Coal pyrolysis apparatus and pulverized coal boiler combined system and method for processing coal

A pulverized coal boiler and coal pyrolysis technology, which can be applied to combustion methods, burners for burning powder fuel, coke ovens, etc. Effect

Pending Publication Date: 2016-11-09

SHENWU TECH GRP CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because the combustion of pulverized coal furnaces has high requirements on the volatile content and p

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

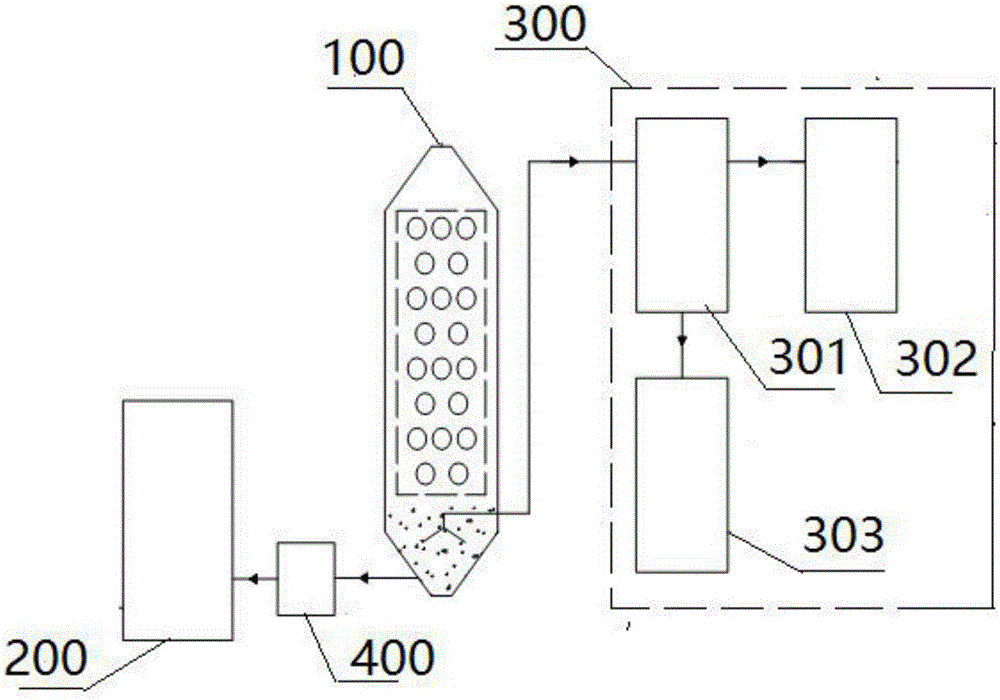

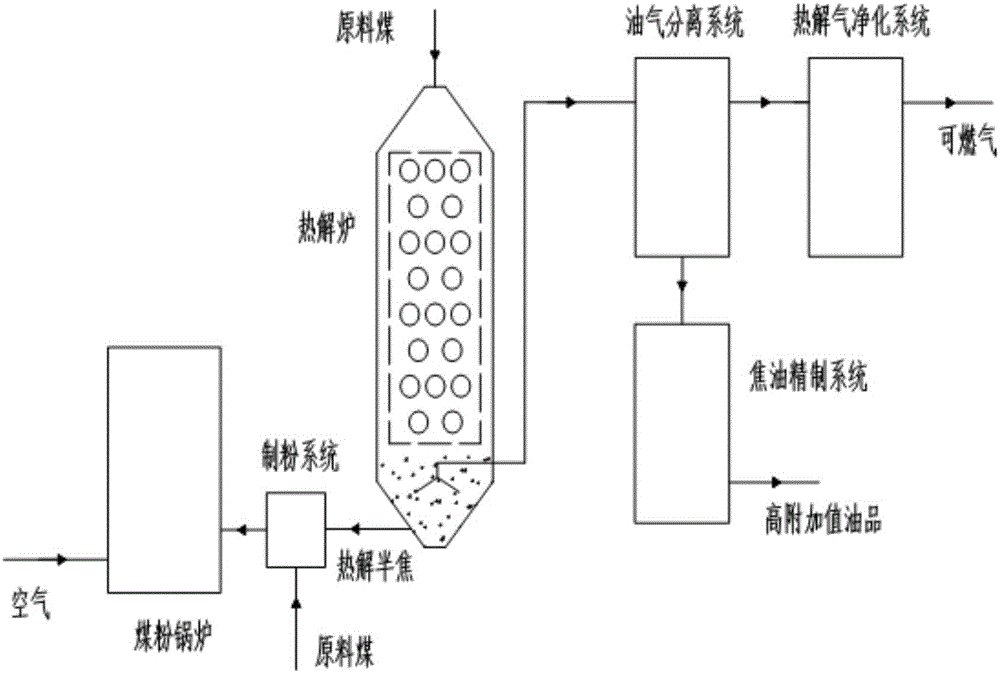

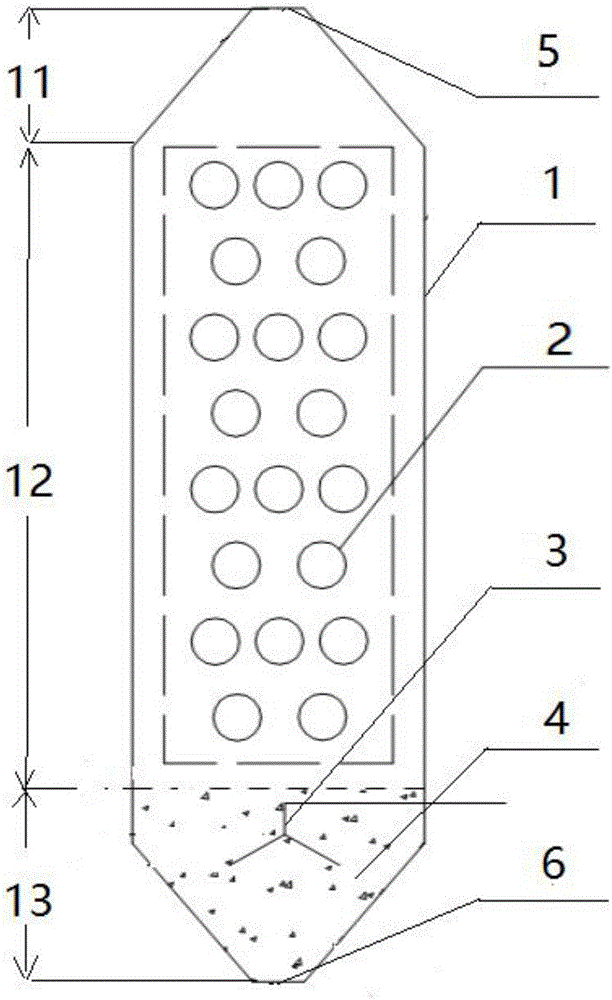

Login to View More Abstract

The invention brings forward a coal pyrolysis apparatus and pulverized coal boiler combined system and a method for processing coal. The coal pyrolysis apparatus and pulverized coal boiler combined system comprises a rapid pyrolysis reactor, a pulverized coal boiler and a pyrolysis oil gas processing system. The rapid pyrolysis reactor comprises a multilayer regenerative type radiant tube, a semi-coke outlet and an air exhaust umbrella. The air exhaust umbrella comprises an umbrella portion and a handle part, which are communicated through gas. The pulverized coal boiler is communicated with the rapid pyrolysis reactor through the semi-coke outlet. The pyrolysis oil gas processing system is communicated with the rapid pyrolysis reactor through the handle part of the air exhaust umbrella. Through the coal pyrolysis apparatus and pulverized coal boiler combined system and the method for processing coal, complexity of the coal pyrolysis technology can be effectively reduced, and subsequent tar processing cost is decreased. Meanwhile, pyrolysis products are reasonably utilized, and generating cost is reduced.

Description

technical field [0001] The invention belongs to the technical field of step-by-step utilization of coal, and in particular relates to a combined system of a coal pyrolysis device and a pulverized coal boiler and a method for processing coal. Background technique [0002] The semi-coke produced after coal pyrolysis can be used as fuel to generate electricity, while the existing coal pyrolysis topping process is mainly aimed at circulating fluidized bed power generation units. For example, the Process Institute of the Chinese Academy of Sciences and Zhejiang University use the hot ash produced by the circulating fluidized bed boiler as the heat carrier, and use the down-bed process to realize the pyrolysis of coal and recover the oil and gas. Because the existing system adopts a relatively complicated coal pyrolysis topping process of solid or gas heat carrier, and the oil and gas resources generated through the coal pyrolysis process, it is necessary to equip a corresponding ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10B53/04C10B47/20C10B57/00C10B57/18C10K1/00C10C1/00F23D1/00F23K1/00F23K3/00

CPCC10B53/04C10B47/20C10B57/005C10B57/18C10C1/00C10K1/00F23D1/00F23K1/00F23K3/00

Inventor 梅磊陈水渺肖磊薛逊姜朝兴吴道洪

Owner SHENWU TECH GRP CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com