Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Guarantee Occupational Health" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

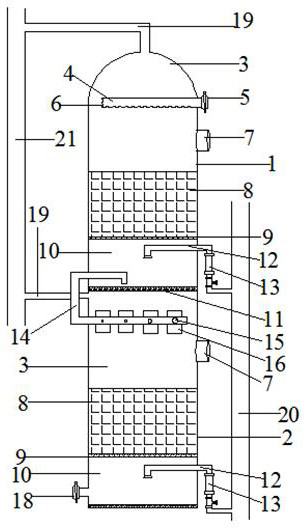

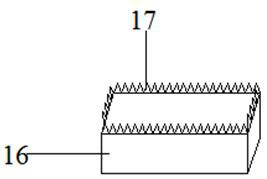

Novel process for preparing germanium dioxide (GeO2)

ActiveCN102774877AReduce lossesHigh degree of automationGermanium dioxideGermanium dioxideHydrolysis

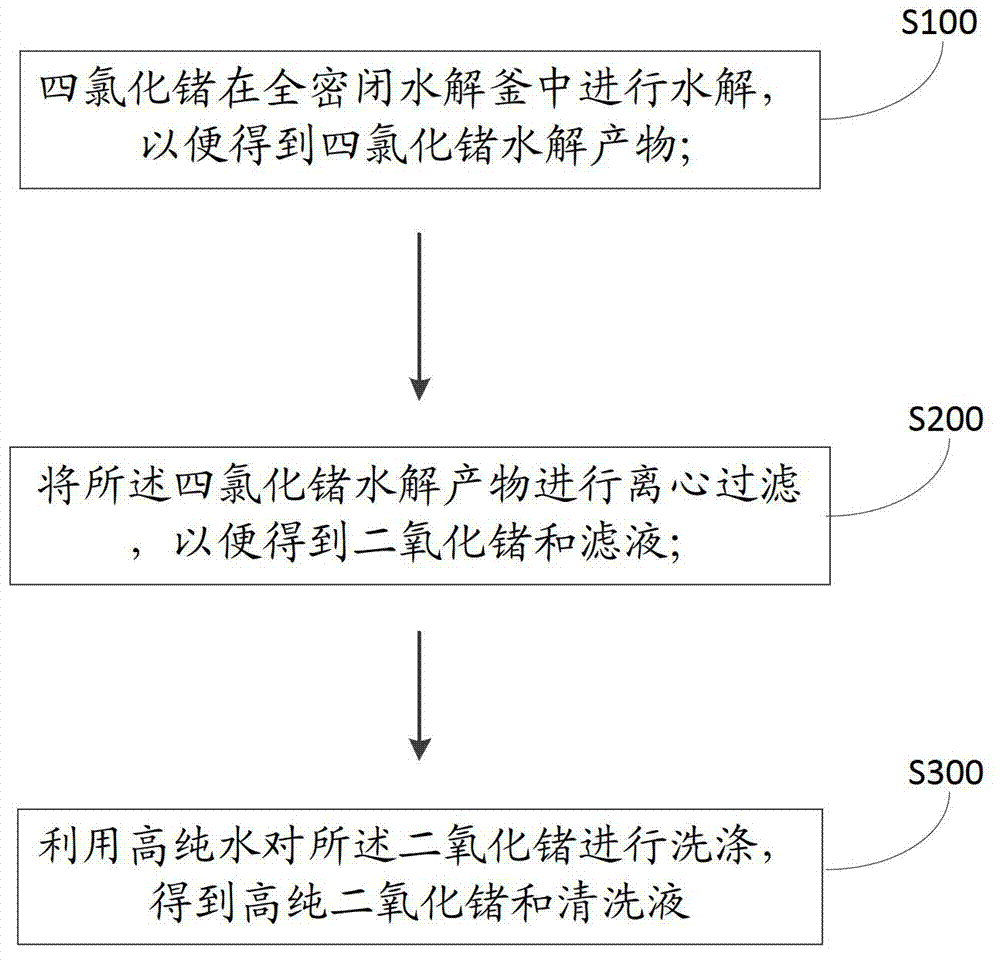

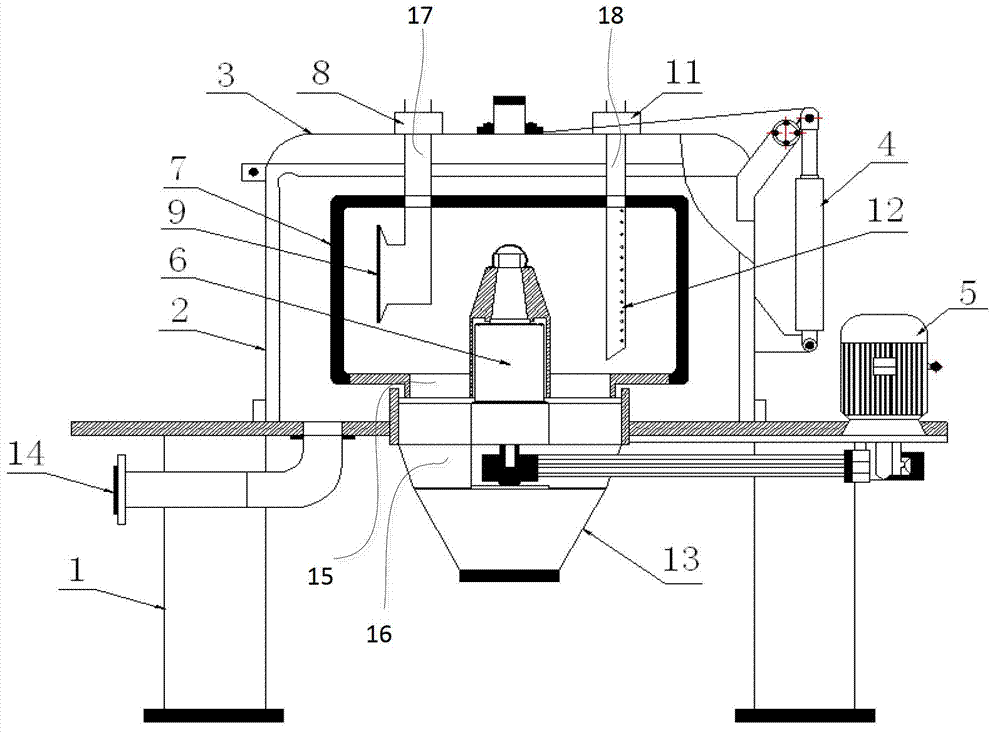

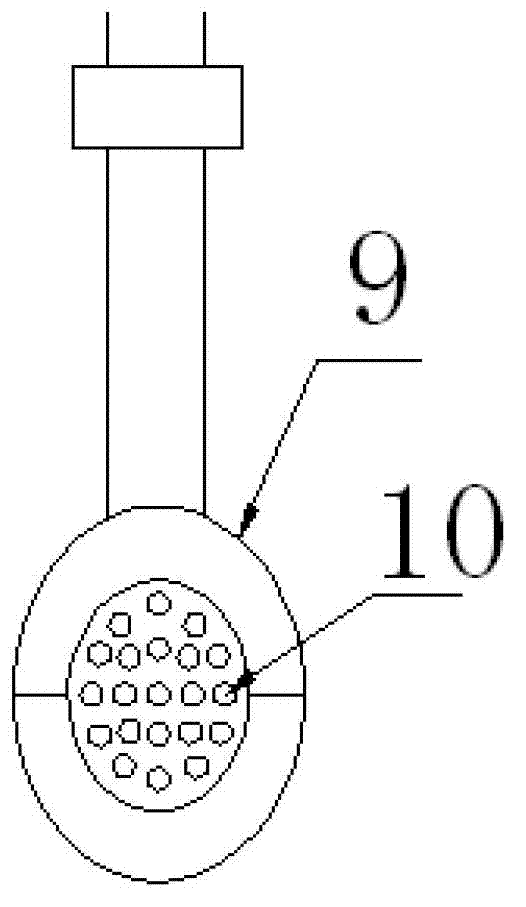

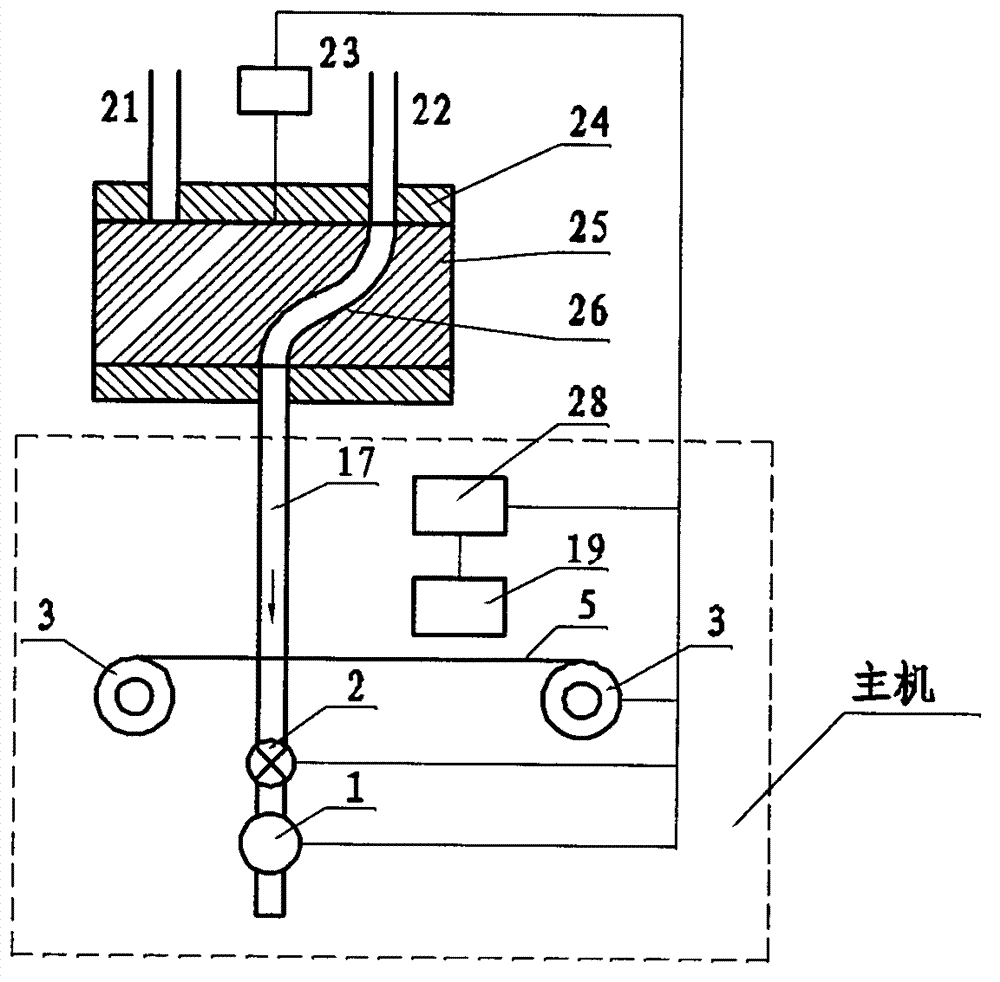

The invention provides a method for preparing germanium dioxide (GeO2). According to the embodiment of the invention, the method comprises the following steps: hydrolyzing the germanium tetrachloride(GeCl4) in a fully-closed hydrolysis reactor to obtain the hydrolysis product of the GeCl4, centrifuging and filtering the hydrolysis product of the GeCl4 to obtain the GeO2 and the filtrate, and cleaning the GeO2 by high-purity water to obtain the high-purity GeO2 and the cleaning solution. According to the embodiment of the invention, the GeO2 hydrolyzing, filtrating and washing method and device have the advantages of high degree of automation, high GeO2 hydrolysis yield, good solid-liquid centrifugal separation effect, low production costs, less metal loss and environment friendliness.

Owner:云南驰宏国际锗业有限公司

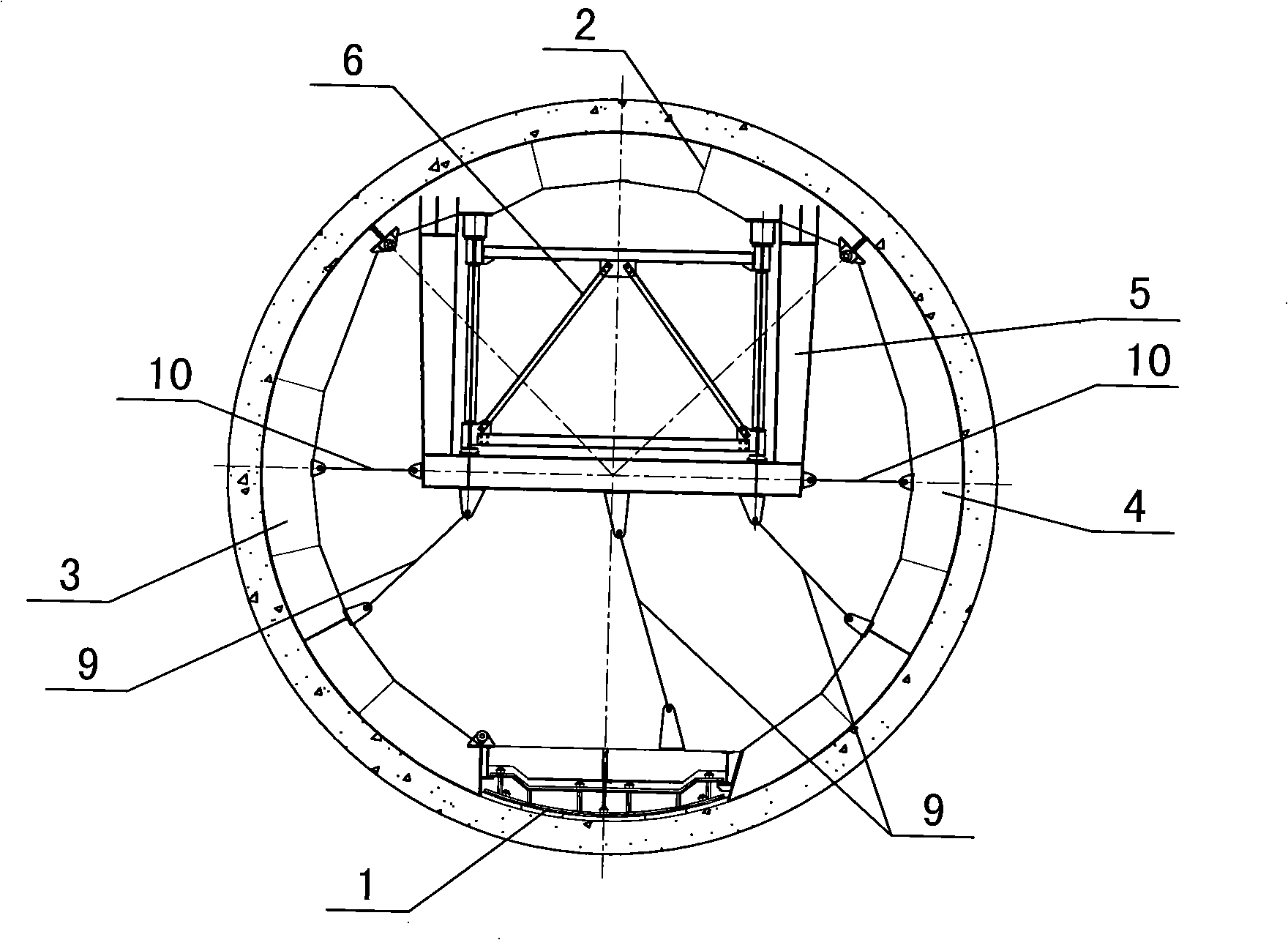

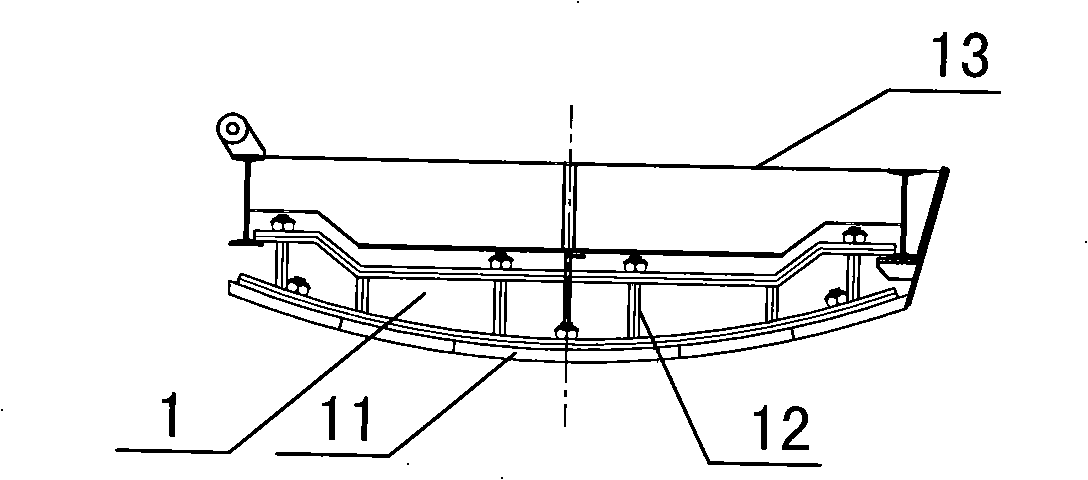

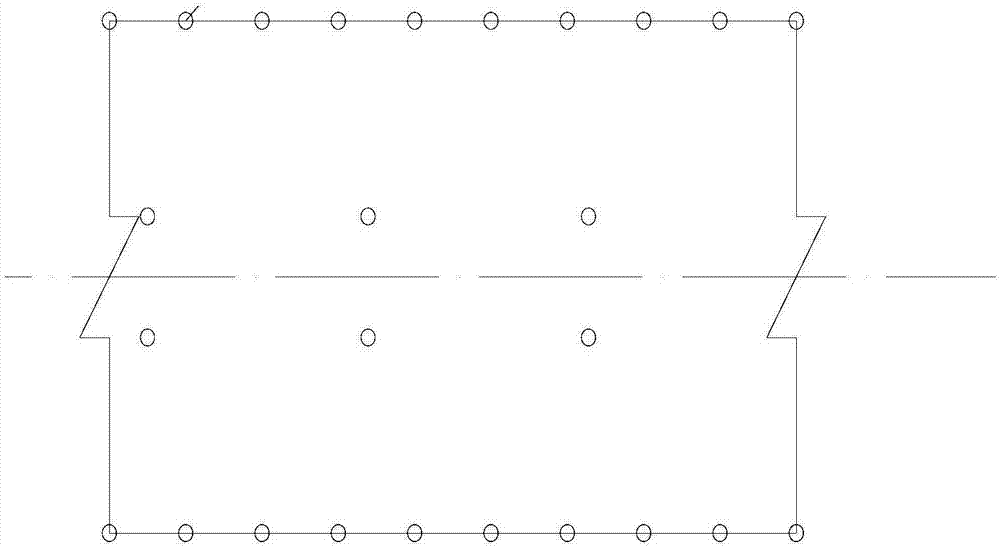

Tunnel concrete lining formwork apparatus

InactiveCN101298839AGood tunnel forming qualityImprove pouring qualityUnderground chambersTunnel liningEngineeringSliding contact

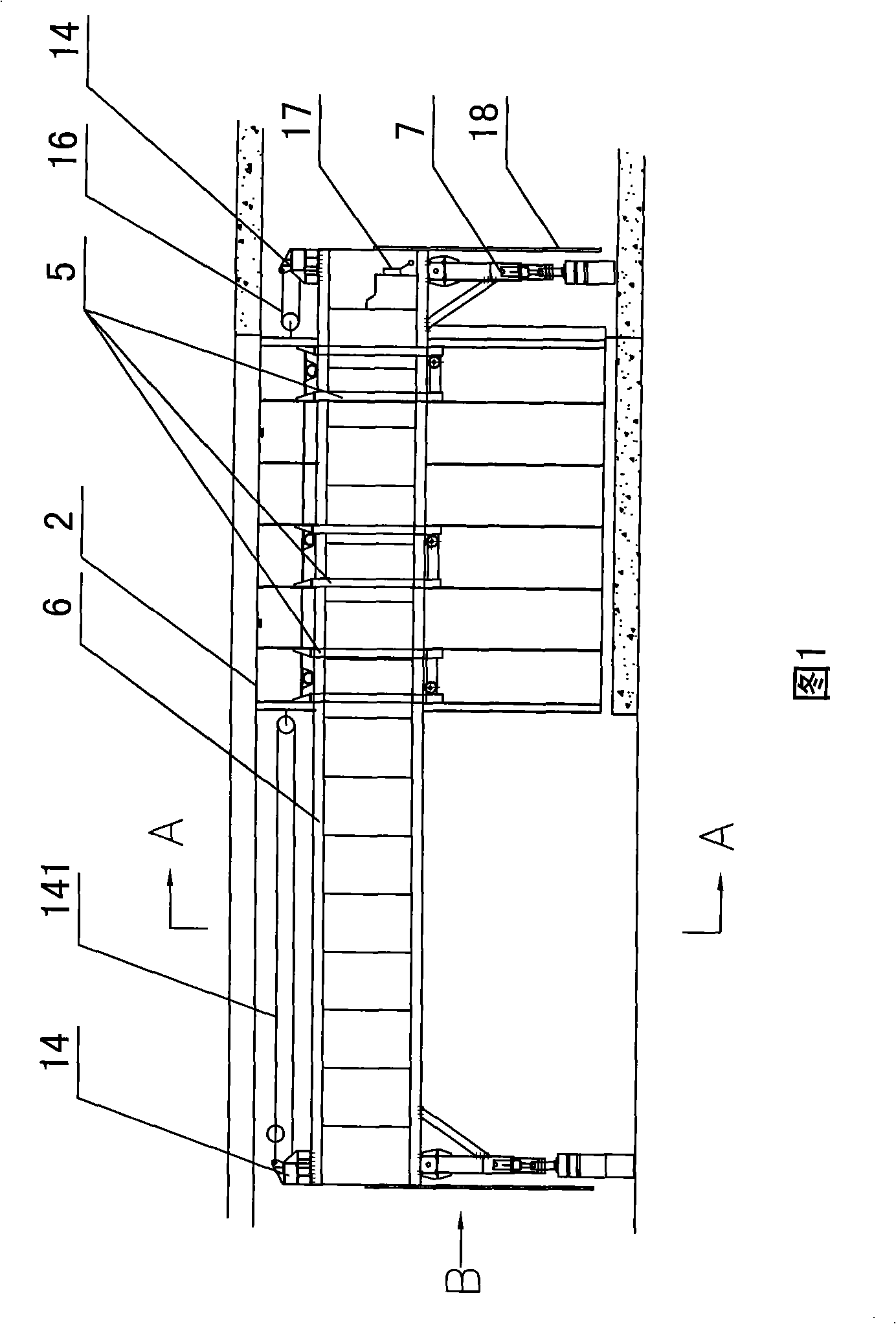

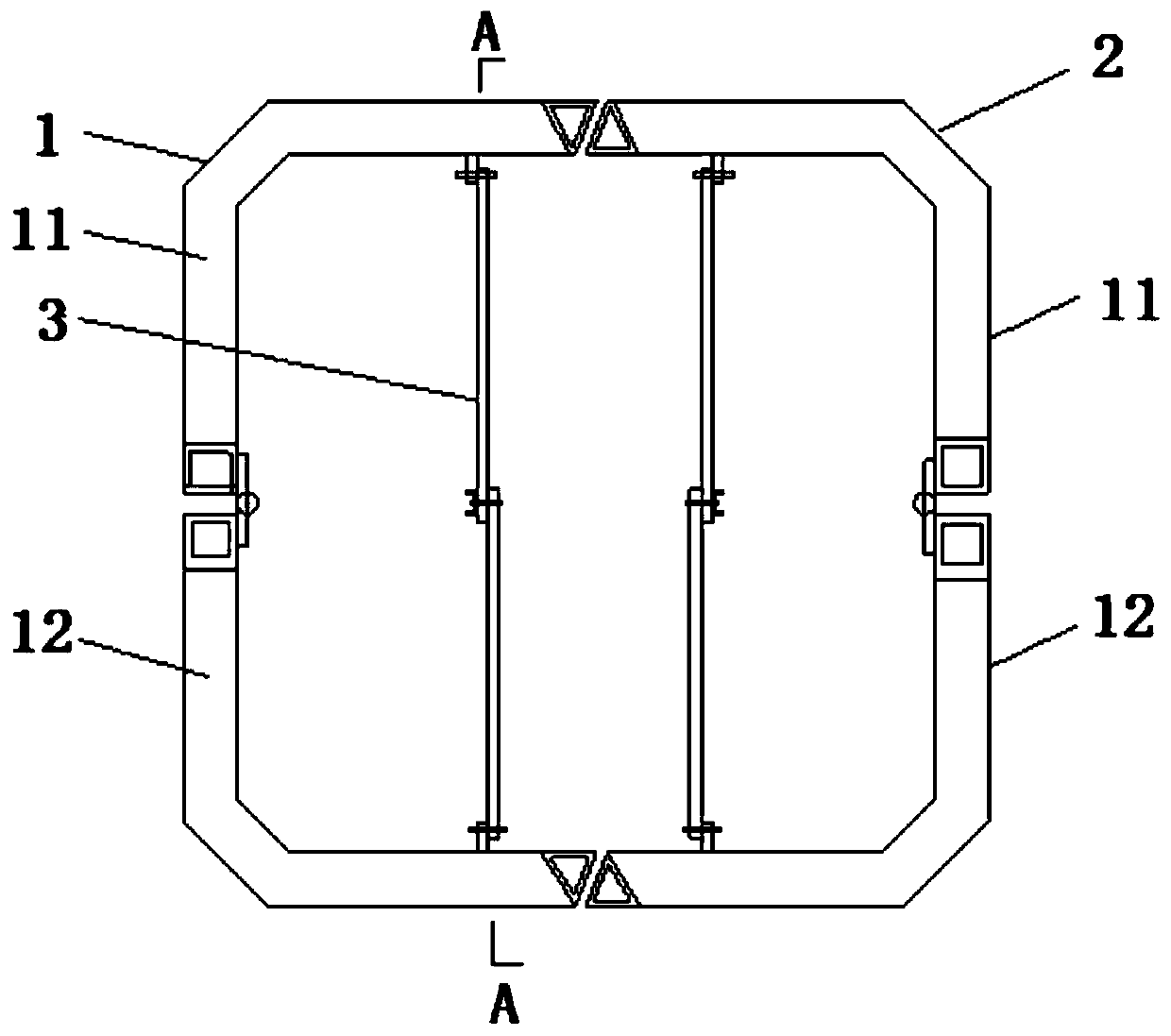

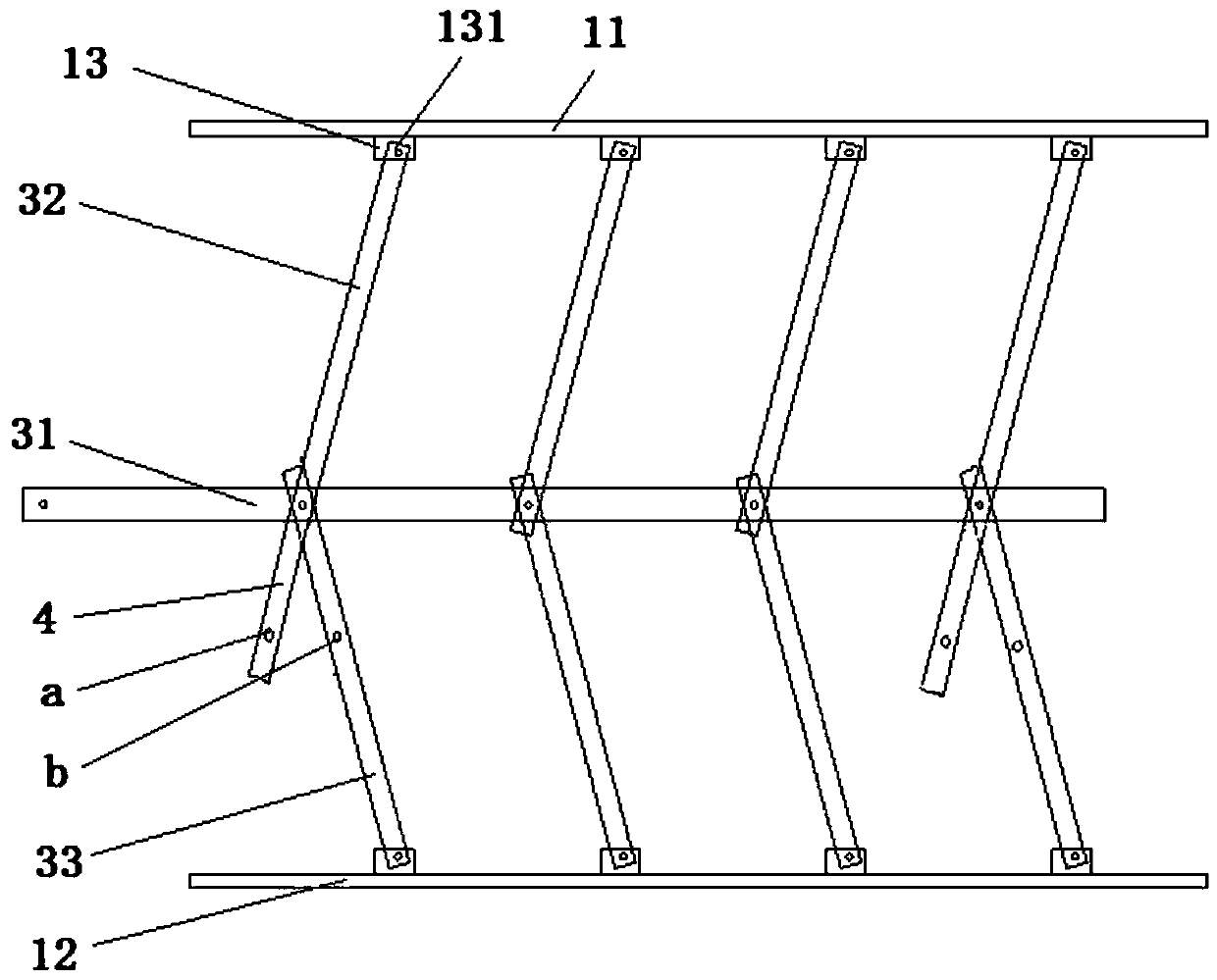

The present invention discloses a tunnel concrete lining template device comprising a template system and needle beam system for bearing; the template system comprises template assembly and template pylon; the template assembly comprises arced left die, right die, top die and bottom die; the left die, right die, top die and bottom die are correspondingly connected to form template assembly with round section; the template pylon is hung on the top die; and bottom of the template pylon is respectively installed with left die, right die and telescopic standing demoulding device connected by the bottom die; the needle beam system comprises bearing needle beam placed in the upper part of the tunnel and pre and post supporting leg device for supporting the bearing needle beam; upper end face of the bearing needle beam is in slide contact with the top die and the needle beam is placed on the template pylon; and the bottom die is in the detachable structure; the bottom die in the detachable structure is installed with opening part which is able to execute trowel-finishing on the surface of the tunnel bottom arch concrete after detaching or turning over when the concrete is initially set. The template device effectively removes the problem of foam of the traditional whole section template bottom arc foam and improves the internal appearance molding quality of the bottom arc concrete.

Owner:SINOHYDRO BUREAU 14 CO LTD

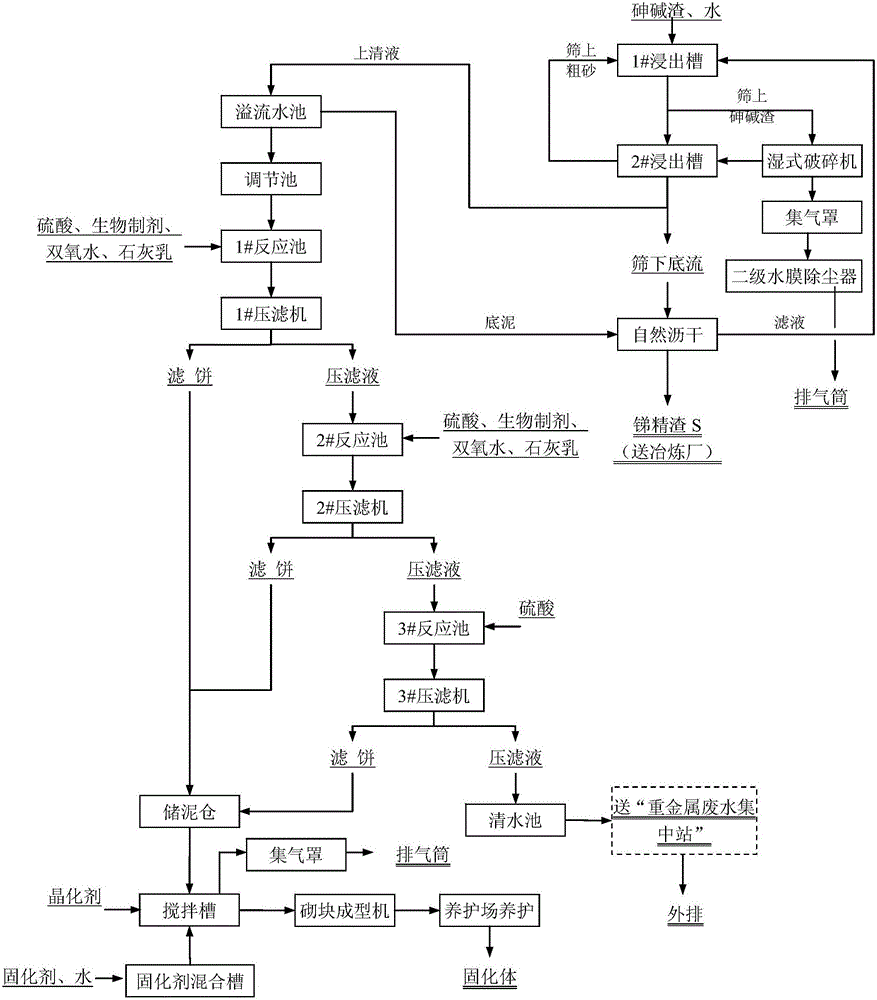

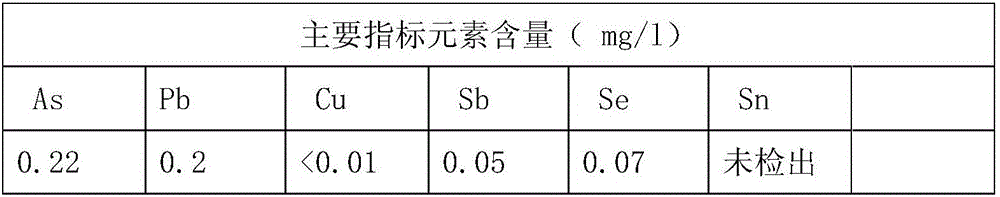

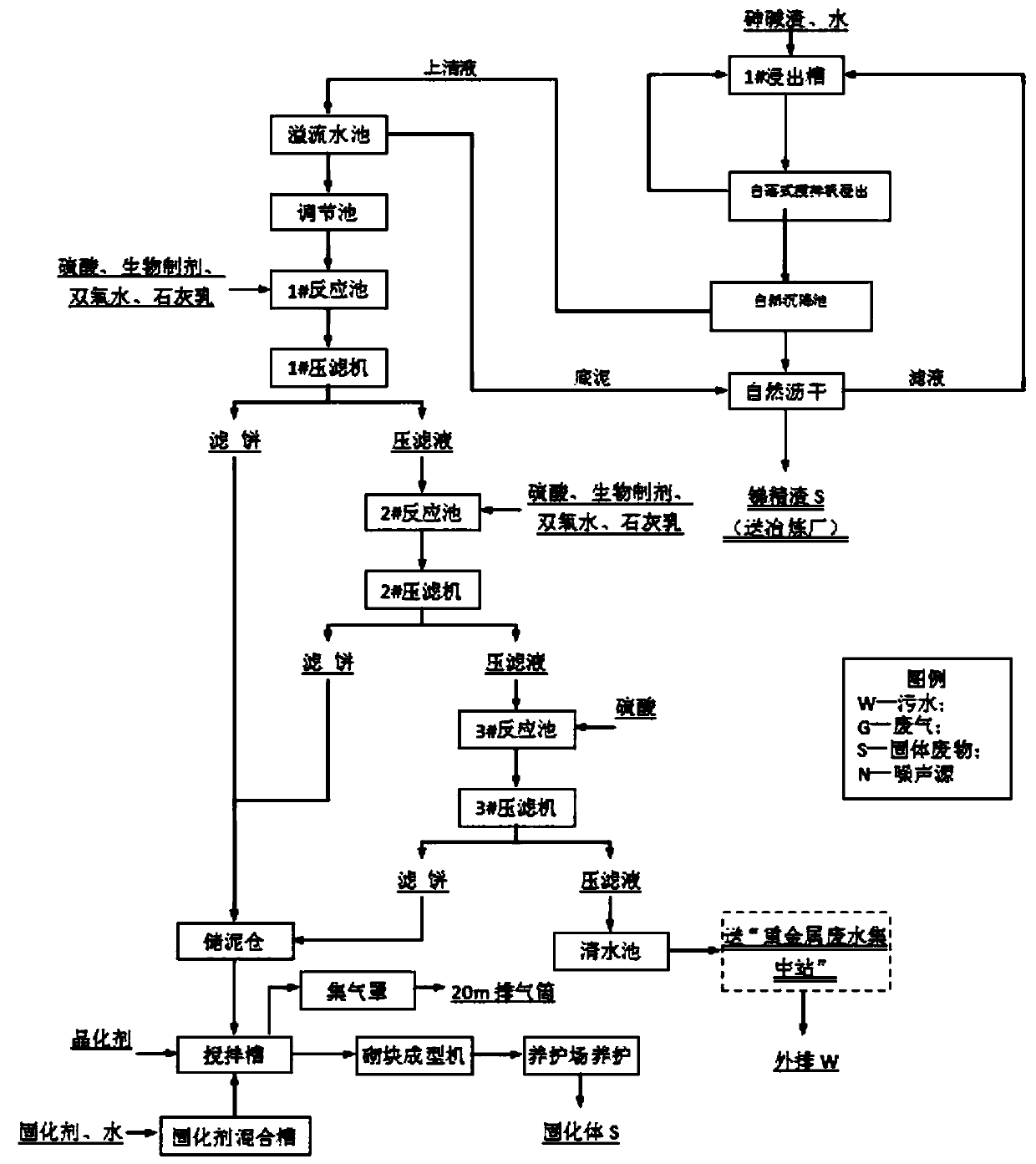

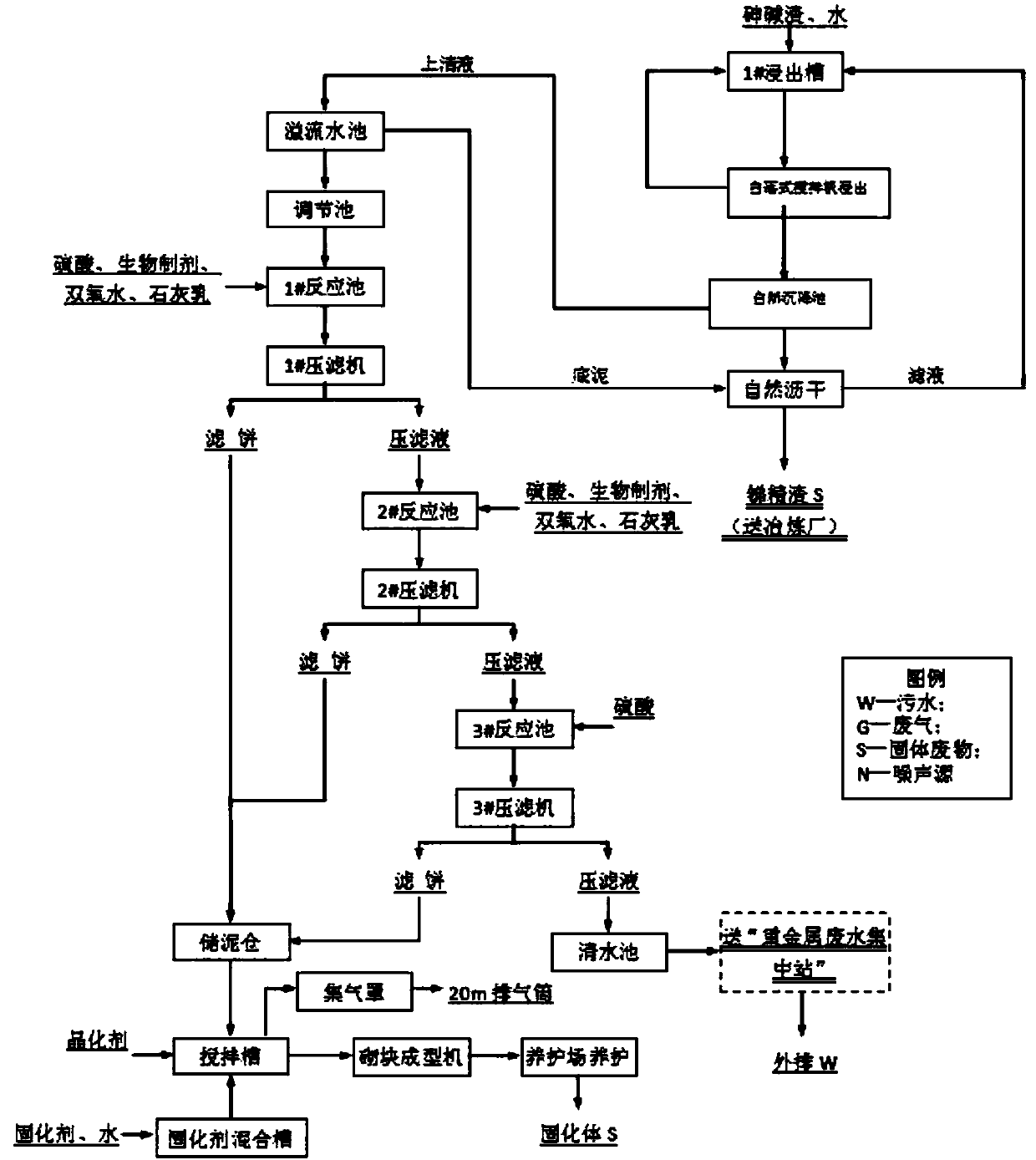

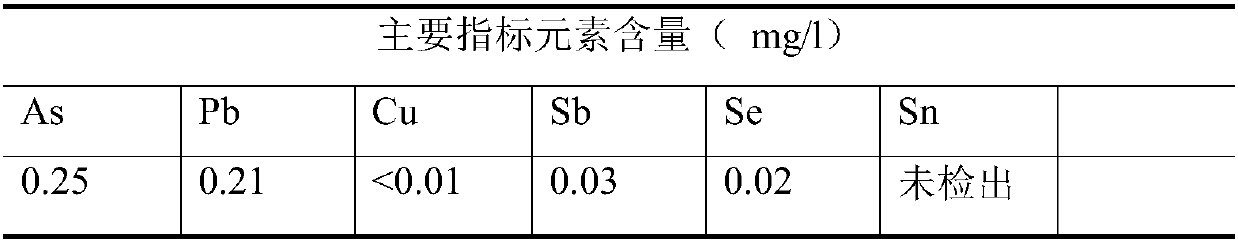

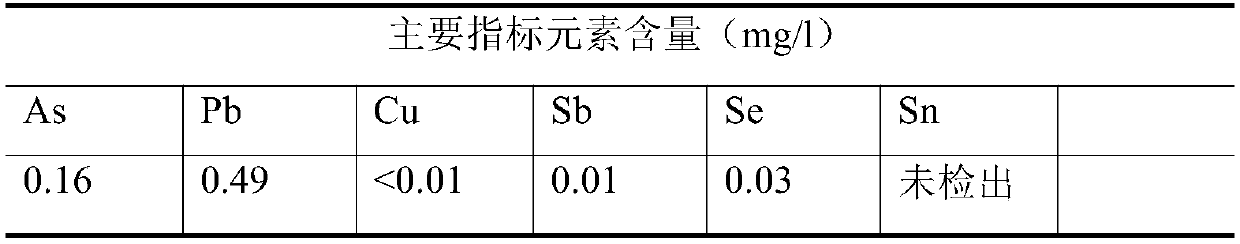

Technology for normal-temperature wet-process harmless treatment of arsenic soda slag

ActiveCN106319233AEfficient recyclingEffectively fixedTransportation and packagingSolid waste disposalHydrometallurgyMaterials science

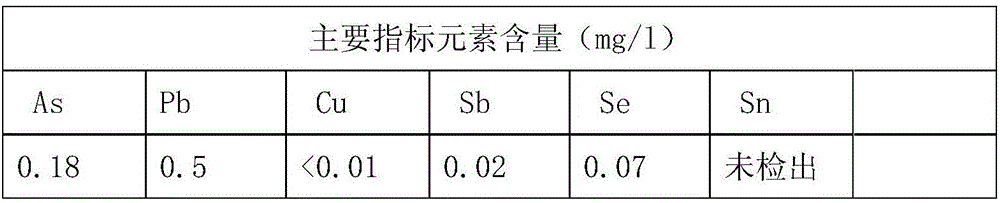

The invention belongs to the field of wet metallurgy and relates to a treatment method of arsenic soda slag produced in a pyrogenic antimony smelting process. The arsenic soda slag is subjected to wet crushing, water is added in the normal-temperature state, the mixture is subjected to solid-liquid separation, metal antimony in the slag is recovered, a high-arsenic leaching liquid after solid-liquid separation is subjected to arsenic precipitation with concentrated sulfuric acid, a biological agent, hydrogen peroxide and lime milk, and water after arsenic removal reaches the standard to be discharged. Produced high-arsenic slag is detoxicated through addition of a crystallization agent, and then a solidified body is prepared through addition of a solidification agent and can reach toxic leaching requirements of general solid waste according to a toxic leaching test. With the technology, environmental pollution caused by storage of the arsenic soda slag can be greatly reduced, the comprehensive utilization rate of mineral resources can be increased, and the valuable metal recovery rate is high. Through one-year production practice, various substances can be effectively recycled at the normal temperature with the technology, and As can be efficiently fixed. Material recrystallization does not occur in the whole technological process, so that the whole technology can be conducted smoothly, and necessary conditions are provided for industrial application.

Owner:HUNAN CHENZHOU MINING CO LTD

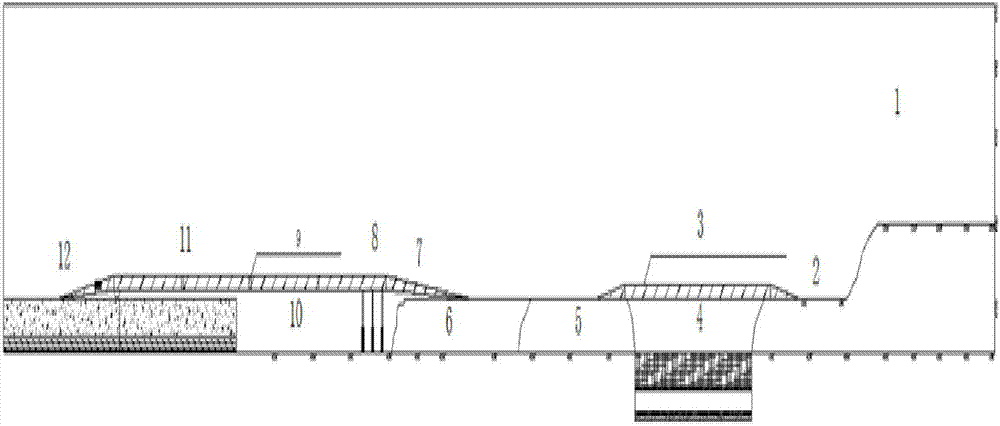

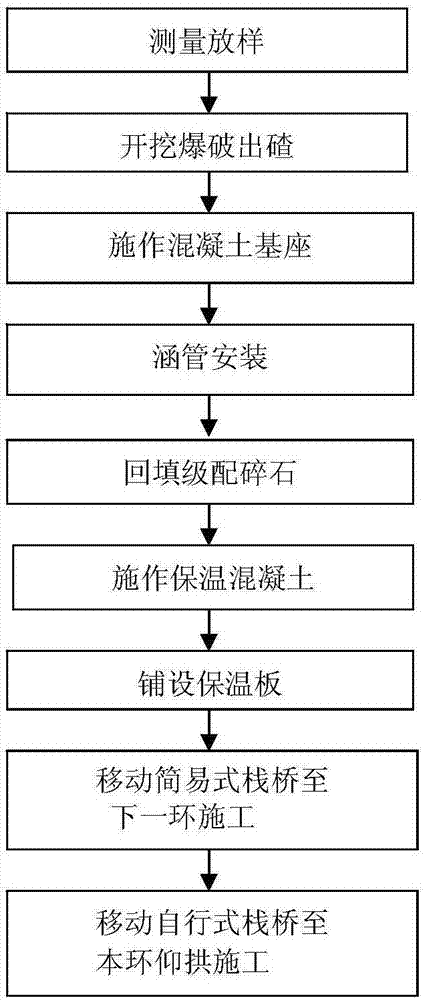

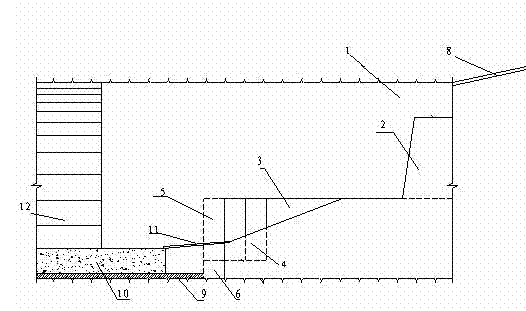

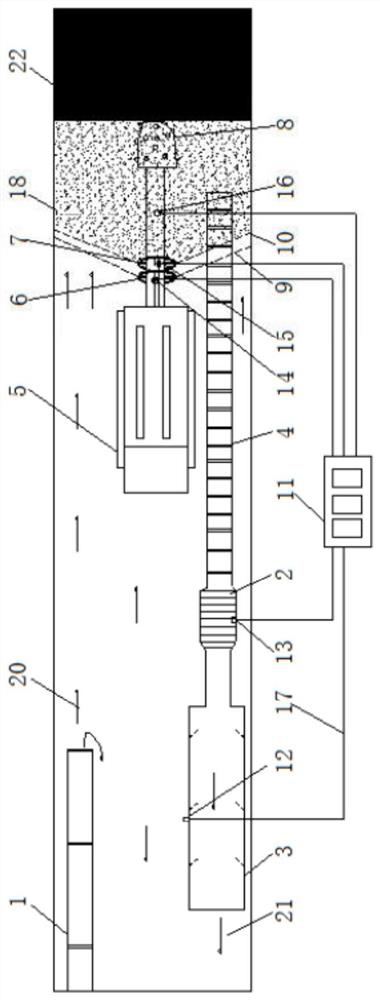

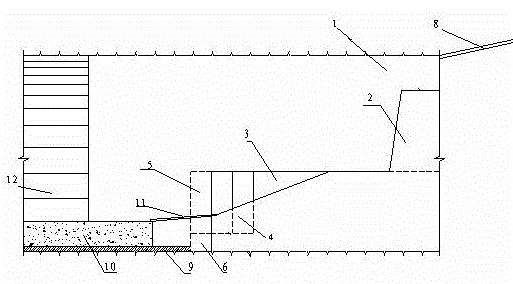

Construction method of deep burying center ditch for tunnel in extremely cold region

ActiveCN107201908AReduce concentrationGuarantee Occupational HealthUnderground chambersDrainagePondingThermal insulation

The invention discloses a construction method of a deep burying center ditch for a tunnel in an extremely cold region; before construction of an inverted arch of the tunnel, advanced construction is performed on the deep burying center ditch via a simple inverted-arch trestle, and then the inverted arch is constructed via a mobile inverted-arch trestle; the method comprises the specific steps of I, controlling blasting construction via boreholes, vertically distributing boreholes to perform deep-hole blasting, excavating by deck blasting, wherein all ditch blastholes incline out of the tunnel; II, excavating a ditch with a small excavator to a designed elevation; III, clearing ditch false dregs and ponding; IV, constructing a foundation; V, burying and installing a culvert; VI, performing graded backfilling; VII, casting thermal insulation concrete; VIII, tiling insulation plates. The problems of the prior art are effectively solved, such as difficulty in construction organization, low working efficiency, slow construction progress, high cost, and great disturbances to surrounding rock, and good service effect is achieved.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

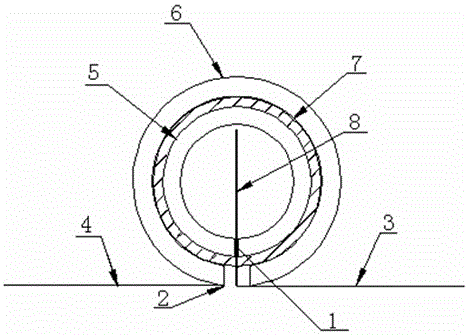

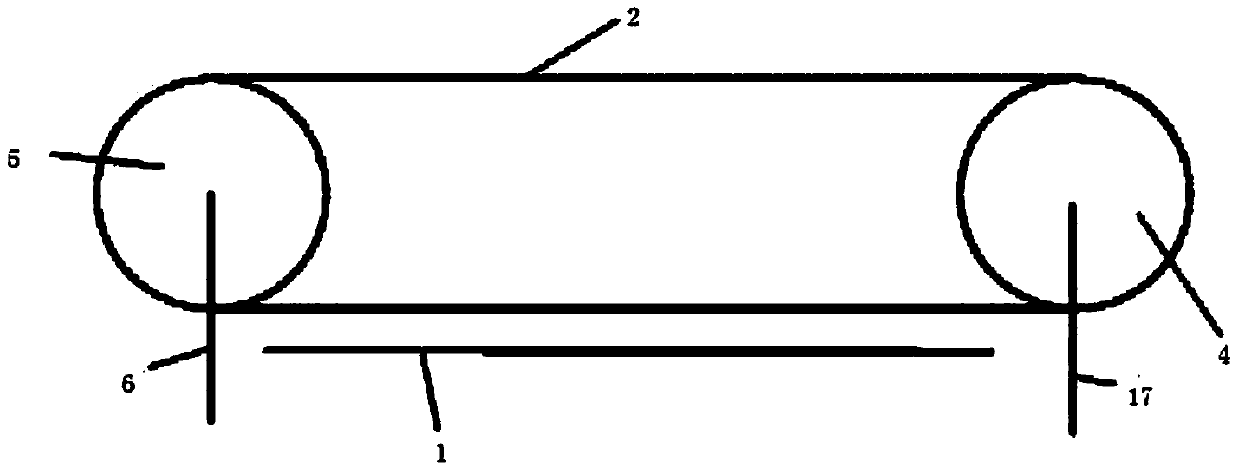

Building foundation impermeable membrane connecting device and building foundation impermeable membrane connecting method

ActiveCN106368172AGuarantee the construction qualityImprove anti-seepage performanceProtective foundationGasketsHydraulic engineeringFunctional requirement

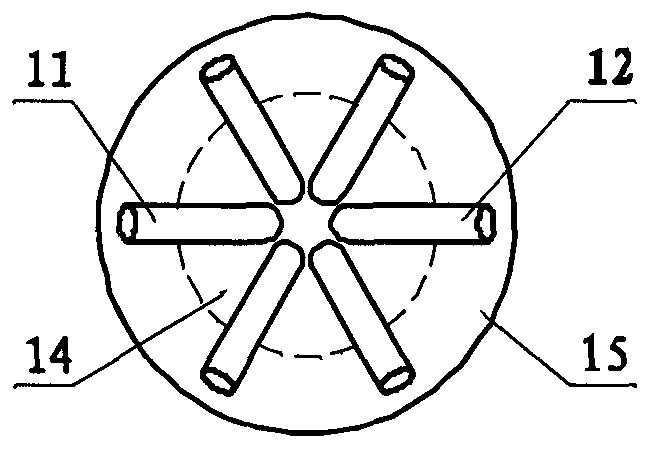

The invention relates to a building foundation impermeable membrane connecting device and a building foundation impermeable membrane connecting method, which are suitable for engineering construction of hydraulic engineering dams, reservoir dams, channels, ponds and the like so as to meet impermeable functional requirements, the tensile strength between new membranes as well as between a new membrane and an old membrane in an impermeable system can be effectively guaranteed, and the impermeable requirements are satisfied. The connecting device comprises inner pipes and outer pipes, wherein insertion openings are axially formed in pipe bodies of the inner pipes, bayonets are axially formed in pipe bodies of the outer pipes, and the outer pipes are clamped on the upper surfaces of impermeable membrane coiling layers which are wrapped outside the inner pipes, so that impermeable membranes I and impermeable membranes II which are used by two building foundations are connected together segment by segment, and the outer pipes as well as the inner pipes are abutted one by one. According to the building foundation impermeable membrane connecting device and the building foundation impermeable membrane connecting method, the leakage problem of the connecting positions of the impermeable membranes is solved, the impermeable purpose is achieved, and the engineering quality is effectively increased.

Owner:中石化石油工程技术服务有限公司 +1

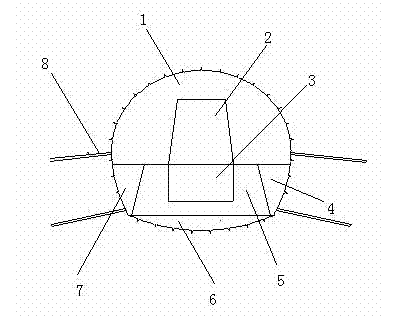

Shallow-buried large-span water conveying tunnel three-stage five-step digging method

ActiveCN103174430AReduce distortionGuaranteed deformationUnderground chambersTunnel liningThree stageEngineering

The invention discloses a shallow-buried large-span water conveying tunnel three-stage five-step digging method which comprises the steps of 1) first-step digging, namely performing forepoling on an upper half tunnel, and digging an upper stage; 2) second-step digging, namely digging a pull trough in the middle of the tunnel; 3) third-step digging, namely digging and supporting the left wall of the tunnel; 4) fourth-step digging, namely digging and supporting the right wall of the tunnel; and 5) fifth-step digging, namely digging and supporting the edge wall of a lower stage. By adopting the digging method, region-by-region digging is effectively executed, overlapping of spaces and time of working procedures are fully used, the digging time periods of the working procedures are rationally used, and the deformation in the tunnel is reduced; and a lining can be quickly closed to form a ring. By adopting the digging method, the digging safety risk is effectively reduced, the digging working efficiency is improved, the digging and supporting closing time is shortened, and the deformation in the tunnel is effectively reduced.

Owner:SINOHYDRO BUREAU 14 CO LTD

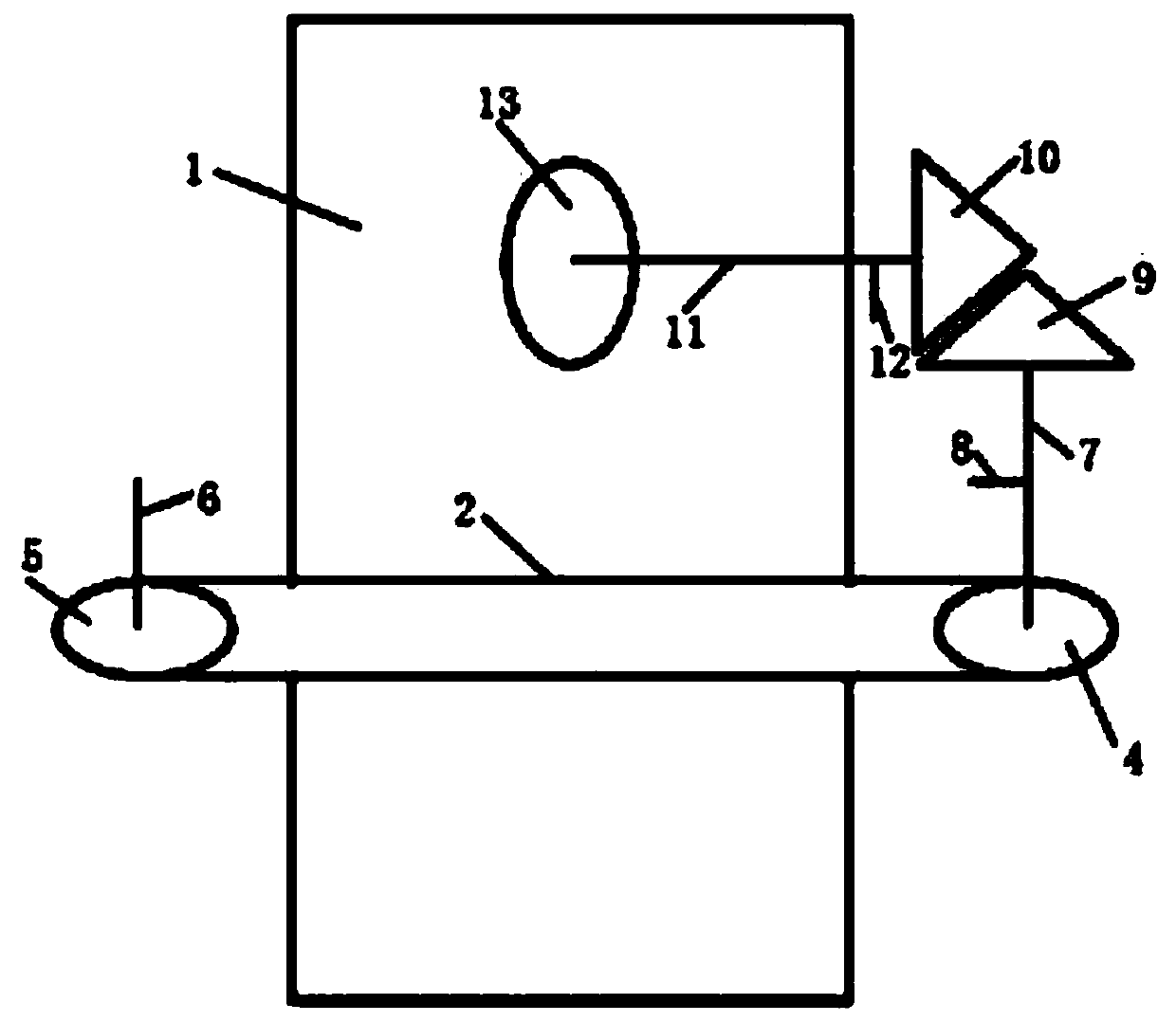

Gripper device, robot and hazardous waste dumping system

PendingCN111421570AGuarantee Occupational HealthReduce labor intensityGripping headsConveyor partsControl engineeringControl theory

The invention provides a gripper device, a robot, and a hazardous waste dumping system. The gripper device comprises a clamp base, a lower clamp, an upper clamp, and a driving mechanism, wherein the clamp base is used for being arranged on a robot arm; a guide rail extending in a vertical direction is arranged on the clamp base; the lower clamp can clamp the bottom of a charging basket and is arranged on the clamp base; the upper clamp can clamp the top of the charging basket and is arranged on the clamp base; and the driving mechanism is used for driving at least one of the lower clamp and the upper clamp to move relative to the clamp base along the guide rail, so that the upper clamp and the lower clamp are matched for clamping and loosening the charging basket. The gripper device can cooperate with the robot arm to realize the non-manual grabbing and handling of the charging basket, and enables the staff to be far away from hazardous waste, thereby ensuring the occupational health of the staff, meanwhile replacing manual operation and reducing labor intensity.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

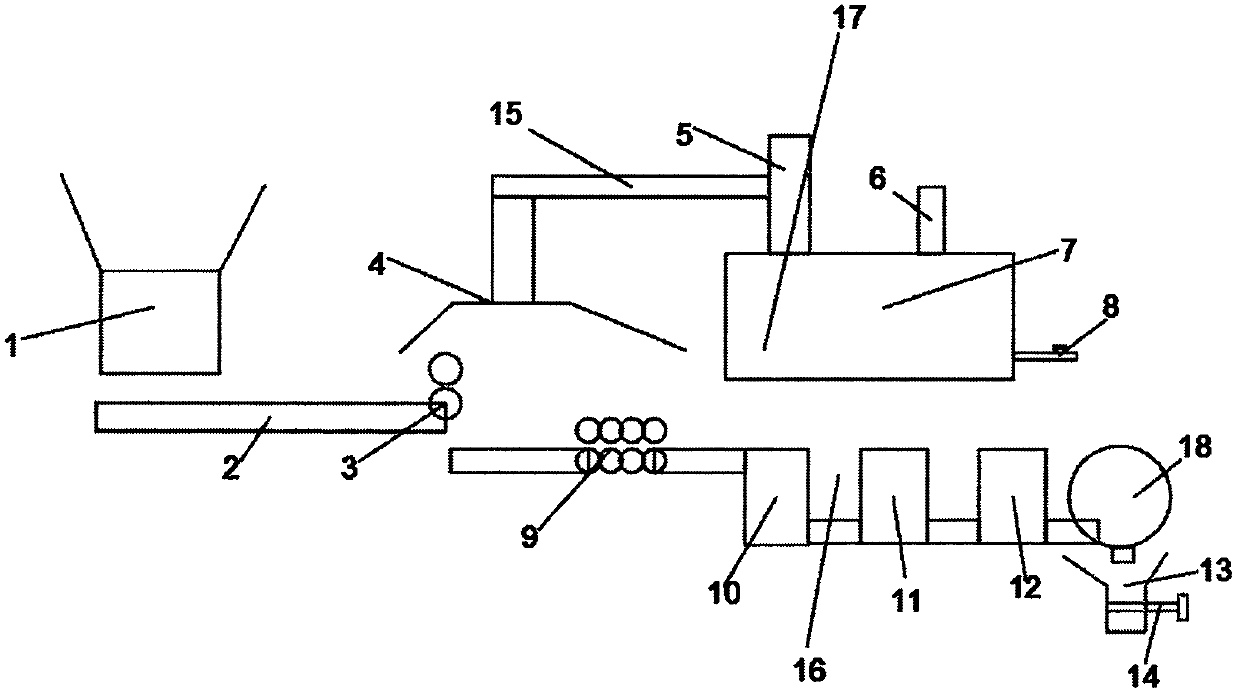

Technology for cleanly and efficiently processing lead-bearing waste residues

PendingCN108950236AGuaranteed temperatureSecurity atmosphereProcess efficiency improvementLead smeltingSmelting process

Disclosed is a technology for cleanly and efficiently processing lead-bearing waste residues. The lead-bearing waste residues produced by lead smelting and lime are matched according to the mass ratioof 1:0.03-0.07 and are then pressed into blocky lead-bearing residue blocks, and after natural drying, by mass, 7%-15% of coke, 9%-11% of silica and 74%-84% of the lead-bearing residue blocks are matched. Materials are sequentially added into a five-section integrated type smelting furnace, ignition blowing-in is conducted for oxygen-enriched intensified smelting, materials added from a smeltingfurnace feeding section (1) pass through a preheating section (2), a sintering section (3), a half-melting section (4), a smelting section (5) and a layering section (6), and the smelting process of the materials is completed. Through the technology, material preheating, sintering, smelting and clarification laying are integrated, heavy metal, valuable metal, gangue and the like are selectively separated well, dangerous waste is processed cleanly and efficiently, and the technology has the advantages that the process is short, operation is simple and convenient, and investment is small.

Owner:个旧市沙甸永和冶炼厂

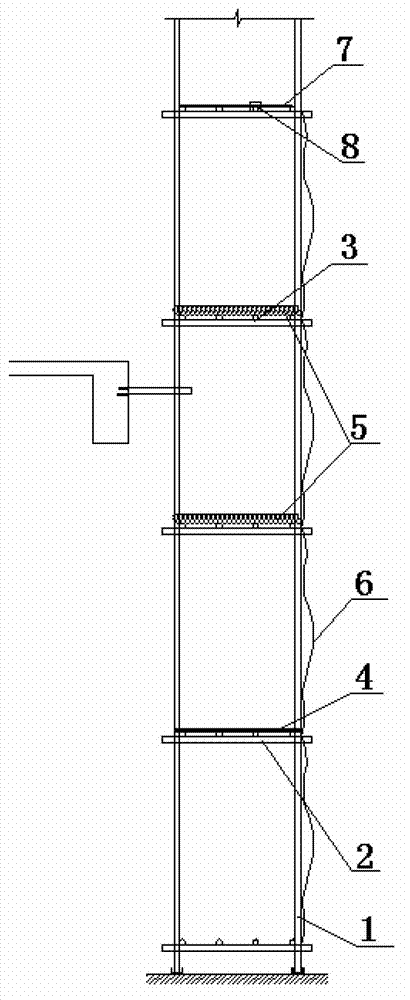

Environment-friendly flame-retardant scaffold system

ActiveCN103046734AImprove fire performanceLong fire resistanceScaffold connectionsScaffold accessoriesSafety netEngineering

The invention discloses an environment-friendly flame-retardant scaffold system. The environment-friendly flame-retardant scaffold system sequentially comprises a plurality of scaffold board rows, a ramp scaffold board and a perforated dustproof safety net from bottom to top, and the perforated dustproof safety net is arranged on one side of a scaffold. The environment-friendly flame-retardant scaffold system is characterized in that the first row of scaffold boards in the bottom layer is steel scaffold boards, steel screen scaffold boards are adopted for layering and separation of the scaffold, each two adjacent steel scaffold boards are connected through a fixing part, and each two adjacent steel screen scaffold boards are connected by a fixing part. By the aid of the scaffold system, dangerousness of construction is lowered, fire accidents can be avoided, occupational health of operators is guaranteed, and accordingly environmental friendliness requirements of environmental friendliness, dust prevention, noise prevention of construction sites are met, and adverse impact on surrounding environments is reduced.

Owner:SHANGHAI CONSTR NO 1 GRP

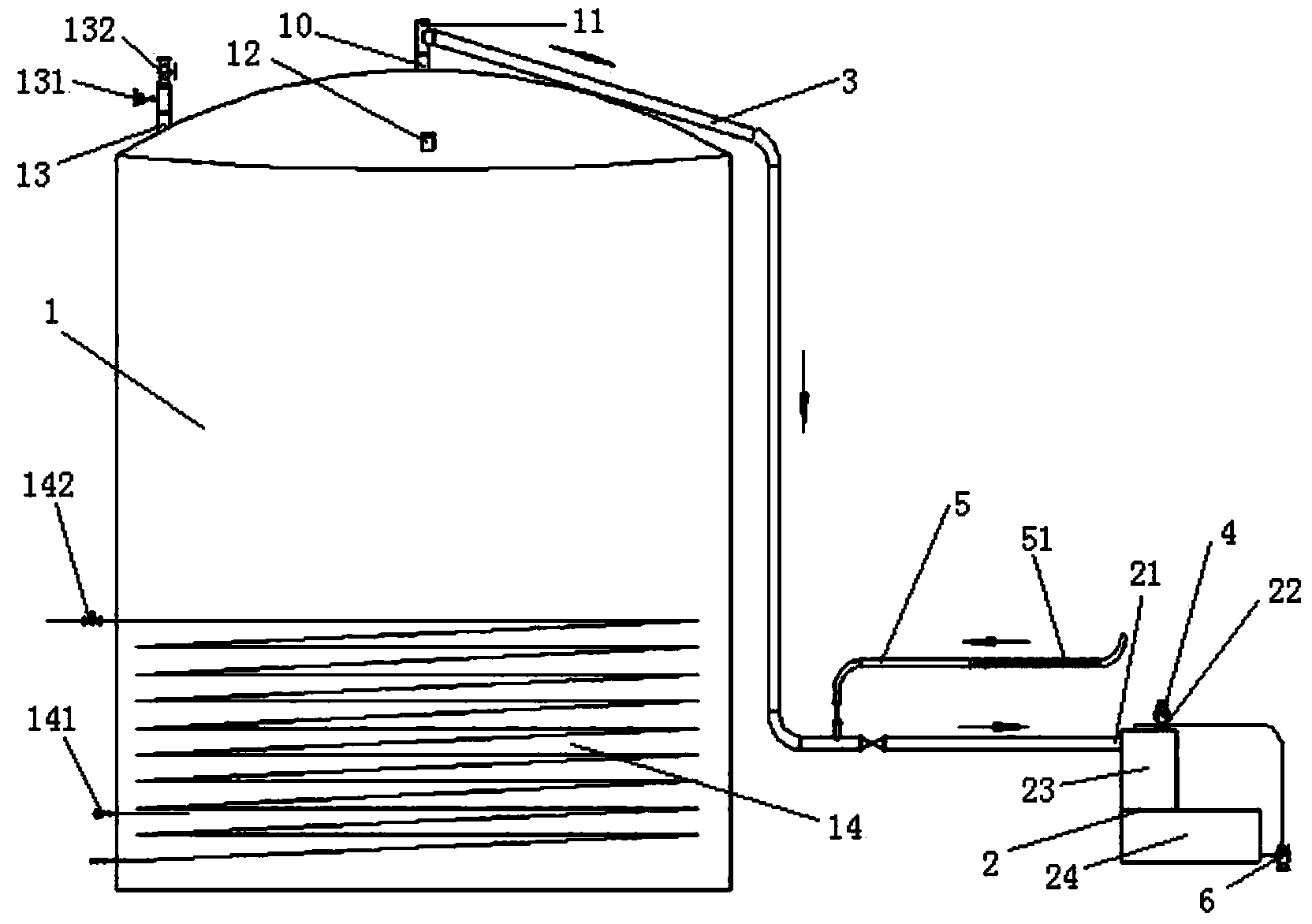

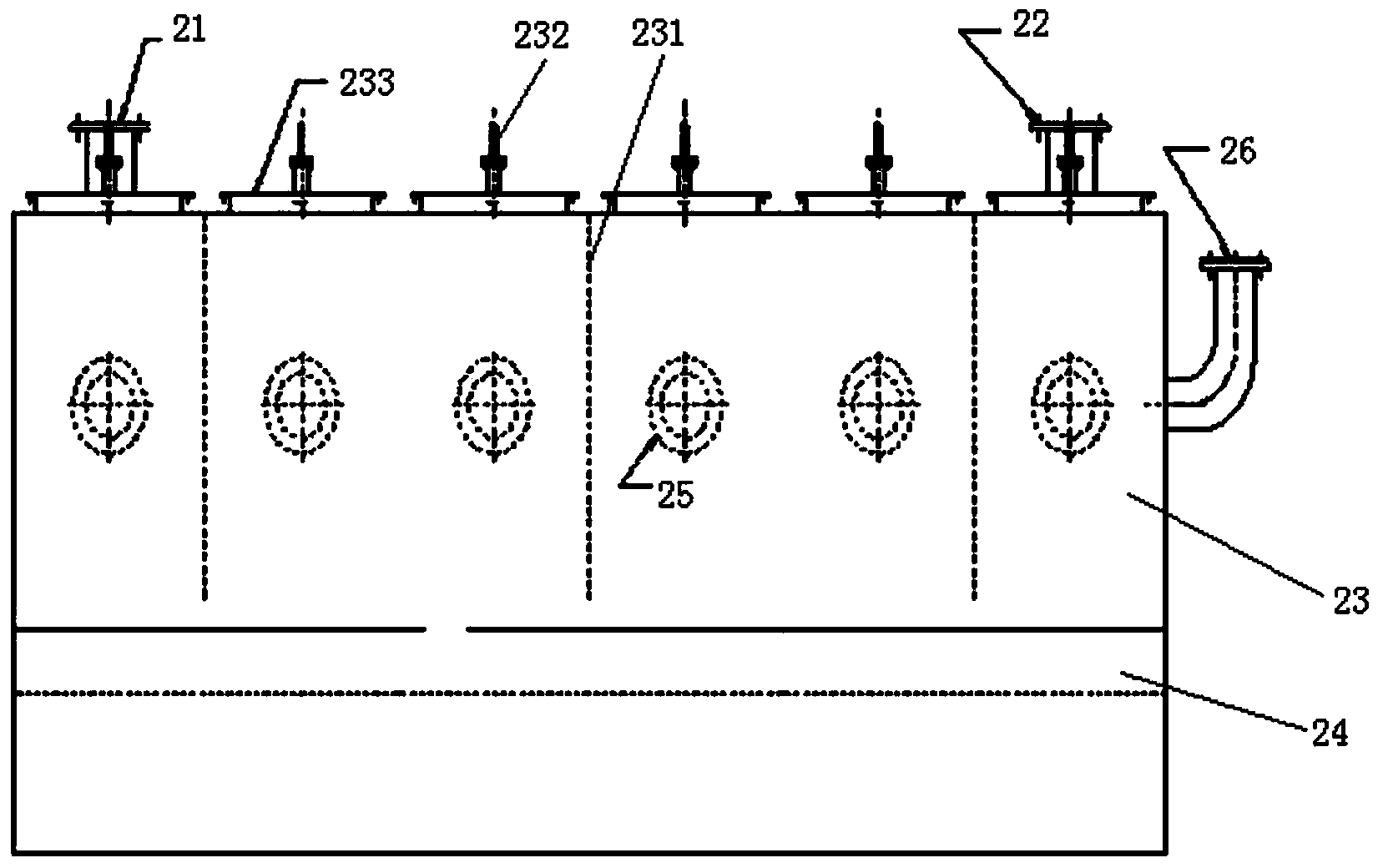

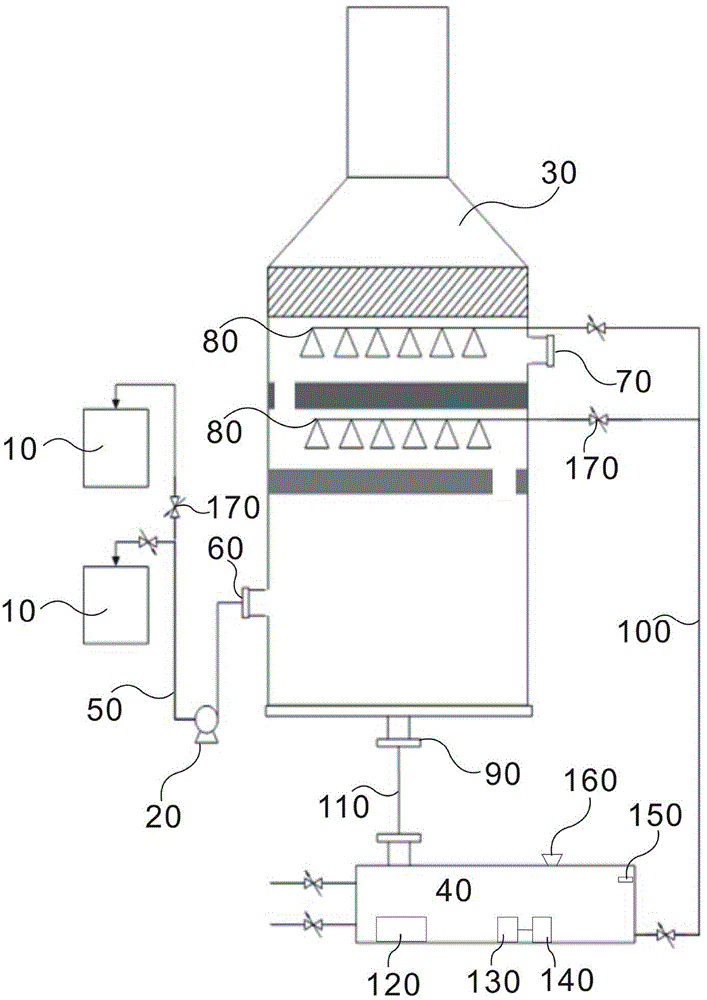

Naphthalene tail gas recycling system

The invention discloses a naphthalene tail gas recycling system which comprises a naphthalene tank body and a naphthalene collector. The top of the naphthalene tank body is provided with a naphthalene ventilation hole, the top of the naphthalene collector is provided with an air inlet and an air outlet, the naphthalene ventilation hole is communicated with the air inlet through a pipe, and an induced draft fan is installed at the position of the air outlet. The naphthalene tail gas recycling system further comprises a pipeline connected with loading vehicle tail gas, the pipeline is connected with the pipe, the tail gas discharged out of the naphthalene ventilation hole and a loading vehicle is introduced to the naphthalene collector through the induced draft fan and the pipe to be recycled, the naphthalene collector comprises a collecting device and a water tank, a grid partition is arranged in the collecting device, a spraying pipe for water curtain cooling is installed at the top of the grid partition, the tail gas in the collecting device is cooled through spraying water, and naphthalene particles in the gas are cooled and fall to the water tank below with the stream to be recycled. The naphthalene tail gas recycling system has the advantages that thermal energy consumption and material loss are reduced, physical health of operators is guaranteed, the atmospheric environment is protected, and large economic loss is reduced for enterprises engaged in naphthalene tank transfer operations.

Owner:NANJING PORT

Method for producing squatting pan by high-pressure molds

InactiveCN103978540AGood surface smoothnessHigh strengthSlip casting mouldsDiaphragm pumpUltimate tensile strength

The invention discloses a method for producing a squatting pan by high-pressure molds. A horizontal high-pressure grouting forming device is used for producing the squatting pan. The high-pressure grouting forming cycle includes the following steps of (1) grout filling, (2) grouting, (3) grout returning and (4) strengthening, wherein in the step of (1) grouting filling, grout is conveyed to the molds through a pneumatic diaphragm pump, in the step of (2) grouting, external pressure acts on the grout in the molds so that the grout can be dehydrated and hardened to be shaped, in the steps of (3) grouting returning, extra grout in a hollow grouting area of a blank is discharged, and in the step of (4) strengthening, compressed air is led to an inner cavity of the blank, so that water in the blank is uniform, and the strength of the blank is improved. The micro-reticular resin mold is adopted, the device is in a horizontal pouring mode, and a reliable guarantee is provided for demolding of the blank, and accordingly the blank is not prone to deforming; the device is of a double-mold structure, multiple high-pressure resin molds can be arranged, and the device can be used for producing wash basins and also can be used for producing squatting pans by replacement of the molds; according to the method, energy conservation and emission reduction can be achieved, clean production can be achieved, the qualified rate of products and production efficiency are greatly improved, and meanwhile, work intensity of workers is greatly reduced.

Owner:HOCHENG CHINA

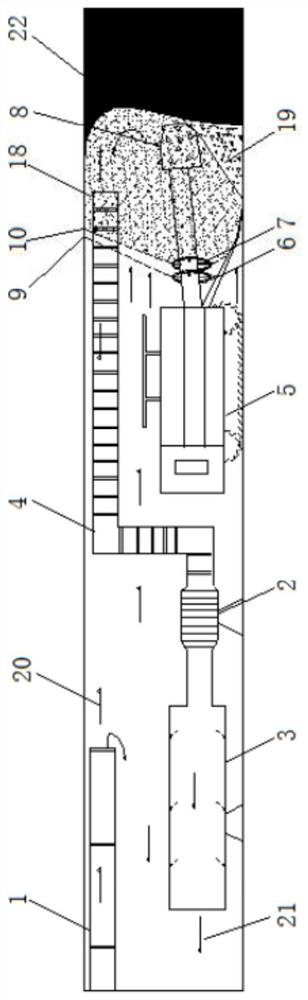

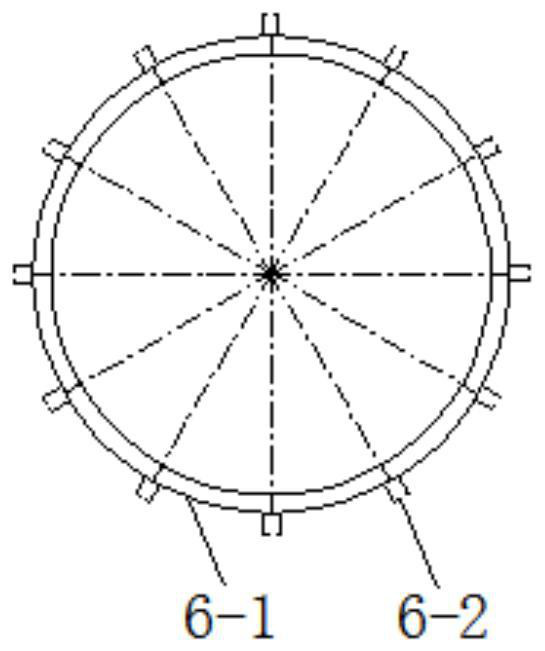

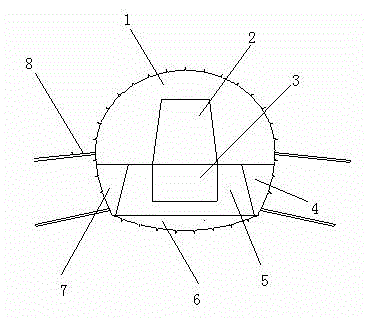

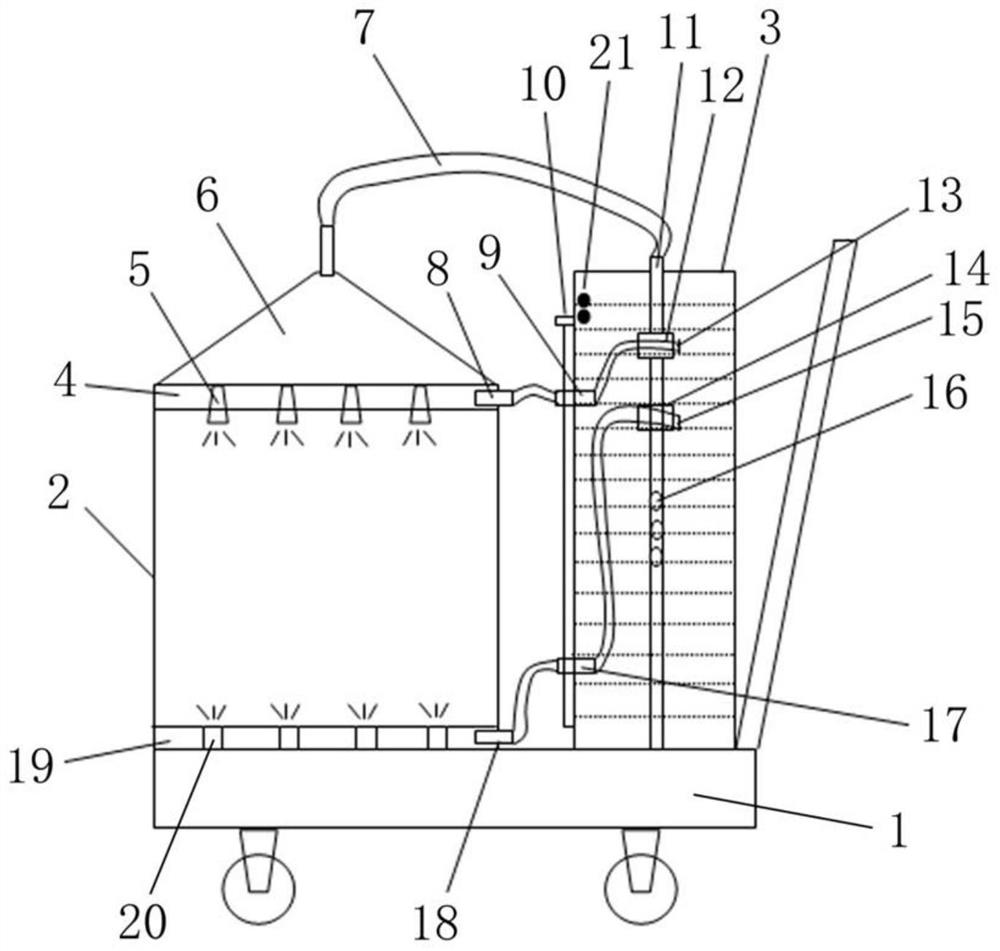

Dust falling device and method for heading face

ActiveCN112343645ALow probability of escapeReduce the spreadMining devicesDust removalWorking environmentEngineering

The invention relates to a dust falling technique for an underground heading face of a coal mine, in particular to a dust falling device for the heading face. The dust falling device for the heading face comprises a heading machine, a spraying device, a compressed air jetting device and a dust removal system, wherein a heading machine rotating head is driven to rotate by the heading machine through a mechanical arm; the spraying device is used for spraying umbrella-shaped water mist to a drill bit and the heading face, and additionally, a spraying range outer contour line is formed; the compressed air jetting device is used for jetting umbrella-shaped compressed air to the drill bit and the heading face, so that the contact opportunity of water mist and dust is increased, an air wall is formed behind the umbrella-shaped water mist, and additionally, a compressed air jetting range outer contour line is formed; and a dust removal suction port is formed in the dust removal system, the dust removal suction port is formed between the spraying range outer contour line and the heading face, and the dust removal system is used for performing active negative-pressure suction type dust removal on flying dust between the spraying range outer contour line and the heading face. According to the dust falling device, the working environment of the heading face is improved, and occupational health of underground workers is guaranteed. In addition, the invention further provides a dust falling method for the heading face.

Owner:CCTEG SHENYANG RES INST

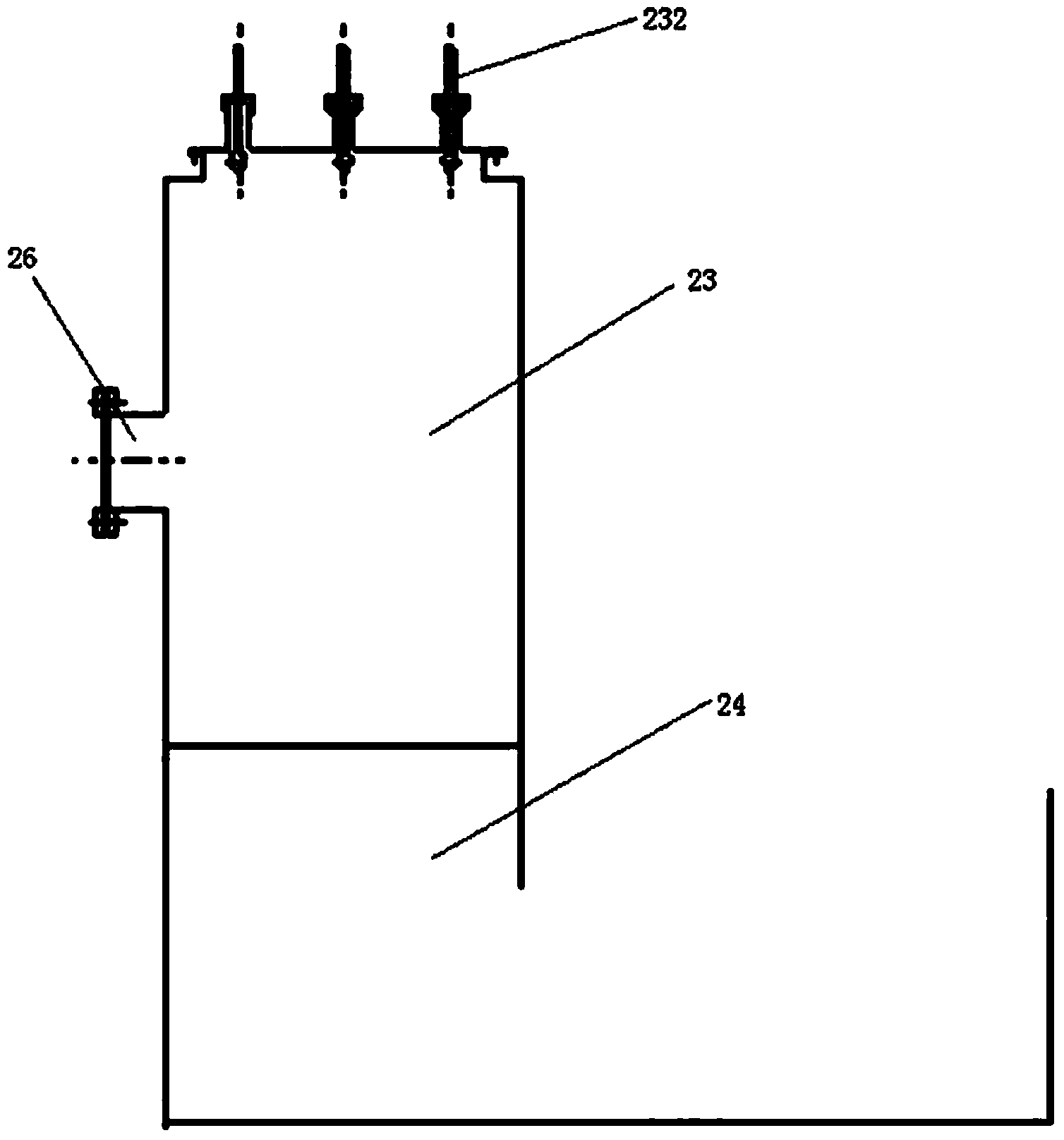

Method and system for recycling industrial naphthalene

InactiveCN104478651AIncrease contact timeIncrease contact areaHydrocarbon purification/separationHydrocarbonsContact timeWater storage tank

The invention provides a method and a system for recycling industrial naphthalene. The system provided by the invention comprises a naphthalene feeding hole, a draught fan, a spray tower and a water storage tank, which are connected in sequence. According to the method and the system for recycling industrial naphthalene provided by the invention, by means of two water curtain spraying devices, the contact time of water and dust collecting gas is prolonged; the contact area of water and gas is increased; gas can be effectively purified; industrial naphthalene in gas is sufficiently recycled; the system is reasonable in design, simple in structure and convenient to use; the method and the system are not beneficial to protecting the environment but also capable of effectively reducing the production cost of enterprises and increasing performance of enterprises; and the system provided by the invention reduces injury of naphthalene to operators, ensures occupational health and safety of staffs and avoids serious pollution of the atmospheric environment.

Owner:TAIZHOU JIANGYAN BOTE NEW MATERIAL

Smoke composite analysis system and method

InactiveCN102928555AGuarantee Occupational HealthComprehensive detectionParticle suspension analysisEngineeringPath switching

The invention relates to a smoke composite analysis system, which comprises a sampling unit, a flow path switching unit, a control unit and a detection analysis unit, wherein the sampling unit at least comprises a first sampling pipeline and a second sampling pipeline; the flow path switching unit comprises an input pipeline and a moving module; the input pipeline is arranged on the moving module; the flow path switching unit is connected with the sampling unit; the control unit controls the moving module to move so that the input pipeline is selectively communicated with the first sampling pipe and the second sampling pipe; and the detection analysis unit is used for analyzing sample information which is input by the input pipe and acquired by the sampling unit through sampling. The invention also provides a smoke composite analysis method. The smoke composite analysis system and the smoke composite analysis method have the advantages of wide application range, strong expansibility and the like.

Owner:FOCUSED PHOTONICS

Precast concrete component environment-friendly intelligent production system design method

InactiveCN111941626AQuality assuranceEnsure safetyCeramic shaping plantsAuxillary shaping apparatusInformatizationSystems design

The invention discloses a design method of a precast concrete component environment-friendly intelligent production system. The precast concrete component environment-friendly intelligent production system comprises a totally-enclosed sandstone aggregate storage and transportation system, a totally-enclosed concrete mixing and conveying system, an integrated sandstone separation and filter pressing workshop, an environment-friendly standard-reaching reinforcement cage processing workshop, an environment-friendly standard-reaching prefabricated part pouring and forming workshop, an intelligentsteam curing system, an intelligent water curing system, an intelligent finished product stacking, storing and shipping system, an informatization and intelligence management system and a production ancillary facility system. A highly-integrated, intelligent, systematic and environment-friendly precast concrete component production factory-like comprehensive solution and a design method based on the solution are provided; and the processes that comprehensive treatment is carried out on pollution sources such as noise, dust, solid waste and waste water are included, technologies such as the Internet of Things, big data and cloud computing are fused, technical means such as an application programming interface (API) are utilized, environmental protection is achieved, secondary utilization ofall materials is achieved, and the recycle environment-friendly requirement is met.

Owner:中电建成都混凝土制品有限公司

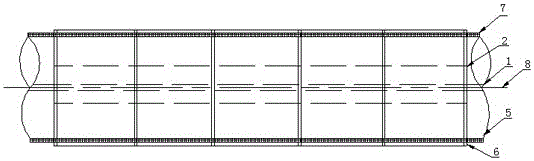

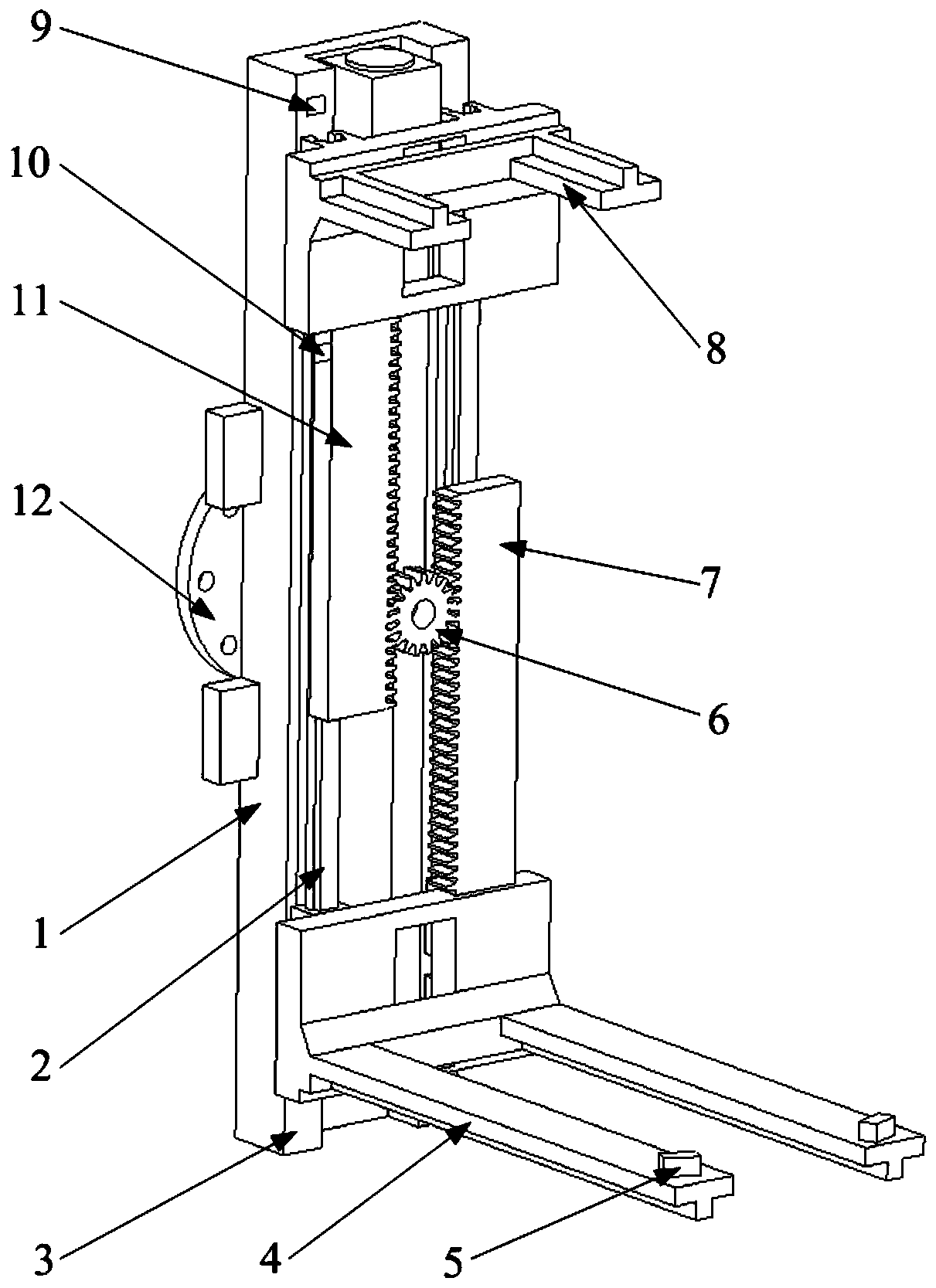

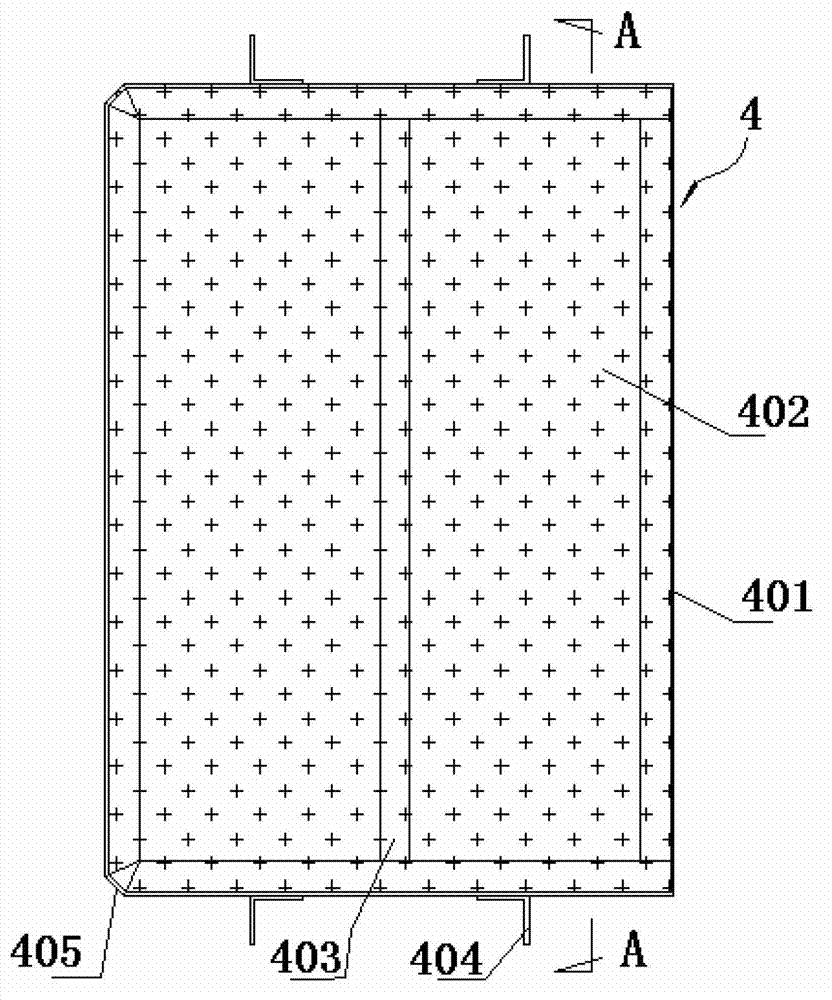

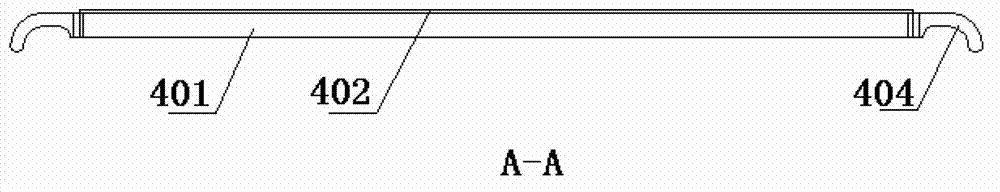

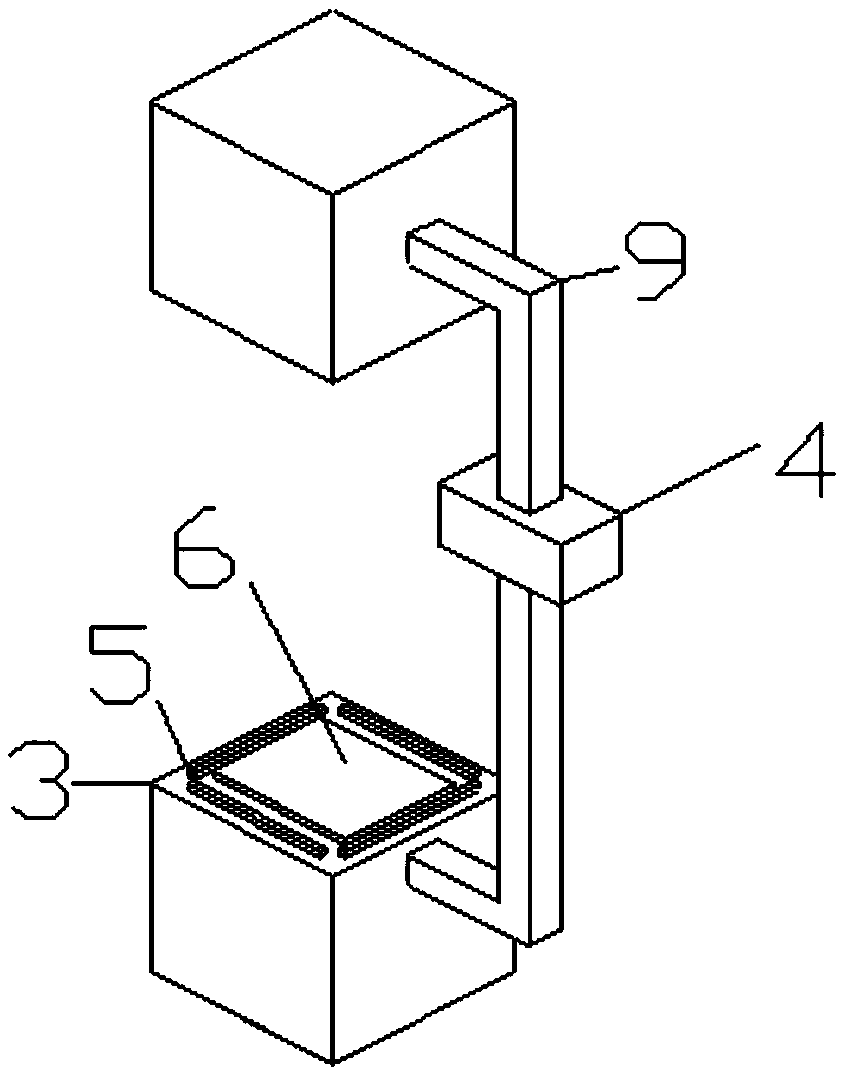

Entry-free integral quick-release type box girder internal mold and mounting and dismounting method thereof

InactiveCN111037718AImprove working environmentGuarantee Occupational HealthMould auxillary partsBridge erection/assemblyStructural engineeringWorking environment

The invention relates to a box girder internal mold, in particular to an entry-free integral quick-release type box girder internal mold. The internal mold comprises a left internal mold panel, a right internal mold panel and an internal mold supporting device arranged in the left internal mold panel and the right internal mold panel; each of the left internal mold panel and the right internal mold panel is formed by mutually hinging an upper internal mold plate and a lower internal mold plate; the internal mold supporting device further comprises a pull rod, an upper supporting rod and a lower supporting rod. One end of the upper supporting rod is hinged with the upper internal mold panel; the other end of the upper supporting rod is hinged with the pull rod; one end of the lower supporting rod is hinged with the lower internal mold template; and the other end of the lower supporting rod is hinged with the pull rod. According to the internal mold, operation can be effectively carriedout outside the box girder, the internal mold can be dismounted and separated, operation in a limited space inside the box girder is not needed, the working environment is greatly improved, occupational health is sufficiently guaranteed, and the safety coefficient is greatly increased.

Owner:广西建工第五建筑工程集团有限公司

Front dust suppression mechanism of coal conveying belt tensioning device

The invention discloses a front dust suppression mechanism of a coal conveying belt tensioning device. The front dust suppression mechanism comprises a cleaning device and a spraying device, wherein the cleaning device comprises a driving wheel, bevel gears and a cleaning belt, the driving wheel is contacted with a lower coal conveying belt and fixedly connected with one end of a horizontal drive shaft, the other end of the horizontal drive shaft is fixedly connected with a first bevel gear, the first bevel gear is meshed with a second bevel gear which is fixedly connected with one end of a vertical drive shaft, the other end of the vertical drive shaft is fixedly connected with a first driving wheel, and a second driving wheel and the first driving wheel are connected through the cleaning belt; and the spraying device comprises a water pipe and a plurality of spraying nozzles which are mounted in front of the cleaning device. The front dust suppression mechanism of the coal conveying belt tensioning device has the characteristics of simplicity, low cost and effective dust suppression, effectively reduces dust produced by the coal conveying belt at the tensioning device, does not require additional power, and is energy-saving.

Owner:STATE GRID CORP OF CHINA +1

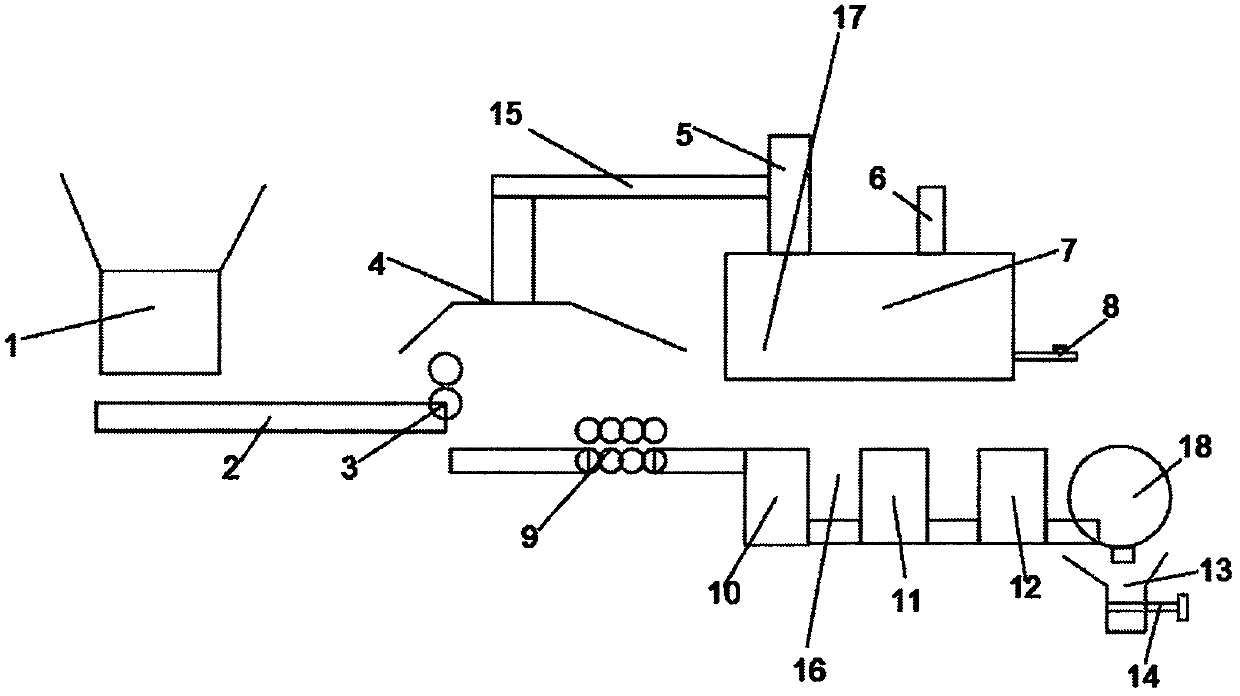

High-efficiency ore processing device

InactiveCN109967220AGood control effectThorough governanceDispersed particle filtrationDirt cleaningDust controlCrusher

The invention discloses a high-efficiency ore processing device comprising a feeding inlet, a dedusting device and a processing unit. A conveying belt is placed below the feeding inlet, and a crusheris installed at the right end of the conveying belt. The dedusting device comprises a dust sucking cover, a dust sucking pipeline, a deduster, a water inlet, a settling pond and a discharging pipe. The dust sucking cover is installed above the crusher and connected with the dust sucking pipeline, the dust sucking pipeline is connected with the deduster, the deduster is connected with the settlingpond, and the water inlet and the discharging pipe are arranged on the settling pond. The processing unit comprises a levigating machine, a stirring machine, a flotation machine, a concentrator and avacuum filter. The device not only has a loading function and improves loading efficiency, but also has an obvious dust prevention and control effect and thoroughly controls dust, thereby achieving dust control change from a temporary solution to a fundamental solution, dramatically improving the quality of air in a workshop and guaranteeing the occupational health of the majority of employees.

Owner:天津凌允科技有限公司

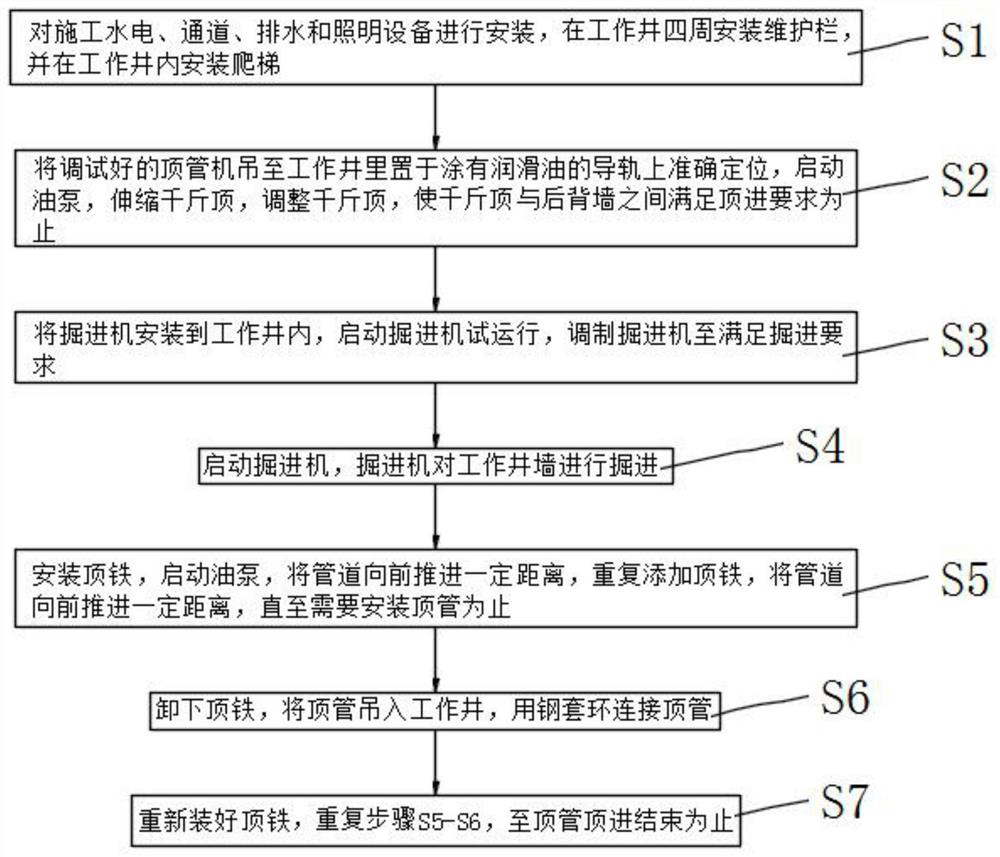

Manual pipe jacking construction process

InactiveCN112815144AQuality improvementEasy to removePipe laying and repairLight equipmentArchitectural engineering

The invention discloses a manual pipe jacking construction process, and belongs to the technical field of pipe jacking construction. The manual pipe jacking construction process comprises the following steps that S1, construction water and electricity, channels, drainage and lighting equipment are installed, maintenance fences are installed around a working well, and a ladder stand is installed in the working well; and S2, a debugged pipe jacking machine is hoisted into the working well, the pipe jacking machine is placed on a guide rail coated with lubricating oil for accurate positioning, an oil pump is started, a jack is stretched and retracted, and the jack is adjusted until the jack and the back wall meet the jacking requirement. According to the manual pipe jacking construction process, before the construction process, construction preparation is carried out, and during construction, a laser instrument is adopted for measuring the advancing trend of a jacking pipe, so that deviation measurement is carried out, deviation correction can be carried out in time, the quality of a constructed pipeline is improved, and the construction progress is guaranteed; and slag is discharged through a manual trolley, so that soil in the pipeline can be conveniently removed, and harmful gas and dust in the pipeline are discharged, so that the occupational health of workers is ensured.

Owner:中核华辰建筑工程有限公司

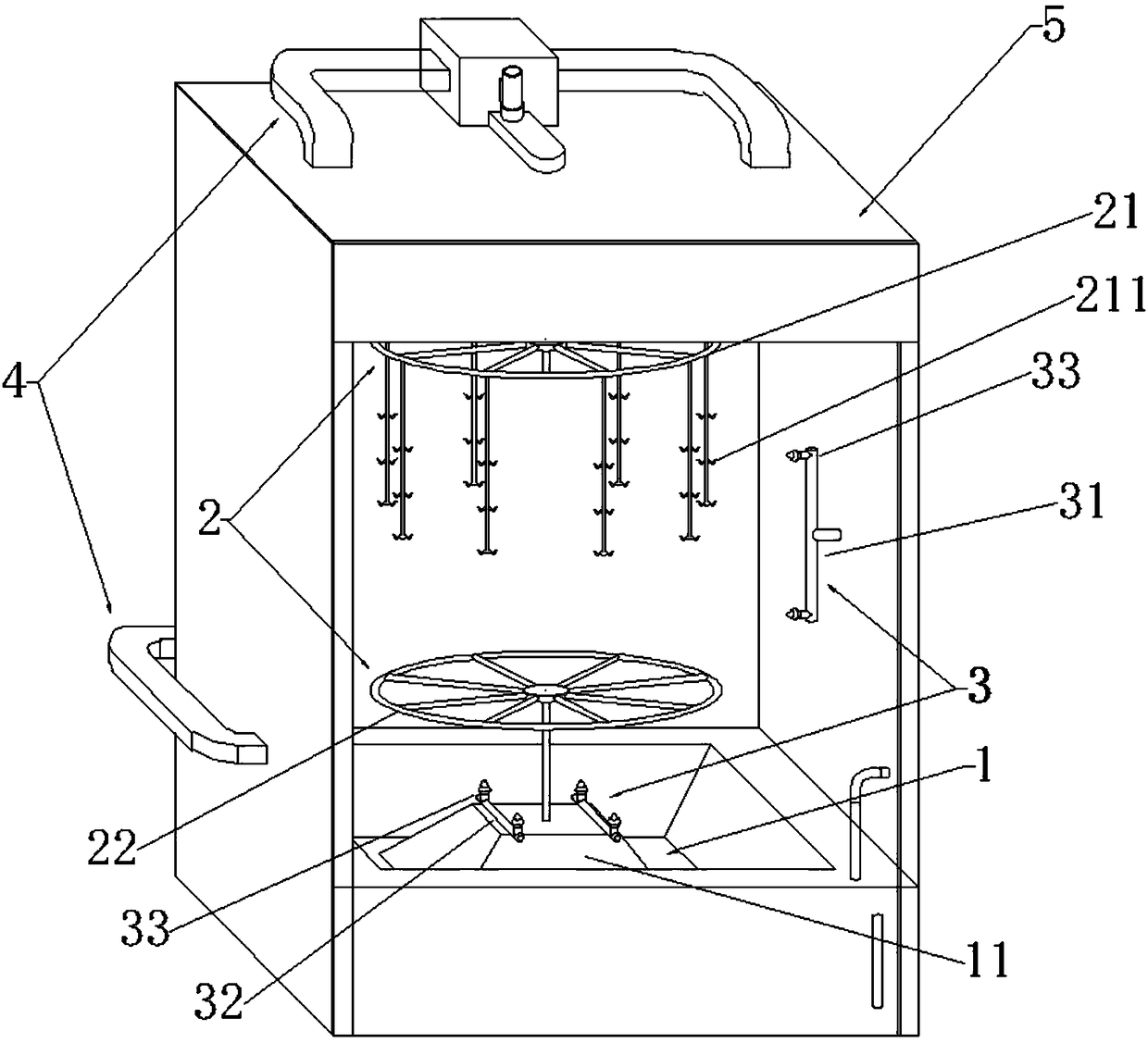

Environment-friendly touchless fluorescent permeating spray system

PendingCN108593671AGuarantee Occupational HealthGuaranteed spraying effectOptically investigating flaws/contaminationNon destructiveWastewater

The invention relates to the field of non-destructive testing of parts, and discloses an environment-friendly touchless fluorescent permeating spray system. The environment-friendly touchless fluorescent permeating spray system comprises a liquid medicine pool, a part rack, a spray mechanism, an air exhausting mechanism and a box body, wherein the liquid medicine pool is arranged at the bottom ofthe box body, the part rack is arranged at the middle of the bottom and / or the middle of the top of the box body, the spray mechanism is arranged below the part rack and on the side wall of the box body, and the side wall and the top of the box body are provided with the air exhausting mechanism. According to the system, a fluorescent permeating spray process is conducted in the airtight box body,so that a fluorescent penetrant is prevented from harming health of workers, further, the sprayed penetrant is collected and recycled, therefore, waste of the fluorescent penetrant is reduced, and wastewater treatment pressure is relieved.

Owner:江苏德意高航空智能装备股份有限公司

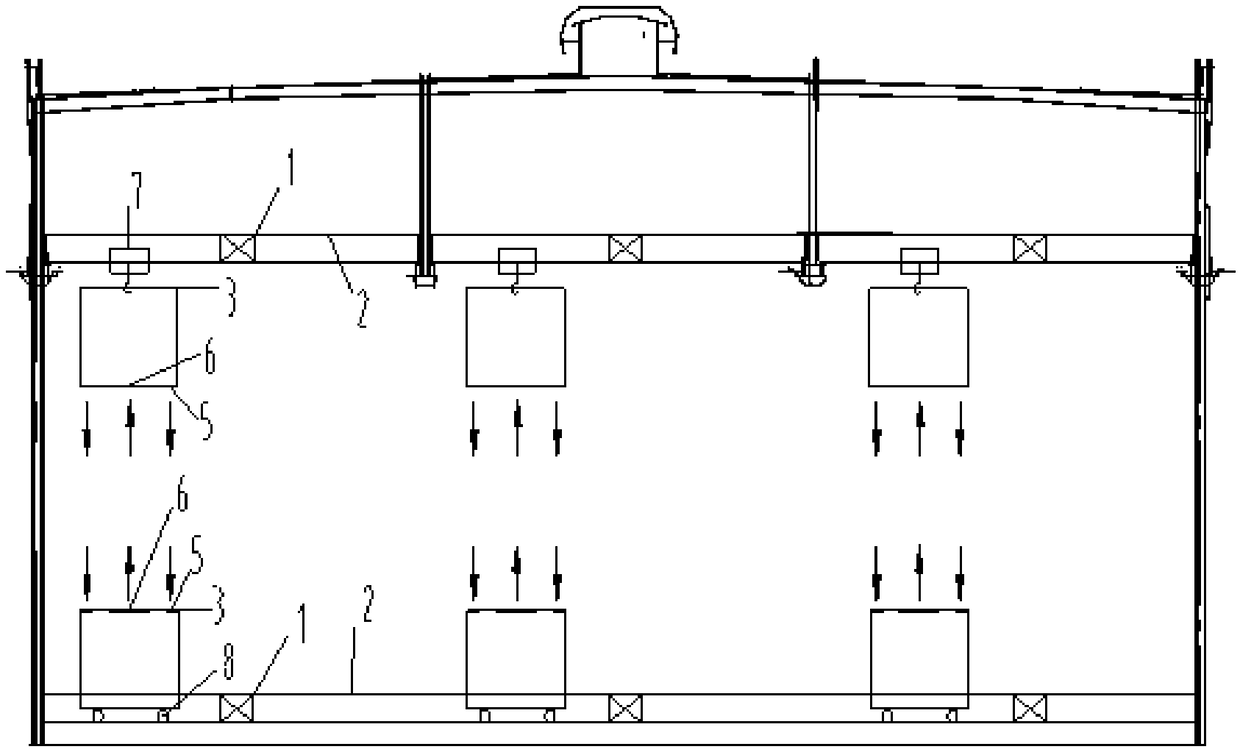

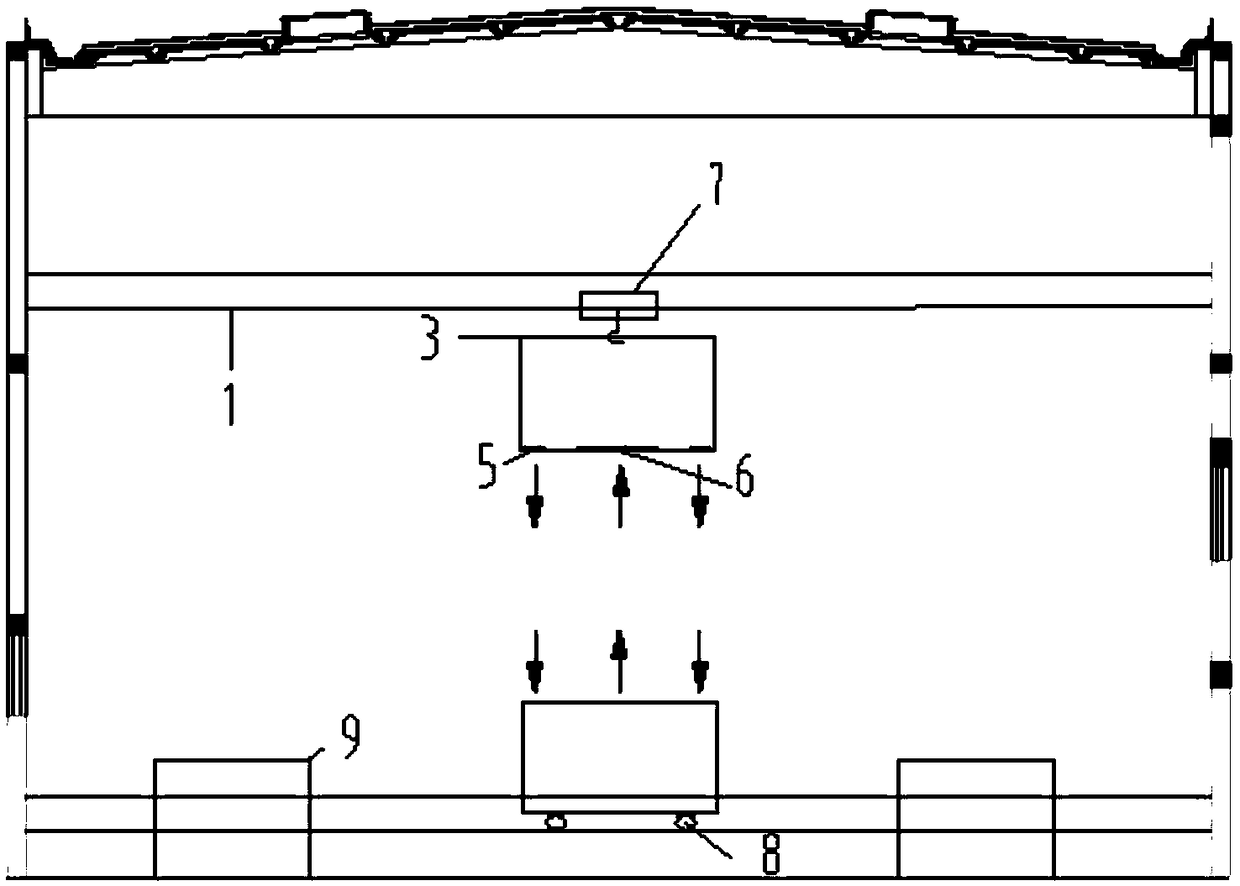

Mobile blowing-sucking type modular dust removal system

ActiveCN109127631AReduce the spreadReduce downtimeGas treatmentDispersed particle filtrationControl systemEngineering

The invention discloses a mobile blowing-sucking type modular dust removal system. The mobile blowing-sucking type modular dust removal system is characterized by comprising at least one set of mobileblowing-sucking type modular dust removal devices, an up-and-down synchronous moving type travelling crane assembly and a pulsating intelligent central control system, wherein the two blowing-suckingtype modular dust removal devices in one set are arranged up and down and communicate with each other, the up-and-down synchronous moving type travelling crane assembly enables the two correspondingmobile blowing-sucking type modular dust removal devices to keep at one horizontal position all the time, and the pulsating intelligent central control system is used for controlling the up-and-down synchronous moving type travelling crane assembly and the mobile blowing-sucking type modular dust removal devices. According to the system, mobile travelling cranes are arranged at the up and down positions at certain heights of a workshop, the two dust removal devices arranged up and down are moved synchronously in a blowing-sucking type to conduct fixed-point fixed-zone dust removal on the large-space workshop, and the dust diffusion range of a dust source point is reduced. The mobile blowing-sucking type modular dust removal system can be matched with the dust removal amount to achieve modular production, when the dust removal devices are damaged or a filter device needs to be replaced, the whole can be replaced, modularized production is realized, the plant downtime is reduced, and theoccupational health of skilled workers is guaranteed.

Owner:DONGHUA UNIV

Intelligent and efficient dust collection workbench for grinding two ends of large workpiece

PendingCN113857955APlay a fixed roleAchieve effectivenessGrinding carriagesDispersed particle filtrationWorking environmentProcess engineering

An intelligent and efficient dust collection workbench for grinding the two ends of a large workpiece, comprising an operation area, a feeding area and a discharging area. The operation area is used for grinding the two ends of the workpiece; the feeding area and the discharging area are used for storing large work before and after grinding, respectively; a supporting platform for large workpieces is arranged in the middle of the workbench, and downward-concave L-shaped exhaust outlets are formed in the left side and the right side of the workbench; a L-shaped air outlet is connected with a dust collecting bin and used for collecting large-particle grinding dust; a rectification structure of an L-shaped air outlet is arranged in the workbench; the workbench is connected with a dust remover through an air pipe, and dusty gas is purified by the dust remover and then emptied; an infrared detector is arranged on the workbench, and intelligent control over air exhaust is achieved according to whether a worker is detected or not. The workbench can reduce the dust concentration of a respiratory zone of a worker to 0.4 mg / m3, and the dust collecting efficiency is 98.43%, so that the working environment is remarkably improved, and the occupational health of the worker is effectively guaranteed.

Owner:CHINA ACAD OF SAFETY SCI & TECH

Shallow-buried large-span water conveying tunnel three-stage five-step digging method

ActiveCN103174430BReduce security risksReduce construction costsUnderground chambersTunnel liningThree stageEngineering

The invention discloses a shallow-buried large-span water conveying tunnel three-stage five-step digging method which comprises the steps of 1) first-step digging, namely performing forepoling on an upper half tunnel, and digging an upper stage; 2) second-step digging, namely digging a pull trough in the middle of the tunnel; 3) third-step digging, namely digging and supporting the left wall of the tunnel; 4) fourth-step digging, namely digging and supporting the right wall of the tunnel; and 5) fifth-step digging, namely digging and supporting the edge wall of a lower stage. By adopting the digging method, region-by-region digging is effectively executed, overlapping of spaces and time of working procedures are fully used, the digging time periods of the working procedures are rationally used, and the deformation in the tunnel is reduced; and a lining can be quickly closed to form a ring. By adopting the digging method, the digging safety risk is effectively reduced, the digging working efficiency is improved, the digging and supporting closing time is shortened, and the deformation in the tunnel is effectively reduced.

Owner:SINOHYDRO BUREAU 14 CO LTD

Cleaning operating solution for stainless steel and iron member composite boards

The invention relates to a cleaning operating solution for stainless steel and iron member composite boards. The cleaning operating solution comprises following components by weight: 11%-17% of a polyoxyethylene alkyl ether, 0.5%-3% of an alkylphenol ethoxylate, 3%-7% of tartaric acid, 8%-13% of a corrosion inhibitor, 7%-13% of hexamethylenetetramine, 2%-8% of a metal complexing agent, 1%-2% of hydrochloric acid, 1%-3% of hydrofluoric acid, 1%-2% of sodium molybdate and 40%-60% of water. The cleaning operating solution is simple and safe to use, and is capable of achieving oil removal, rust removal, sinter removal, oxide-scale removal and dirt removal all at once. The cleaning operating solution has no harm to human bodies or pollution to the environment. The cleaning operating solution can be repeatedly used and added without the need of being heated, is free from irritating smells or harm when contacting skin, thus guaranteeing occupation health of operating workers. The cleaning operating solution is low-carbon, cost-saving and environmental-friendly.

Owner:SUZHOU YIFANG METAL SURFACE TREATMENT TECH

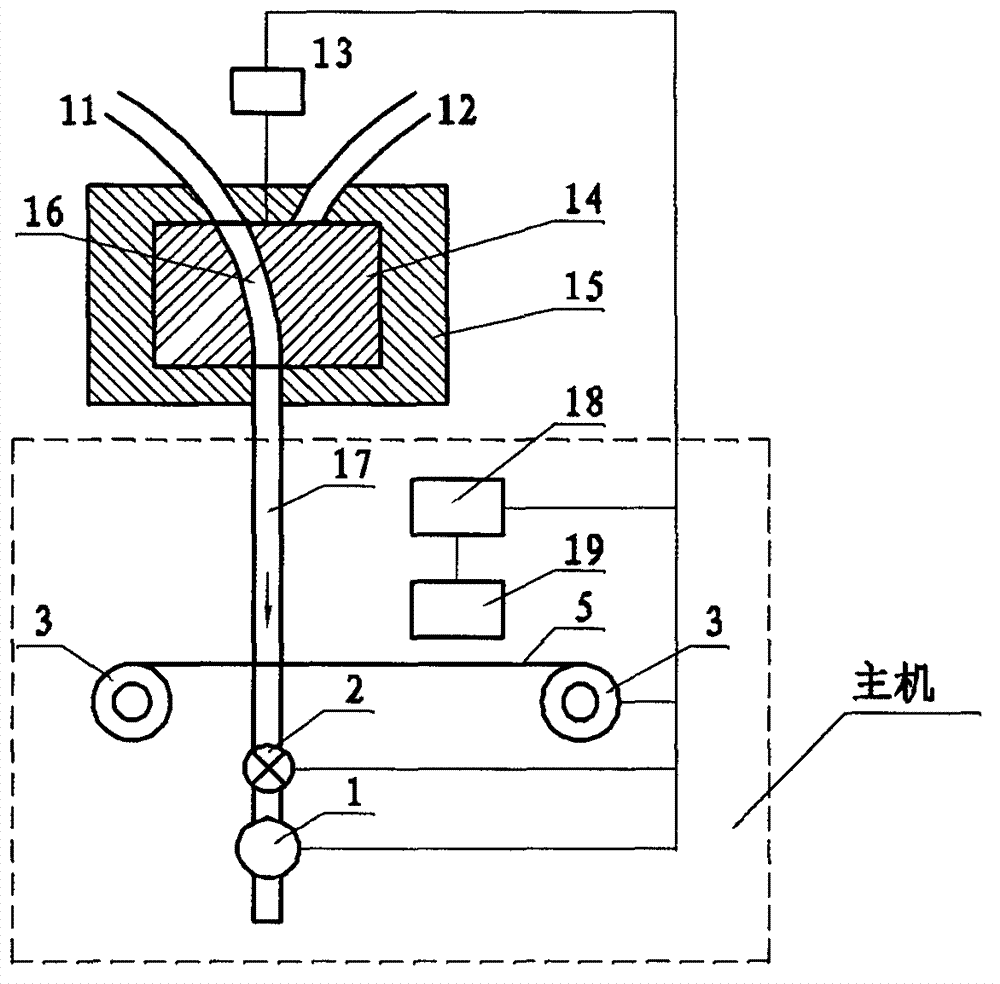

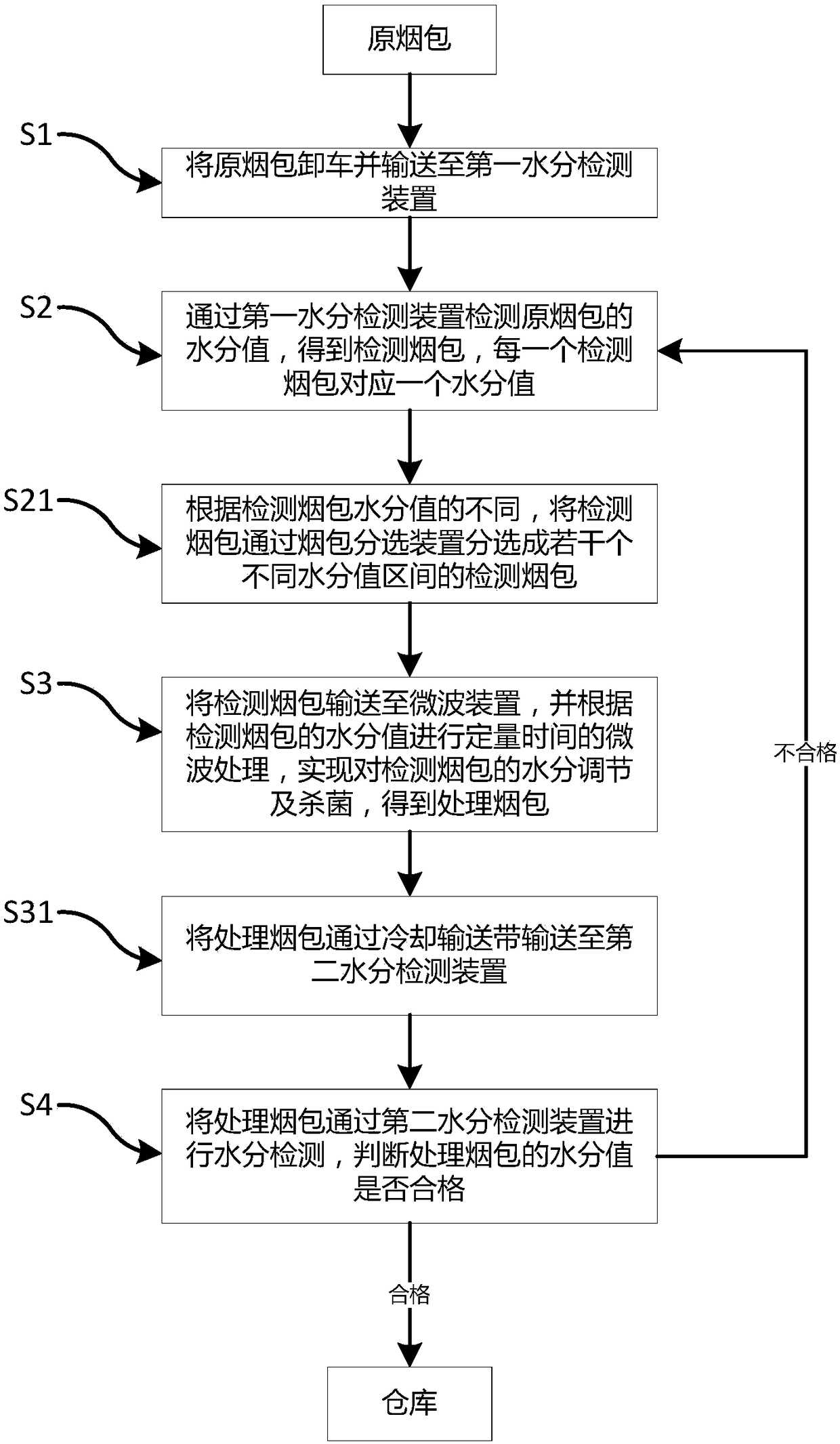

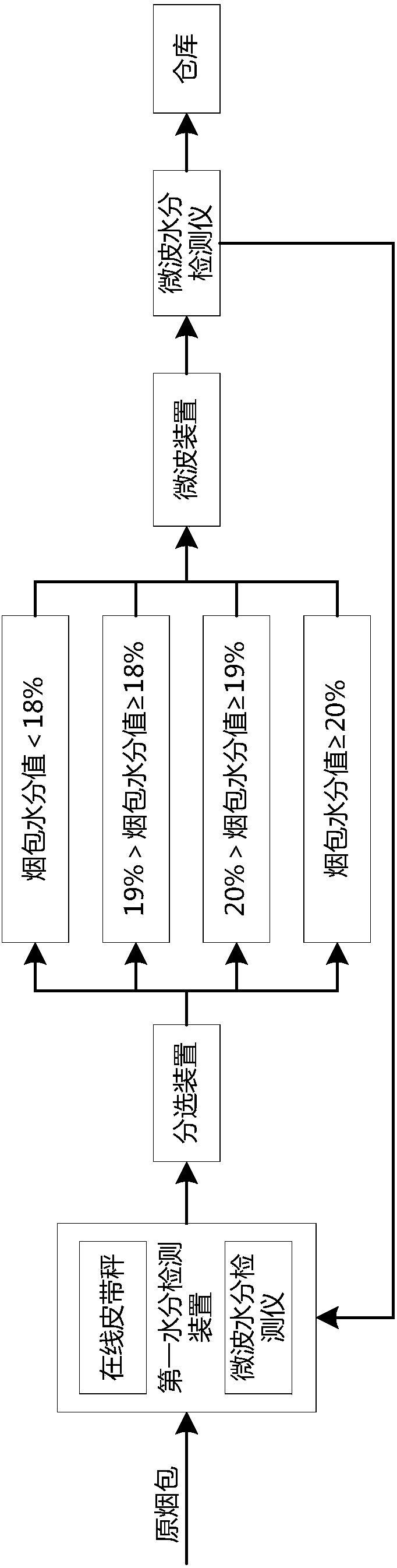

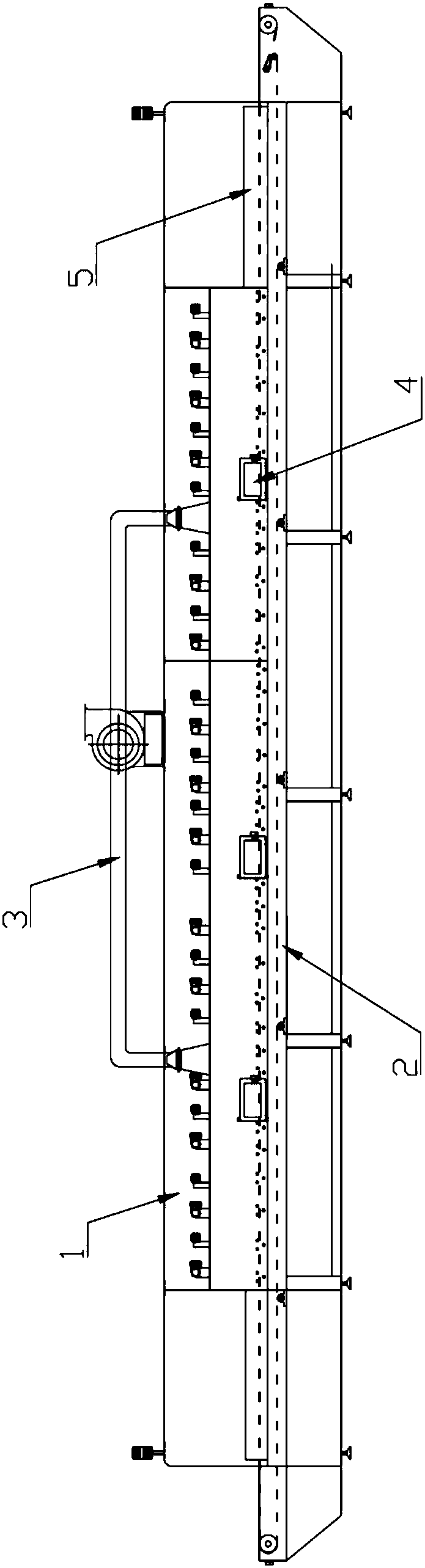

Method and apparatus for on-line sterilization and moisture adjustment of crude tobacco packers

InactiveCN108097602AMoisture adjustmentEffective adjustment of moisture valueDrying solid materials with heatSortingWorking environmentEconomic benefits

The invention discloses a method and an apparatus for on-line sterilization and moisture adjustment of crude tobacco packers. A moisture detection apparatus detects moisture value of the crude tobaccopackers, according to different moisture values of the detected crude tobacco packers, tobacco packers of different moisture value regions are sorted, tobacco packers of different moisture value regions are respectively treated by a microwave apparatus, in order to effectively adjust moisture of the tobacco packers; the moisture value contents of the tobacco packers accord with storage standards,and hand labor in subsequent processes is reduced; at the same time, the microwave apparatus also can be used for carrying out sterilization treatment, in order to inhibit insect pest generation of stored tobacco packers; microwave sterilization can replace medicament fumigating, in order to avoid damage of medicament on tobacco leaves and pollution of medicament on atmospheric environment, improve working environment of workers, and guarantee occupation health of workers. The apparatus has the advantages of reasonable structure, high automation degree, and good economic benefit; requirementson storage environment of the tobacco packers are substantially reduced, and the technical scheme can be used for effectively reducing cost of enterprise production, improving production environment,and improving production benefit.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

A kind of processing method of arsenic-alkali slag

ActiveCN107630142BSuitable for industrial mass productionSmooth circulationProcess efficiency improvementPregnant leach solutionEnvironmental engineering

Owner:HUNAN CHENZHOU MINING CO LTD

Method for removing sulfur trioxide in production of heavy alkyl benzene sulfonic acid

ActiveCN113004176AImprove qualityHigh deacidification efficiency and stabilityOrganic chemistryOrganic compound preparationEnvironmental engineeringSulfur trioxide

The invention discloses a method for removing sulfur trioxide in production of heavy alkyl benzene sulfonic acid, which comprises a removal device and a removal method, and the removal device comprises a first removal unit and a second removal unit which are separated by a separation plate, the first removal unit and the second removal unit are sequentially provided with a feed liquid distribution chamber, a Pall ring packing layer and a liquid storage chamber from top to bottom, an air inlet pipe with a downward pipe orifice is arranged at the upper part in the liquid storage chamber, a flow meter is arranged on the air inlet pipe, the air inlet pipe is connected with a waste heat air pipeline, an exhaust pipe is arranged at the top of the feed liquid distribution chamber, and the exhaust pipe is connected with a tail gas pipeline. According to the invention, the waste hot air which is uniformly distributed upwards is in full contact with the heavy alkyl benzene sulfonic acid feed liquid which is uniformly distributed downwards, and unreacted sulfur trioxide in the feed liquid is blown to the tail gas pipeline through the exhaust pipe, so that excessive sulfur trioxide can be effectively removed, the content of sulfuric acid in the product is controlled, the average deacidification rate is 86.8%, the deacidification efficiency is high and stable, and the quality of the heavy alkyl benzene sulfonic acid can be effectively improved.

Owner:甘肃森瀚石油科技有限公司

Crane single-beam walking wheel forging technology

The invention relates to a crane single-beam walking wheel forging technology. The forging technology comprises raw material ingredient inspection, raw material metallographic analysis, automatic discharging, automatic feeding, workblank heating, workblank automatic station transformation, first forging and pressing, second forging and pressing, center hole punching, center hole enlarging, mill groove forming, workpiece temperature control and cooling, station transformation, primary machining, digital machine tool finish machining, heat treatment and inspection warehousing. The crane single-beam walking wheel forging technology has the advantages that the quality is high, energy consumption is low, material loss is small, and production efficiency is high.

Owner:HENAN MINE CRANE +1

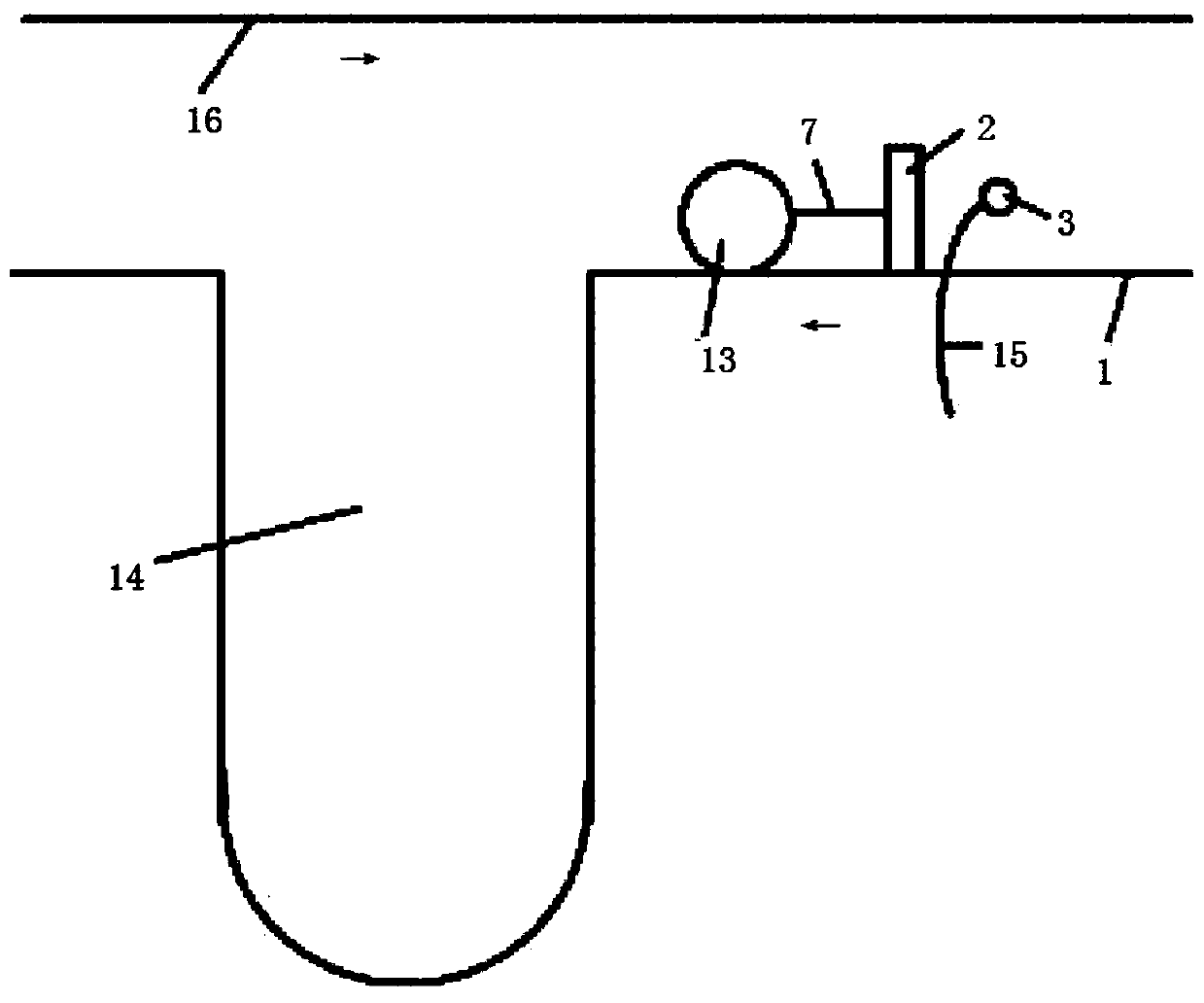

Low-moisture environment-friendly quenching car for small coke oven, and operation process thereof

The invention discloses a low-moisture environment-friendly quenching car for a small coke oven, and an operation process thereof. The coke quenching car comprises a cart, a coke quenching box, a water tank, a water feeding pipe, an atomizing nozzle, a dust removal cover, a dust removal hose, a water feeding pipe connector, a water feeding valve, a water valve switch, a positioning rod, a water feeding pipe water inlet positioning part, a water feeding pipe hose, a water discharging pipe water inlet positioning part, a water discharging pipe hose, a steam outlet, a water discharging valve, a water discharging pipe connector, a water discharging pipe and a water discharging hole, and the coke quenching box and the water tank are arranged on the cart side by side. According to the low-moisture environment-friendly quenching car for the small coke oven, a top quenching and bottom quenching combined wet quenching mode is adopted, the top quenching water amount and the bottom quenching water amount can be independently and accurately adjusted, the coke moisture can be more stably controlled while the quenching time is shortened, and the situation that local moisture is too high is avoided. Steam generated in the coke quenching process is introduced into water for purification and dust removal, the environment is not polluted, and the occupational health of operators can be guaranteed.

Owner:SHAGANG GROUP +1

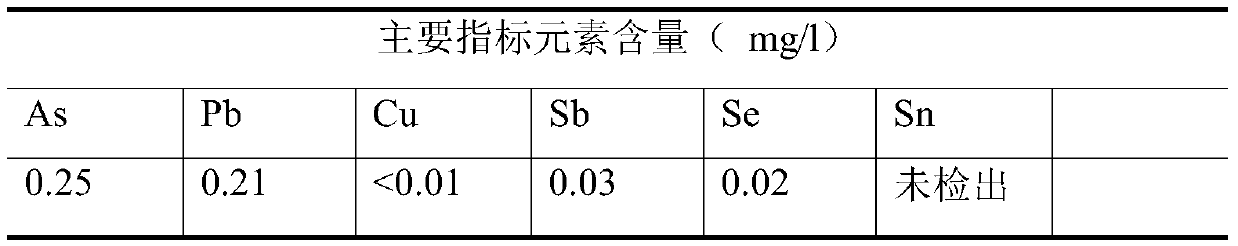

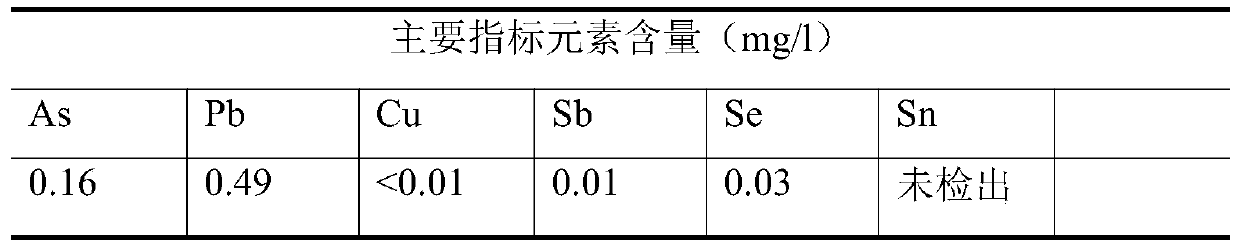

Treatment method for arsenic-alkali residue

ActiveCN107630142AReduce the ratioLow difficulty of solid-liquid separationProcess efficiency improvementPrecipitationAntimony

Provided is an arsenic-containing waste residue normal temperature wet method innocent treatment process. After arsenic-containing waste residue is subjected to wet type crushing, water is added to the arsenic-containing waste residue under the normal temperature condition to recycle metallic antimony in the arsenic-containing waste residue through solid-liquid separation, arsenic-rich leaching solutions after solid-liquid separation are subjected to arsenic precipitation with concentrated sulfuric acid, biological agents, hydrogen peroxide and lime milk, and up-to-standard discharge of wateris realized after dearsenification. Produced arsenic residue is made into a solidified body by adding crystallization agents to detoxify and then adding curing agents. The toxicity leaching test of the solidified body can reach the toxicity leaching requirement of general solid waste. The process can greatly reduce environmental pollution brought by accumulation of arsenic-containing waste residue, the comprehensive utilization rate of mineral resources is improved, and the recovery rate of valuable metal is high. After production practice of one year, the recovery rate of antimony is verifiedto be stably more than 90%.

Owner:HUNAN CHENZHOU MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com