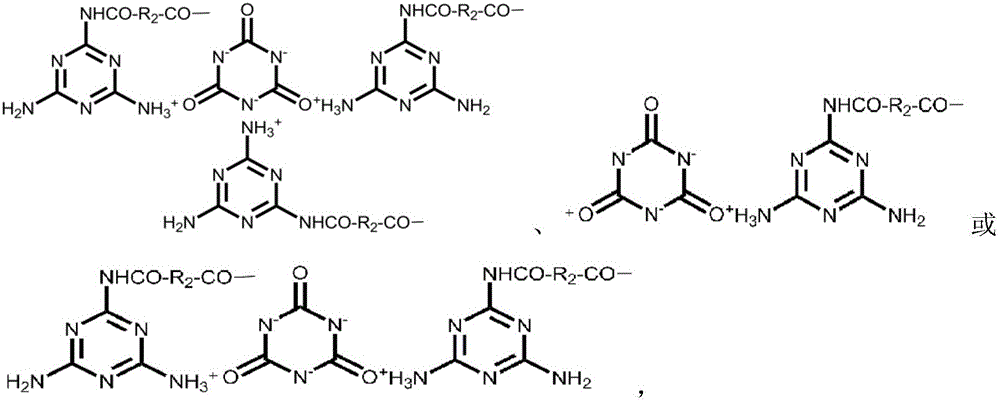

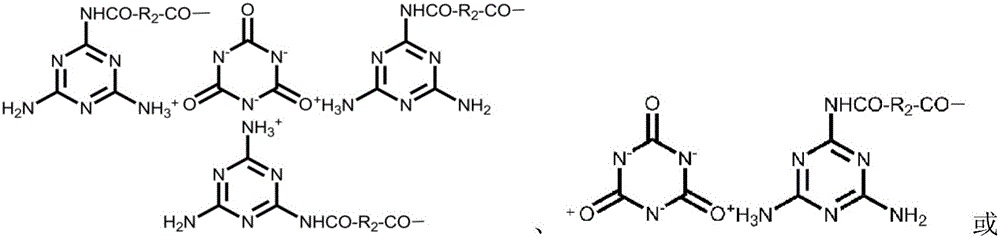

N-P synergetic flame retardant nylon 66 and preparation method thereof

A synergistic flame retardant and nylon technology, applied in the field of organic polymer compound polyamide and its preparation, can solve the problems of high smoke density, poor anti-melting effect of flame retardant nylon, influence of resin mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

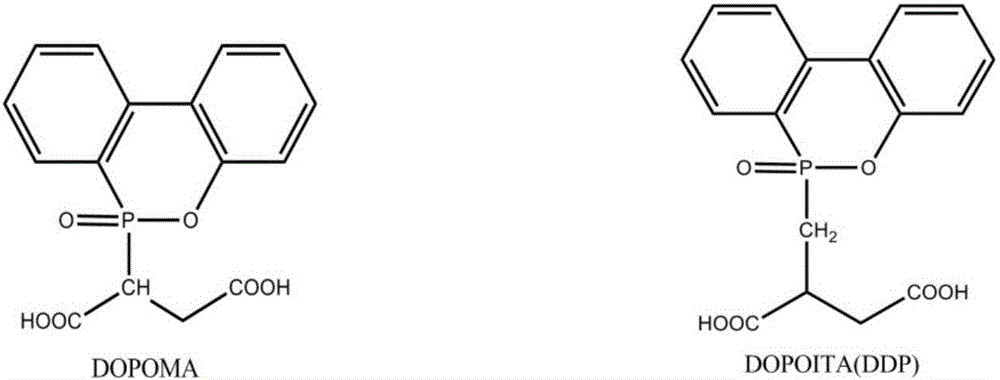

[0069] According to the raw material ratio of the above basic process, select 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) derivative (DOPOMA) and 1,6 hexamethylenediamine as reactants , set the temperature A and B to be 80°C and 50°C respectively, and prepare 10 moles of flame retardant A (1-1#) per time, for later use.

Embodiment 1-2

[0071] According to the raw material ratio of the above basic process, select 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) derivative (DOPOITA) and 1,6 hexamethylenediamine as reactants , set the temperature A and B to be 80°C and 50°C respectively, prepare flame retardant A (1-2#) 10 mol / time, and set aside.

Embodiment 1-3

[0073] According to the raw material proportioning of above-mentioned basic technique, select 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) derivative (DOPOMA) and p-phenylenediamine as reactant, design Set the temperature A and B at 80°C and 50°C respectively, and prepare 10 moles of flame retardant A (1-3#) for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com