P-N intumescent flame retardant and preparation method thereof

An intumescent flame retardant, P-N technology, applied in the field of chemistry, can solve the problems of large amount of addition, smoke, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Preparation of P-N series intumescent flame retardant

[0023] (a) Add solvent glacial acetic acid, 0.10mol bisphenol A, 0.2mol phenylphosphonic dichloride, catalyst aluminum trichloride, and 200rpm magnetic stirring and heating up to 80°C, and continued stirring reaction at 200rpm for 4h. After the reaction was completed, the solution was light yellow and viscous, which was the intermediate product poly 2,2-bis(4-phenylphosphonochlorophenyl)propane ;

[0024] (b) Add 0.2 mol of p-aminobenzoic acid dissolved in glacial acetic acid to the above intermediate product, then raise the temperature to 90°C, stir and react at 200rpm for 4h, continue to raise the temperature to 130°C, keep stirring at 200rpm for 2h, and then end the reaction;

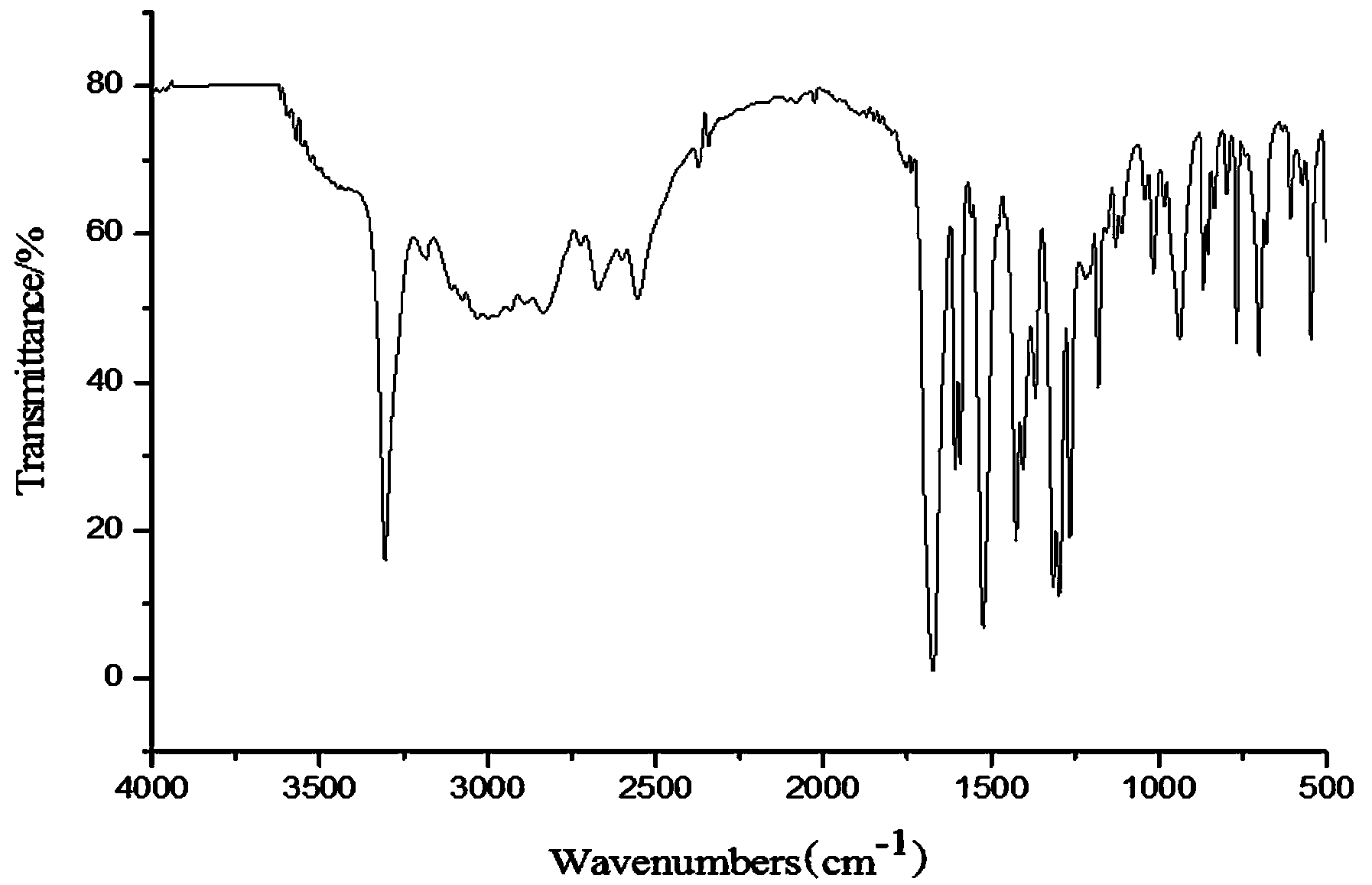

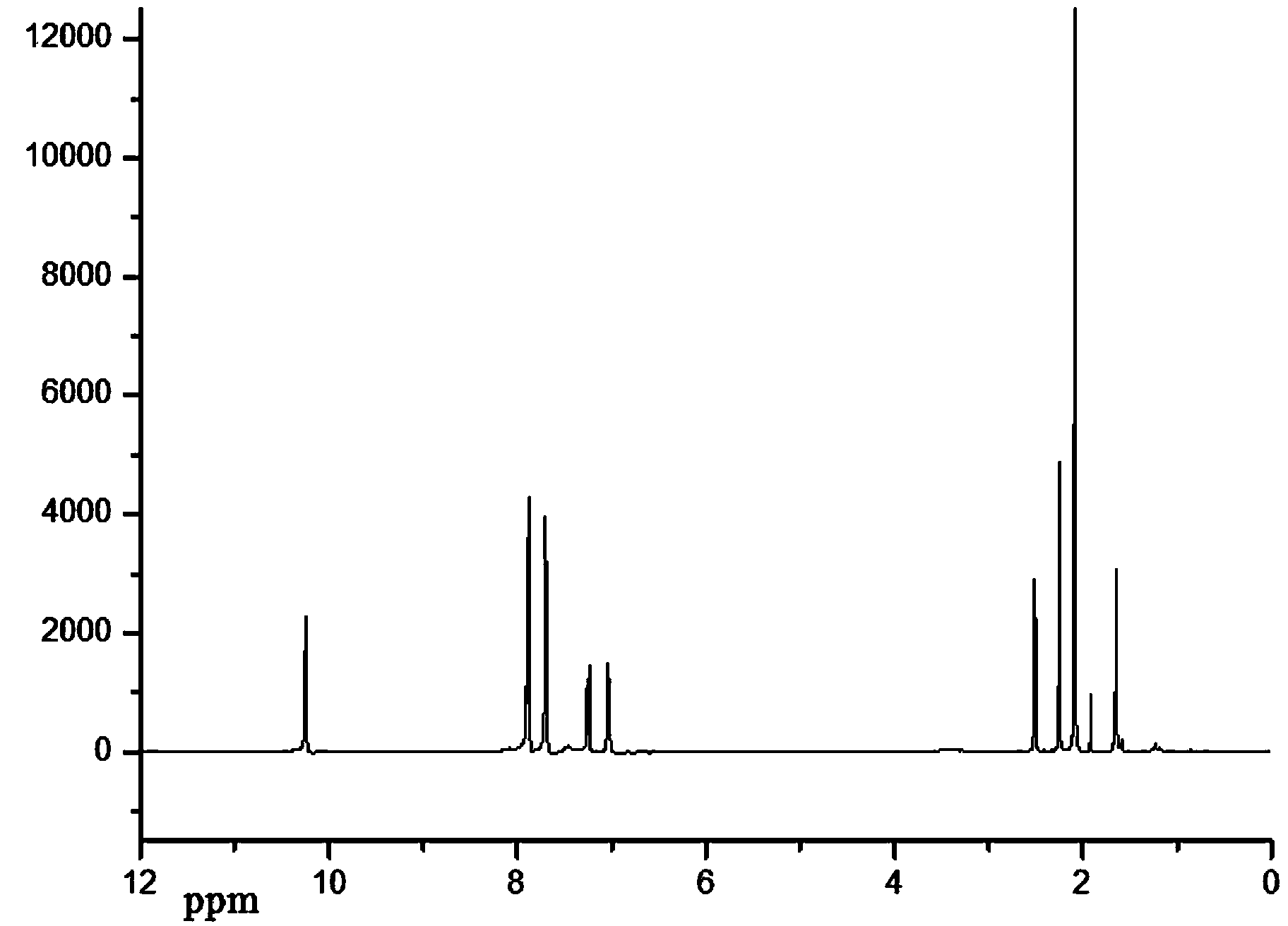

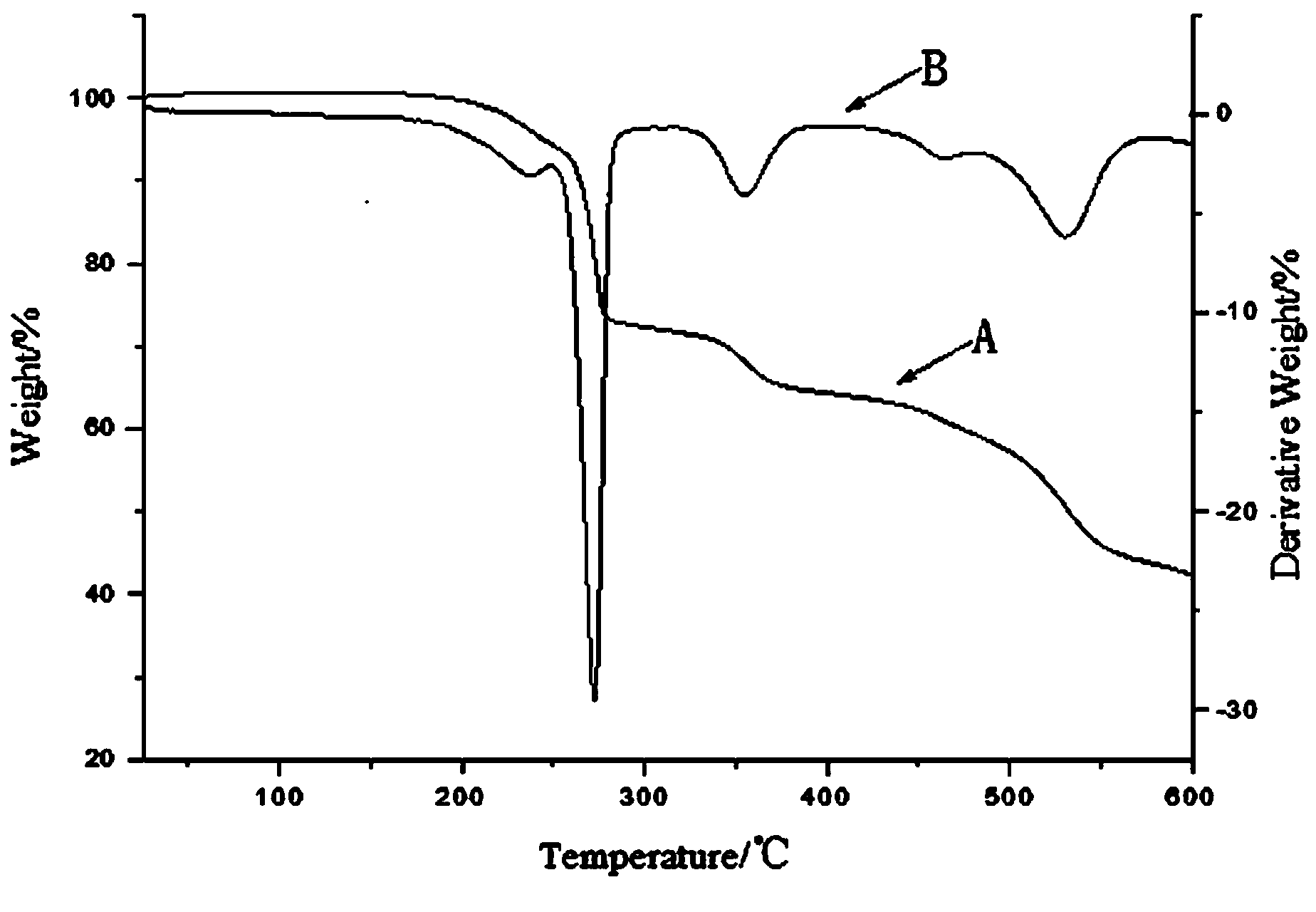

[0025] (c) cooling, hydrolyzing, suction filtering, alkali washing, suction filtering, water washing, and drying the reaction product obtained in step b to obtain a white powder, which is the P-N series intumescent flam...

Embodiment 2

[0036] Add solvent glacial acetic acid, 0.10mol bisphenol A, 0.19mol phenylphosphonic dichloride, catalyst aluminum trichloride, 200rpm magnetic stirring and Raise the temperature to 80°C, and continue stirring at 200 rpm for 4 hours. After the reaction is completed, the solution is light yellow and viscous, which is the intermediate product poly-2,2-bis(4-phenylphosphonochlorophenyl)propane;

[0037] Add 0.21mol p-aminobenzoic acid dissolved in glacial acetic acid to the intermediate product obtained in the above steps, then raise the temperature to 90°C, stir at 200rpm for 4h, continue to raise the temperature to 130°C, stir at 200rpm for 2h; After the product is cooled, hydrolyzed, filtered with suction, washed with alkali, filtered with suction, washed with water, and dried, a white powder is obtained, which is the P-N series intumescent flame retardant poly(2,2-bis(4-p-aminobenzoic acid) - phenylphosphine oxide phenyl)) propane.

Embodiment 3

[0039] Add solvent glacial acetic acid, 0.10mol bisphenol A, 0.21mol phenylphosphonic dichloride, catalyst aluminum trichloride, 200rpm magnetic stirring and Raise the temperature to 80°C, and continue to stir and react at 200rpm for 4 hours. After the reaction is completed, the solution is light yellow and viscous, which is poly-2,2-bis(4-phenylphosphonochlorophenyl)propane;

[0040] Add 0.19mol p-aminobenzoic acid dissolved in glacial acetic acid to the above intermediate product, then raise the temperature to 90°C, stir and react at 200rpm for 4h, continue to raise the temperature to 130°C, stir and react at 200rpm for 2h; after the reaction is completed, cool the reaction product , hydrolysis, suction filtration, alkali washing, suction filtration, water washing, and drying, a white powder is obtained, which is the P-N series intumescent flame retardant poly(2,2-bis(4-p-aminobenzoic acid-benzene Phosphine oxide phenyl)) propane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com