Multi-stage clean and efficient domestic waste pyrolysis gasification furnace and process

A technology of pyrolysis gasification and domestic waste, applied in the direction of incinerators, lighting and heating equipment, combustion methods, etc., can solve the problems of polluted environment, backward waste treatment methods, and poor treatment effects, and achieve high-efficiency utilization, waste heat The effect of high degasification efficiency and accelerated combustion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

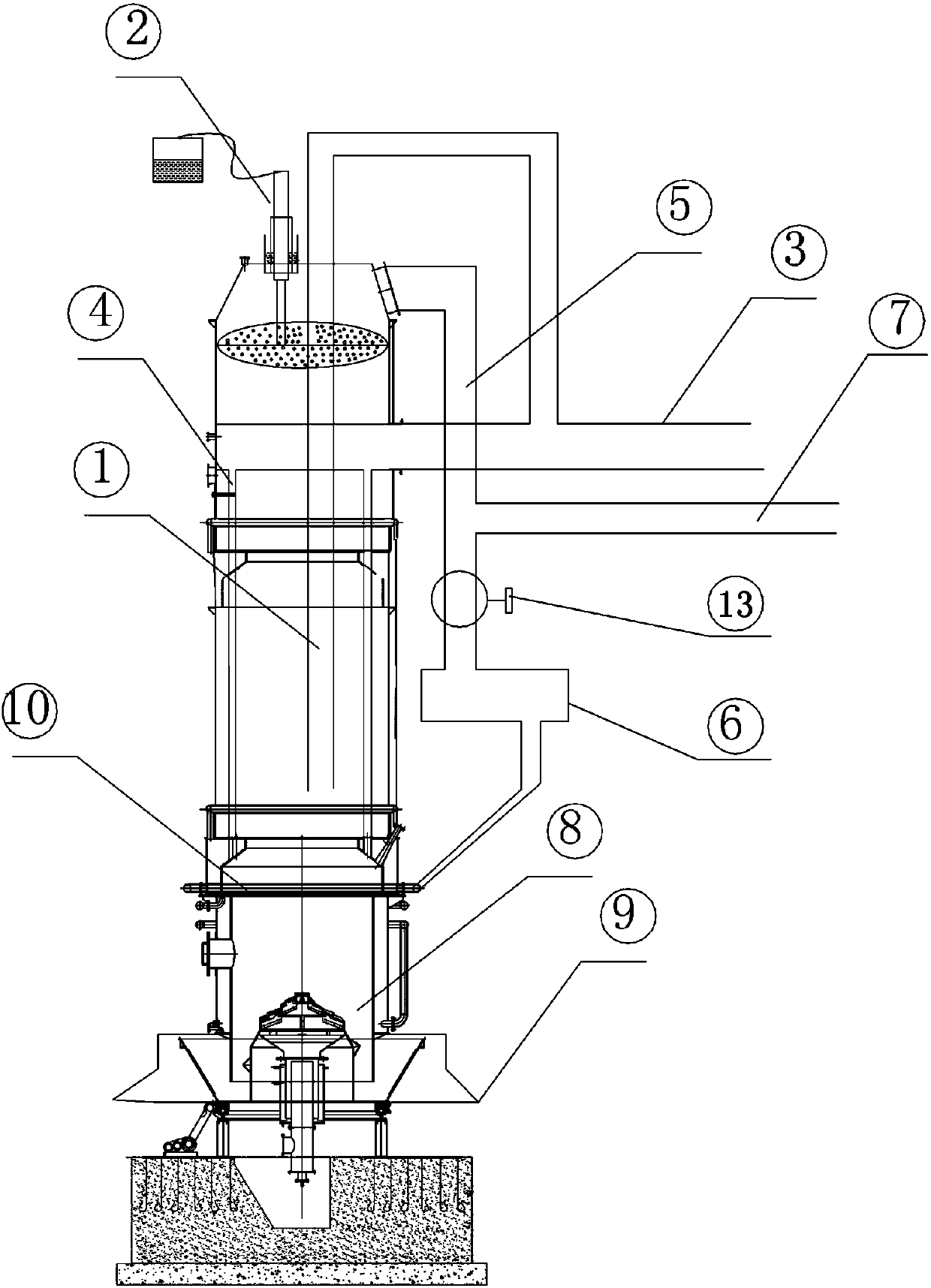

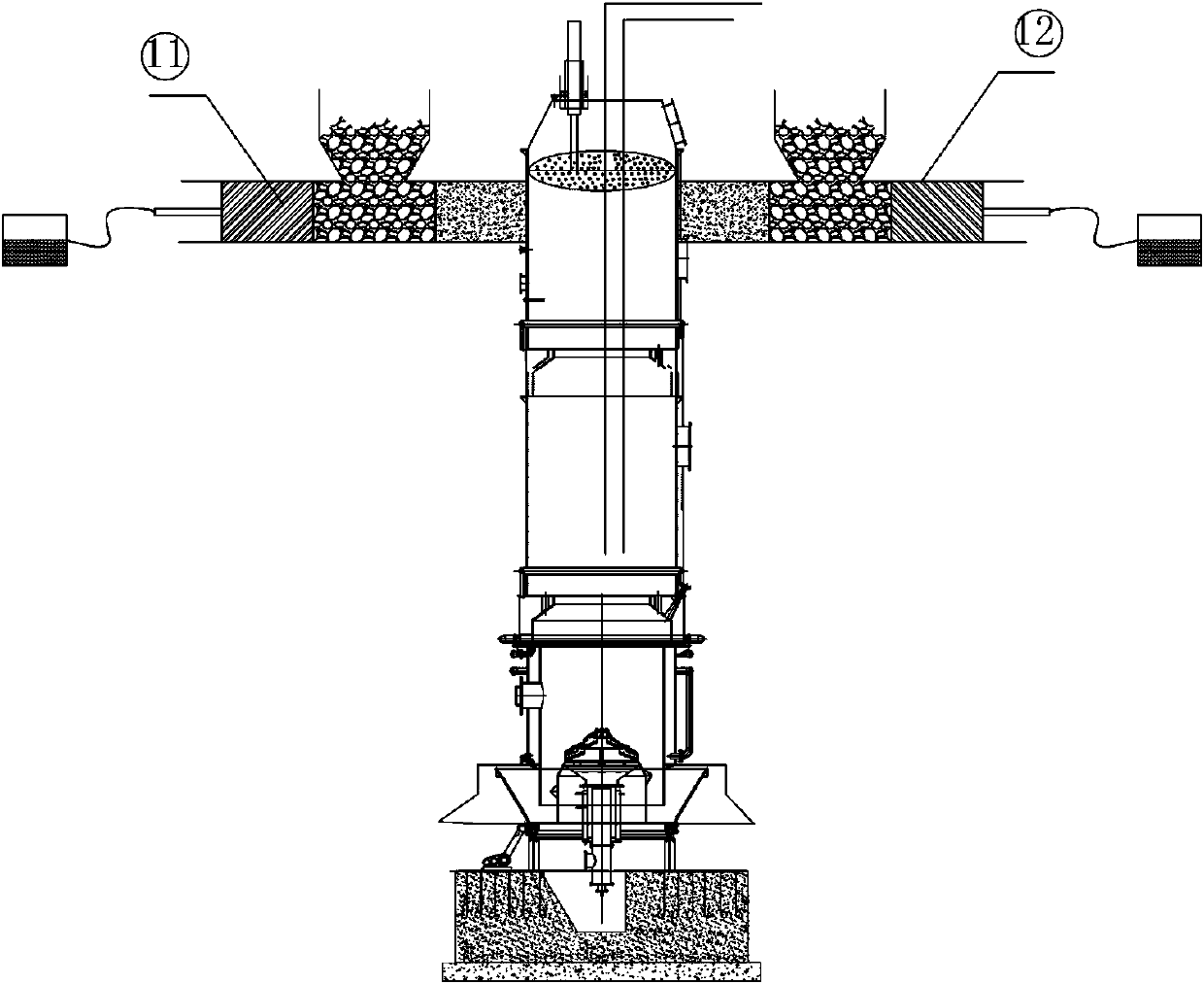

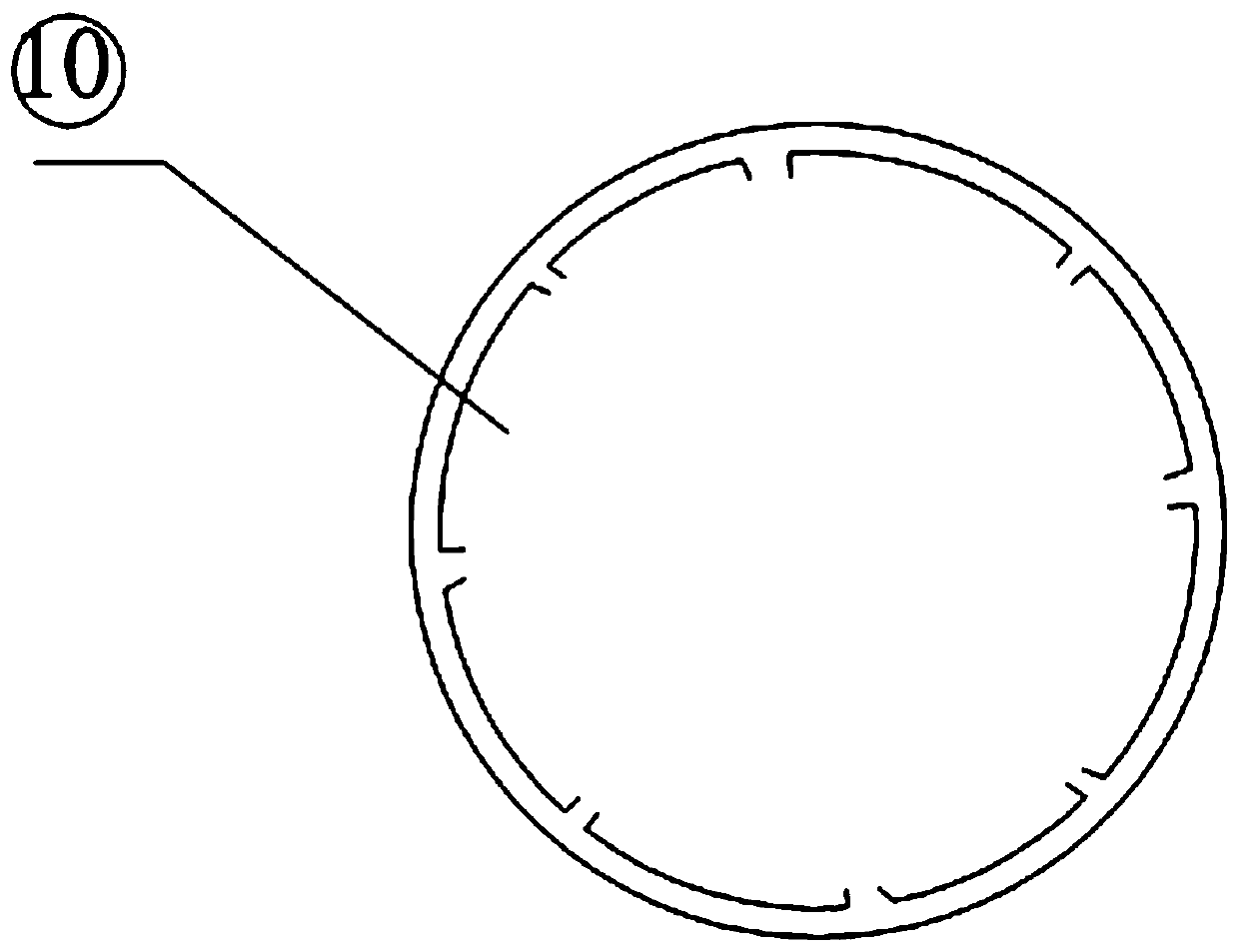

[0021] Example 1: A multi-stage clean and efficient household waste pyrolysis gasifier, see figure 1 , comprising a furnace body, a water jacket is provided at the lower end of the furnace body, and the lower end of the water jacket is a slag discharge area 9, see Figure 4 The water jacket is composed of two layers of steel plates inside and outside. The two layers of steel plates form annular concentric circles with different diameters. A cavity is formed between the two steel plates. The diameter of the upper end of the water jacket is reduced, and the air outlet is embedded in the top of the water jacket. The diameter of the upper end of the water jacket is reduced, which is convenient for the air outlet to gather and discharge air. see image 3 A fully enclosed two-way feed pipe 11 and a fully enclosed two-way feed pipe 2 12 are respectively installed on the opposite sides of the upper end of the furnace body, two sealed feed ports are arranged, the directions of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com