Large-tonnage four-column vertical-pressure rubbish compression station

A garbage compression station and large-tonnage technology, which is applied in the direction of garbage transmission, garbage collection, loading/unloading, etc., can solve the problems of small garbage processing volume, unfavorable garbage disposal, and small box volume, so as to improve efficiency and improve daily processing Quantity, the effect of overcoming structural constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

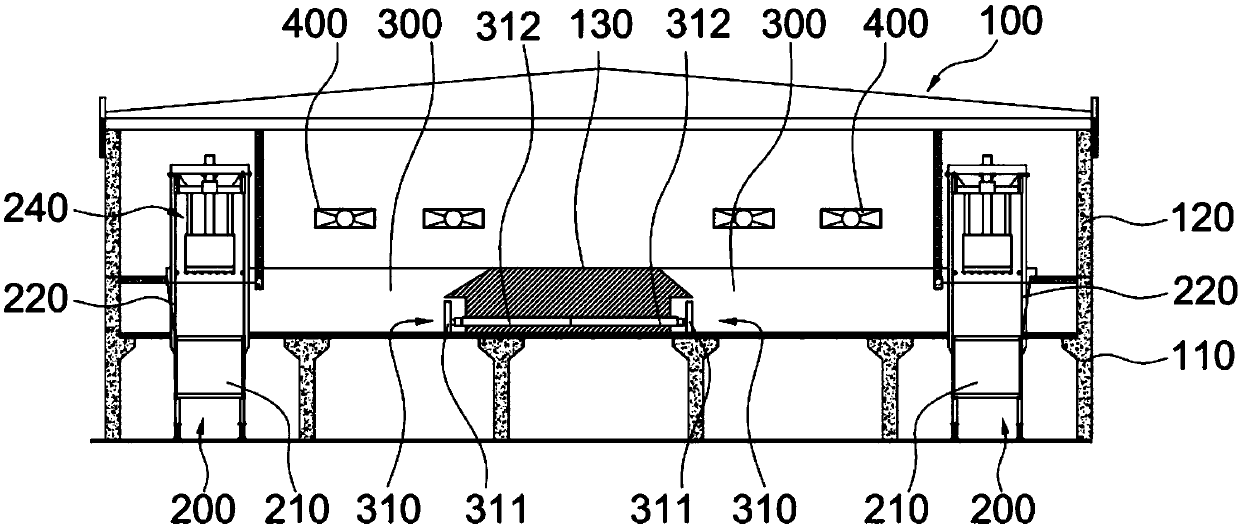

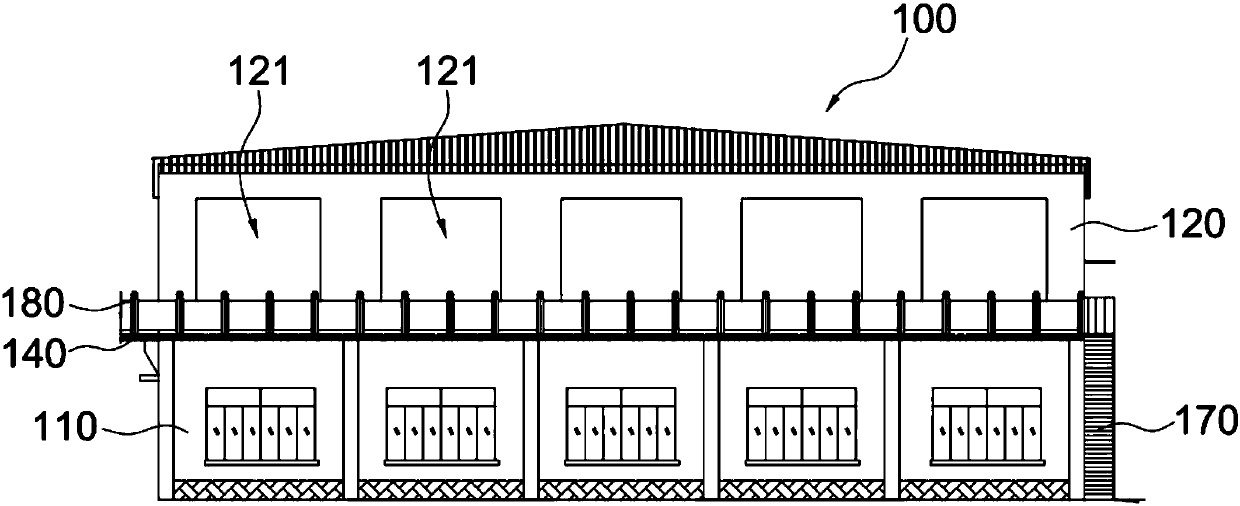

[0031] Embodiment 1, combining Figure 1 to Figure 8 As shown, a large-tonnage four-column vertical compression garbage compression station includes a building 100 , a four-column vertical compression compressor 200 and a storage tank 300 . The building body 100 comprises a building body 110 on the first floor and a building body 120 on the second floor. A discharge platform 130 is arranged between the building body 110 on the first floor and the building body 120 on the second floor. 140 is connected to the ground through the entrance ramp 150, the second floor building body 120 is provided with an entrance entrance 121 on one side of the entrance platform 140, and the other side of the second floor building body 120 is provided with an exit entrance 122, and the exit entrance 122 passes through An outbound ramp 160 connects to the ground.

[0032] The four-column vertical pressure compressor 200 includes a box body 210, a guide column 220, and a vertical compression mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com