Treatment device and treatment method for high-calorific-value carbon-containing solid waste

A solid waste and treatment device technology, applied in the direction of manufacturing combustible gas, special form of dry distillation, gasification process, etc., can solve the problems of unstable combustion performance of solid waste, secondary pollution, system operation interruption, etc., to improve thermal efficiency Decompose gasification efficiency, increase air resistance, improve the effect of gasification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

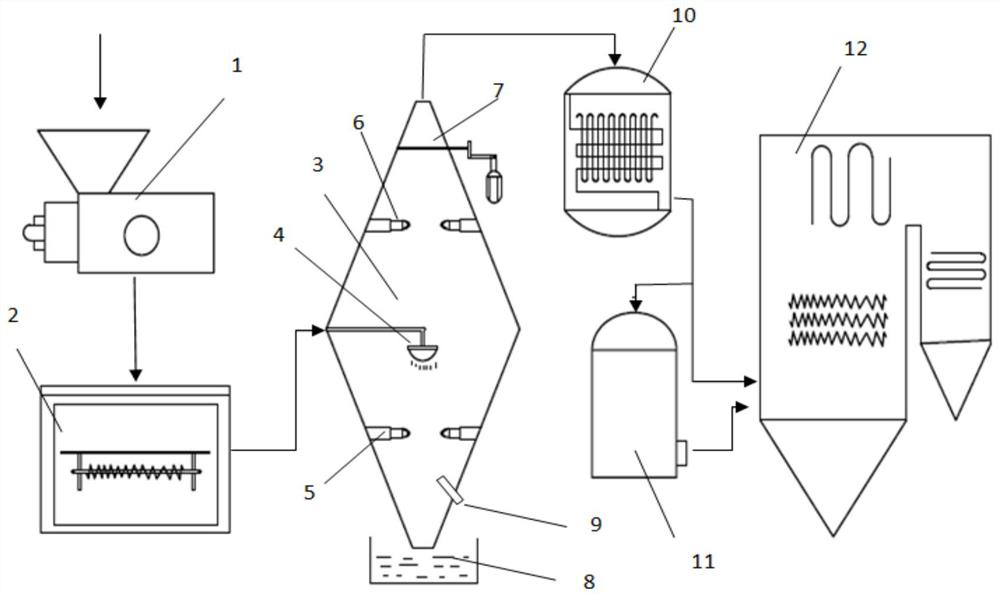

[0031] Embodiment 1: as figure 1 as shown,

[0032] A treatment device for high calorific value carbon-containing solid waste, including a crusher 1, a pulper 2, a pyrolysis furnace 3, a cooling and drying device 10, and a gas storage tank 11; the longitudinal section of the pyrolysis furnace 3 is a diamond-shaped structure, The top of the pyrolysis furnace 3 is provided with a gas outlet, the middle of the wall of the pyrolysis furnace 3 is provided with a feed port for the pyrolysis furnace, the bottom half of the pyrolysis furnace 3 is provided with a nitrogen inlet 9, and the bottom of the pyrolysis furnace 3 is provided with an outlet. The slag mouth, the middle position in the pyrolysis furnace 3 is provided with a spray device 4, the spray device 4 is connected with the feed port of the pyrolysis furnace, and a plasma torch is also arranged in the pyrolysis furnace 3, and the plasma torch is divided into an upper plasma torch 6 and a The lower plasma torch 5 and the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com