Alkenyl silicon phosphorus-vinyl acetate copolymer emulsion as well as preparation method and application thereof

A technology of vinyl acetate and copolymerization emulsion, which is applied in the manufacture of tools, polymerization impregnation, textiles and papermaking, etc. It can solve the problems of life and environmental threats, social and economic losses, non-flammability, etc., and achieve large market competitiveness , high flame retardant efficiency, good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

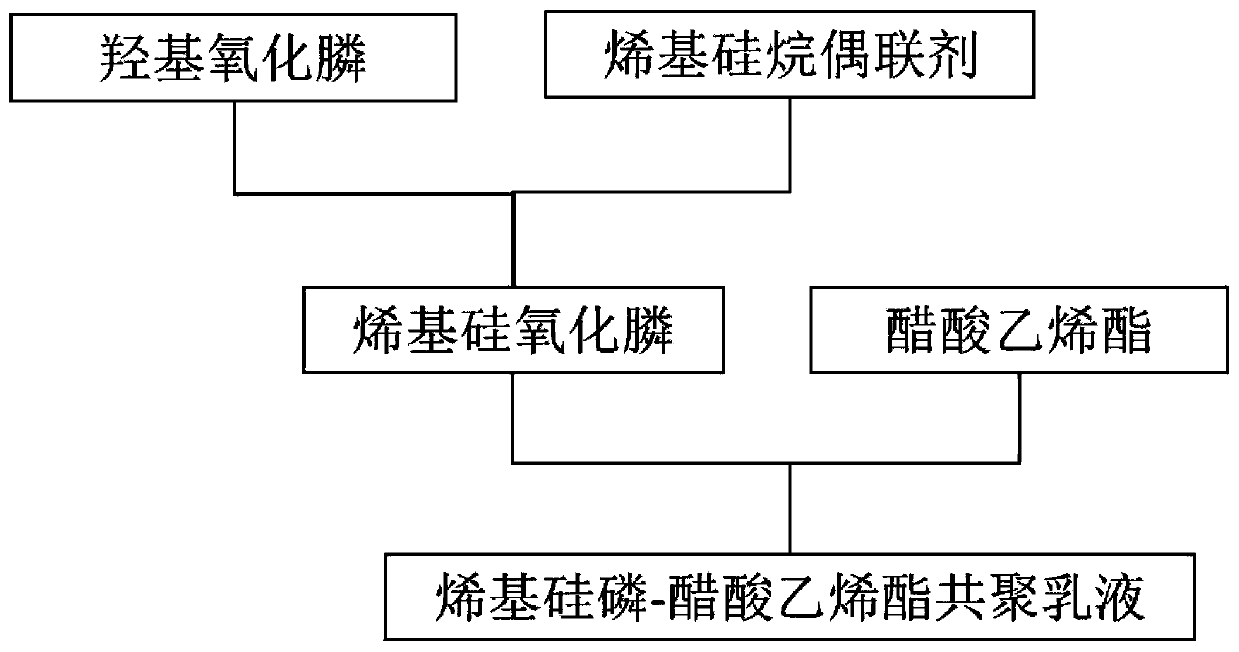

[0068] Another aspect of the present invention provides a method for preparing an alkenyl silicon phosphorus-vinyl acetate copolymer emulsion, preferably the method for preparing the alkenyl silicon phosphorus-vinyl acetate copolymer emulsion described in the first aspect of the present invention, the method comprising The following steps:

[0069] Step 1, adding a protective colloid and an emulsifier into a solvent to obtain a reaction system;

[0070] Step 2, adding alkenyl silicon phosphine oxide and vinyl acetate monomer to the reaction system, and reacting;

[0071] Step 3, post-processing to obtain alkenyl silicon phosphorus-vinyl acetate copolymer emulsion.

[0072] In the present invention, vinyl acetate monomers are copolymerized with alkenyl silicon phosphine oxide (silicon-phosphorene-based monomers) to obtain copolymer emulsions, which are used as surface modifiers for paper, fabrics, and wood, and are applied to paper, fabrics, and wood. On the surface, it can f...

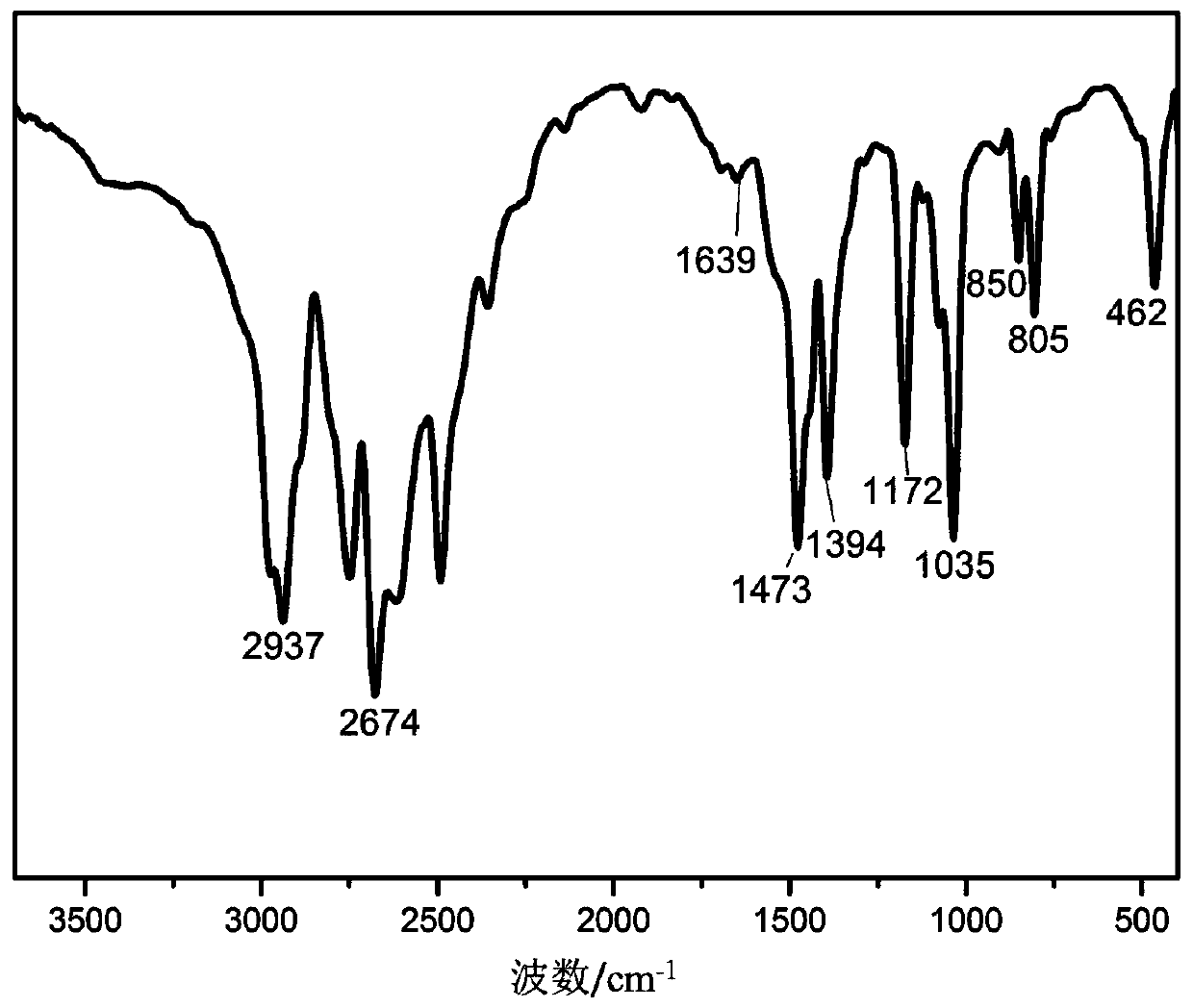

Embodiment 1

[0095] Mix 3mL of hydroxymethylphosphine oxide (THPO) and 20mL of DMF evenly, then add 1.5mL of triethylamine, stir and mix evenly to obtain a mixed solution;

[0096] Introduce nitrogen, heat up to 60°C, add 6mL MVDCS while stirring, reflux for 5h, cool to obtain the reaction product;

[0097] The resulting reaction product was extracted, concentrated by evaporation, and dried under vacuum at 50° C. to obtain alkenyl silicon phosphine oxide with a yield of 68%.

Embodiment 2

[0099] The preparation process of Example 1 was repeated, the only difference being that the reflux reaction time was 4 h, and other steps were the same as in Example 1 to obtain alkenyl silicon phosphine oxide with a yield of 52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com