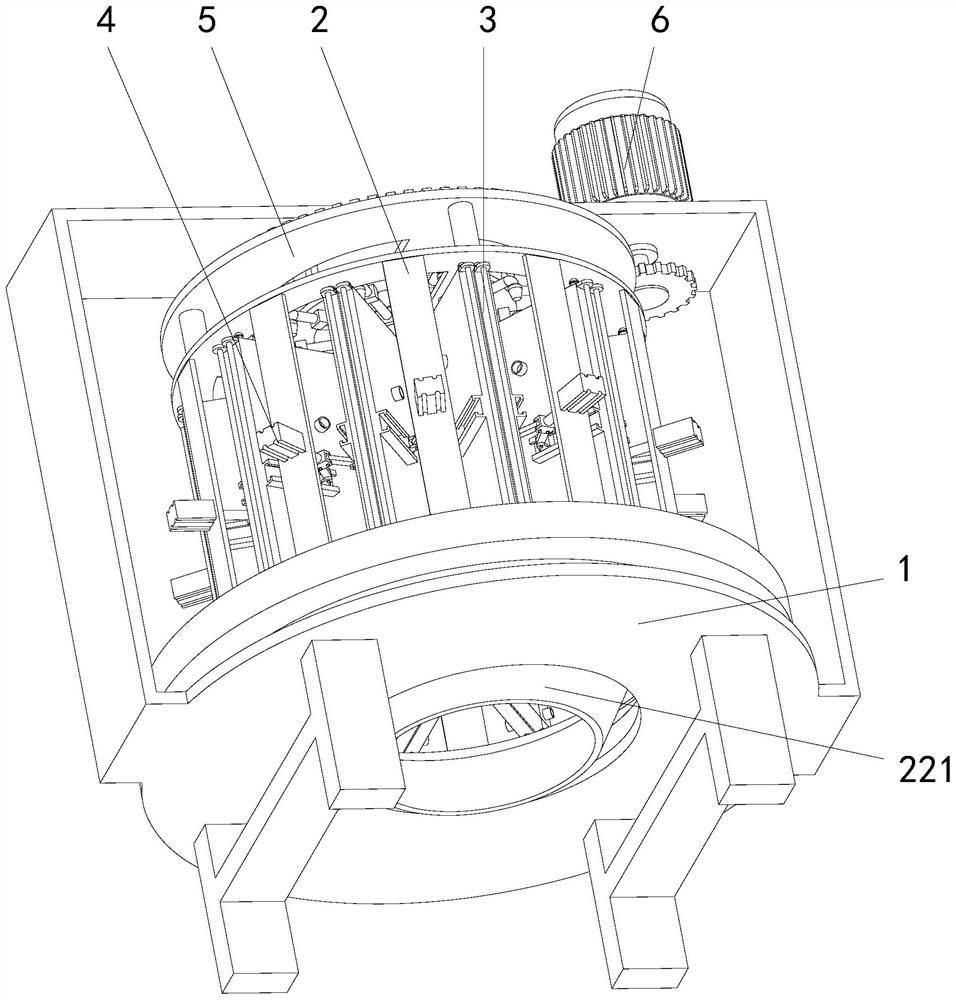

Microwave pyrolysis equipment

PendingCN111139099AImprove daily throughputOvercome the defects that need to be processed in batches and batchesProductsReagentsMicrowave pyrolysisWaveguide

The invention relates to the technical field of pyrolysis, and provides pyrolysis equipment. The equipment comprises a machine frame, a shell, a microwave generating device, a waveguide protection device and a stirring device, wherein the shell is arranged on the machine frame, and a containing cavity used for containing materials is formed in the machine frame; the microwave generating device comprises at least one microwave generator and a wave absorbing assembly, the microwave generator is communicated with the containing cavity through a waveguide, and the wave absorbing assembly is arranged in the containing cavity; the waveguide protection device is arranged on the waveguide, and a dielectric protection layer is formed between the containing cavity and the waveguide; the stirring device is arranged on the shell, and one end of the stirring device extends into the containing cavity and is inserted into the material for stirring. The pyrolysis equipment is reasonable in structuraldesign, pyrolysis treatment can be carried out on a large batch of materials, all the devices operate independently, maintenance is convenient, the treatment efficiency is high, and the defect that the large batch of materials need to be treated in batches is overcome.

Owner:北京诺芯环境科技有限公司

Large tonnage sludge dehydration treatment device and sludge treatment method

ActiveCN108623121BEfficient dissociationLarge daily processing capacitySludge treatment by oxidationSludge treatment by pyrolysisSludgeCatalytic oxidation

The invention discloses a large-tonnage sludge dehydration treatment device and a sludge treatment method, including a sludge storage and transportation area and a sludge treatment area. Transported to the sludge treatment area, the sludge treatment area is composed of four pyrolysis chambers, the second-level pyrolysis chamber is equipped with two horizontal pyrolysis pipes that are not connected to each other, the third-level pyrolysis chamber is parallel to the first-level pyrolysis chamber, There are six horizontal pyrolysis tubes not communicating with each other, and the fourth-level pyrolysis chamber is parallel to the second-level pyrolysis chamber; each pyrolysis tube is equipped with a hollow spiral impeller. The large-tonnage sludge dehydration treatment device of the present invention adopts four-stage pyrolysis chambers to carry out pyrolysis treatment on sludge in stages, six-pipe pyrolysis chambers and double-pipe pyrolysis chambers are arranged alternately, the pipes are heated outside the pipes and filtered inside the pipes, and the electrocatalytic oxidation method is used. Realize rapid and efficient dissociation of sludge bound water, low dissociation cost and long service life, large daily processing capacity and high processing efficiency, the daily processing capacity can reach 150 tons, and the dryness is 10-15%. It is suitable for large-scale promotion and use.

Owner:湖南金保树环保科技有限公司

Cold plasma fusion technology waste treatment system and method

InactiveCN107377585BWon't happenEfficient recyclingWaste processingCarbon compoundsSewageWaste treatment

The invention discloses a garbage treatment system of cold plasma fusion technology, comprising: a cold plasma fusion device, a garbage treatment reaction chamber, an air-cooled heat exchange system, an antiparticle generator, a dryer, a gas turbine generator and a temperature-controlled Cold plasma decomposer. The invention also discloses a garbage treatment method using cold plasma fusion reactor technology. The invention provides the waste treatment system of the cold plasma fusion technology, which is a combined and three-dimensional configuration. In addition to solving the shortcomings of traditional waste treatment such as composting, incineration, and landfilling, it also solves the overall problem of the current arc gasification waste. The quantity is small and the practical application is limited. Compared with other methods, the daily treatment capacity of urban and rural garbage and sewage is greatly improved.

Owner:广州仁廙环保技术有限公司

A garbage pyrolysis gasifier

ActiveCN105737164BImprove pyrolysis gasification efficiencyReduce generationIncinerator apparatusInlet channelCombustion chamber

The invention discloses a garbage pyrolysis gasification furnace. A base of a furnace body is arranged in an ash pan. An air and steam inlet channel is formed in the center of the ash pan. An air and steam inlet of the air and steam inlet channel communicates with the interior of the garbage pyrolysis gasification furnace. An air and steam outlet is formed in the top end of the air and steam inlet channel, and the lower end of the air and steam inlet channel is connected with an air blower. A pyrolysis gasification chamber in the garbage pyrolysis gasification furnace is provided with an ash layer, a combustion gasification chamber, a destructive distillation layer and a drying layer from bottom to top. The combustion gasification chamber is provided with an ignition opening. A pyrolysis gasification gas outlet is formed in the drying layer and is connected with a secondary combustion chamber. A feeding opening is formed in the top of the garbage pyrolysis gasification furnace. A scraper is welded to the ash pan, the ash pan is driven by a motor to rotate, ash entering the ash pan is brought out by the scraper, and two rows of small gas holes are formed in the two sides of the scraper. According to the garbage pyrolysis gasification furnace, the optimal efficiency of garbage pyrolysis gasification can be achieved, and the garbage pyrolysis gasification furnace is more economical and environment-friendly.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

A waste incineration treatment device

ActiveCN104165365BImprove utilizationImprove daily throughputIncinerator apparatusActivated carbonCombustor

The invention discloses a garbage incineration disposal device which comprises an incinerator, a shock cooling type high-pressure spraying dust collection device, an induced draft fan, a smoke and melt water exchange treatment device, a smoke treatment condenser, a winding plate combination ash-sticking dust remover and an activated carbon adsorption chamber, wherein the incinerator, the shock cooling type high-pressure spraying dust collection device, the induced draft fan, the smoke and melt water exchange treatment device, the smoke treatment condenser, the winding plate combination ash-sticking dust remover and the activated carbon adsorption chamber are sequentially connected. The incinerator comprises an incinerator body, a hearth combustor, two combustors and an incinerator body base. The shock cooling type high-pressure spraying dust collection device comprises a spraying case, a smoke inlet pipe joint, a spraying water gathering hopper and a smoke outlet pipe joint. The smoke and melt water exchange treatment device comprises a smoke and melted water exchange treatment action tank, a water and smoke passing tank and an overflow gap water line control sideboard. The smoke treatment condenser comprises a condenser case, a smoke outlet pipe joint and a second smoke inlet pipe joint. The winding plate combination ash-sticking dust remover comprises an upper dust remover body and a lower dust remover body. The activated carbon adsorption chamber comprises an adsorption chamber case, a third smoke outlet pipe joint and a third smoke inlet pipe joint. The device saves energy, is environmentally friendly, generation of dioxin can be effectively restrained, garbage is combusted fully, and the maintenance cost is low.

Owner:SHE COUNTY LVYUAN ENVIRONMENTAL PROTECTION EQUIP CO LTD

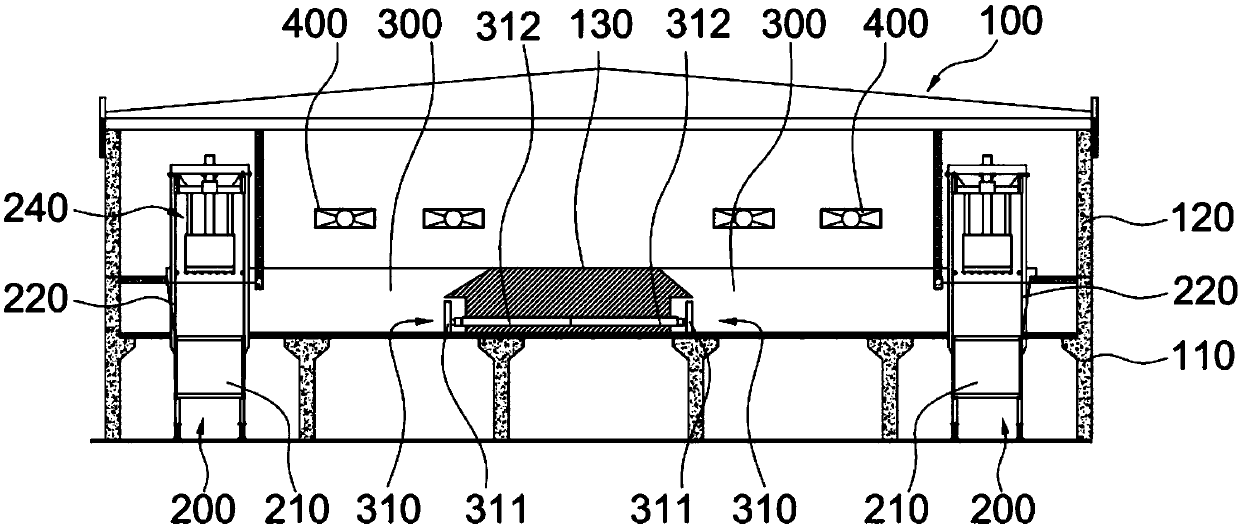

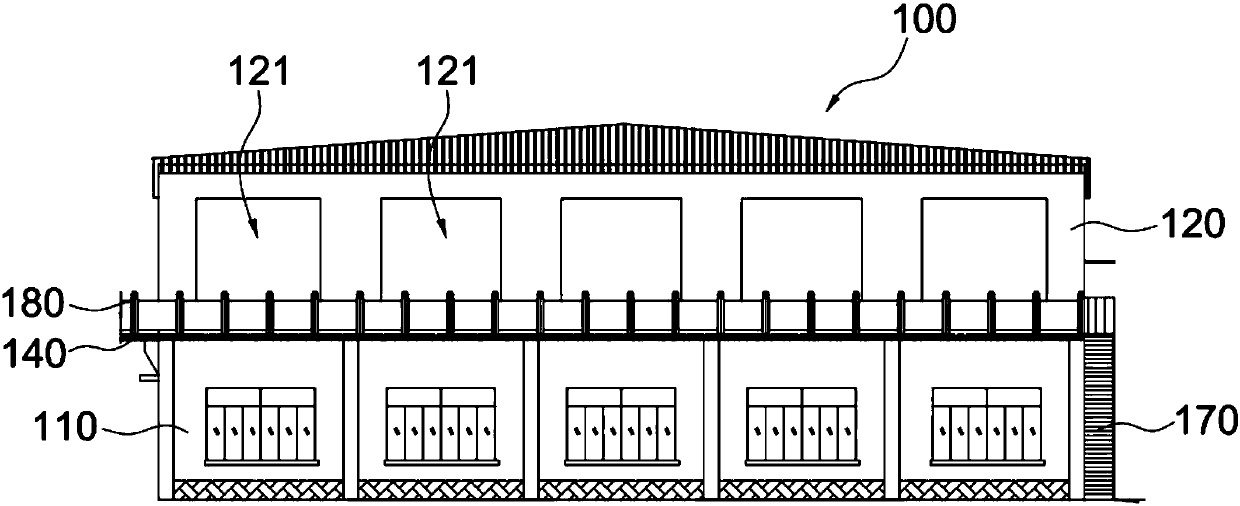

Large-tonnage four-column vertical-pressure rubbish compression station

PendingCN107720061AImprove daily throughputOvercome structural constraintsRefuse transferringLoading/unloadingLarge capacityArchitectural engineering

Owner:SICHUAN ZHONGLIANHENG ENVIRONMENTAL PROTECTION ENG CO LTD

A process for producing cathode copper from low-grade anode plates

ActiveCN109628954BInnovative technologyRaise the gradeElectrolysis componentsPhotography auxillary processesElectrolytic agentEthyl acetate

The invention relates to a process for producing cathode copper by low-grade anode plates. Low-grade high-nickel tin black copper is used as raw materials for direct electrolysis refining to prepare qualified cathode copper; through such modes as adjustment of process conditions, selection of reasonable current density, flow and temperature, adjustment of the additive ratio and adding of modifiedpolyacrylamide, the obtained cathode copper is higher in grade, smooth in surface, clear and compact in grain, uniform in thickness and beautiful; meanwhile, the purification and replacement period ofelectrolyte is prolonged, so that the production cost is greatly reduced when the recovery rate is increased; anode mud is treated by adopting ethyl acetate and phenolic resins, so that the problem of difficult gold and silver separation of the anode mud due to adding of polyacrylamide is solved, and the daily treatment quantity of the anode mud is increased; and copper sulfate crystal seeds areintroduced to accelerate separation of copper sulfate crystals, so that the recycling rate of metal copper and nickel is improved.

Owner:江西新金叶实业有限公司

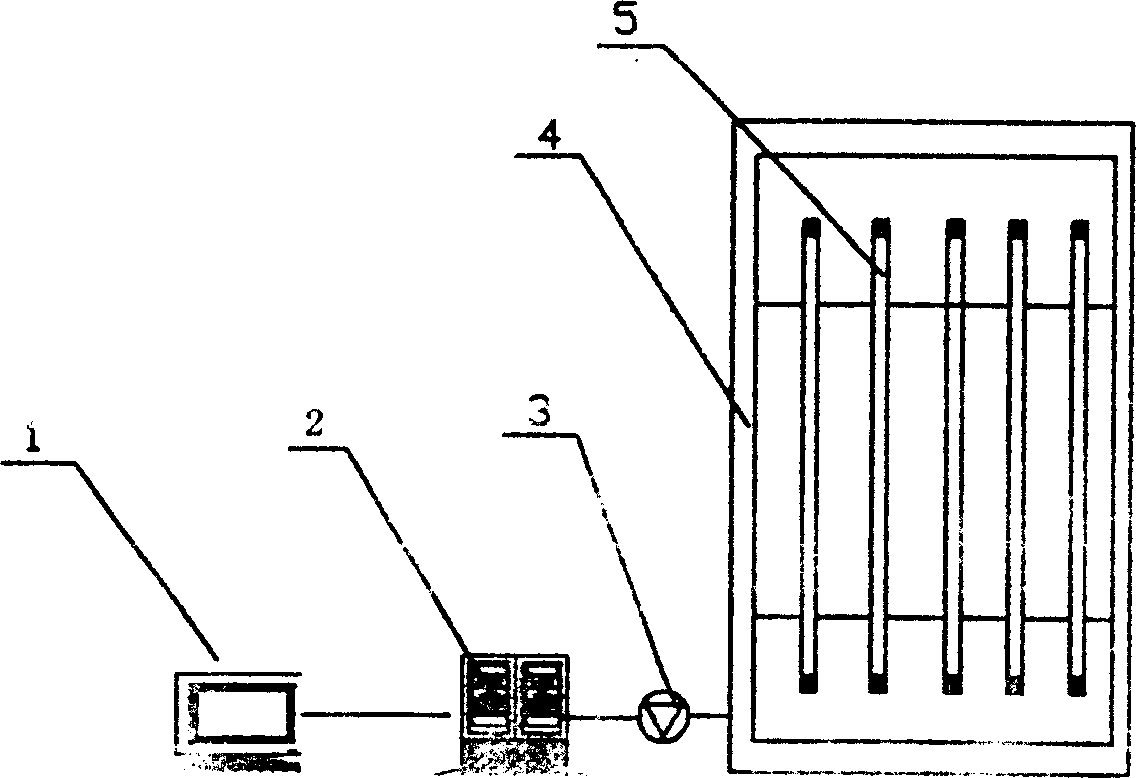

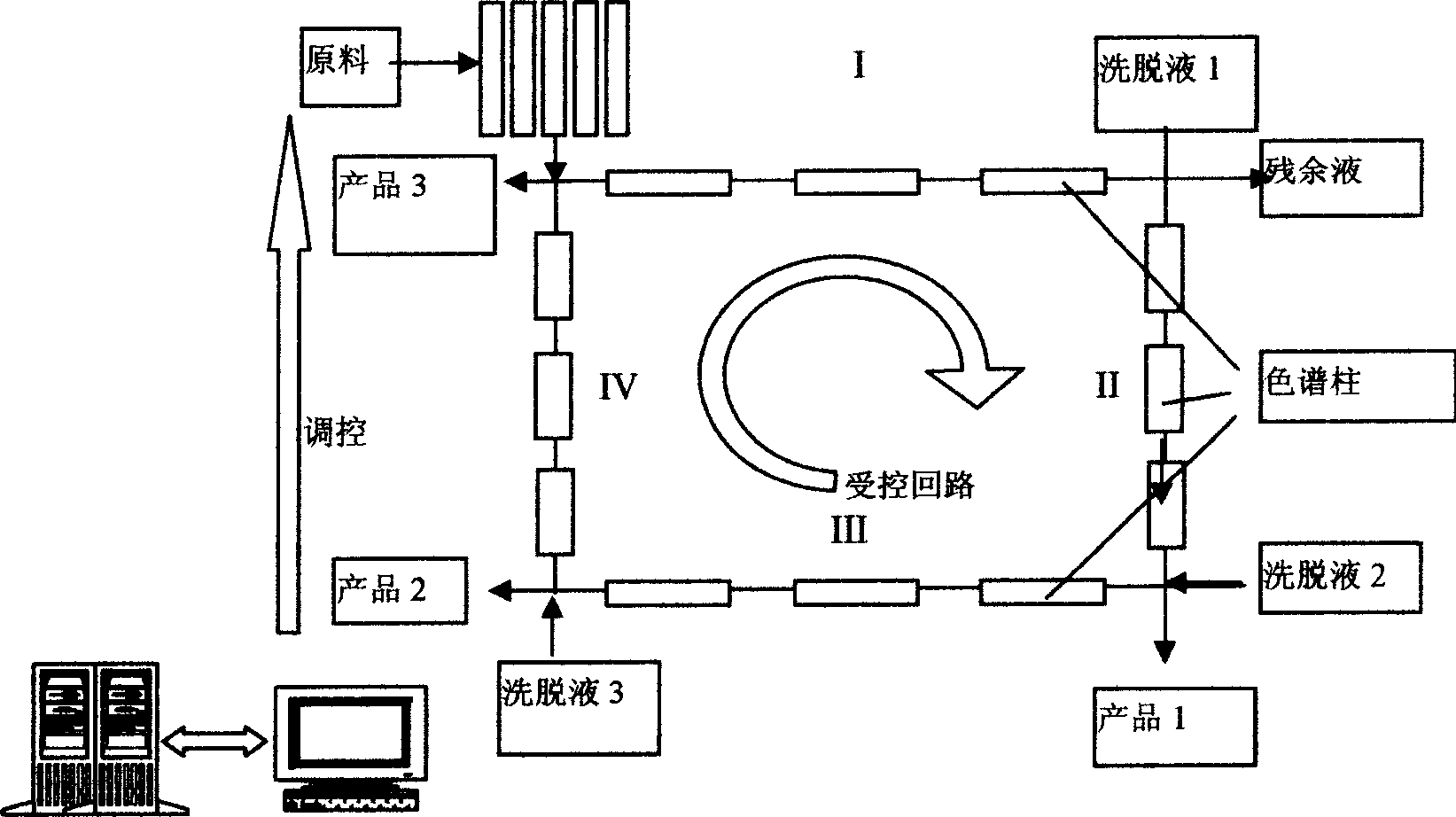

Method for extracting active substances from cow colostrums and equipment therefor

InactiveCN1883505ASimplified separation stepsHigh yieldUnknown materialsImmunological disordersBiotechnologyBiochemical engineering

The present invention relates to a method for extracting active substances from cow colostrums and its equipment. The invention uses continuous ion exchange equipment to extract active substances from cow colostrums. The process simplifies cow colostrums separation steps, increases its yield and purity, reduces separation cost for industrialization and improves cow colostrums resource utility ratio. The present invention also provides a kind of equipment, which realizes continuous ion exchange, increases yield and purity, reduces separation cost for industrialization and reaches the target of comprehensive utilization of cow colostrums.

Owner:ZHEJIANG UNIV

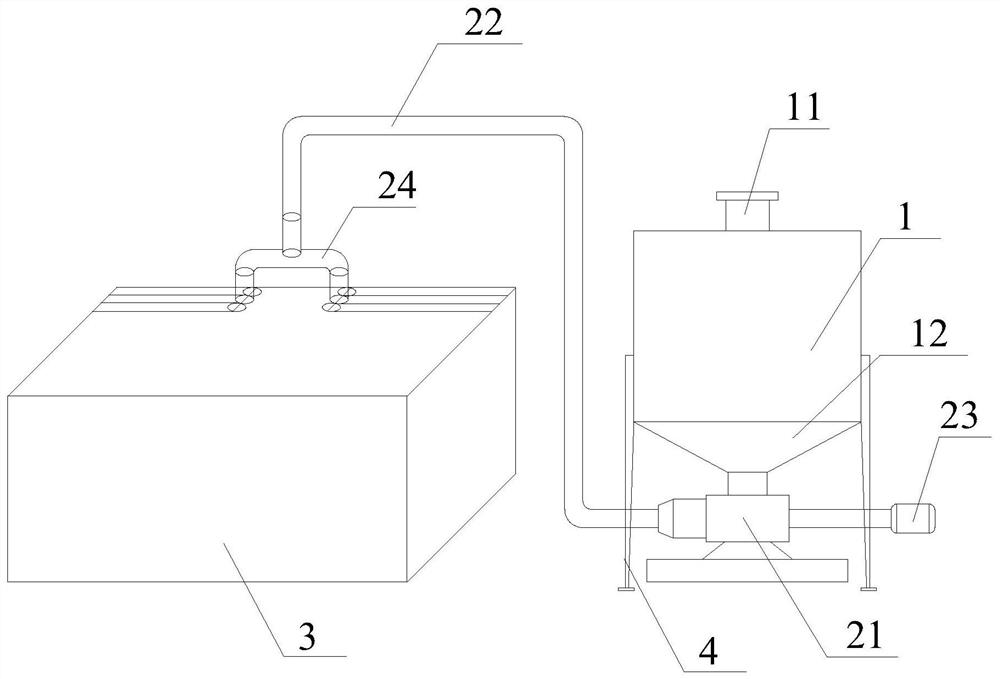

A kind of livestock and poultry manure continuous processing system and processing method

ActiveCN112759431BEfficient conversionCompletely convertedClimate change adaptationExcrement fertilisersAgricultural scienceEnvironmental engineering

A continuous processing system and processing method for livestock and poultry manure, the system comprises a storage tank (1) containing livestock and poultry manure, a stirring device (2) arranged beside the storage tank, a debris removal device (3), a grinding A device (4), a bait storage bin (5), a first feeding device (6) is connected between the storage tank and the stirring device, and a second feeding device (7) is connected between the stirring device and the debris removing device , the discharge port of the debris removal device and the feed port of the grinding device are directly connected or connected through a connecting pipe, and the discharge port of the grinding device is connected to an external storage device (5). The invention can carry out continuous ecological and harmless treatment of livestock and poultry manure, has small floor space, simple and efficient processing equipment, short processing period, little environmental pollution, and the treated livestock and poultry manure can be directly used for energy saving and environmental protection.

Owner:云南正承融创科技有限公司

A rapid construction method for methanogenesis under acidic conditions

ActiveCN104357486BImprove daily throughputEnhanced methanogenic activityWaste based fuelFermentationMicroorganismSymbiotic bacteria

The invention relates to a quick construction method for generating methane under an acidic condition. The quick construction method comprises the following steps: pretreating seed sludge, performing habituated culture on the seed sludge to form acid-resisting acidophilus microorganism agglomerate rich in acid-resisting acidophilus methanogens and other symbiotic bacteria, inoculating the acid-resisting acidophilus microorganism agglomerate to a closed reactor containing fresh or acidulated perishable organic waste, and conducting anaerobic digestion to generate methane. Compared to the prior art, the methane generating method disclosed by the invention can maintain the methane generating activity under the acidic condition (at the pH value of 5.5-6.2), implement high organic loading anaerobic treatment to generate the methane with the organic waste at a lower inoculation rate, and further can be used for quickly enabling a rancidified anaerobic digester to restore generation of methane.

Owner:TONGJI UNIV

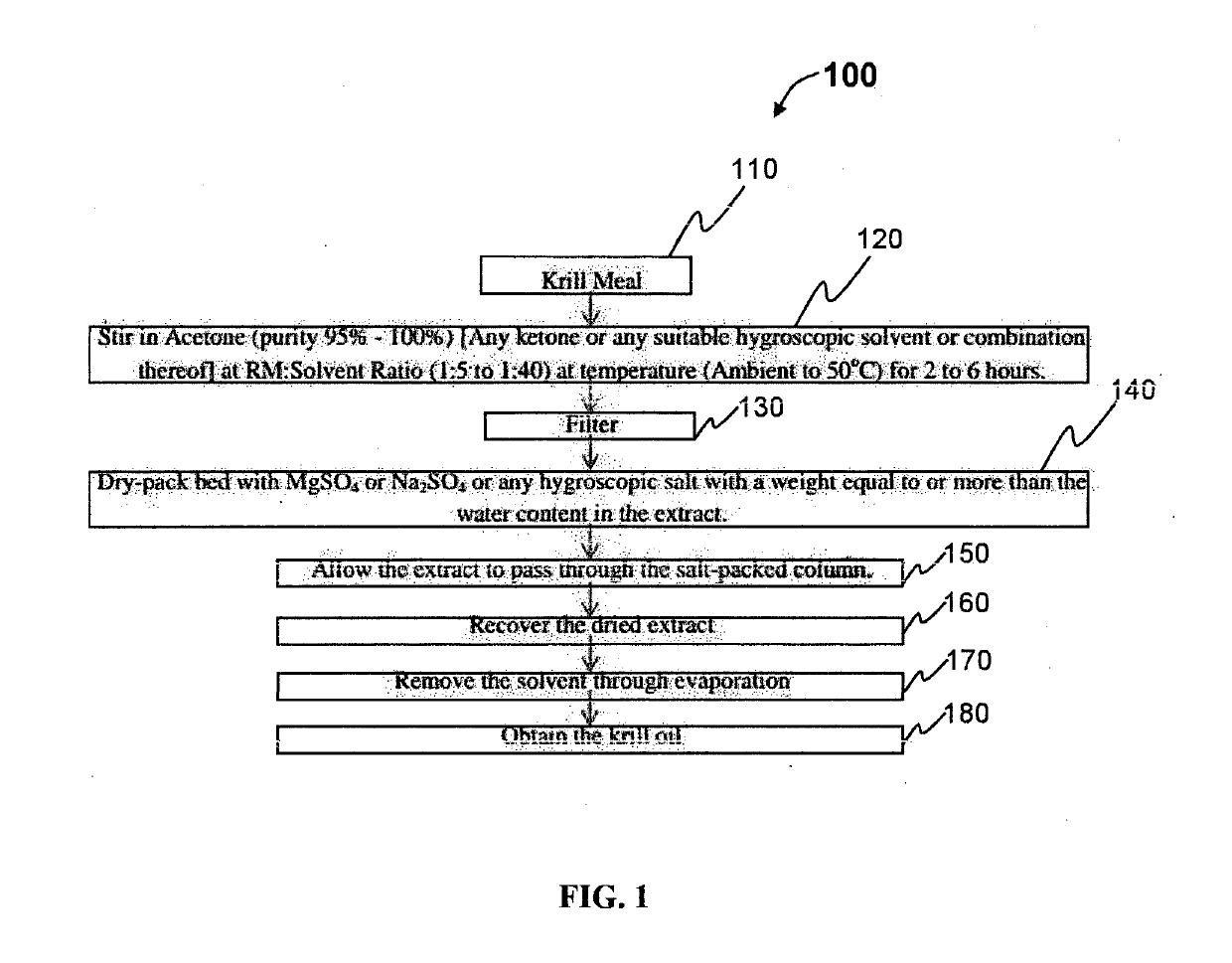

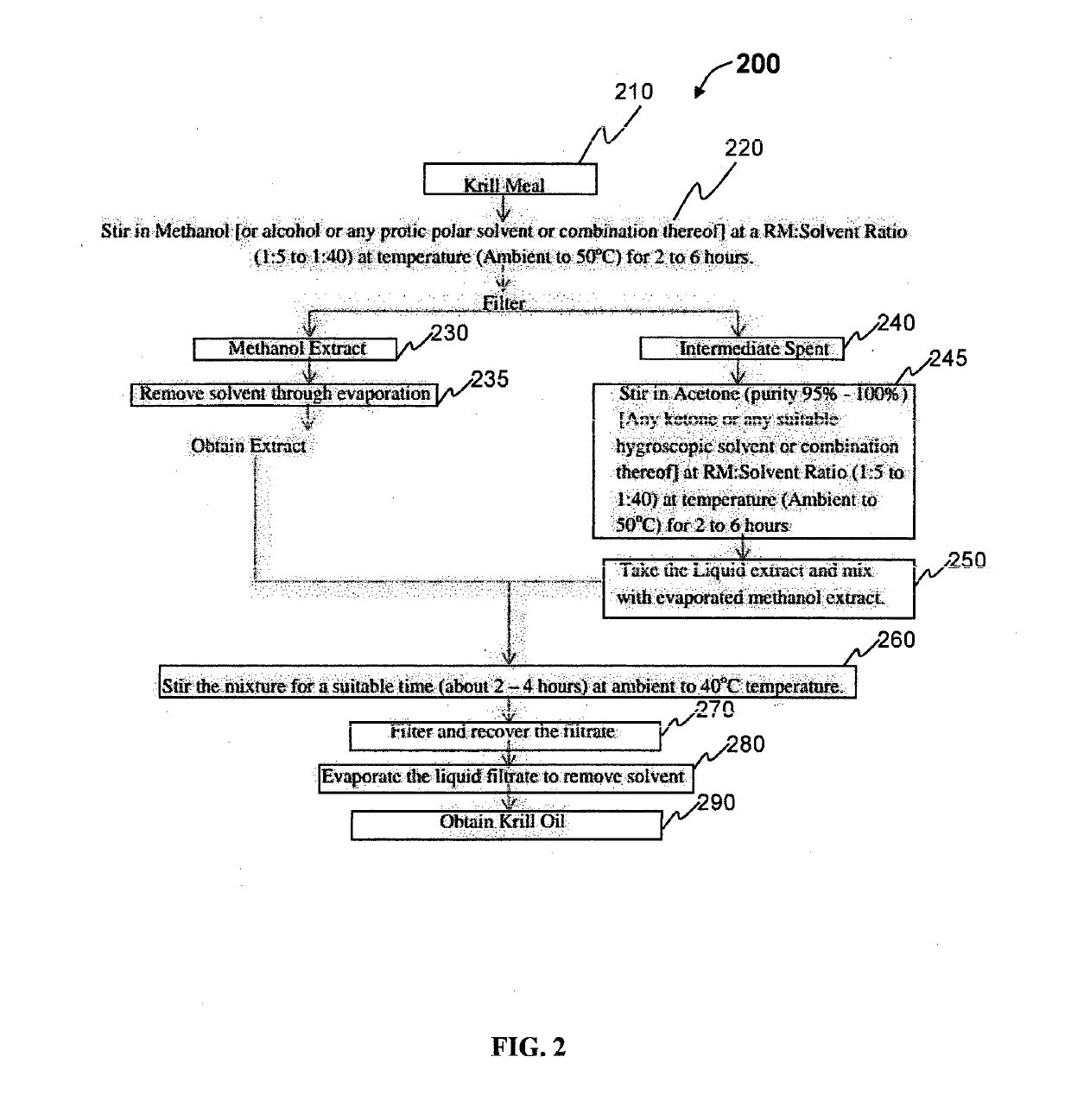

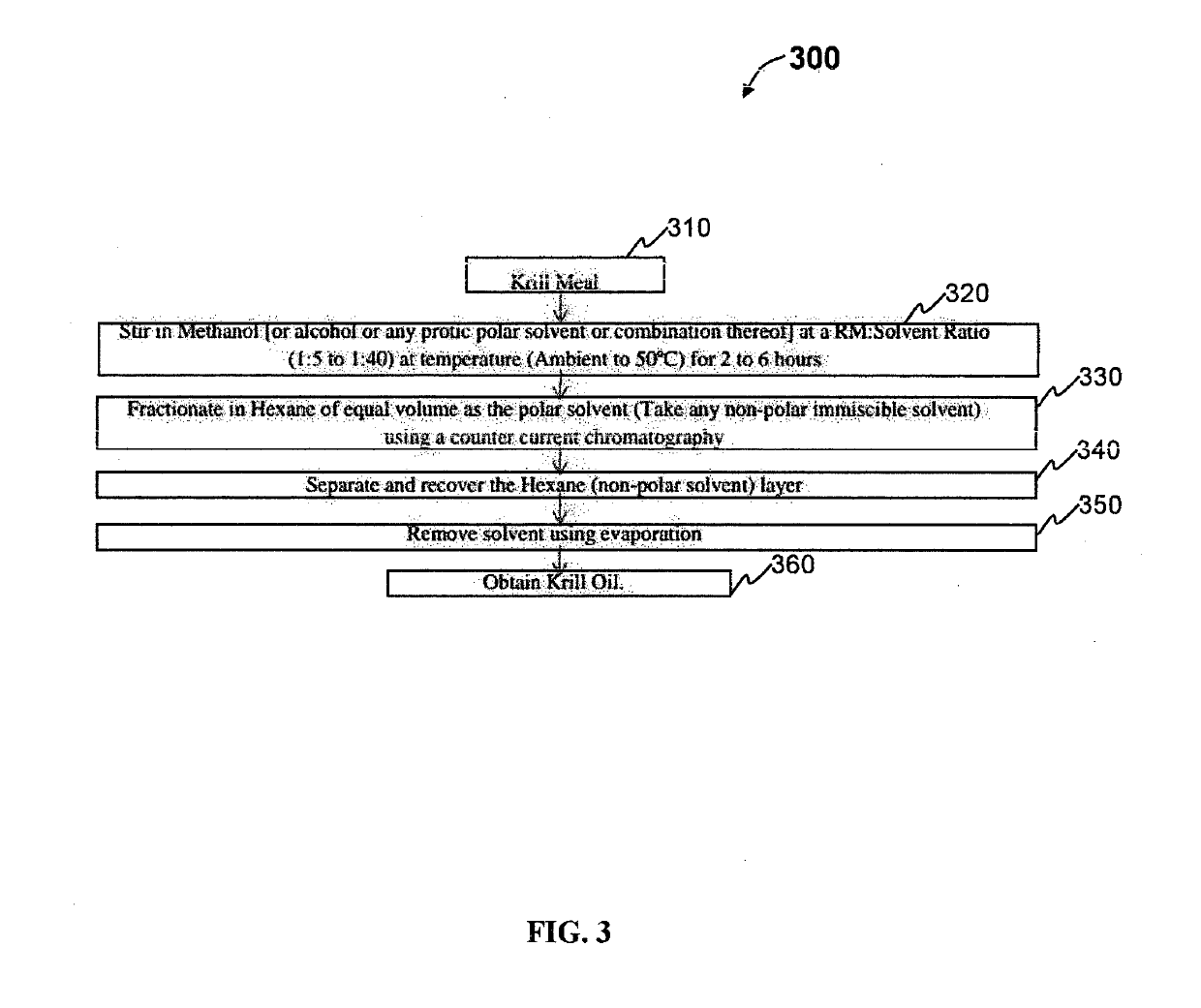

Improved Method for Processing and Extracting Oil from Marine Organisms

InactiveUS20190230950A1Improve daily throughputReduce the smellFatty-oils/fats productionEdible oils/fatsShrimpImproved method

An improved method for processing and extracting krill oil from krill meal / fresh krill. The proposed method for processing and extracting of krill oil from krill meal / fresh krill can be a very simple, cost effective and productive approach. The krill oil obtained herein can meet industrial standards and requirements of a wide range of applications including nutraceuticals and pharmaceutical applications. The method can be’ alternatively adapted to process and extract a wide range of marine oils including, but not limited to, Fish, Salmon, Shrimp, Cod and other marine product varieties.

Owner:SAMUEL PHILIP +1

Turbulent and boiling combined-circulation fluidized bed refuse incinerator

InactiveCN101532668BAlleviate high temperature slaggingReduce wearIncinerator apparatusFluidized bedHigh energy

The invention provides a turbulent and boiling combined-circulation fluidized bed refuse incinerator, belonging to the garbage disposer field. The present circulation fluidized bed refuse incinerator has unstable bed temperature, inadequate burning and high energy consumption. The turbulent and boiling combined-circulation fluidized bed refuse incinerator comprises a hearth and a cyclone separator, a boiling chamber is arranged at the lower part of the hearth, a refuse inlet is opened in the middle of the hearth, the upper part of the hearth is communicated with the cyclone separator, the lower part of the cyclone separator is communicated with the hearth by a feedback device, the turbulent and boiling combined-circulation fluidized bed refuse incinerator is characterized in that a turbulent chamber capable of slantly moving and transferring the refuse is arranged under the refuse inlet. The turbulent and boiling combined-circulation fluidized bed refuse incinerator provided by the invention solves the problems of inadequate burning and high coal doping, saves the energy and improves the treating capacity of single refuse incinerator per day.

Owner:HANGZHOU NENGDA HUAWEI EQUIP

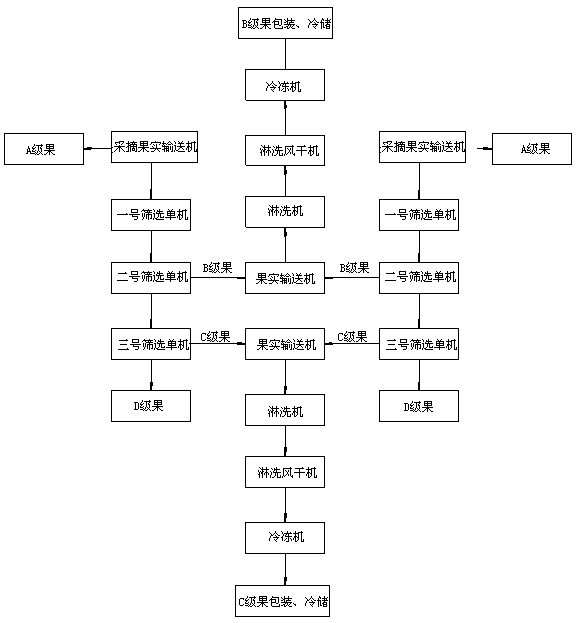

Blueberry producing and processing method

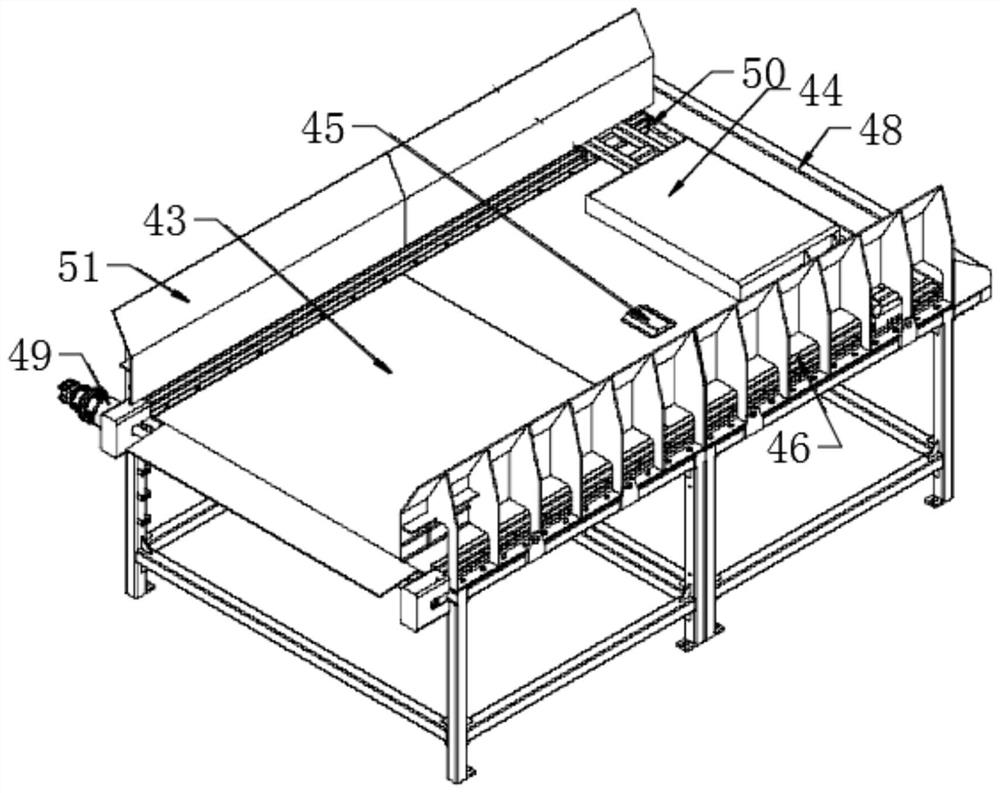

InactiveCN108391720AImprove daily throughputGuaranteed FreshnessFruits/vegetable preservation by freezing/coolingFood treatmentBiologySieve

The invention provides a blueberry producing and processing method. At current, the blueberry harvesting season is short and only lasts for more than 20 days, a processing manner of the picked blueberries mainly comprises single-machine sorting, single-machine washing with water and freezing in a freezer, linkage production is not used, the cross quantity of production working procedures is large,the fruit utilization rate is low, the labor intensity of staff is large, and the production efficiency is low. The method disclosed by the invention comprises the following steps of respectively putting picked blueberry fruits into two fruit picking and transferring lines, respectively conveying the blueberry fruits to the upper parts of two sets of sieve belt classifying fruit selecting machinegroups through a horseshoe-shaped line PVC conveyer belt, performing continuous screening through a No. 1 screening single machine, a No. 2 screening single machine and a No. 3 screening single machine, performing sorting according to the diameters of the fruits to obtain A-grade fruits, B-grade fruits, C-grade fruits and D-grade fruits, then performing classified treatment, performing collection, and performing cold storage. The blueberry producing and processing method disclosed by the invention is used for producing and processing blueberries.

Owner:刘良

A kind of sludge dewatering treatment process using biological flocculant

The present invention relates to a sludge dehydration treatment process using biological flocculants, in particular to a rotary diaphragm plate frame sludge press filter dewatering treatment system, including a base, a rotary frame, a diaphragm plate frame assembly, and a plate frame pressing mechanism , a sewage injection mechanism and a rotary drive mechanism; the treatment system involved in the treatment process provided by the present invention uses a circular distribution arrangement to replace the structural layout of a traditional plate and frame filter press machine that adopts a linear distribution arrangement, and the use of a rotary structure design can reduce the biological flocculant conditioning time. The overall processing efficiency can be improved by a short stirring time, which can promote the further flocculation effect of the biological flocculant in the filter press machine, thereby improving the dehydration efficiency and reducing the moisture content of the mud cake. In addition, the circumferential layout reduces the space occupied by the site.

Owner:南京恒邦生物环保有限公司

Complex enzyme preparation for sewage treatment and application method thereof

InactiveCN101898830BThere is no risk of ecological runawayGuaranteed uptimeHydrolasesTreatment with aerobic and anaerobic processesCelluloseEutrophication

The invention relates to a complex enzyme preparation for sewage treatment. The complex enzyme preparation is compounded by mixing complex enzyme and mineral water, wherein the weight ratio of the complex enzyme to the mineral water is 1:9-50; and the complex enzyme contains the following components in volume content: 50 to 80 mg / L of bromelain, 50 to 80 mg / L of papain, 15 to 30 mg / L of L-aspartase, 15 to 30 mg / L of glutathione, 100 to 150 mg / L of yeast extract and 50 to 80 mg / L of cellulose. The complex enzyme preparation improves the treatment capability of a sewage plant, reduces the running cost, basically achieves zero release of residual organic sludge, prevents environmental secondary pollution of the sewage treatment, improves the self-purification capability of yielding water of the sewage plant, prevents secondary pollution of the yielding water, prevents secondary eutrophication of the yielding water, and radically solves the problem of environmental protection in operationof the sewage treatment plant.

Owner:麦广鸿 +2

Novel process for producing coal gangue ceramsite through dry-method powder preparation and static sintering

InactiveCN113651595AEvenly heatedAccurate granularityCeramic materials productionClaywaresTunnel kilnHot blast

The embodiment of the invention discloses a novel process for producing coal gangue ceramsite through dry-method powder preparation and static sintering, and belongs to the technical field of comprehensive utilization of coal gangue. The specific technological process of the new process comprises the following steps: firstly, crushing and stockpiling and homogenizing coal gangue, carrying out dry-method powder preparation on the homogenized coal gangue and auxiliary materials, storing and homogenizing powder obtained by dry-method powder preparation in a homogenizing bin, humidifying and premixing homogenized raw material fine powder to form master batches, adding water into the master batches to prepare green ceramsite, sieving to obtain qualified green pellet particles; paving a bottom material and an edge material, then distributing green pellet particles into a trolley, and finally feeding the trolley on which the materials are distributed into a static sintering tunnel kiln through a trolley system for static sintering to produce the coal gangue ceramsite. Static sintering is adopted in the sintering section, ceramsite drying is achieved through waste heat circulation, hot air of the ceramsite soaking section serves as secondary air to be fed into the high-temperature section to be recycled in the roasting section, waste heat of the first cooling section serves as combustion-supporting air in a combustion-supporting mode, the combustion-supporting air temperature is increased, and fuel gas energy consumption is reduced.

Owner:SHANDONG ECON ENERGY SAVING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com