Blueberry producing and processing method

A processing method and technology for blueberries, applied in food processing, food science, preservation of fruits/vegetables through freezing/refrigeration, etc., can solve the problems of large crossover of production processes, lack of linkage production, and high labor intensity of employees, reducing The effect of cross-process volume, daily processing volume, and economic benefit improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

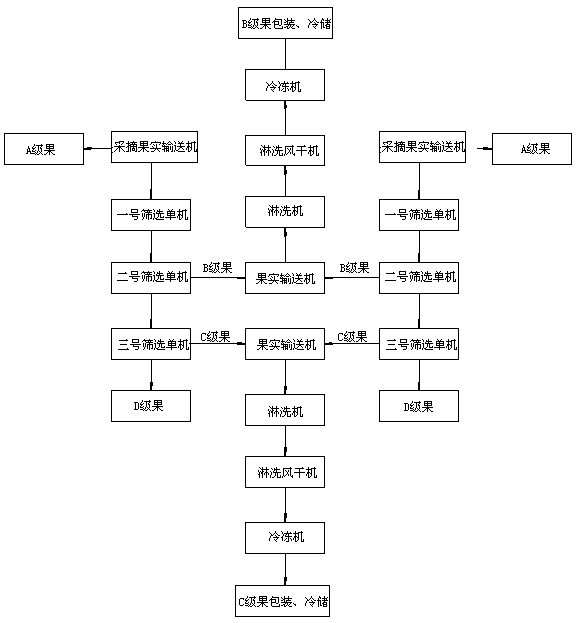

[0015] A blueberry production and processing method, the steps of the production and processing method are as follows: the picked blueberry fruits are respectively put into two picking fruit conveying lines, and sent to two sets of sieve belt grading and fruit sorting units respectively through horseshoe pattern PVC conveyor belts In the upper part, through No. 1, No. 2 and No. 3 screening machines, the fruit is continuously screened and sorted into A-grade fruit, B-grade fruit, C-grade fruit, and D-grade fruit according to the diameter of the fruit, and then classified, collected, and cold stored.

Embodiment 2

[0017] According to a kind of blueberry production and processing method described in Example 1, the steps of the A-grade fruit production and processing method are as follows: after the A-grade fruit is graded and screened, its fruit diameter is <9mm, and the number of fruits after screening Accounting for 10% of the total amount, the grade A fruits are exported and packaged from the No. 1 screening machine to the two sides of the plane respectively.

Embodiment 3

[0019] According to a kind of blueberry production and processing method described in Example 1, the steps of the B-grade fruit production and processing method are as follows: after the B-grade fruit is graded and screened, its fruit diameter is 9 ~ 12mm, and the number of fruits after screening is 9-12 mm. Accounting for 50% of the total, the B-grade fruit is exported from the No. 2 screening machine to the center of the plane, and then enters the central fruit selection climbing conveyor line on one side, and is transported to the washing machine through the horseshoe pattern PVC conveyor belt. , the conveying speed is controlled at 20mm / s. During the rinsing process, through the blowing pipe, the spiral high-pressure air is passed through the PVC chain plate to blow the B-grade fruit into the water, and the suspending state is fully leached. After rinsing with water for 10 minutes, it falls into the water-spraying air-drying machine, and its transmission speed is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com