Flame-retardant antibacterial compound containing halloysite, and preparation method thereof

A compound and halloysite nanotube technology, which is applied in the field of flame-retardant antibacterial compound and its preparation, can solve the problem of insignificant flame-retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

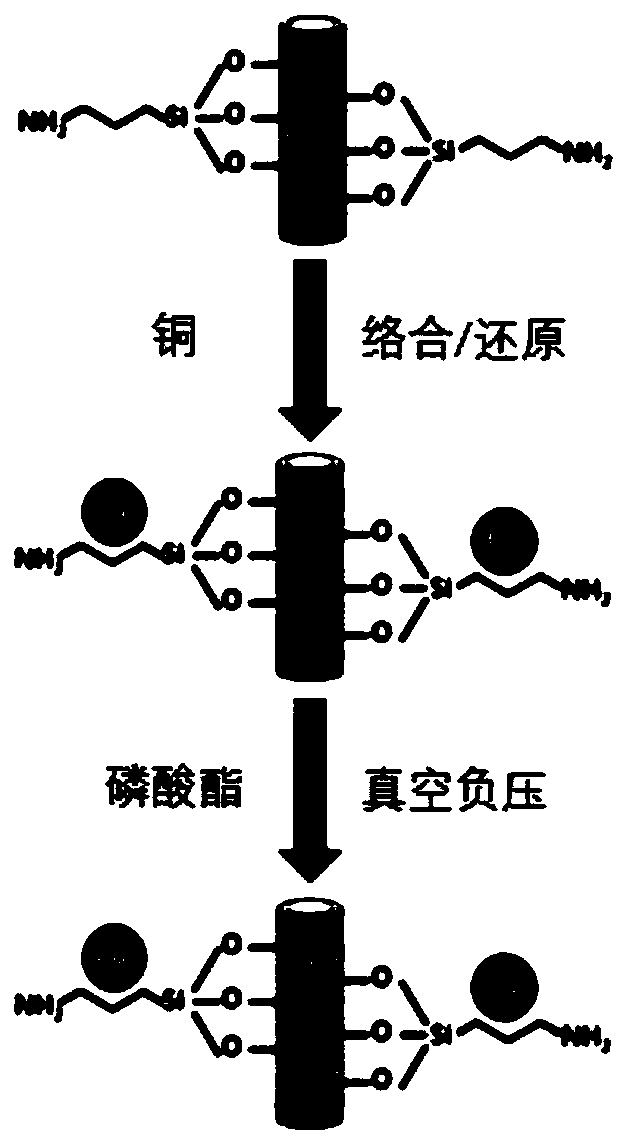

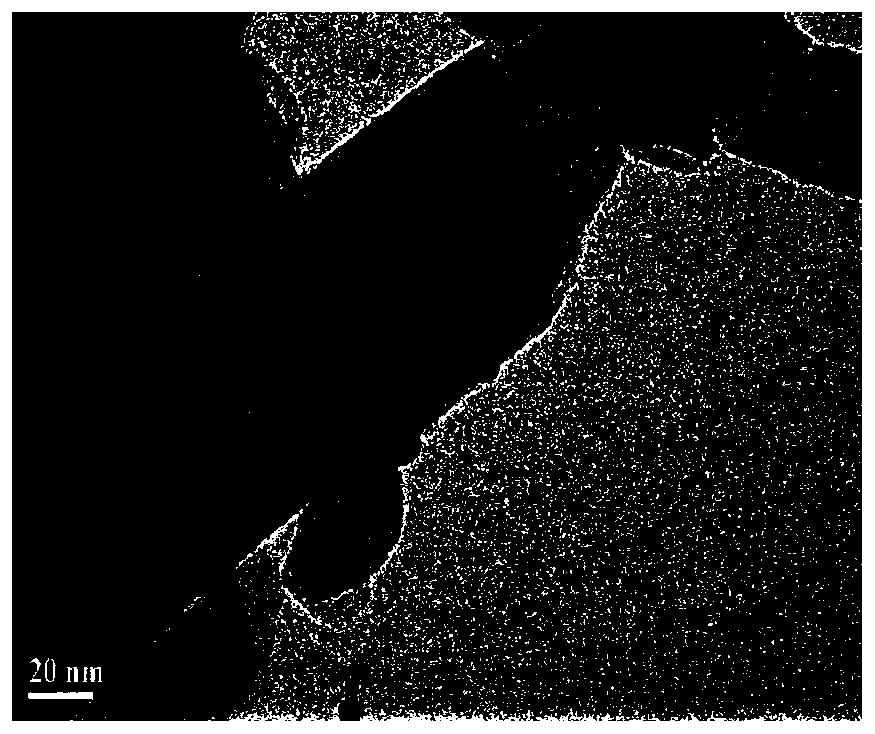

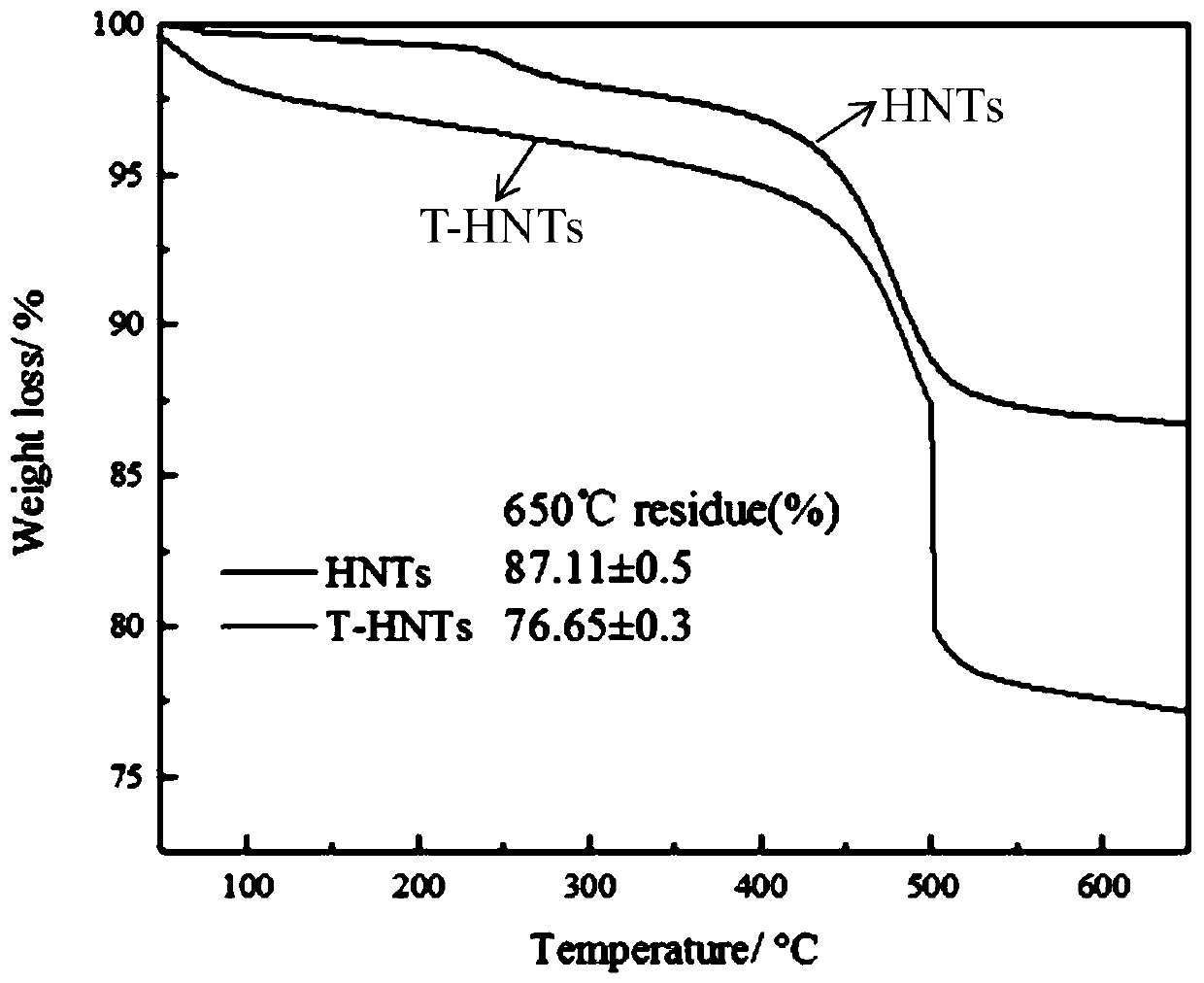

[0072] 1. Preparation of halloysite nanotubes loaded with copper:

[0073] Disperse 10g of halloysite nanotubes in 100ml of toluene, add 10g of A-1110 coupling agent, ultrasonically treat at room temperature for 20min, then raise the temperature to 60°C, reflux and stir for 4h, then wash the product twice with toluene , dried in vacuum at 80°C for 4h to obtain modified halloysite nanotubes. Dissolve 7.5g of copper chloride in 100ml of water, add 5g of modified halloysite nanotubes, ultrasonically treat at room temperature for 15min, then raise the temperature to 60°C, stir for 7h, and wash the resulting product twice with deionized water , dried under vacuum at 80°C for 4h to obtain halloysite nanotubes loaded with copper ions. Add 4g of halloysite nanotubes loaded with copper ions into 50ml of deionized water, ultrasonically treat for 15min, then slowly raise the temperature to 85°C, add 0.25g of ascorbic acid, stir for 2h, wash with deionized water, and heat at 60°C After ...

Embodiment 2

[0077] 1. Preparation of halloysite nanotubes loaded with copper:

[0078] Disperse 10g of halloysite nanotubes in 100ml of toluene, add 10g of KH-602 coupling agent, ultrasonically treat at room temperature for 20min, then raise the temperature to 60°C, reflux and stir for 4h, then wash the product twice with toluene , dried in vacuum at 80°C for 4h to obtain modified halloysite nanotubes. Dissolve 7.5g of copper nitrate in 50ml of water, add 5g of modified halloysite nanotubes, ultrasonically treat at room temperature for 15min, then raise the temperature to 60°C, stir and react for 6h, and wash the obtained product twice with deionized water, Vacuum drying at 80° C. for 4 h yielded halloysite nanotubes loaded with copper ions. Add 4 g of halloysite nanotubes loaded with copper ions into 50 ml of deionized water, ultrasonically treat for 15 min, then slowly raise the temperature to 85 °C, add 0.25 g of sodium borohydride, stir for 2 h, wash with deionized water, and and dr...

Embodiment 3

[0082] 1. Preparation of halloysite nanotubes loaded with copper:

[0083] Disperse 10g of halloysite nanotubes in 100ml of ethanol, add 5g of KH-550 coupling agent, ultrasonically treat at room temperature for 20min, then raise the temperature to 60°C, stir and react for 4h, then wash the obtained product twice with ethanol, Vacuum drying at 80° C. for 4 h yielded modified halloysite nanotubes. Dissolve 5g of copper sulfate in 50ml of water, add 5g of modified halloysite nanotubes, ultrasonically treat at room temperature for 15min, then raise the temperature to 60°C, stir and react for 6h, and wash the obtained product twice with deionized water. Vacuum drying at 80° C. for 4 hours to obtain halloysite nanotubes loaded with copper ions. Add 4g of halloysite nanotubes loaded with copper ions into 50ml of deionized water, ultrasonically treat for 15min, then slowly raise the temperature to 85°C, add 0.25g of ascorbic acid, stir for 2h, wash with deionized water, and heat at 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com