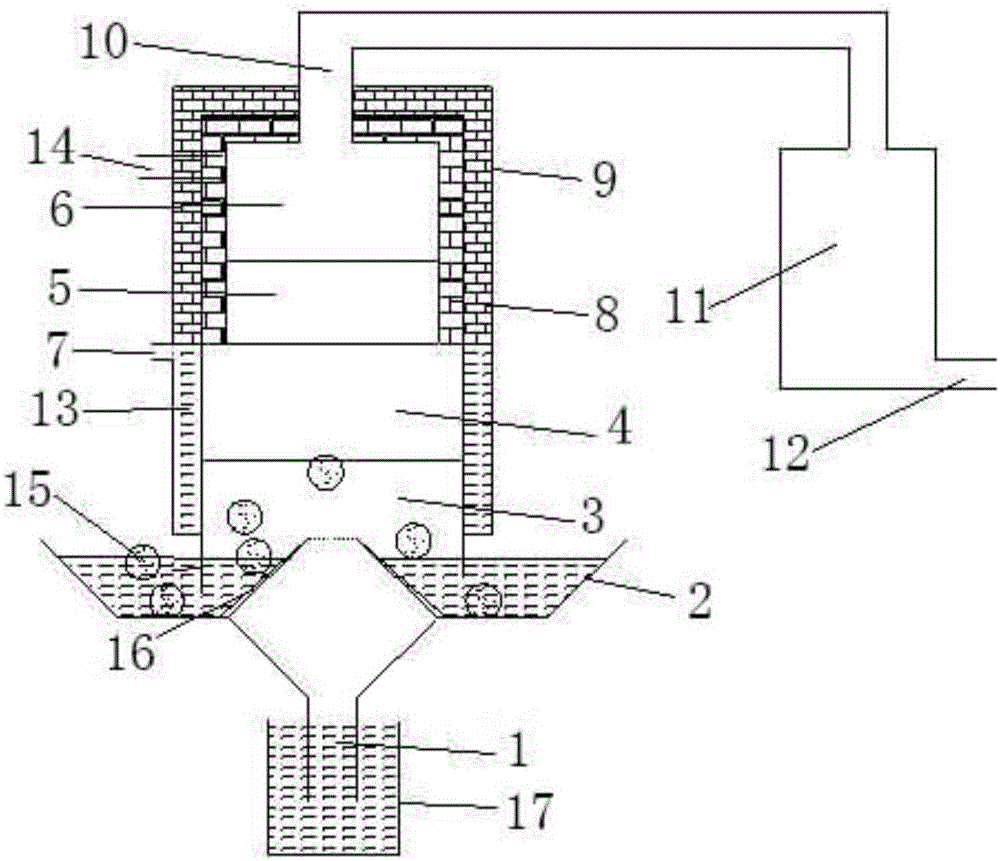

Garbage pyrolysis gasification furnace

A pyrolysis gasification and garbage technology, applied in the direction of incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of large footprint, secondary pollution, dust pollution, etc., to increase the content of combustible gas and reduce secondary pollution The production of oxins and the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

[0018] The garbage pyrolysis gasification furnace of the present invention enables materials to be pyrolyzed under anaerobic or oxygen-deficient conditions, and finally converted into high-temperature combustible gas, tar, and solid residues. Due to its pyrolysis and gasification at a high temperature above 1000°C, the amount of dioxin produced is very small, far below the national standard, and a secondary combustion chamber is connected to further process the dioxin formed by cooling. At the same time, it can be processed at any time, The characteristics of thorough treatment make it avoid the generation of stench and save a lot of land. The high-temperature gas collects tar through electric coke capture, and the remaining gas is used for power generation and brick burning, which can maximize the utilization of resources.

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com