Environment-friendly flame-retardant scaffold system

A scaffolding and flame-retardant technology, which is applied to scaffolding accessories, scaffolding connections, housing structure support, etc. performance, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

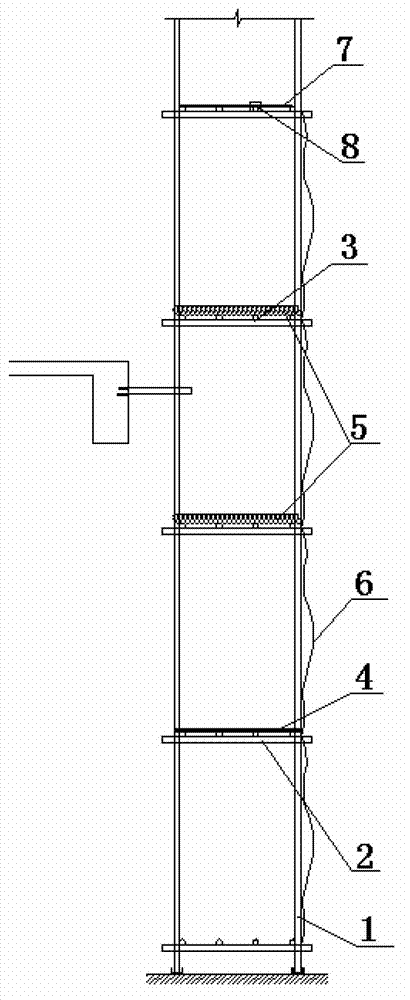

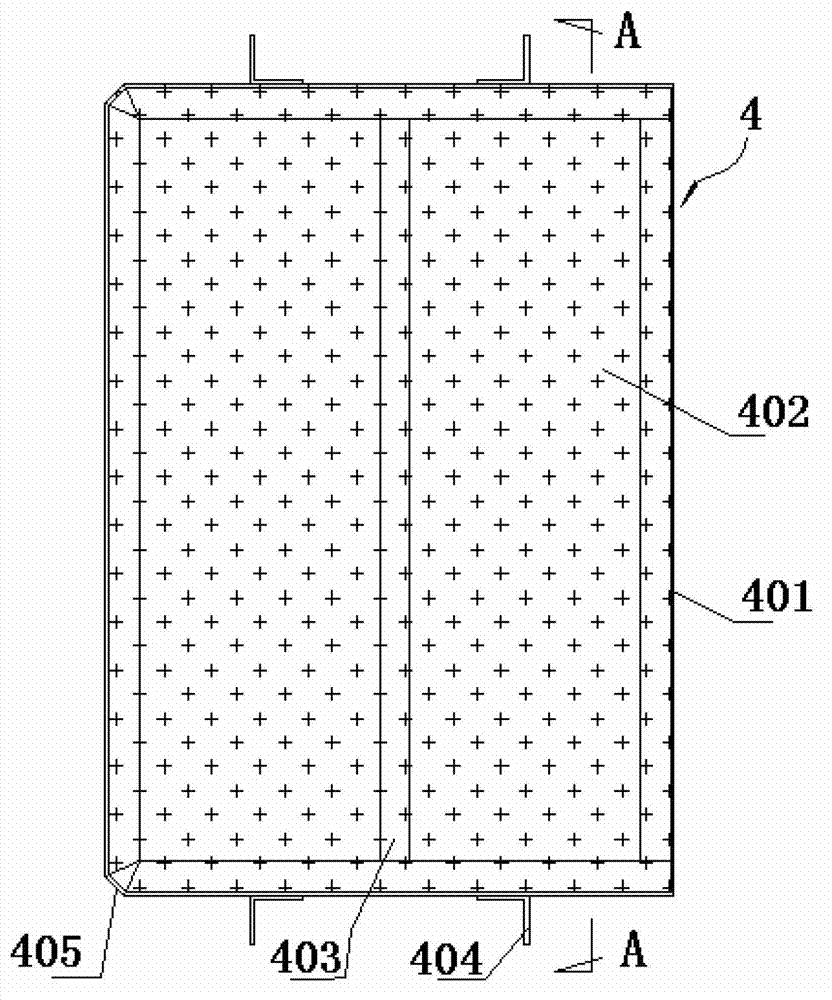

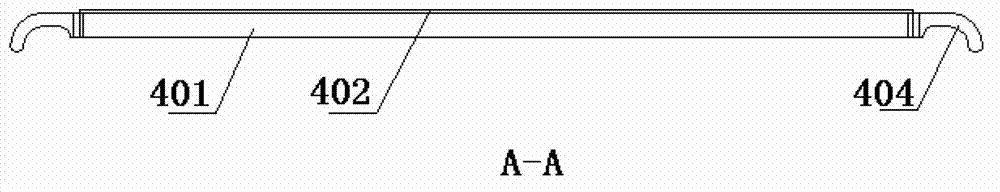

[0023] Such as figure 1 As shown, the environment-friendly flame-retardant scaffolding system of the present invention includes several rows of scaffolding boards, ramp scaffolding boards 9 and an open-hole dustproof safety net 6 arranged on one side of the scaffolding from bottom to top. The scaffolding is steel plate scaffolding 4, and the scaffolding takes three steps as a unit, one layer of expanded metal scaffolding combined with the second layer of traditional bamboo scaffolding, as shown in the figure, the second and third layers are bamboo scaffolding 5, the second The fourth floor adopts expanded metal scaffolding board 7 as the layered isolation of the scaffolding, the adjacent steel scaffolding boards 4 are connected by fixing parts 8, and the adjacent expanded metal scaffolding boards 7 are connected by fixing parts 8.

[0024] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com