Mobile type rural garbage multi-stage divided chamber pyrolysis water heating system

A village and town garbage, mobile technology, applied in residential hot water supply systems, heating methods, household heating and other directions, can solve the problems of scattered sources of garbage, difficult temperature control, high energy consumption, etc., to achieve reliable and continuous operation capability, The effect of improving energy utilization and increasing operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

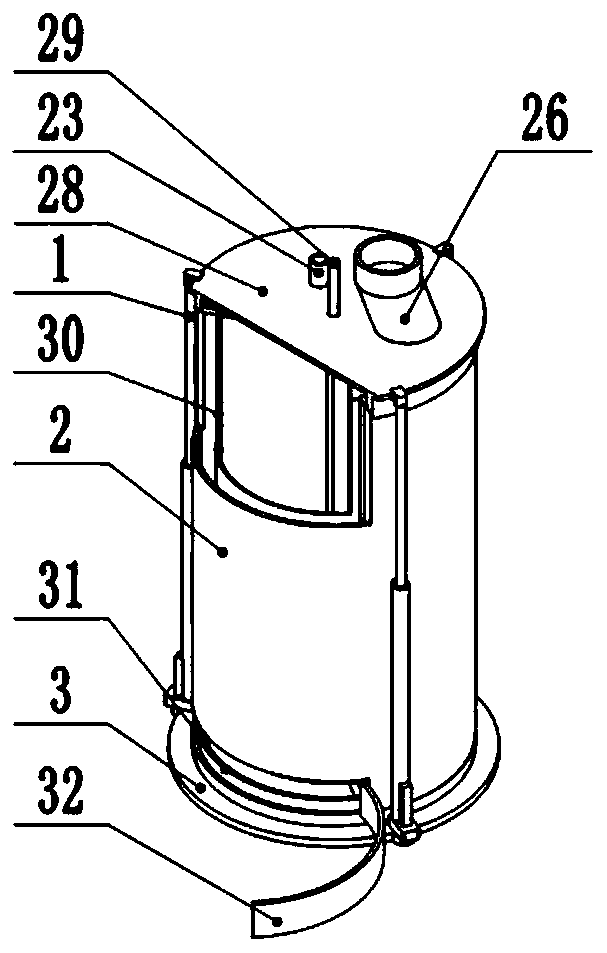

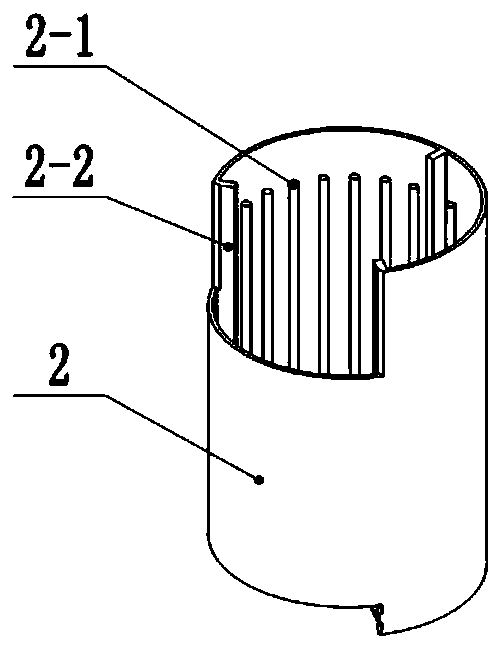

[0038] refer to Figure 1 to Figure 12 , a movable multi-stage compartment pyrolysis hot water system for village and township garbage, including a feeding mechanism with a crushing device, a rotary low-temperature pyrolysis furnace, a high-temperature pyrolysis chamber 19, an exhaust gas treatment system, and a PLC control device. The feed mechanism with the crushing device, the rotary low-temperature pyrolysis furnace, the high-temperature pyrolysis chamber 19, and the tail gas treatment system are respectively connected with the PLC control device. The tail gas treatment system includes a cooling chamber 7, an acid removal chamber 8, and a dust removal chamber. 9. Fan 12 and boiler 14 for heating hot water, the feed mechanism is installed above the rotary low-temperature pyrolysis furnace, and the discharge end of the feed mechanism is connected to the feed port of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com