Large tonnage sludge dehydration treatment device and sludge treatment method

A technology of sludge dewatering and treatment device, applied in pyrolysis treatment of sludge, oxidation treatment of sludge, vaporization of by-products, etc., can solve the problems of discontinuity, large area, small processing capacity, etc., and achieve fast and efficient The effect of dissociation, long service life and large daily processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The large-tonnage sludge dehydration treatment device and the sludge treatment method provided by the present invention will be further described in detail and completely below in conjunction with the embodiments. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0045] The experimental methods in the following examples are conventional methods unless otherwise specified. The experimental materials used in the following examples were purchased from the market unless otherwise specified.

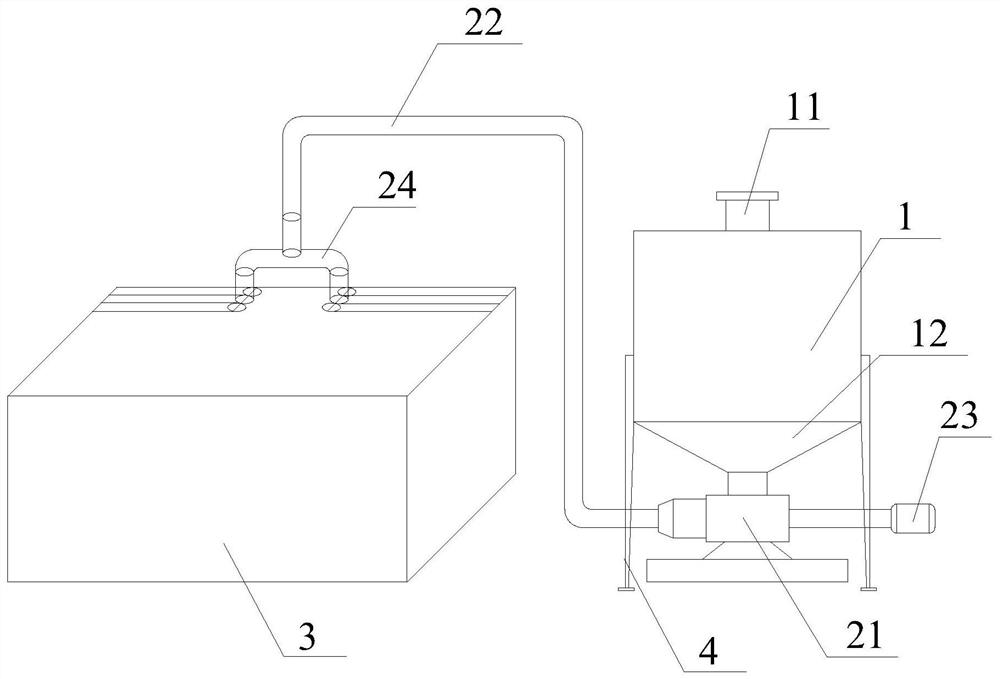

[0046] Such as figure 1 As shown, the large-tonnage sludge dehydration treatment device of the present invention includes a silo 1, a feeding pipeline 2, a sludge treatment area 3 and a support 4, wherein the sludge treatment area 3 is set on the ground, and the support 4 supports the silo 1 And the conveying pipeline 2, the sludge to be treated enters the silo 1 from the silo inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com