Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Has a synergistic flame retardant effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

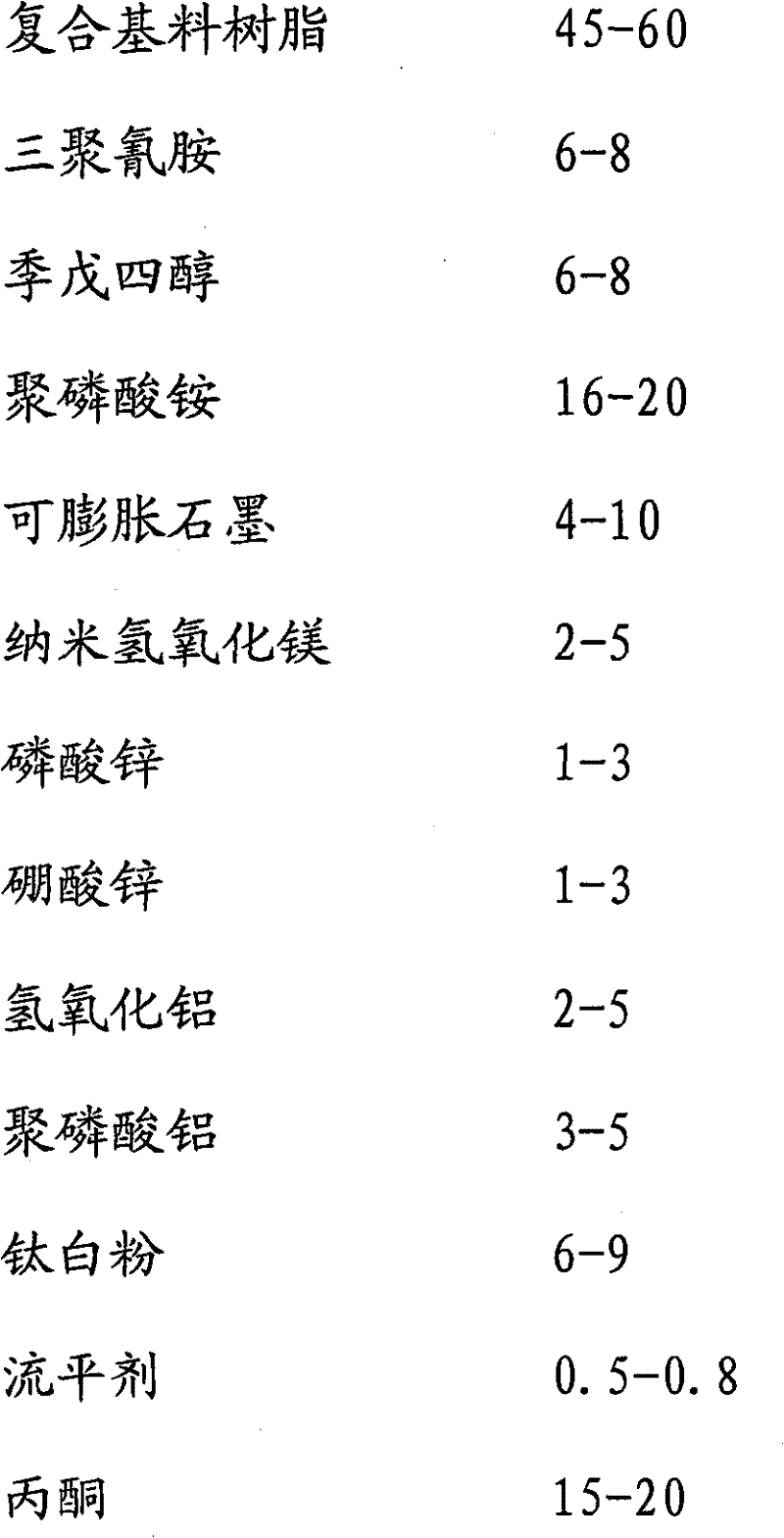

Fire-retardant paint with steel structure

ActiveCN101857756AExtend fire resistance timeImprove fire resistanceFireproof paintsPolyurea/polyurethane coatingsPhosphoric acidComposite substrate

The invention relates to fire-retardant paint with a steel structure, which is prepared from the following raw materials proportioning by weight: 45 to 60 of composite substrate resin, 6 to 8 of melamine, 6 to 8 of pentaerythritol, 16 to 20 of ammonium polyphosphate, 4 to 10 of expansible graphite, 2 to 5 of nano magnesium hydroxide, 1 to 3 of zinc phosphate, 1 to 3 of zinc borate, 2 to 5 of aluminum hydroxide, 3 to 5 of aluminum polyphosphate, 6 to 9 of titanium dioxide, 0.5 to 0.8 of flatting agent and 15 to 20 of acetone. The paint has excellent capabilities of fire prevention and corrosion prevention.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

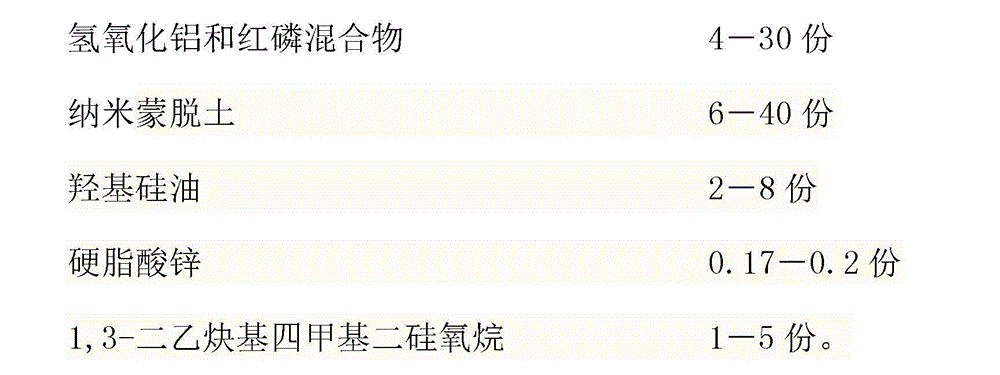

Ceramic silicon rubber and preparation method thereof

ActiveCN102876049ADoes not affect other mechanical propertiesImprove thermal stabilityPolymer scienceMechanical property

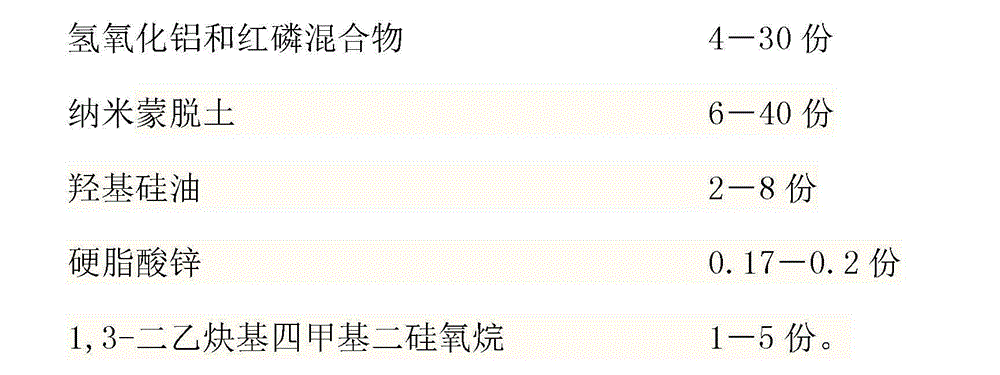

The invention discloses a ceramic silicon rubber and a preparation method thereof. A plurality of inorganic fillers are added into the raw silicon rubber, so that the ceramic silicon rubber prepared by the method has high flame retardant property due to the synergistic flame retardant function between the inorganic fillers and the raw silicon rubber; and meanwhile, other mechanical performances of the silicon rubber are not influenced by the added fillers.

Owner:JIANGSU TIANCHEN NEW MATERIALS

Phosphorus-containing essence inflaming-retarding cellulose-based thermal insulation material and preparation method thereof

The invention discloses a phosphorus-containing essence inflaming-retarding cellulose-based thermal insulation material and a preparation method thereof. The preparation method comprises the followingsteps that 1, urea and a phosphorylation modifier are added to a cellulose suspension solution with the concentration of 1-10wt%, and at 150-165 DEG C, after even stirring and a sufficient reaction,through washing, phosphorus-containing cellulose is obtained; 2, the phosphorus-containing cellulose is prepared into a suspension solution with the concentration of 0.5-2wt%, the pH of the suspensionsolution is adjusted to be 9.5-12, and under the stirring condition, after a sufficient reaction, through washing and fiber separation, phosphorus-containing cellulose nanofibers are obtained; 3, phosphorus-containing groups in the phosphorus-containing cellulose nanofibers are subjected to ionization modification through an in-situ formation method or an after-treatment crosslinking method for obtaining the phosphorus-containing essence inflaming-retarding cellulose-based thermal insulation material. The preparation technology is simple, the raw material source is wide, the cost is low, theenvironment protection is achieved, and the obtained thermal insulation material is low in heat conductivity coefficient and density and good in flame retardant property.

Owner:应急管理部四川消防研究所

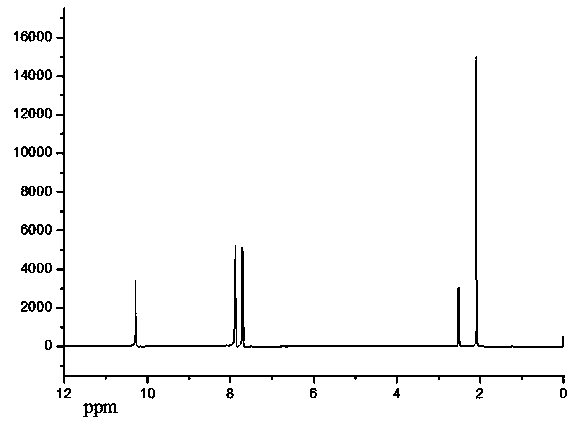

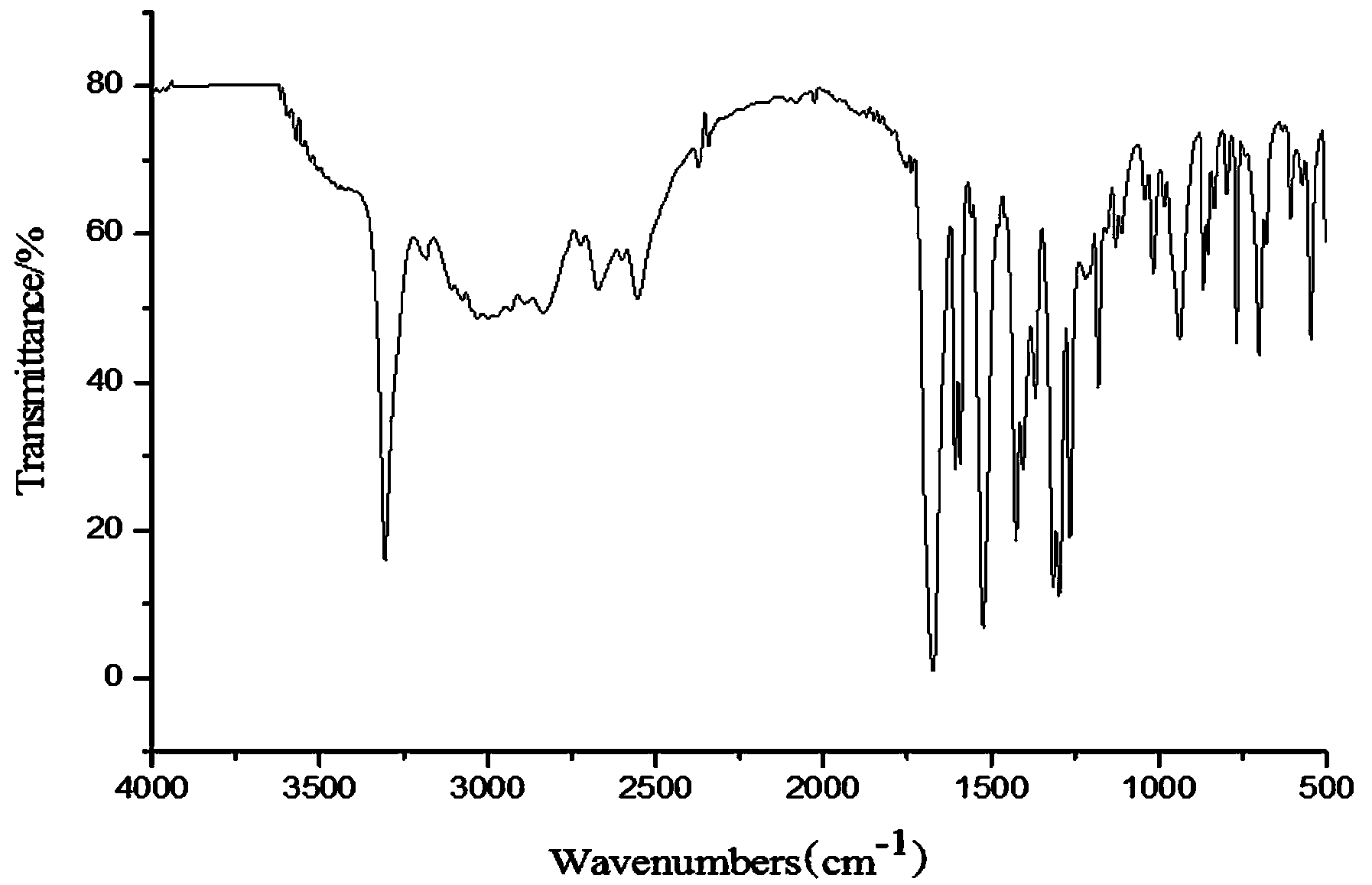

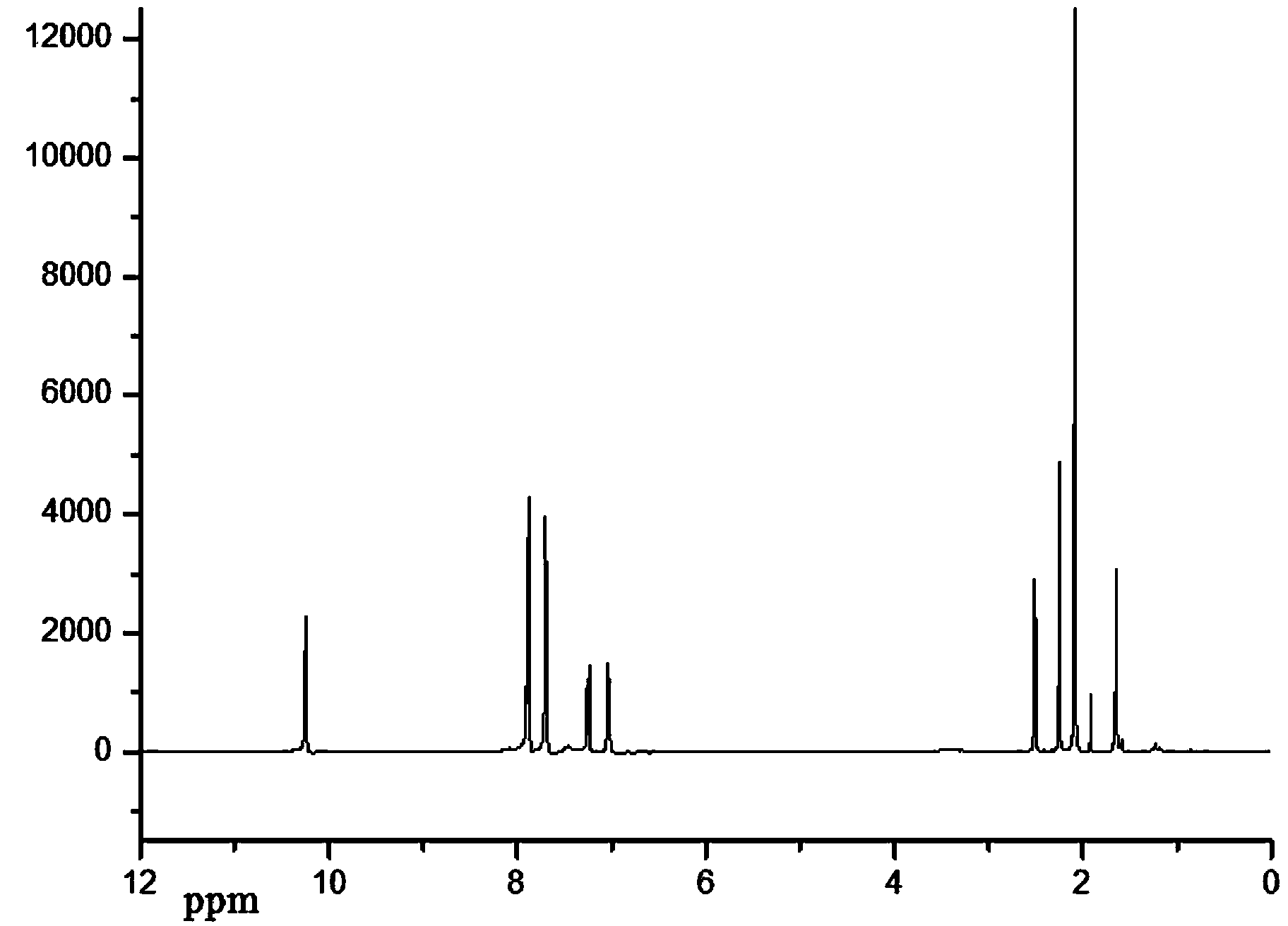

P-N expanded reaction type flame retardant and preparation method thereof

InactiveCN104072759AWith smoke suppressionEfficientGroup 5/15 element organic compoundsFiltrationEnd-group

The invention discloses a P-N expanded reaction type flame retardant p-(carboxyphenyl-amino)-(carboxyphenyl-amidoethyl) phenylphosphine oxide and a preparation method thereof. The preparation method comprises the following steps: (a) adding a p-aminobenzoic acid solution into glacial acetic acid; (b) adding triethylamine and mixed solution obtained in the step (a) into a 2-carboxethylphenyl hypophosphorous acid solution, stirring at a high speed and reacting for 2 hours, raising the temperature to 80 DEG C, reacting for 4 hours, cooling, hydrolyzing, performing suction filtration, washing and drying to obtain white powder, namely the P-N expanded reaction type flame retardant. The defects that harmful gases are generated by general flame retardants, the environment is polluted, fuming is caused and the mechanical property is influenced are overcome, the P-N expanded reaction type flame retardant has double-carboxyl end groups, effective flame retardant components are bonded to a PA66 main chain, an inherently flame retardant effect is achieved, and the flame retardant has the advantages of harmlessness, smoke inhibition, high efficiency, environmental friendliness and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

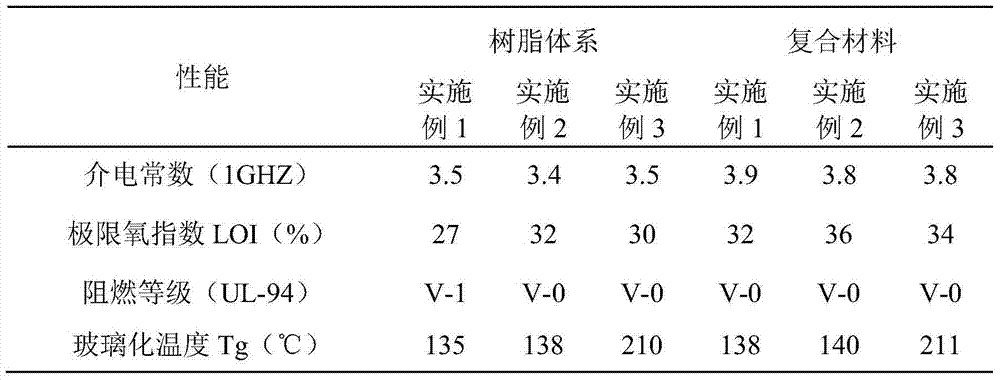

Thermosetting resin composition and prepregs and laminates produced by using the same

ActiveCN106349442AImprove toughnessImprove heat resistanceSynthetic resin layered productsElectrical equipmentImideEpoxy

The invention discloses a thermosetting resin composition. The thermosetting resin composition is prepared from, by solid weight: (a) 10-80 parts of hydrocarbon resin; (b) 100 parts of phosphoric maleimide; (c) 0.1-8 parts of initiator; (d) 5-100 parts of epoxy resin. he thermosetting resin composition applies the maleimide with multi-functional long-chain structure and rigid imide ring and combines with a flexible hydrocarbon resin to form a thermosetting composition through the interaction, and finally makes the thermosetting resin composition and prepregs and laminates produced by using the same for the printed circuit have the characteristics of excellent dielectrical property, heat resistance, adhesion, flame resistance, bending strength, toughness, high peel strength, low water absorption, excellent processing performance and others.

Owner:SHENGYI TECH SUZHOU

Thermosetting resin composition and prepreg and laminated board prepared from same

ActiveCN106243430AImprove toughnessImprove heat resistanceSynthetic resin layered productsElectrical equipmentImideHeat resistance

The invention discloses a thermosetting resin composition. The thermosetting resin composition is prepared from, by solid weight, 10-100 parts of hydrocarbon resin, 20-100 parts of phosphorus-containing maleimide ester and 0.1-8 parts of an initiating agent. According to the thermosetting resin composition, the maleimide ester with multifunctional long-strain structures and rigid imide rings is adopted to cooperate with the flexible hydrocarbon resin to form the thermosetting resin composition, the maleimide ester and the hydrocarbon resin achieve interaction, and finally the thermosetting resin composition and prepreg and a laminated board which are used for a printed circuit and prepared from the thermosetting resin composition have the advantages of being excellent in dielectric property, heat resistance, adhesive property, flame resistance, bending strength and toughness, high in peel strength, low in water absorption, excellent in processing technology property and the like.

Owner:SHENGYI TECH SUZHOU

Halogen-free flame-retarding polyamide composition

The invention relates to a halogen-free flame-retarding polyamide composition, which includes, by weight, 73-93 parts of polyamide, 7-23 parts of melamine or a derivative thereof, 0.1-3 parts of silsesquioxane, and 0.1-1 part of an antioxidant, wherein the melamine or the derivative thereof is subjected to organic treatment. Compared with the prior art, the composition has excellent flame-retarding performance. The composition reaches 0.8 mm UL 94 V-0 in flame-retarding performance and 90 J / m in notch impact strength. The composition has simple process, is convenient to produce and can be applied in the fields of electronic appliances, automobiles and the like.

Owner:上海安凸塑料添加剂有限公司

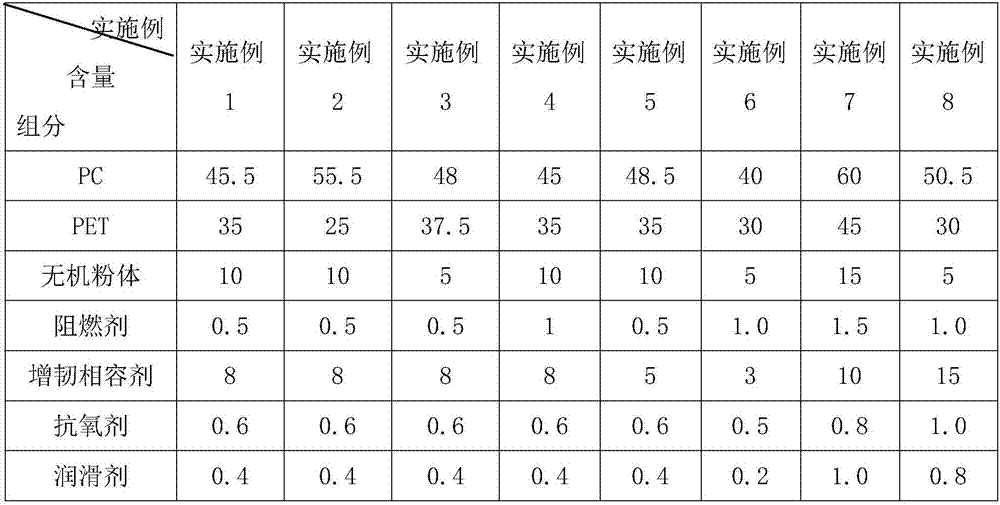

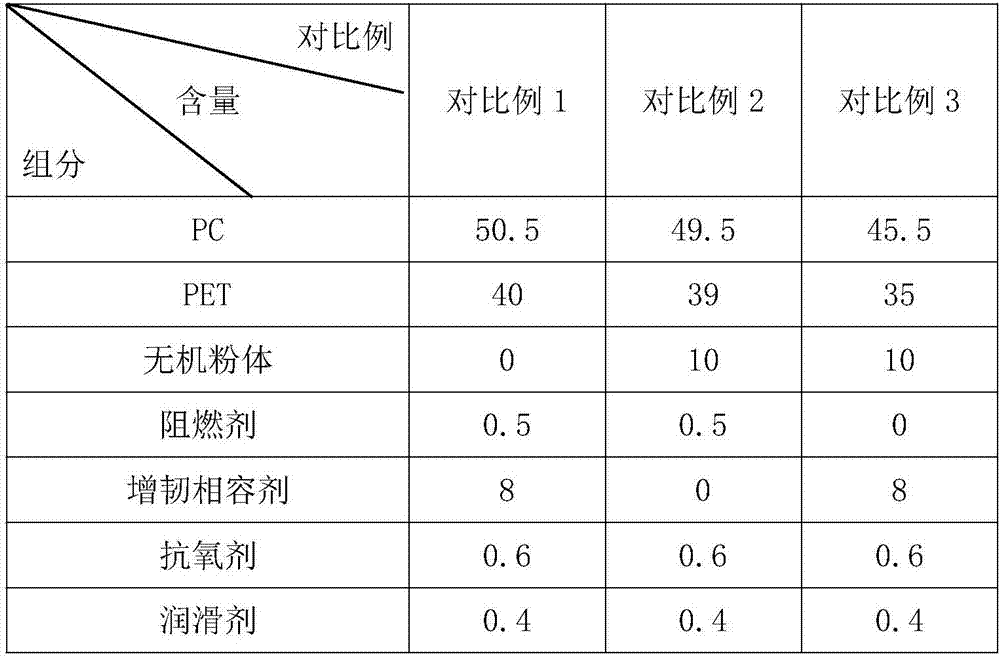

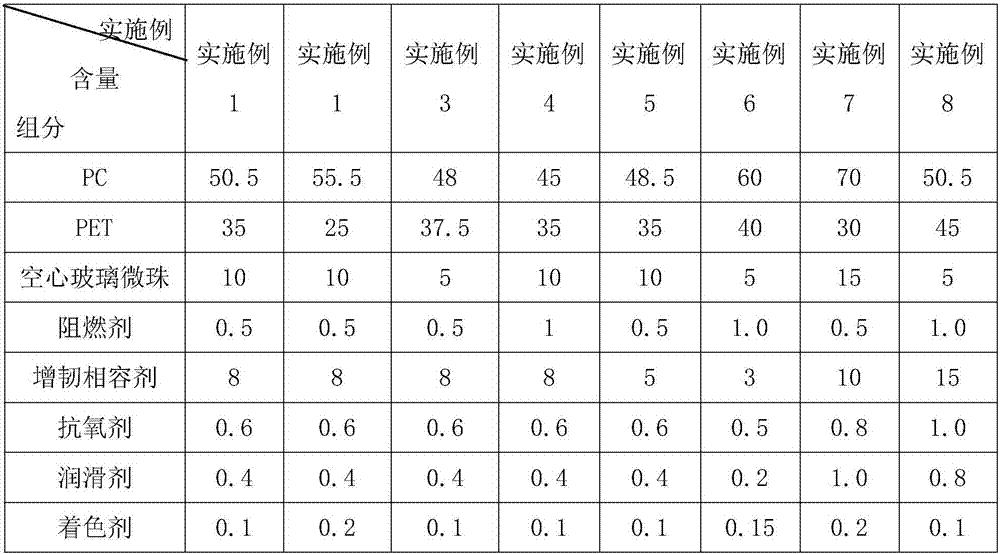

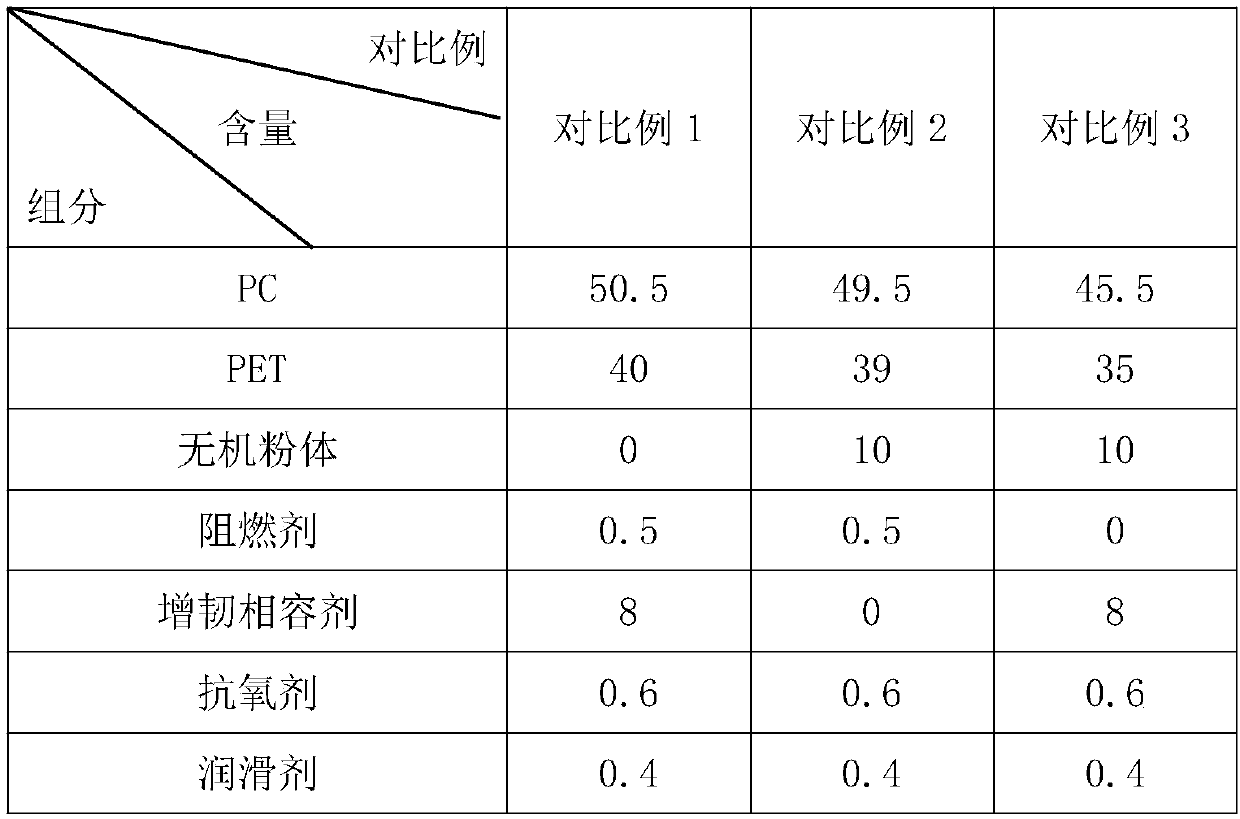

Flame-retardant PET and PC composite material and preparation method thereof

The invention discloses a flame-retardant PET and PC composite material and a preparation method thereof. The composite material comprises the following raw materials, by weight part, 40-60 parts of polycarbonate, 25-45 parts of polyethylene glycol terephthalate, 5-15 parts of inorganic powder, 0.5-1.5 parts of a flame retardant, 3-15 parts of a toughening compatilizer, 0.5-1 part of an anti-oxidant, and 0.2-1 part of a lubricant. The toughening compatilizer is one of an ethylene-butyl acrylate-glycidyl methacrylate copolymer and an ethylene-methyl acrylate-glycidyl methacrylate copolymer. The flame-retardant PET and PC composite material is improved in toughening effect at a certain degree and is light in weight and good in flame retardance.

Owner:NINGBO ZHETIE DAPHOON CHEM

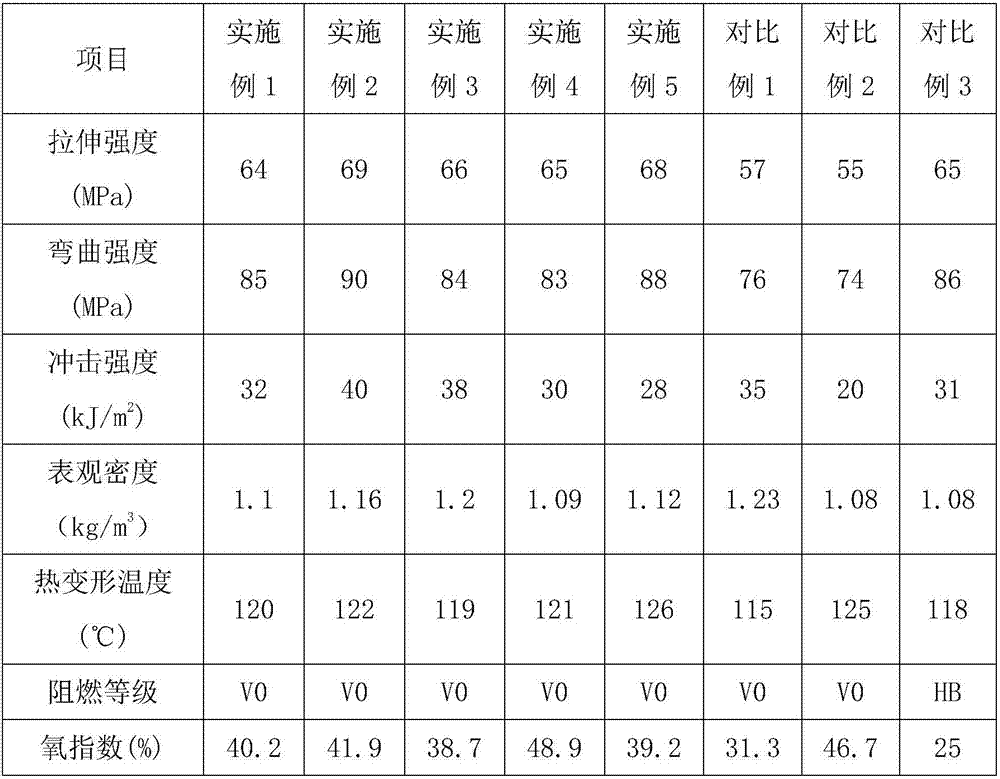

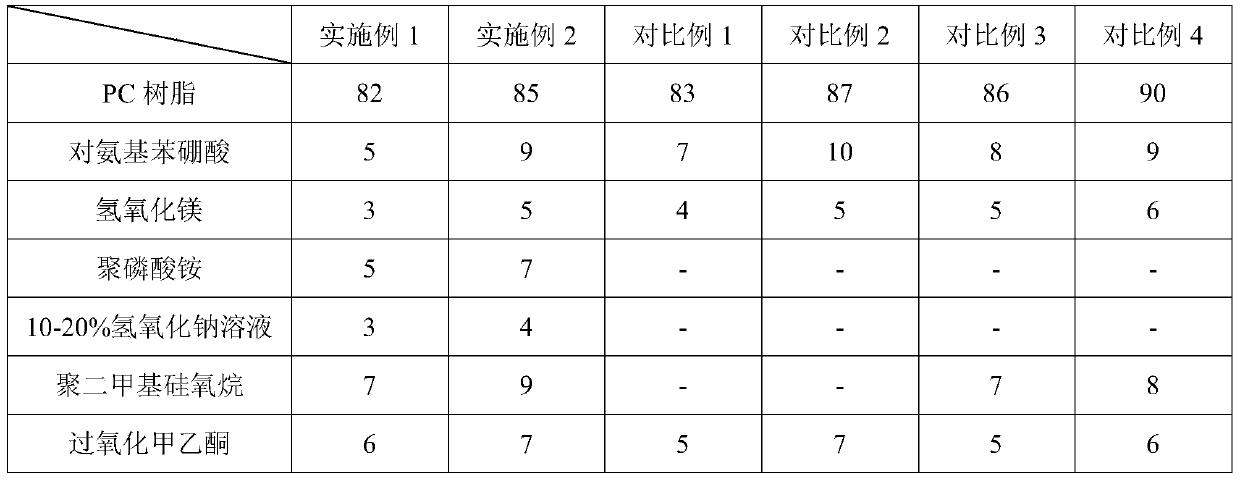

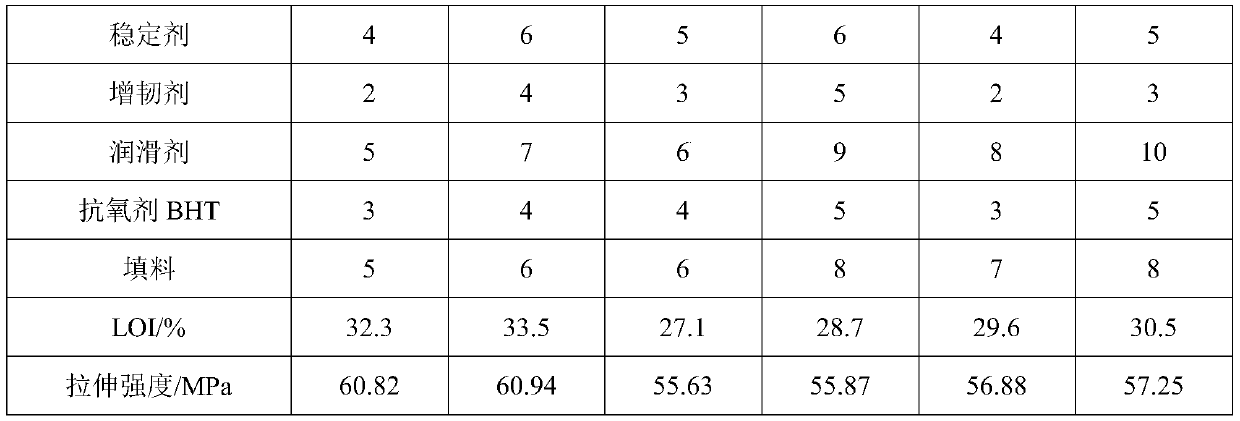

Modified engineering plastic and preparation method thereof

The invention relates to the technical field of engineering plastics, and discloses modified engineering plastic and a preparation method thereof. The engineering plastic comprises the following components: in parts by weight, 80-90 parts of PC resin, 4-6 parts of a stabilizer, 2-5 parts of a toughening agent, 5-10 parts of a lubricant and 3-5 parts of an antioxidant BHT, and a halogen-free flameretardant is also included, and comprises 7-10 parts of p-aminophenyl boronic acid and 3-6 parts of magnesium hydroxide. The modified engineering plastic has the following advantages that a synergistic flame retardant effect is achieved by magnesium hydroxide and p-aminophenyl boronic acid, on the one hand, the amount of magnesium hydroxide can be reduced, and on the other hand, a double-layer flame retardant structure is formed through a magnesium oxide protective film and a B-O-C carbon layer, so that a better flame retardant effect is achieved.

Owner:WENZHOU CITY FANHUA ENG PLASTIC

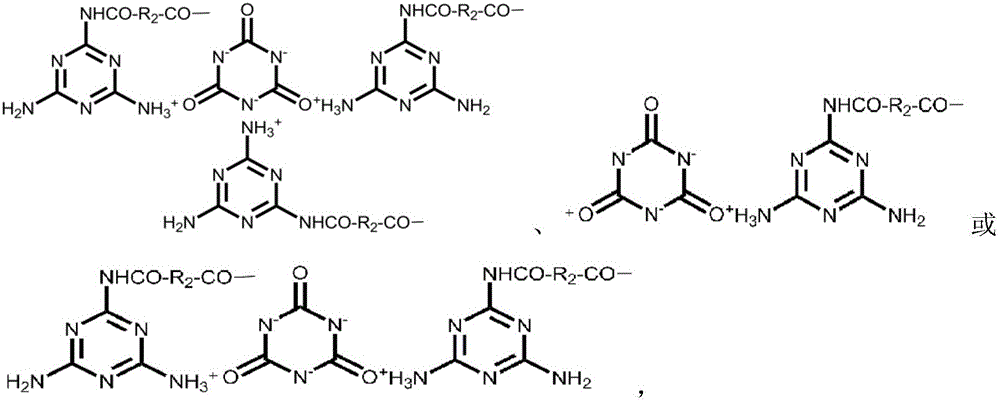

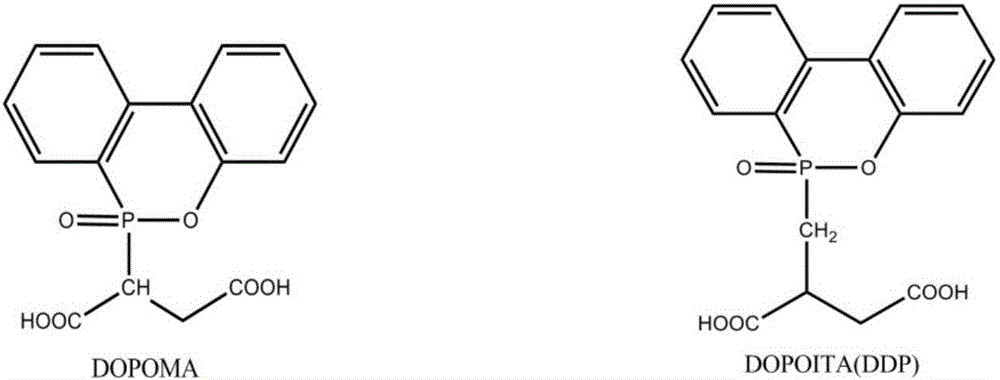

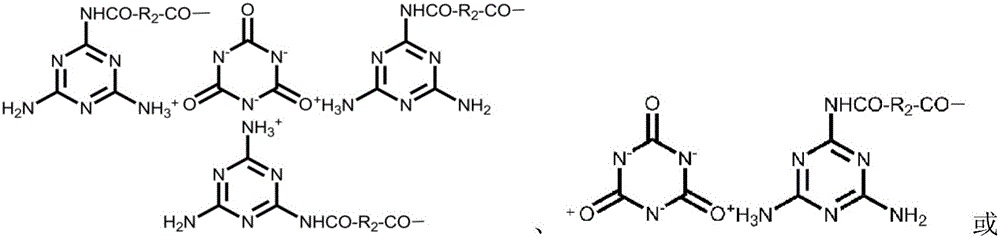

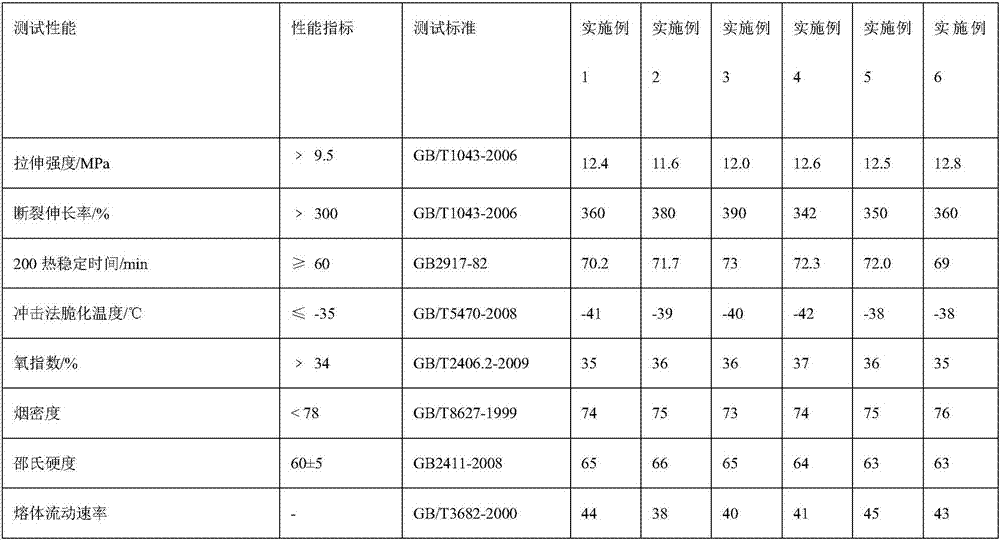

N-P synergetic flame retardant nylon 66 and preparation method thereof

The invention discloses N-P synergetic flame retardant nylon 66 and a preparation method thereof. The N-P synergetic flame retardant nylon 66 is characterized in that a derivative of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide react with diamine to prepare a flame retardant A containing P; a binary acid melamine salt and a cyanuric acid diamine salt which are equal in molar mass are mixed to prepare a flame retardant B containing N; the flame retardant A and the flame retardant B react with a nylon 66 salt to prepare the N-P synergetic flame retardant nylon 66, wherein the flame retardant A and the nylon 66 are subjected to copolymerization, and the flame retardant B and the nylon 66 are subjected to in-situ polymerization. The N-P synergetic flame retardant nylon 66 has a melting point range of 255-265 DEG C, a relative viscosity range of 2.0-3.0, a flame retardant rating of V0, tensile strength of 70.0-82.0 MPa, notch impact strength of 3.5-5.0 KJ / m<2>, bending strength of 100-120 MPa and smoke density of 10-15%. The N-P synergetic flame retardant nylon 66 can be used for spinning and manufacture of engineering plastics.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

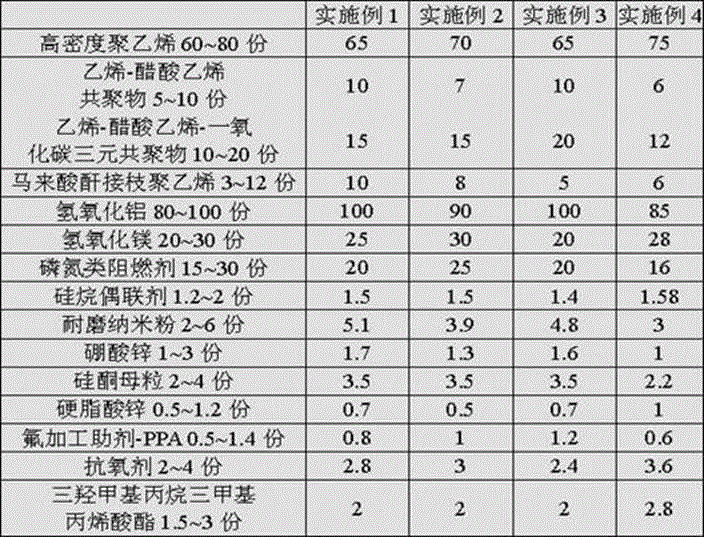

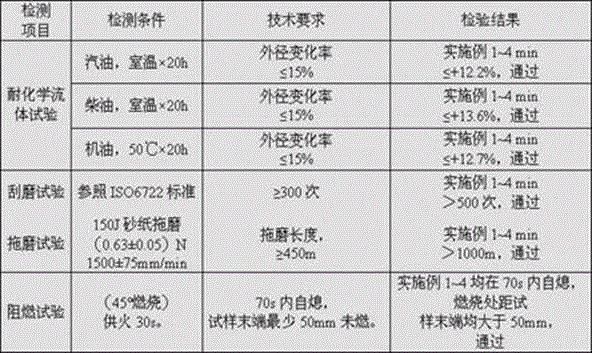

High-wear-resistant irradiation crosslinked halogen-free flame-retardant automotive wire cable material and preparation process thereof

InactiveCN105400045ADifficult to disperseImprove wear resistancePlastic/resin/waxes insulatorsMeth-Vinyl acetate

The invention relates to a high-wear-resistant irradiation crosslinked halogen-free flame-retardant automotive wire cable material composed of the following components in parts by weight: high density polyethylene, an ethylene-vinyl acetate copolymer, an ethylene-vinyl acetate-carbon monoxide terpolymer, maleic anhydride grafted polyethylene, aluminum hydroxide, magnesium hydroxide, a phosphorus-nitrogen flame retardant, a silane coupling agent, a wear-resistant nano-powder, zinc borate, silicone master batch, zinc stearate, a fluorine processing auxiliary agent-PPA, an antioxidant, and trimethylolpropane trimethacrylate. The wear-resistant nano-powder comprises a main component of a nitrogen-silicon-oxygen compound, the melt flow index of high density polyethylene is 0.08-2 g / 10 min, the content of vinyl acetate in the ethylene-vinyl acetate copolymer is 20-40%, and the melt flow index of the ethylene-vinyl acetate copolymer is 0.2-5 g / 10 min. The high-wear-resistant halogen-free flame-retardant cable material has the characteristics of high mechanical strength, low smoke, no poison, excellent wear resistance, good high-temperature resistance, good oil resistance and the like, and has the tensile strength of more than 17 MPa and the elongation at break of more than 600%.

Owner:中广核三角洲(苏州)高聚物有限公司

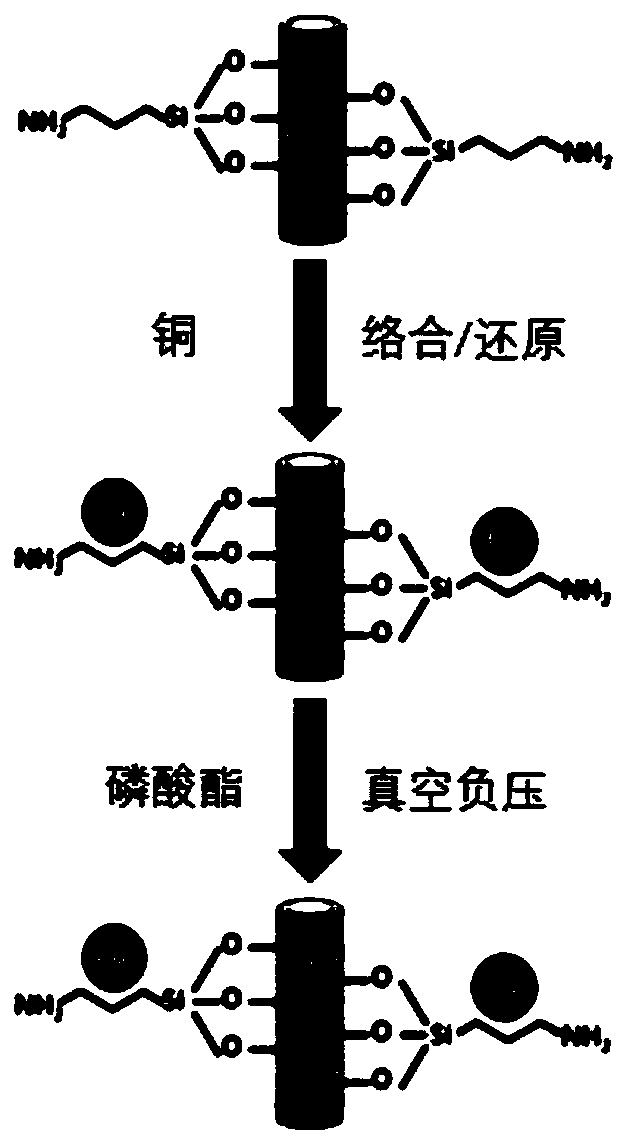

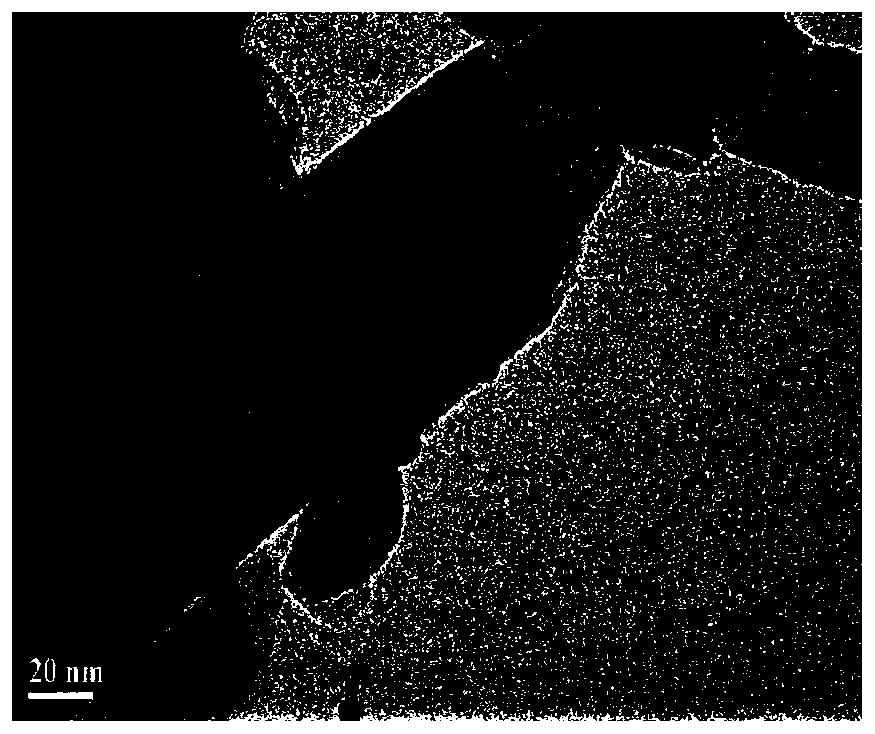

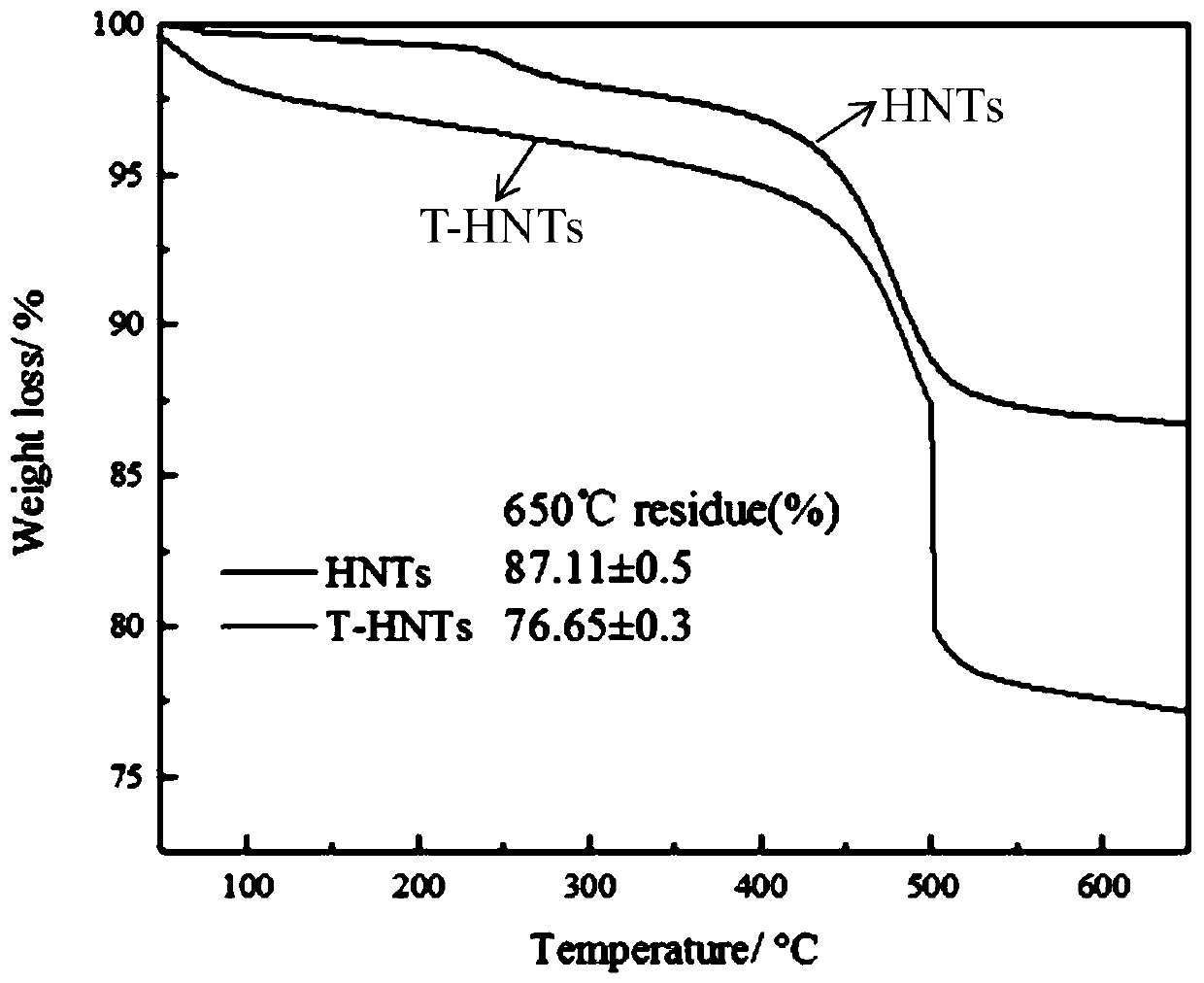

Flame-retardant antibacterial compound containing halloysite, and preparation method thereof

ActiveCN110746654ARaw materials are easy to getImprove antibacterial propertiesPolymer sciencePhosphate

The invention relates to a flame-retardant antibacterial compound containing halloysite, and a preparation method thereof. The flame-retardant antibacterial compound containing halloysite nanotubes ishalloysite nanotubes loaded with elemental copper and phosphate. The flame-retardant antibacterial compound containing halloysite nanotubes can be uniformly dispersed in a polymer matrix, so the polymer has the antibacterial property and the flame-retardant property, the mechanical properties of the polymer are not obviously influence, and the application range of the polymer is expanded.

Owner:EAST CHINA UNIV OF SCI & TECH +2

Color modified flame retardant PET (polyethylene terephthalate) and PC (polycarbonate) composite material and preparation method thereof

InactiveCN106977893AImprove flame retardant performanceGood compatibilityPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a color modified flame retardant PET (polyethylene terephthalate) and PC (polycarbonate) composite material and a preparation method thereof. The color modified flame retardant PET and PC composite material is prepared from the following raw materials in parts by weight: 45 to 70 parts of PC, 30 to 45 parts of PET, 5 to 15 parts of hollow glass microspheres, 0.5 to 1.0 part of flame retardants, 3 to 15 parts of toughening compatilizers, 0.5 to 1 part of antioxidizers, 0.2 to 1 part of lubricating agents and 0.1 to 0.2 part of coloring agents, wherein the color agents are one or several of anthraquinone organic transparent dyestuff and anthraquinone type organic transparent purple dyestuff. The good flame retardant effect is achieved; meanwhile, good color and transparency are realized.

Owner:NINGBO ZHETIE DAPHOON CHEM

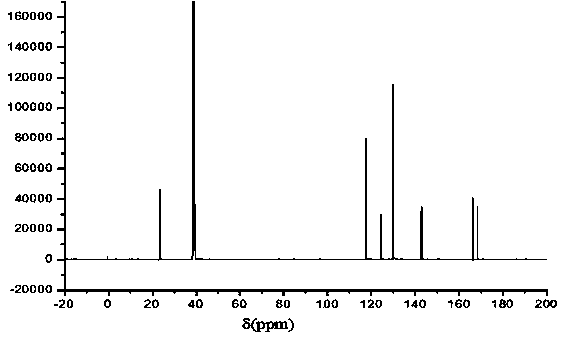

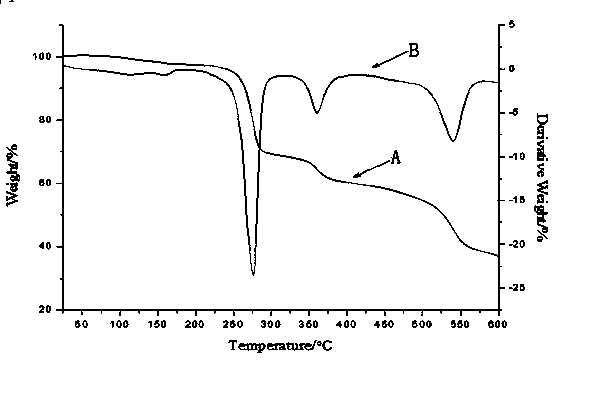

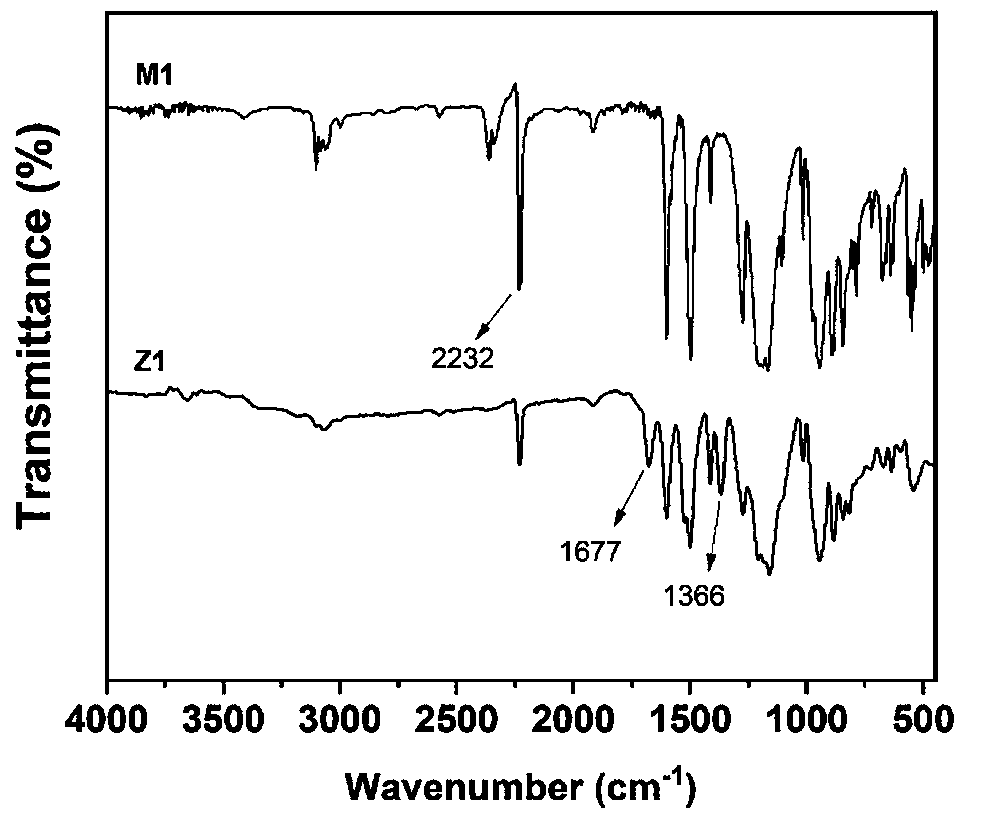

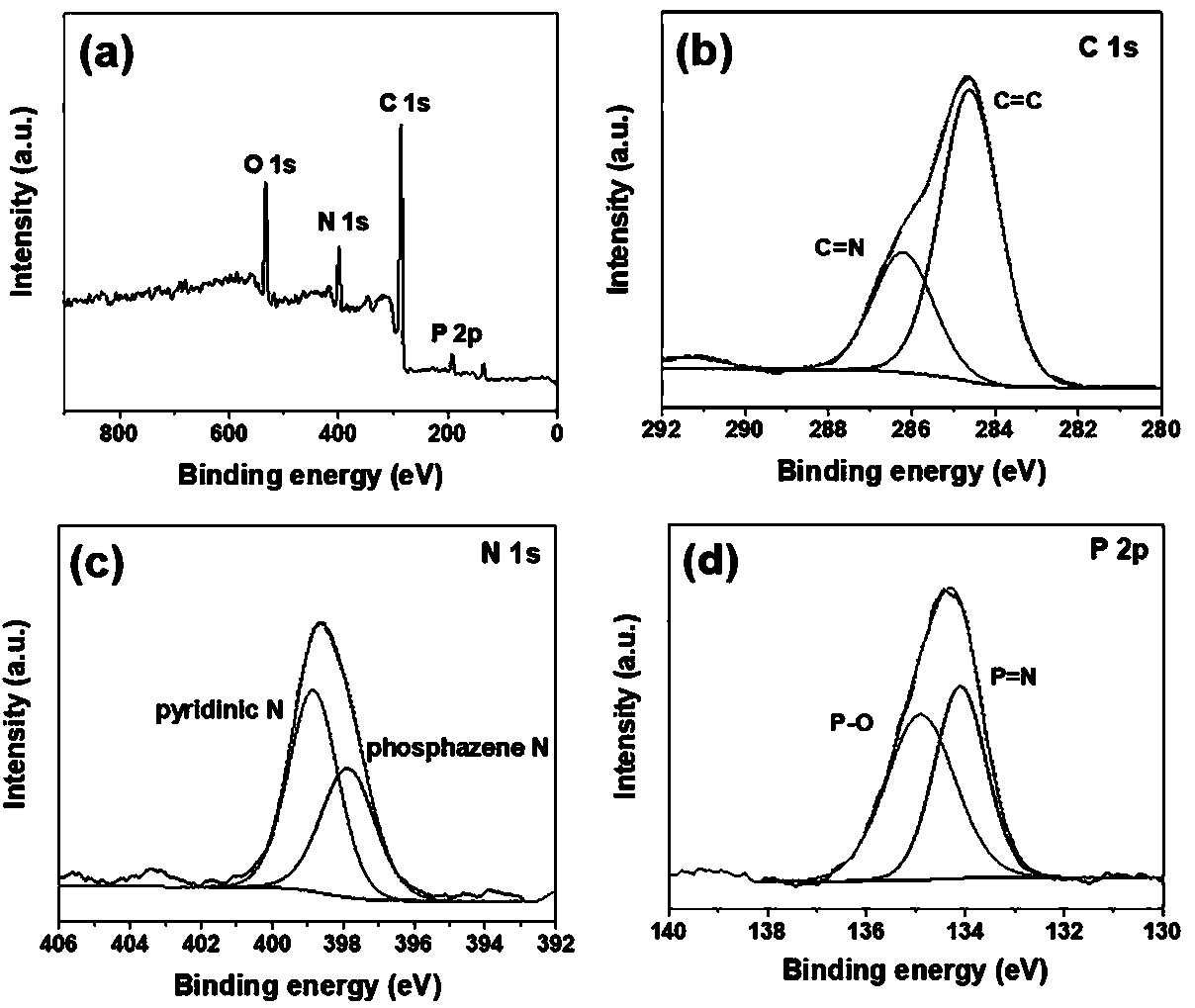

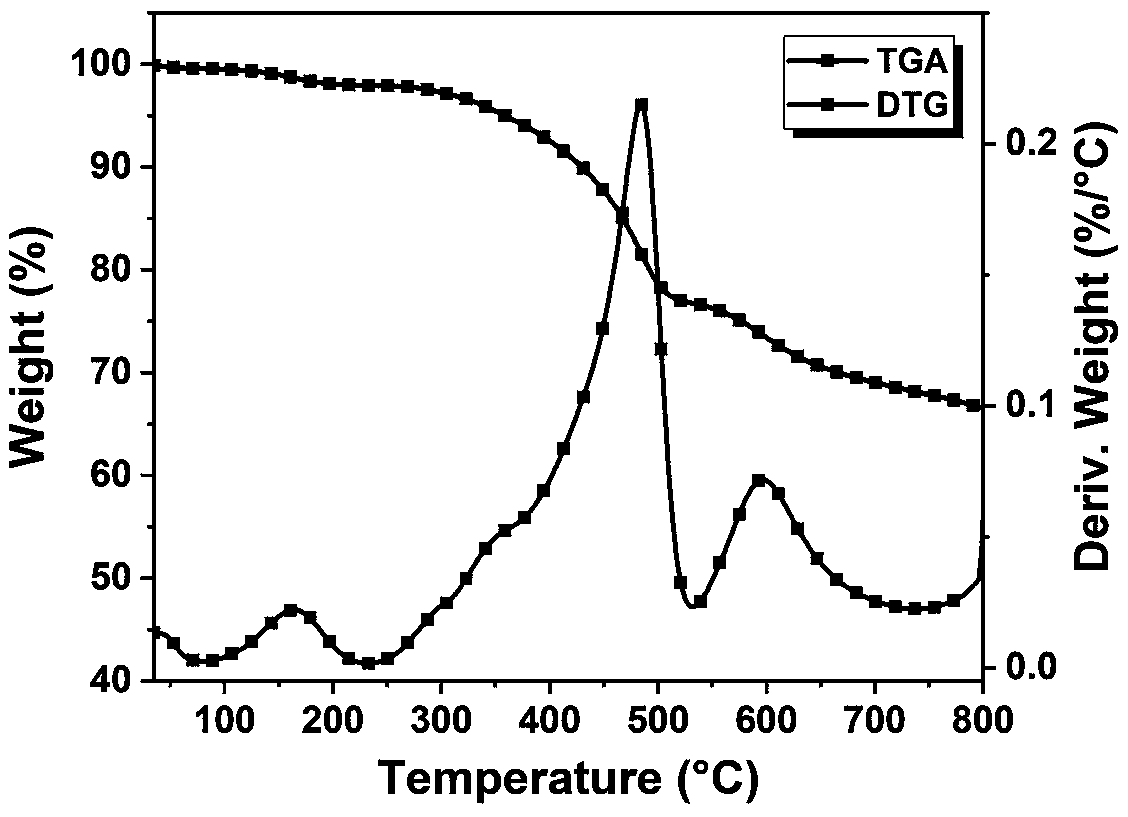

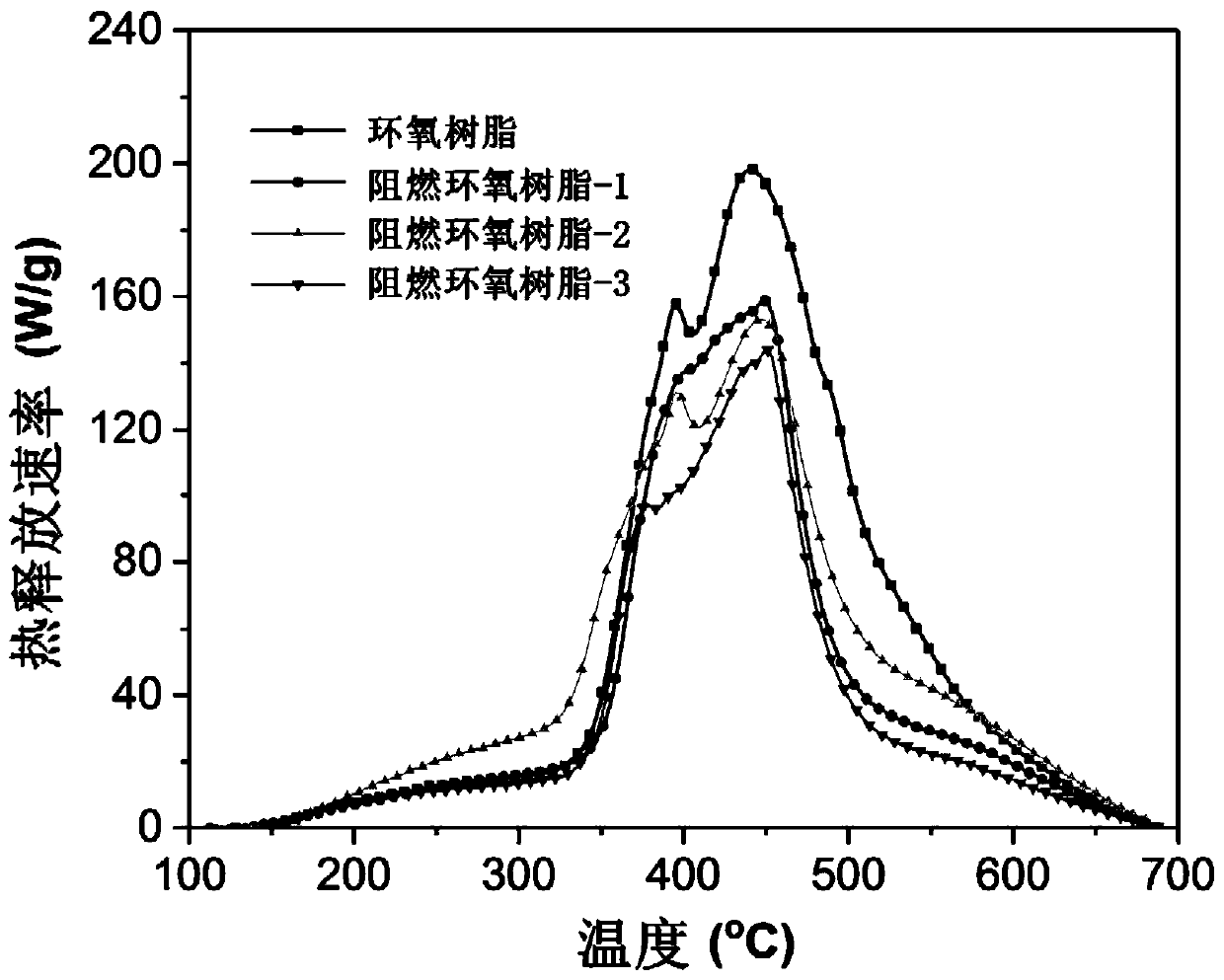

Polyphosphazene covalent triazine polymer and preparation method and application thereof

The invention discloses a polyphosphazene covalent triazine polymer and a preparation method and application thereof. According to the invention, a phosphazene derivative containing a cyano group at an end group is used as a precursor, and a cyclotrimerization reaction is carried out under the catalysis of protonic acid to prepare the covalent triazine polymer containing a phosphazene structure. The polyphosphazene covalent triazine polymer prepared by using the method has the characteristics of simple preparation process, mild reaction conditions, good thermal stability and the like. When theprepared polyphosphazene covalent triazine polymer is applied to flame retardance of epoxy resin, a synergistic flame-retardant effect is obtained, and the polyphosphazene covalent triazine polymer is high in flame-retardant efficiency, does not damage the mechanical properties of the epoxy resin and has great practical application value.

Owner:EAST CHINA UNIV OF SCI & TECH

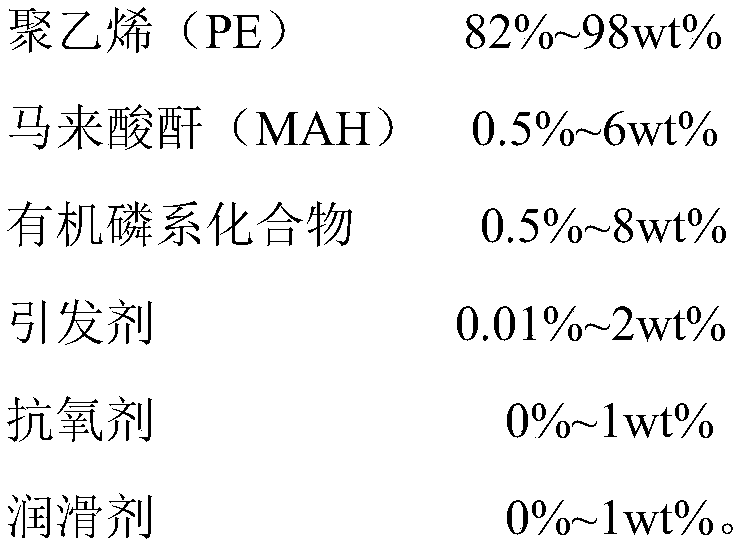

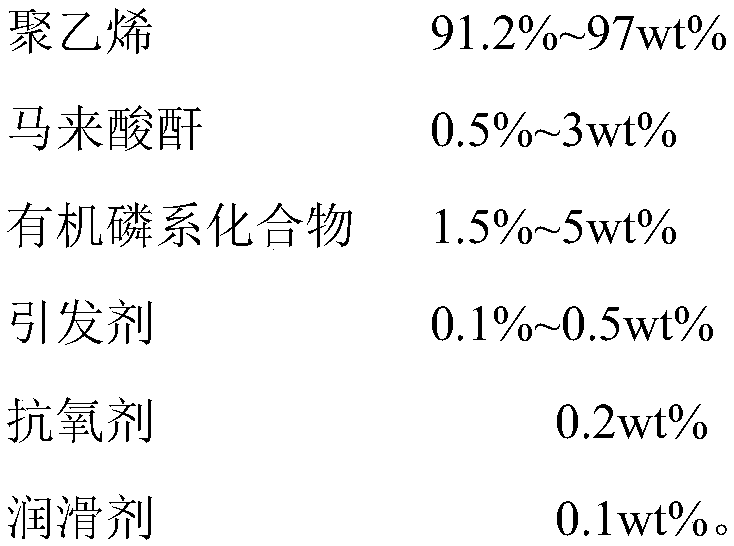

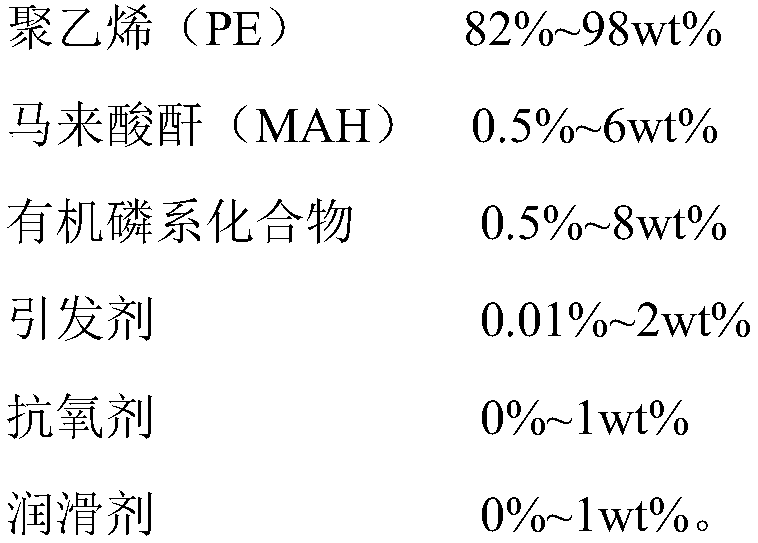

Phosphorus-containing polyethylene and maleic anhydride graft copolymer with synergistic flame-retardant effects and method for preparing phosphorus-containing polyethylene and maleic anhydride graft copolymer

The invention discloses a phosphorus-containing polyethylene and maleic anhydride graft copolymer with synergistic flame-retardant effects and a method for preparing the phosphorus-containing polyethylene and maleic anhydride graft copolymer. The phosphorus-containing polyethylene and maleic anhydride graft copolymer is a graft copolymer with polyethylene, maleic anhydride and organic phosphorus compounds. The phosphorus-containing polyethylene and maleic anhydride graft copolymer comprises 82-98 wt% of polyethylene, 0.5-6 wt% of maleic anhydride, 0.5-8 wt% of organic phosphorus compounds, 0.01-2 wt% of initiators,0-1 wt% of antioxidants and 0-1 wt% of lubricants. The phosphorus-containing polyethylene and maleic anhydride graft copolymer and the method have the advantages that excellent coupling effects can be realized by functional groups with the maleic anhydride for ethylene matrix polymers and polar substances such as inorganic mineral, inorganic flame retardants and glass fibers;the organic phosphorus compounds in systems have double synergistic flame-retardant and plasticization functions, influence on the processing properties and the mechanical properties of materials canbe prevented, the phosphorus-containing polyethylene and maleic anhydride graft copolymer is easy to process, and the phosphorus-containing polyethylene and maleic anhydride graft copolymer and the method conform to the current green and environment-friendly development trend.

Owner:FINE BLEND COMPATILIZER JIANGSU CO LTD

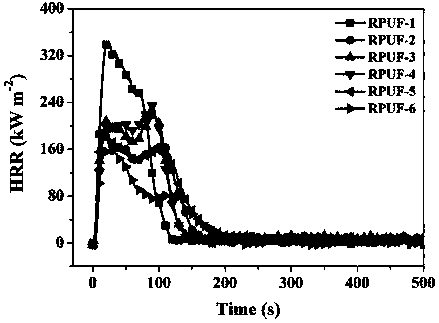

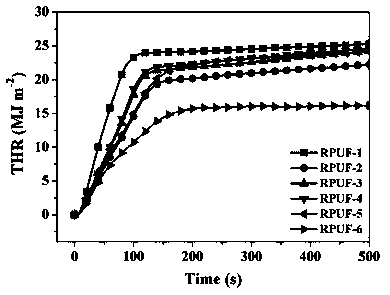

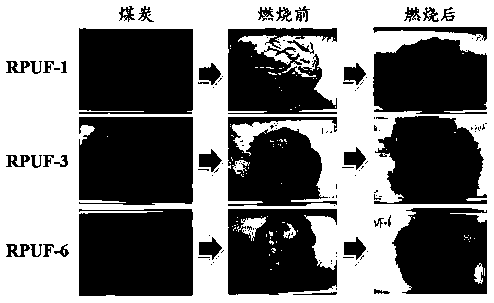

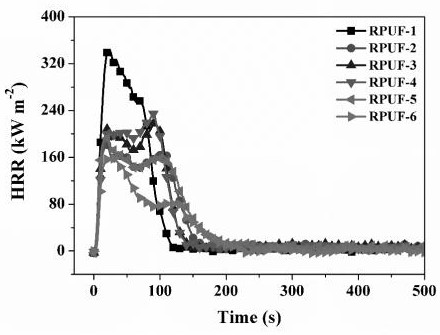

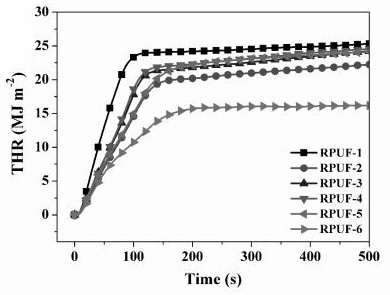

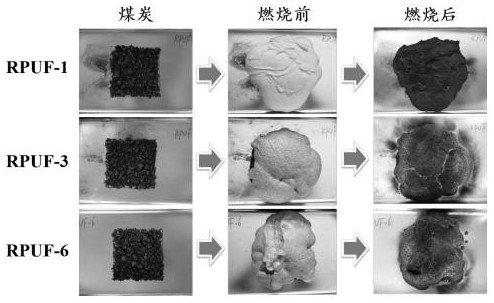

Flame-retardant rigid polyurethane foam material, and preparation method and application thereof

The invention belongs to the field of preparation of inhibition materials, and particularly relates to a flame-retardant rigid polyurethane foam material, and a preparation method and application thereof. The material comprises a mixture A and a mixture B, wherein the mixture A comprises the following components in parts by weight: 77.47-100 parts of a polyol, 0-22.53 parts of a glycol phosphinate, 1 part of an amine catalyst, 0.5 part of an organic tin catalyst, 2 parts of water, 2 parts of a foam stabilizer and 3 parts of triethanolamine; the mixture B is prepared from the following components in parts by weight: 149 to 152 parts of an isocyanate, 0 to 20.25 parts of expandable graphite, 0 to 20.25 parts of a phosphate and 0 to 7.5 parts of coal ash. The flame-retardant rigid polyurethane foam material possesses integrated condensed phase flame resistance, gas phase flame resistance and expanded graphite physical flame resistance, and the coal ash with synergistic flame resistance effect and excellent bonding performance is added, so that the rigid polyurethane foam material has excellent flame resistance, can not only be taken as a inhibition material for preventing and treatingspontaneous combustion of coal, and can also be taken as a sealing material and a thermal insulation material.

Owner:FUZHOU UNIV

P-N intumescent flame retardant and preparation method thereof

The invention discloses a P-N intumescent flame retardant and a preparation method thereof. The P-N intumescent flame retardant is poly2, 2-bis(4-para-aminobenzoic acid-phenylphosphine oxide phenyl)propane. The preparation method includes: (a) adding a solvent glacial acetic acid, a catalyst aluminium trichloride, phenylphosphonic dichloride and bisphenol A into a flask in order to react for 4h; (b) dissolving para-aminobenzoic acid in glacial acetic acid to form a mixed solution, then adding the solution obtained in step a, firstly raising the temperature to 90DEG C and conducting high speed stirring reaction for 4h, then further raising the temperature to 130DEG C, and performing high speed stirring reaction for 2h; and (c) subjecting the reaction product obtained in step b to cooling, hydrolysis, alkali washing, water washing, suction filtration and drying so as to obtain white powder, i.e. the P-N intumescent flame retardant. The P-N intumescent flame retardant provided by the invention overcomes the disadvantages of generation of harmful gas, environment pollution, fuming, influence to mechanical properties and the like of common flame retardants, has double carboxyl terminal group, can key effective flame retardant components to a PA66 main chain to play an essential flame retardant role, and has the advantages of no harm, fume suppression, high efficiency and environmental protection, etc.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

A kind of preparation method of flame-retardant polyether and the application of obtained product

The invention discloses a preparation method and application of flame-retardant polyether. The flame-retardant polyether contains N, P and Br elements and is reactive flame-retardant polyether. According to the preparation method, the flame-retardant polyether is prepared from the following raw materials in parts by weight: 5-10 parts of ethylenediamine, 20-30 parts of tri(3-hydroxypropyl)phosphine, 23-28 parts of dibromoneopentyl glycol, 0.5-2.0 parts of dimethylamine and 30-51.5 parts of epoxy propane. Polyurethane foaming plastics prepared from the flame-retardant polyether have a favorable flame-retardant effect and have the advantages of stable flame retardance and better foam quality as comparison with polyurethane foaming plastics prepared by additionally adding a flame retardant.

Owner:JURONG NINGWU NEW MATERIAL CO LTD BY SHARES

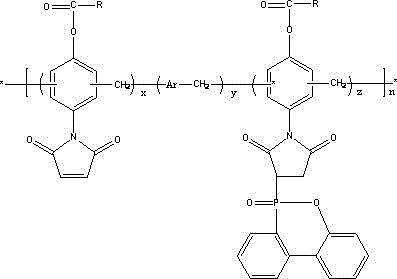

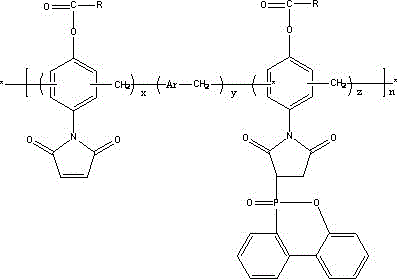

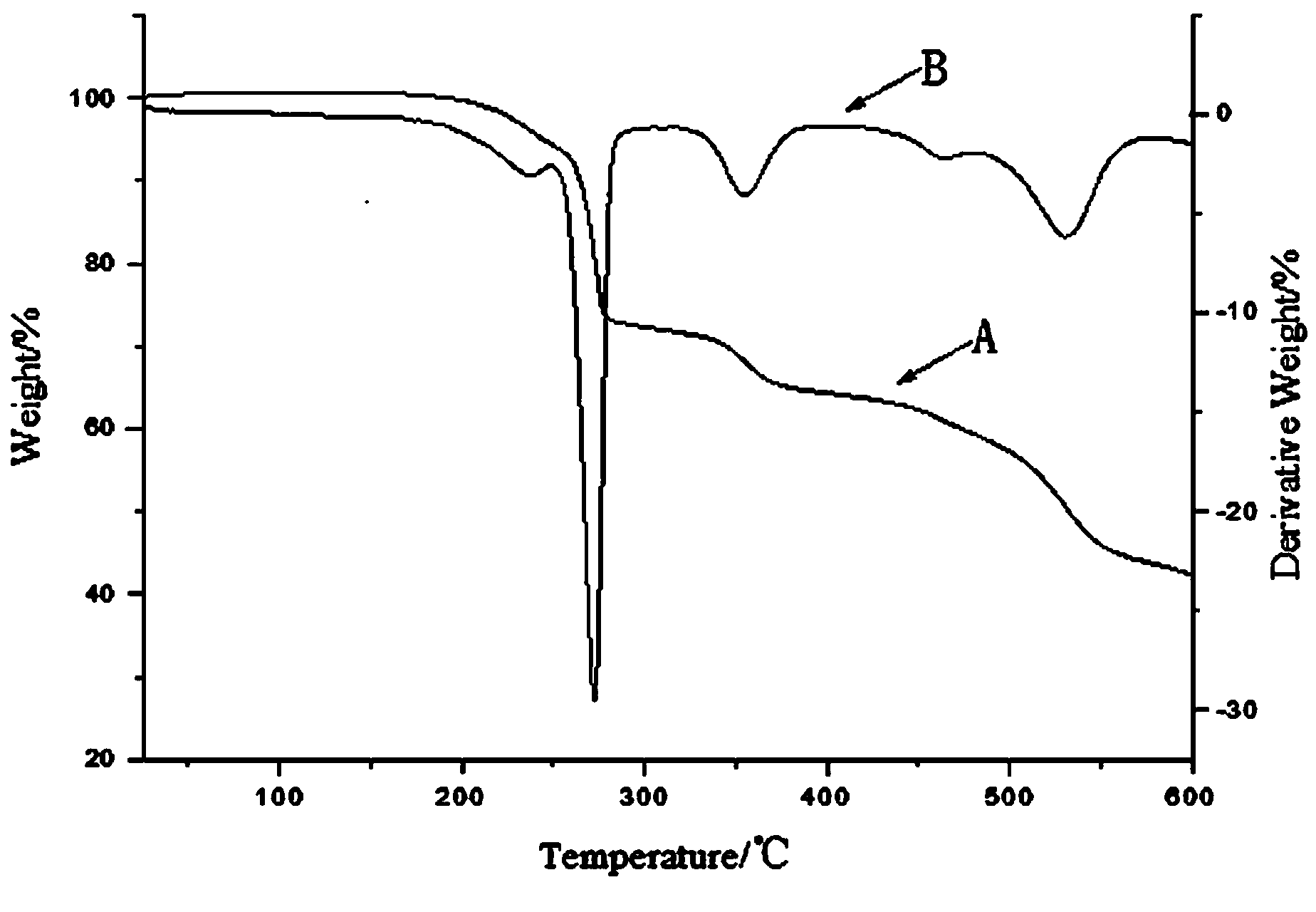

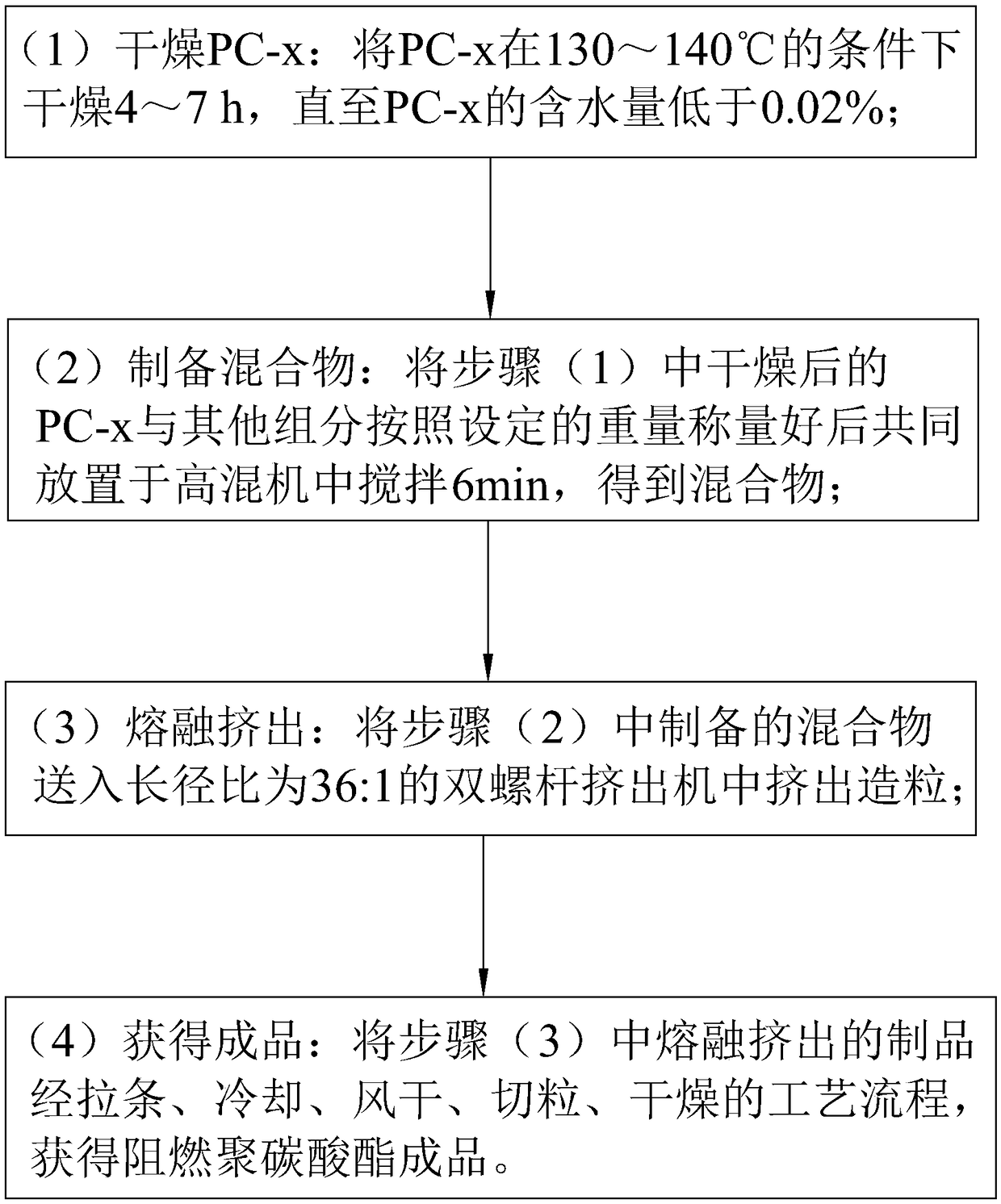

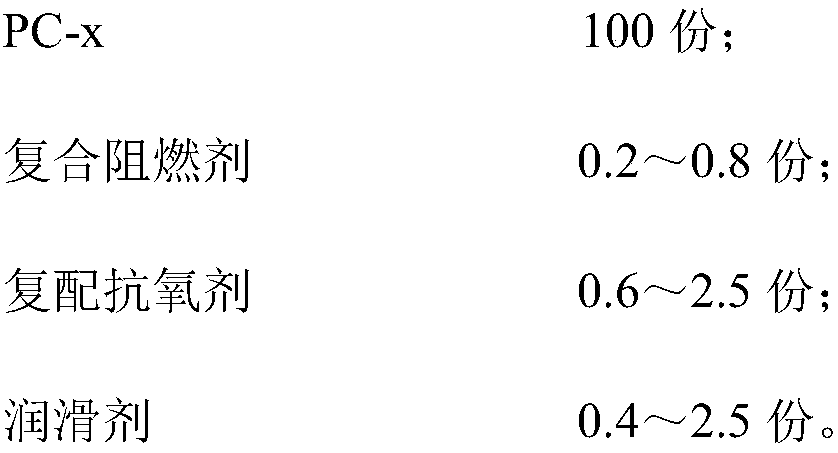

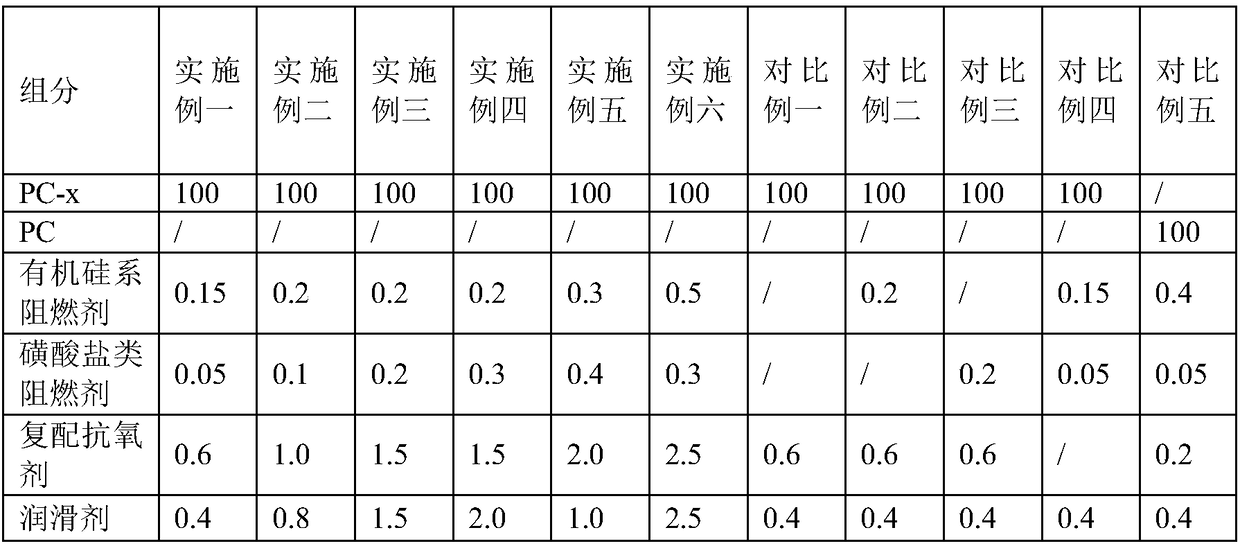

Flame-retardant polycarbonate and preparation method thereof

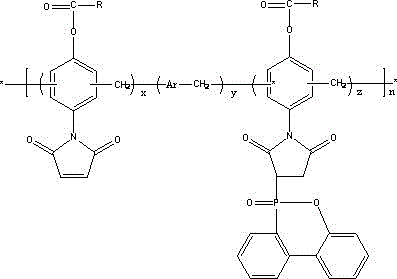

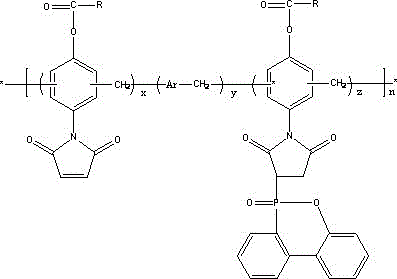

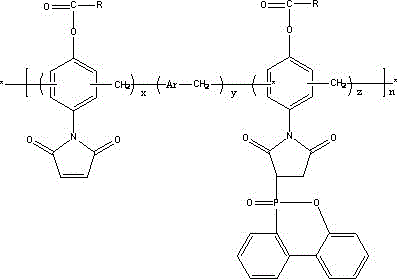

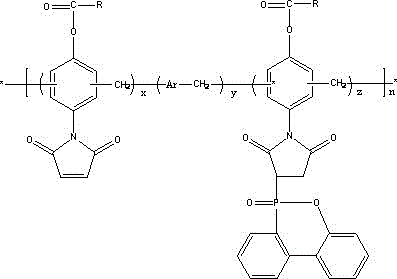

The invention provides flame-retardant polycarbonate and a preparation method thereof, and relates to the field of polymer materials. The flame-retardant polycarbonate comprises the following components (by weight): 100 parts of PC-x, 0.2-0.8 part of a composite flame retardant, 0.6-2.5 parts of a compound antioxidant and 0.4-2.5 parts of a lubricant, wherein the molecular structural formula of PC-x is as shown in the specification. The polycarbonate is prepared by the processes of stirring-mixing and melt-extrusion, has an obvious shear thinning effect, and has high melt strength at low shear, which can effectively suppress dripping during combustion to improve the flame retardancy of the resin itself. The high-efficiency composite flame retardant is one of an organosilicon flame retardant and a sulfonate-based flame retardant or formed by compounding more than one of the organosilicon flame retardant and the sulfonate-based flame retardant. By matching the PC-X with a special molecular structure and the high-efficiency composite flame retardant, the oxygen index is significantly improved, the flame retardant performance is excellent, and it is ensured that the product has high transparency, good strength and stiffness and resistance to chemical reagents.

Owner:NINGBO ZHETIE DAPHOON CHEM

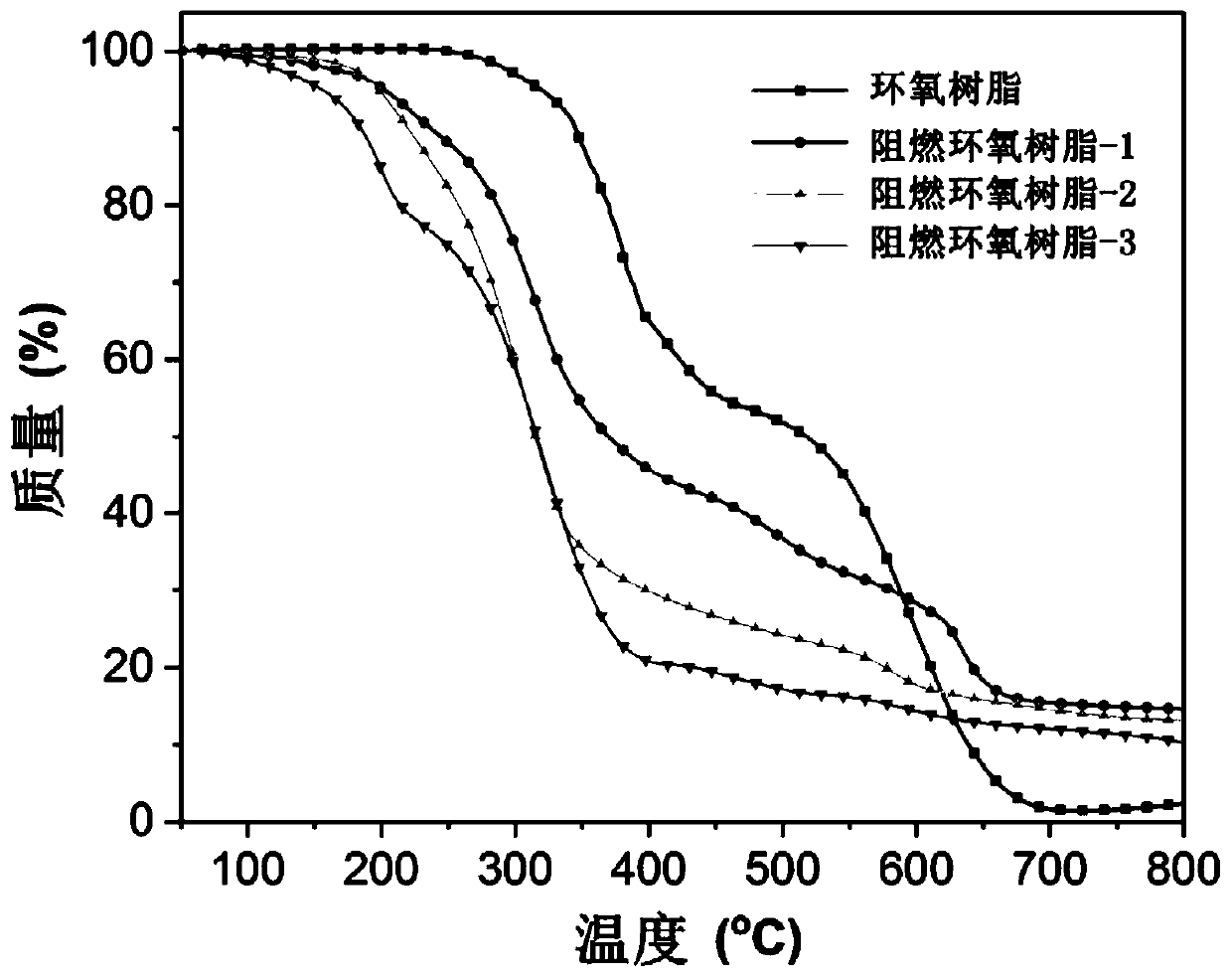

Flame retardant containing multivalent phosphorus element and preparation method thereof

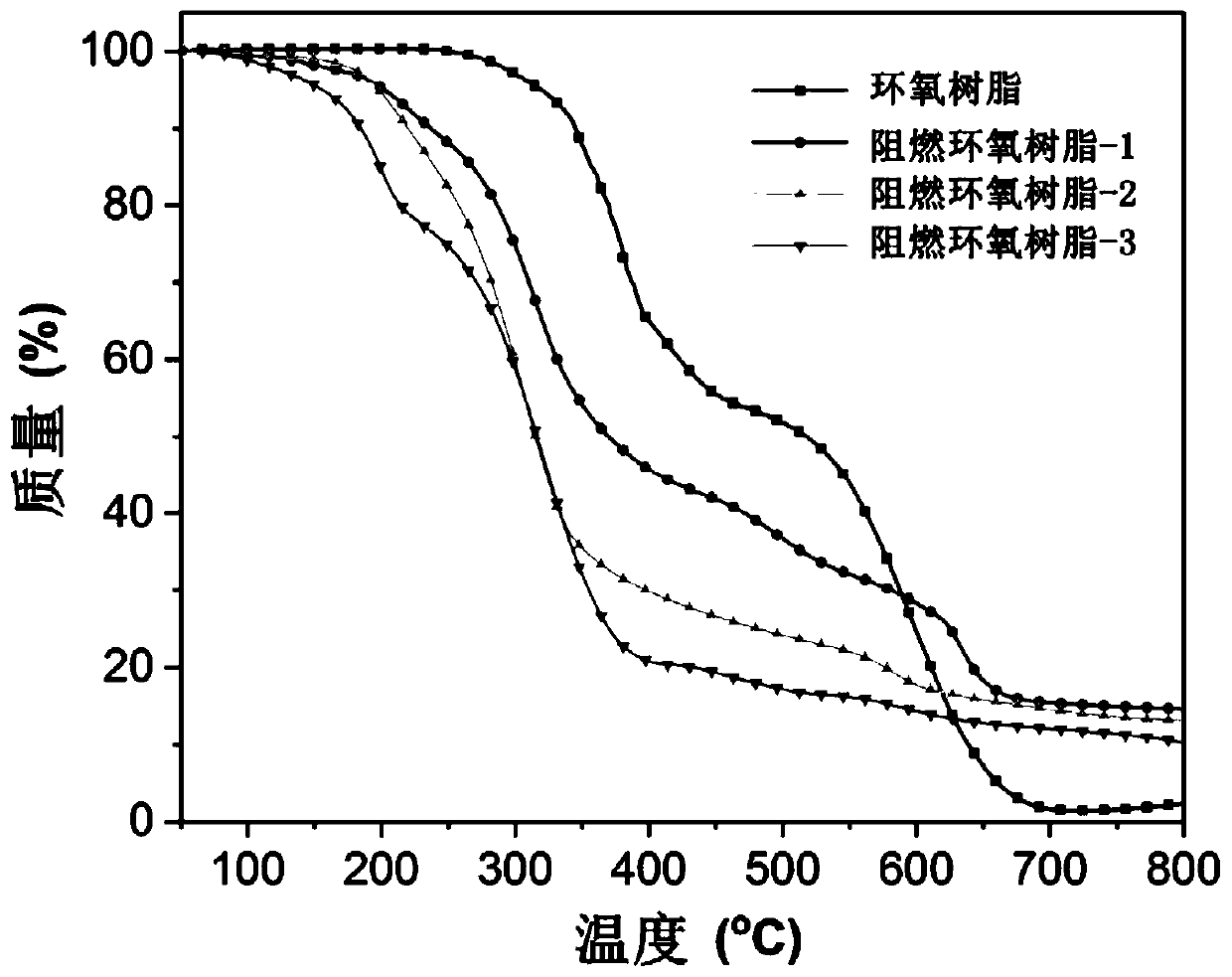

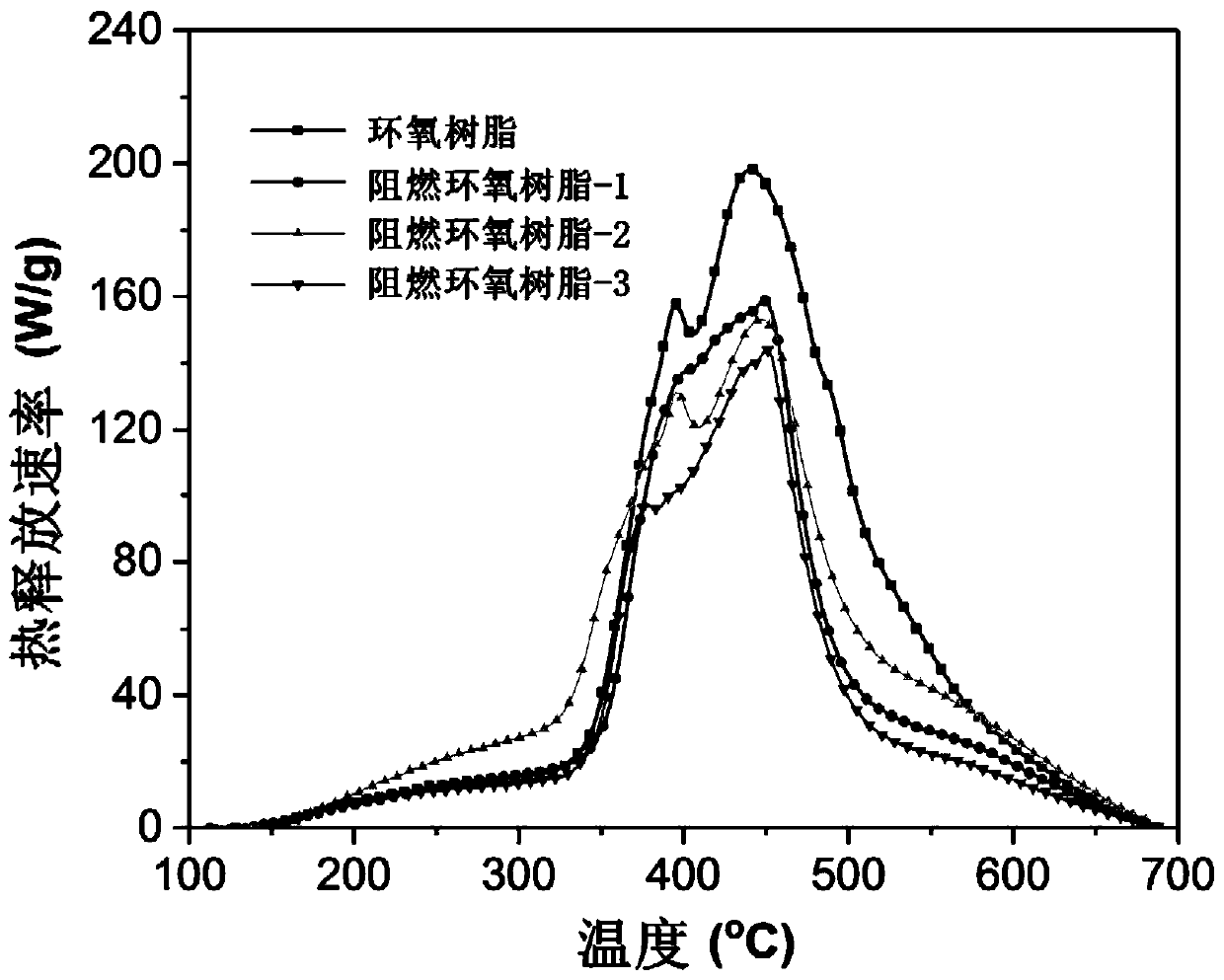

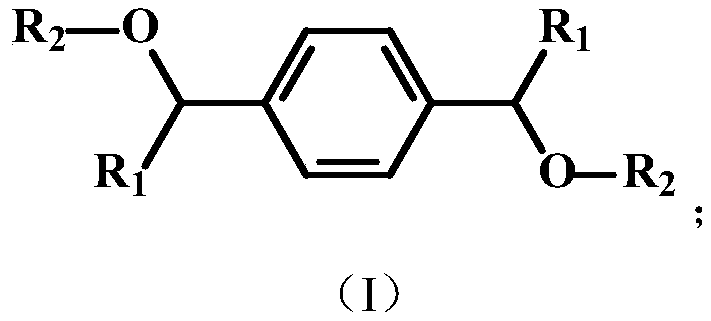

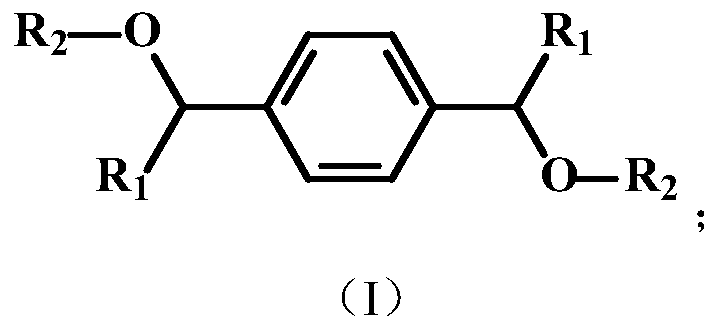

ActiveCN110229190AHigh flame retardant efficiencyHas a synergistic flame retardant effectGroup 5/15 element organic compoundsChemical structureFire retardant

The invention discloses a flame retardant containing multivalent phosphorus element and a preparation method thereof. A chemical structure of the flame retardant containing multivalent phosphorus element is as shown in a formula (I), wherein R1 and R2 are respectively phosphorus-containing structures with different valence states. The chemical structure of the flame retardant containing multivalent phosphorus element simultaneously contains a plurality of phosphorus atoms with different valence states, a condensed phase flame retardant mechanism can be exerted to promote carbon formation of apolymer in a combustion process, and a gas phase flame retardant mechanism can be also exerted to captures active radicals in the combustion process. The phosphorus content and the number of aromaticrings can be adjusted, so that the flame retardant is suitable for flame retardant treatment of different polymer matrices. A limit oxygen index of epoxy resin treated with the flame retardant is obviously increased, the vertical burning grade is up to V-0 grade, and the flame retardant has the advantages of good carbon formation property, high flame retardant efficiency and the like.

Owner:UNIV OF SCI & TECH OF CHINA

Expandable graphite flame retardant coated with nano particles on surface and preparation method thereof

The invention relates to an expandable graphite flame retardant coated with nano particles on the surface. The surface of expandable graphite is coated with one or more layers of metal hydroxide nanoparticles. Moreover, the invention further discloses a preparation method of the expandable graphite flame retardant coated with the nano particles on the surface. Compared with traditional expandablegraphite, the flame retardant provided by the invention has the benefits that the expansion rate of the flame retardant is further improved; by taking a metal hydroxide nano particle layer as a housing, on one hand, the gas release of the expandable graphite in the expansion process can be prevented, so that the expansion rate is improved; on the other hand, the compatibility of the flame retardant with a polyurethane material can be improved, so that the interaction between the flame retardant and a matrix is increased, and the problem of poor compatibility of the expandable graphite flame retardant with the polyurethane material is solved.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Low-viscosity, low-smoke and flame-retardant high-speed elevator balance compensating chain PVC sheath material and preparation method thereof

The invention provides a formula of a low-viscosity, low-smoke and flame-retardant high-speed elevator balance compensating chain PVC sheath material, which is adapted to a rapid moulding technology and meets an environment-friendly requirement, and a preparation method thereof. The raw material formula of the low-viscosity, low-smoke and flame-retardant high-speed elevator balance compensating chain PVC sheath material comprises the following components in parts by weight: 100-150 parts of PVC resin, 60-120 parts of a plasticizer, 4-8 parts of a stabilizer, 2-8 parts of a lubricant, 30-60 parts of a flame retardant, 5-15 parts of a smoke suppressant, 5-20 parts of a viscosity reducer and 0.3-1.0 part of a pigment. The preparation method comprises the following steps: mixing the PVC resin to 70-80 DEG C in a kneading machine, then adding a certain amount of an auxiliary agent, continuing mixing, and discharging after the temperature of a mixed material reaches 85-95 DEG C; sending the mixed material into a cooling stirrer, and cooling to 40-50 DEG C; finally, placing in a conical twin-screw extruder, and performing extrusion granulation at the extruding temperature of 130-170 DEG C to obtain a low-viscosity, low-smoke and flame-retardant elastic PVC material. The special low-viscosity, low-smoke and flame-retardant high-speed elevator balance compensating chain PVC sheath material prepared by the preparation method provided by the invention can be applied to the rapid moulding technology of an elevator balance compensating chain sheath, has relatively good appearance, high toughness, high heat aging resistance and high heat stability, and has low viscosity, low smoke performance and flame retardance.

Owner:CHANGZHOU UNIV

A kind of flame retardant containing polyvalent phosphorus element and preparation method thereof

ActiveCN110229190BHas a synergistic flame retardant effectHigh flame retardant efficiencyGroup 5/15 element organic compoundsEpoxyGas phase

The invention discloses a flame retardant containing multivalent phosphorus element and a preparation method thereof. A chemical structure of the flame retardant containing multivalent phosphorus element is as shown in a formula (I), wherein R1 and R2 are respectively phosphorus-containing structures with different valence states. The chemical structure of the flame retardant containing multivalent phosphorus element simultaneously contains a plurality of phosphorus atoms with different valence states, a condensed phase flame retardant mechanism can be exerted to promote carbon formation of apolymer in a combustion process, and a gas phase flame retardant mechanism can be also exerted to captures active radicals in the combustion process. The phosphorus content and the number of aromaticrings can be adjusted, so that the flame retardant is suitable for flame retardant treatment of different polymer matrices. A limit oxygen index of epoxy resin treated with the flame retardant is obviously increased, the vertical burning grade is up to V-0 grade, and the flame retardant has the advantages of good carbon formation property, high flame retardant efficiency and the like.

Owner:UNIV OF SCI & TECH OF CHINA

Ceramic silicon rubber and preparation method thereof

ActiveCN102876049BDoes not affect other mechanical propertiesImprove thermal stabilityPolymer scienceMechanical property

The invention discloses a ceramic silicon rubber and a preparation method thereof. A plurality of inorganic fillers are added into the raw silicon rubber, so that the ceramic silicon rubber prepared by the method has high flame retardant property due to the synergistic flame retardant function between the inorganic fillers and the raw silicon rubber; and meanwhile, other mechanical performances of the silicon rubber are not influenced by the added fillers.

Owner:JIANGSU TIANCHEN NEW MATERIALS

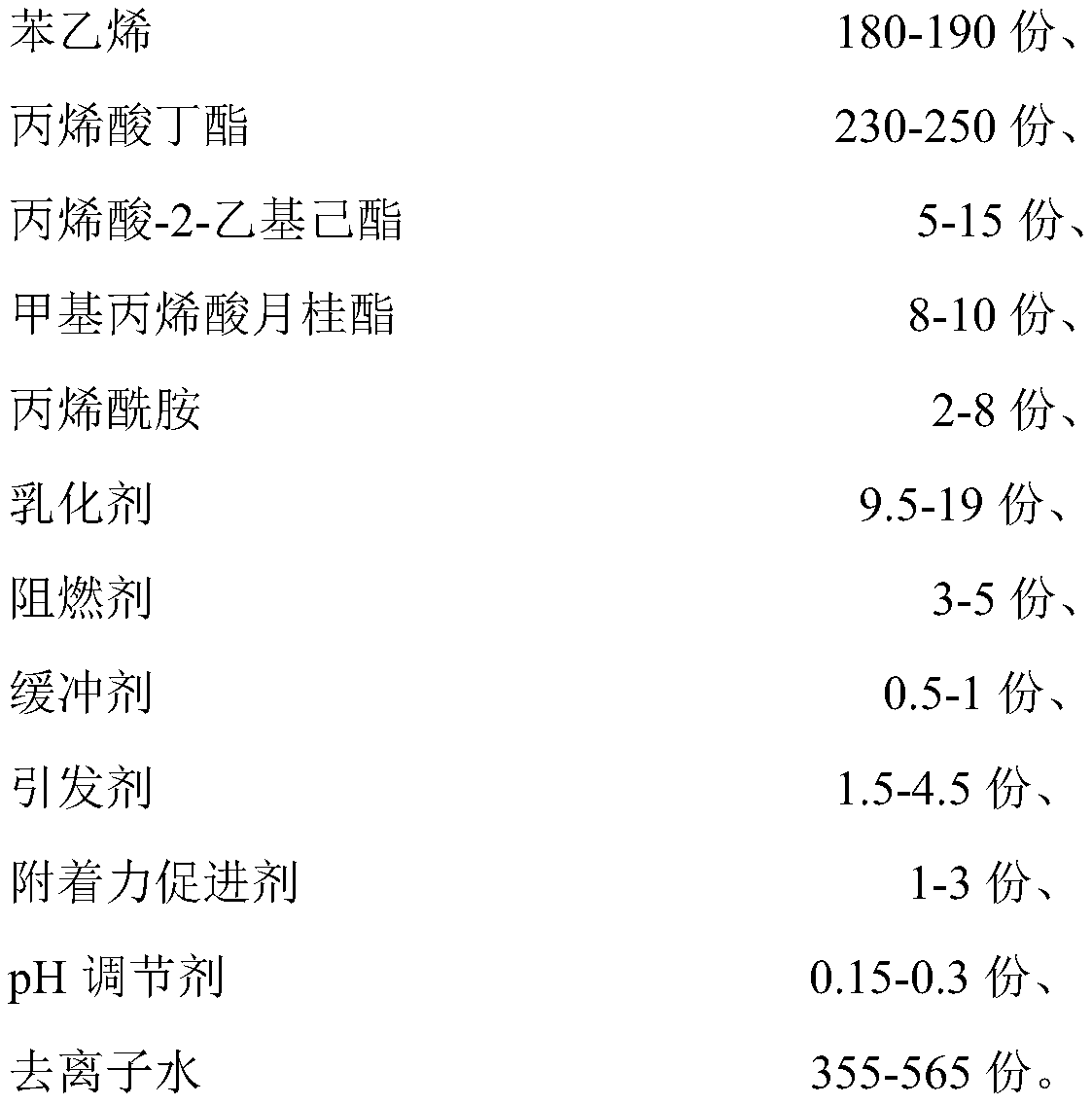

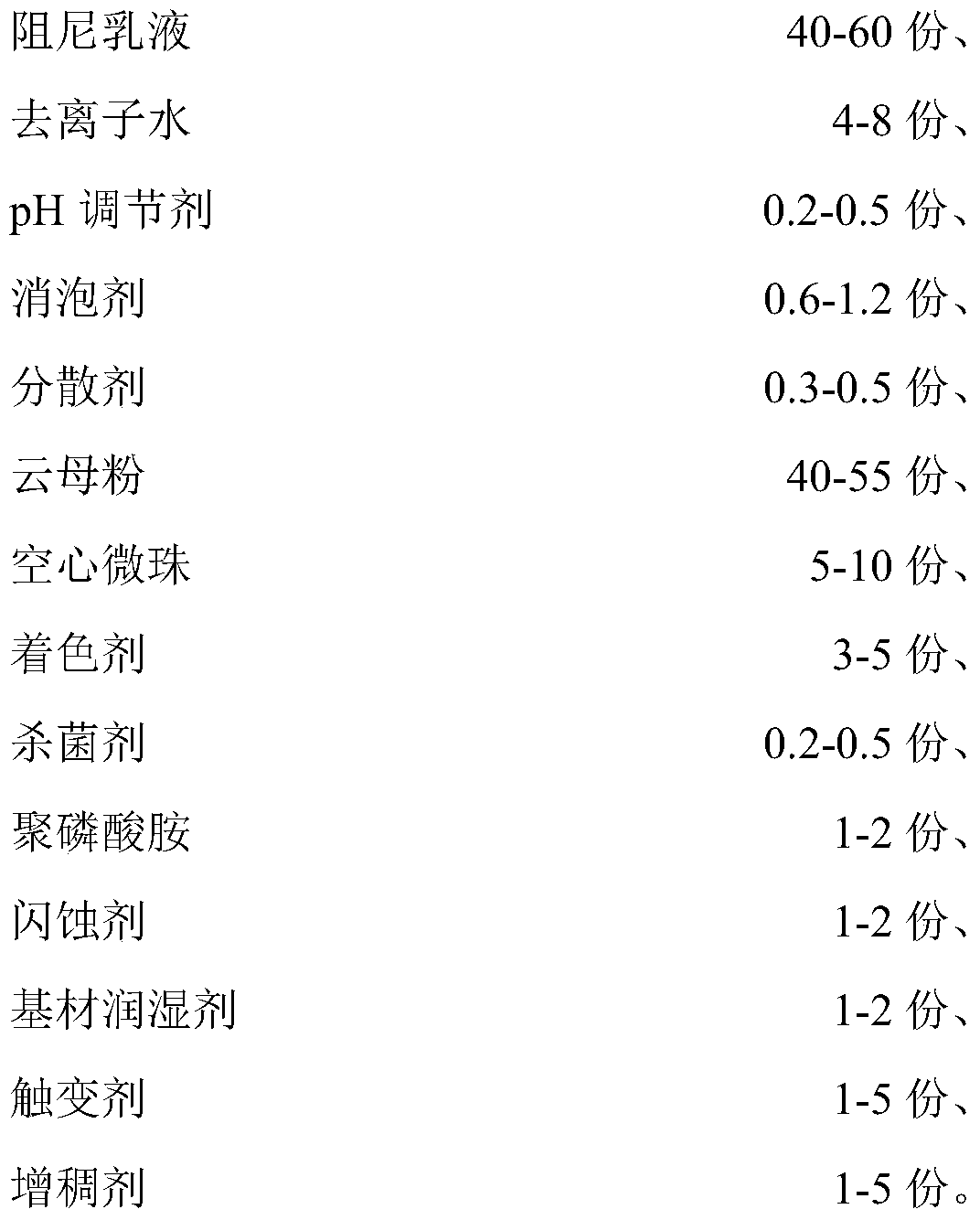

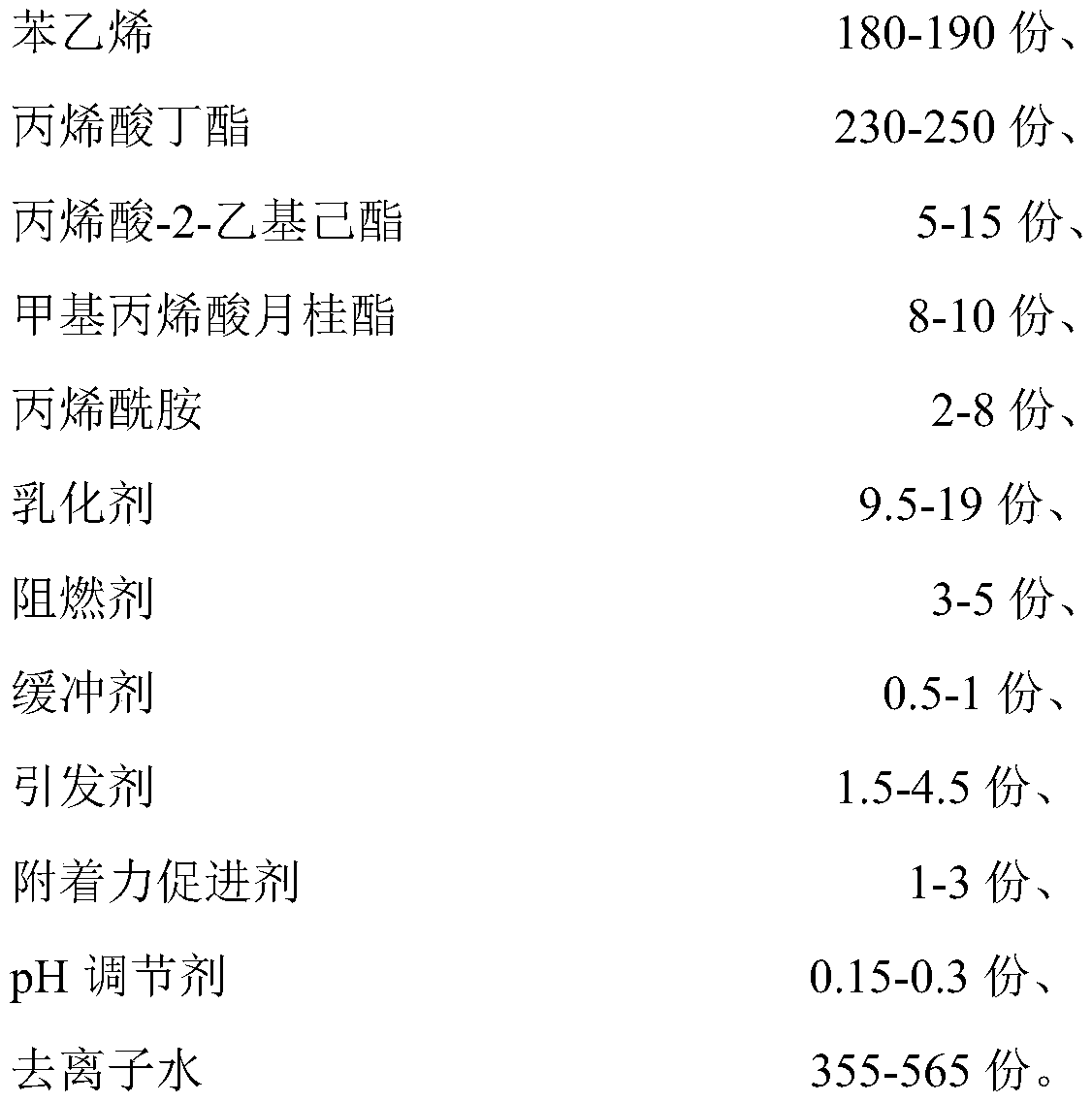

Damping emulsion, preparation method thereof, low-VOC, low-odor and high-flame-retardance water-based damping coating and preparation method of coating

PendingCN110105491AImprove performance indicatorsImprove loss factorFireproof paintsAmmonium polyphosphateChemistry

The invention provides a damping emulsion, a preparation method thereof, a low-VOC, low-odor and high-flame-retardance water-based damping coating prepared from the damping emulsion, and a preparationmethod of the coating. The damping emulsion comprises styrene, butyl acrylate, 2-ethylhexyl acrylate, lauryl methacrylate, acrylamide, an emulsifier, a flame retardant, a buffer agent, an initiator,an adhesion promoter, a pH regulator and deionized water. The water-based damping coating prepared from the damping emulsion comprises the damping emulsion, deionized water, the pH regulator, an antifoaming agent, a dispersant, mica powder, hollow beads, a coloring agent, a bactericide, ammonium polyphosphate, a flash etchant, a substrate wetting agent, a thixotropic agent and a thickener. The damping emulsion has the advantages of high flame retardance, high loss factor, low film forming temperature, interpenetrating network structure and excellent damping performance, and the obtained damping coating has the characteristics of damping, cracking resistance and flame retardation.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

Fire-retardant paint with steel structure

ActiveCN101857756BExtend fire resistance timeImprove fire resistanceFireproof paintsPolyurea/polyurethane coatingsPhosphoric acidComposite substrate

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

Preparation method for low-dielectric halogen-free flame retardant glass fiber pre-impregnation material

The invention provides a preparation method for a low-dielectric halogen-free flame retardant glass fiber pre-impregnation material. The preparation method comprises the following steps of: preparing low-dielectric flame retardant epoxy resin by adopting a two-step process of enabling a phosphorus flame retardant and low-molecular-weight double-end hydroxyl polyphenyl ether to respectively react with epoxy resin according to phosphor-nitrogen cooperative flame retardant effect and the low-dielectric characteristic of polyphenyl ether; compounding the low-dielectric epoxy flame retardant resin with liquid epoxy resin, and uniformly mixing the compound with a latent curing agent to prepare a resin system for pre-impregnation material; and preparing the resin system for the pre-impregnation material into a film by a film laminating machine, compounding the film with the glass fiber or fabric by a compounding machine to obtain the low-dielectric halogen-free flame retardant pre-impregnation material. The glass fiber pre-impregnation material disclosed by the invention is excellent in flame retardant performances, small in dielectric constant, capable of satisfying the production process adopting the two-step process of thermally melting the pre-impregnation material, and suitable for large-scale production of the pre-impregnation material for electric appliances.

Owner:山东光轩新材料有限公司

A kind of flame-retardant rigid polyurethane foam material and its preparation method and application

ActiveCN110527054BHas a synergistic flame retardant effectAdhesiveSpontaneous combustionPolymer science

The invention belongs to the field of preparation of chemical retardation materials, and in particular relates to a flame-retardant rigid polyurethane foam material and its preparation method and application. The material includes mixture A and mixture B, and the mixture A includes the following components in parts by weight: 77.47-100 parts of polyol, 0-22.53 parts of ethylene glycol phosphinate, 1 part of amine catalyst, organic tin 0.5 parts of catalyst, 2 parts of water, 2 parts of foam stabilizer, 3 parts of triethanolamine; the mixture B includes the following components in parts by weight: 149-152 parts of isocyanate, 0-20.25 parts of expandable graphite, 0-20.25 parts of phosphate part, 0-7.5 part of fly ash. The flame-retardant rigid polyurethane foam material obtained in the present invention integrates condensed phase flame-retardant, gas-phase flame-retardant and physical flame-retardant effects of expanded graphite, and adds fly ash with synergistic flame-retardant effect and excellent adhesive performance, so that Rigid polyurethane foam has excellent flame retardant properties and can not only be used as a chemical retardant material for preventing coal spontaneous combustion, but also as a sealing material and insulation material.

Owner:FUZHOU UNIV

A kind of flame-retardant pet and pc composite material and preparation method thereof

Owner:NINGBO ZHETIE DAPHOON CHEM

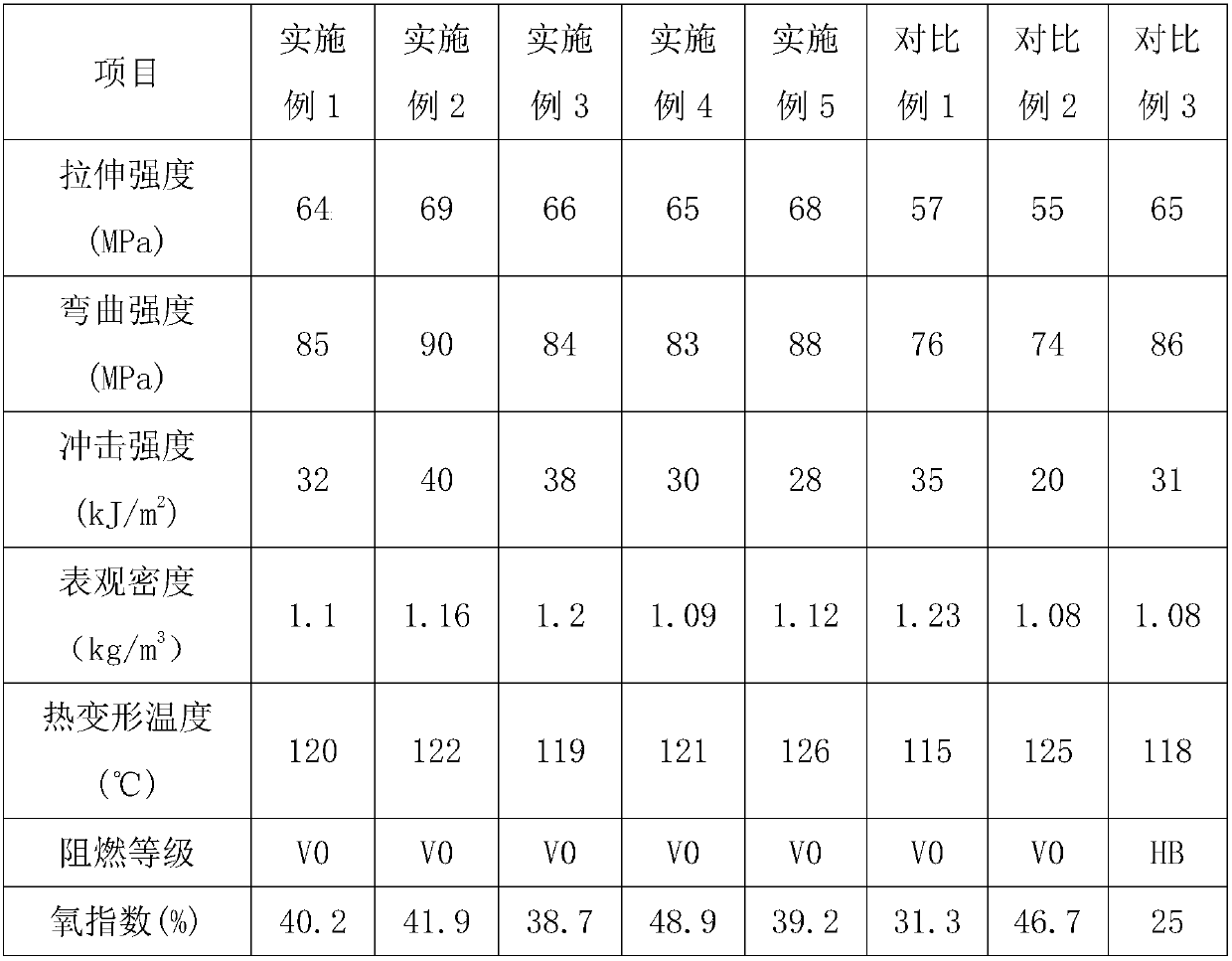

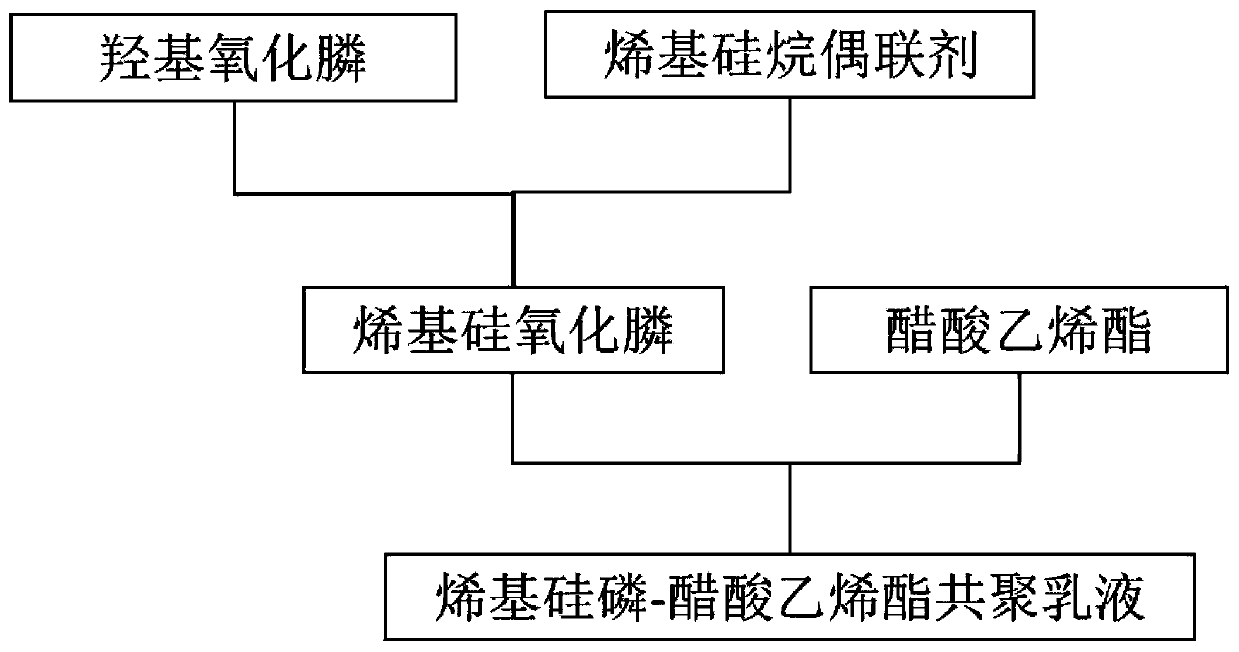

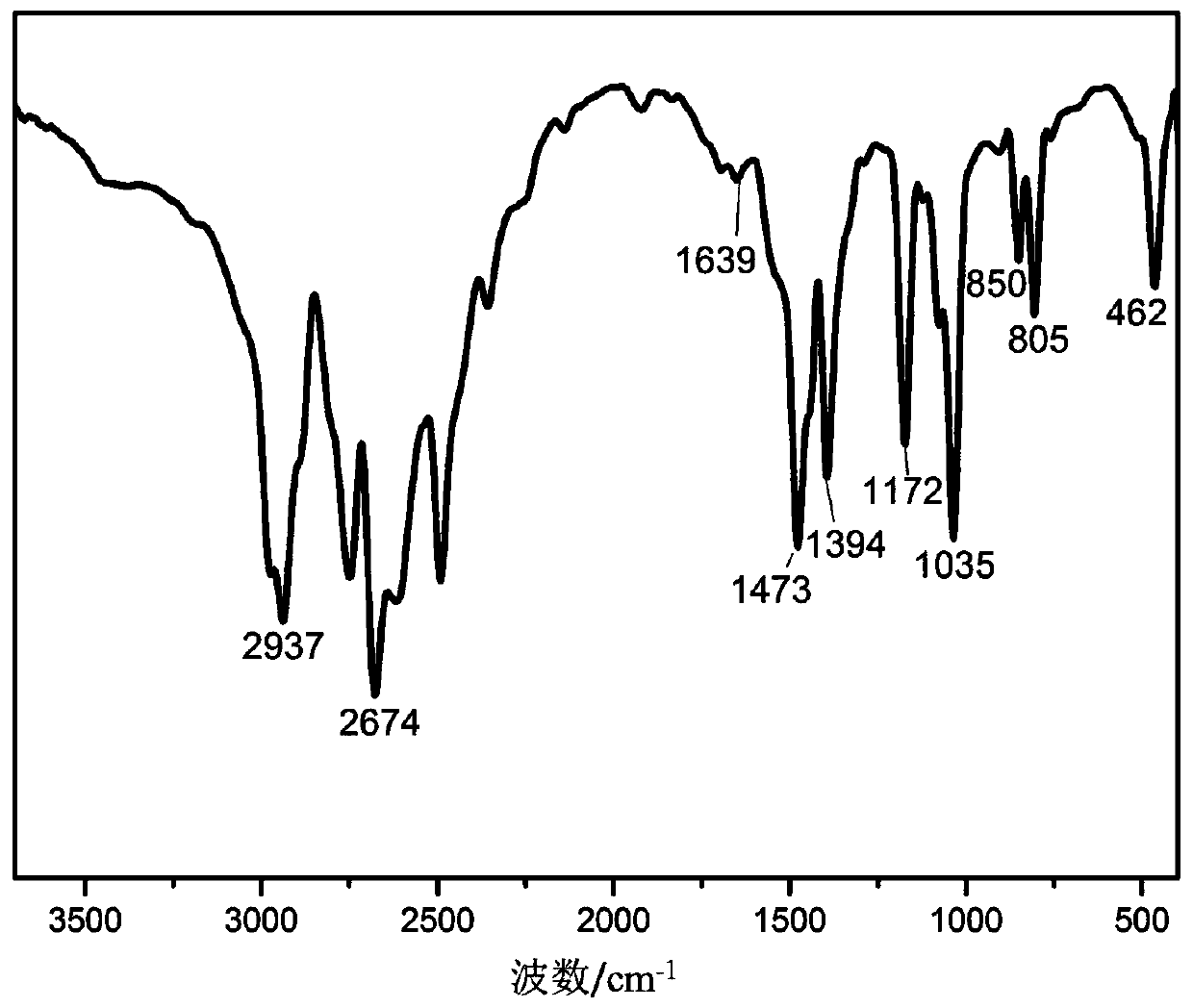

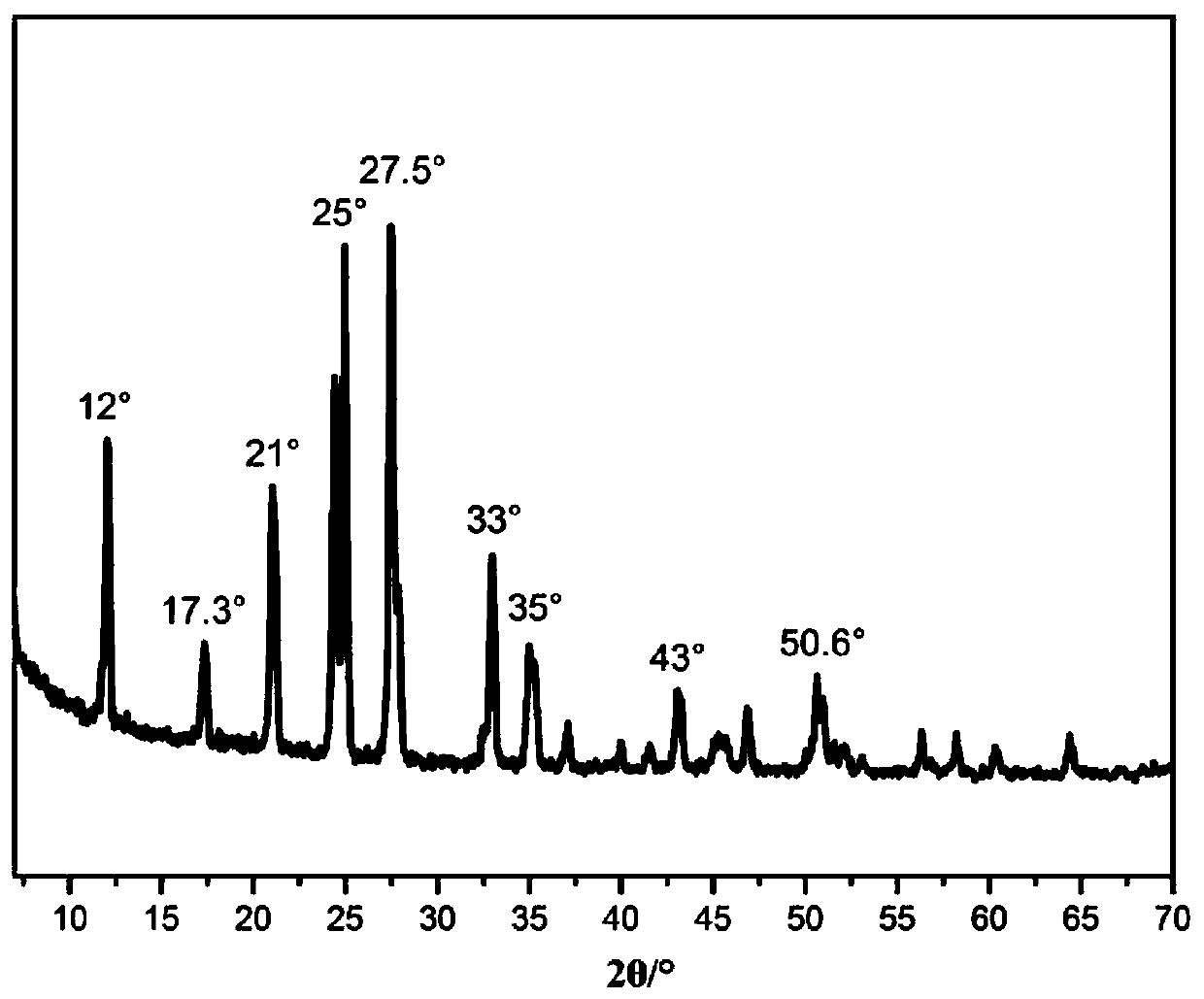

Alkenyl silicon phosphorus-vinyl acetate copolymer emulsion as well as preparation method and application thereof

ActiveCN110655600AImprove thermal stabilityImprove hydrolysis resistanceWood treatment detailsPaper coatingPhosphine oxideCarvacryl acetate

The invention relates to the field of material surface modification, and discloses alkenyl silicon phosphine oxide and a preparation method thereof, and alkenyl silicon phosphorus-vinyl acetate copolymer emulsion and a preparation method and application thereof. The alkenyl silicon phosphine oxide is prepared from hydroxyl phosphine oxide and an alkenyl silane coupling agent; the alkenyl silicon phosphine oxide and vinyl acetate are copolymerized to obtain the alkenyl silicon phosphorus-vinyl acetate copolymer emulsion, the copolymer emulsion contains rich silicon and phosphorus elements, thesilicon and phosphorus are synergistically flame-retardant, and the obtained copolymer emulsion can be used as a material surface modifier and has excellent thermal stability, hydrolysis resistance and hydrophobicity. The copolymer emulsion is applied to the surfaces of materials such as paper, fabrics, wood and the like, and can endow the materials with excellent surface properties and flame retardancy. The preparation method of the copolymer emulsion provided by the invention is simple in process, low in cost, green and environment-friendly, wide in application range and easy for industriallarge-scale popularization, and has a good application prospect and great market competitiveness.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com