Entry-free integral quick-release type box girder internal mold and mounting and dismounting method thereof

A quick-release, internal mold technology, used in bridges, bridge construction, mold auxiliary parts, etc., can solve the problems of harsh working environment, small box girder space, difficult assembly, etc., to improve the working environment, reduce the difficulty of assembly, Difficult to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

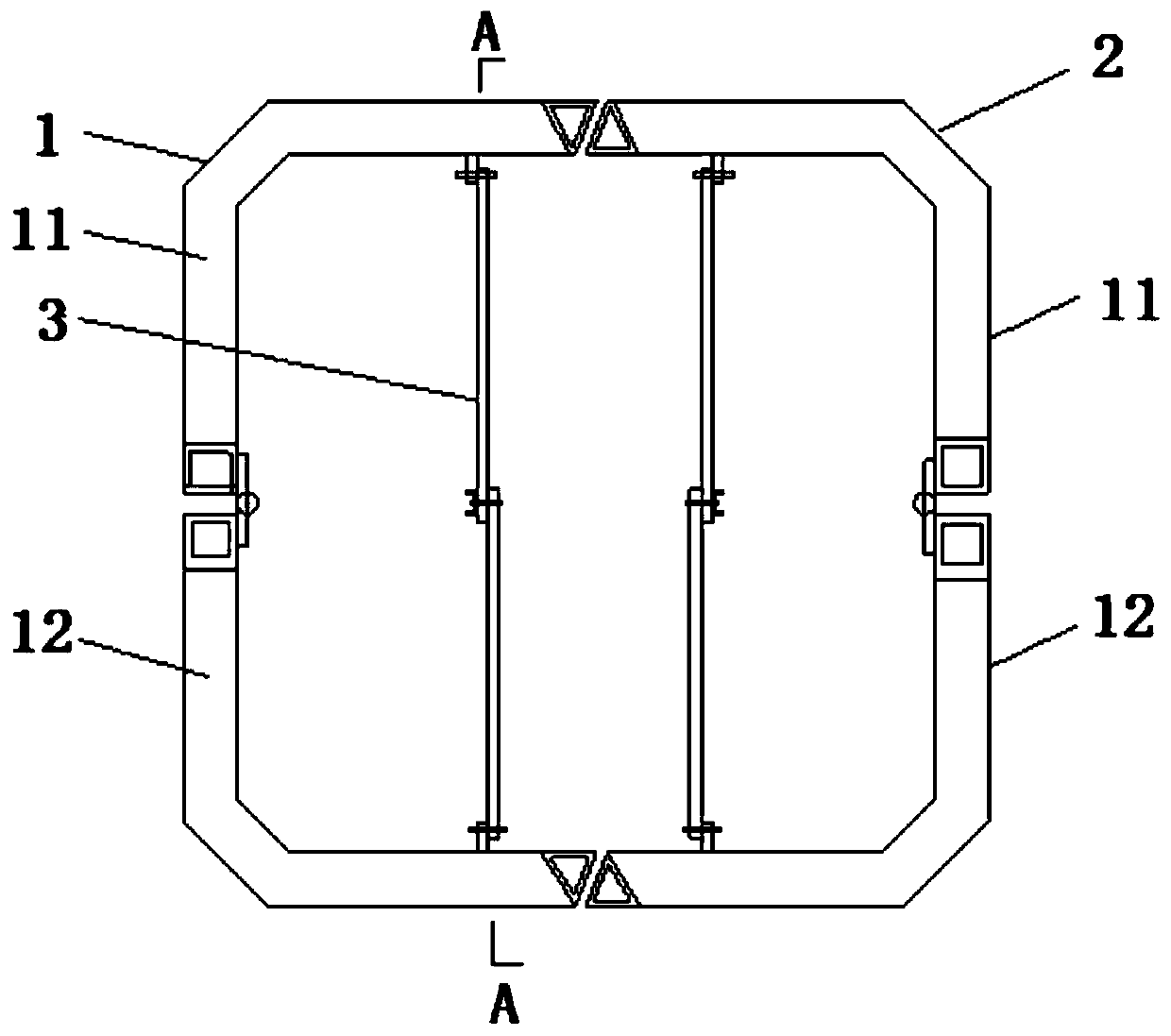

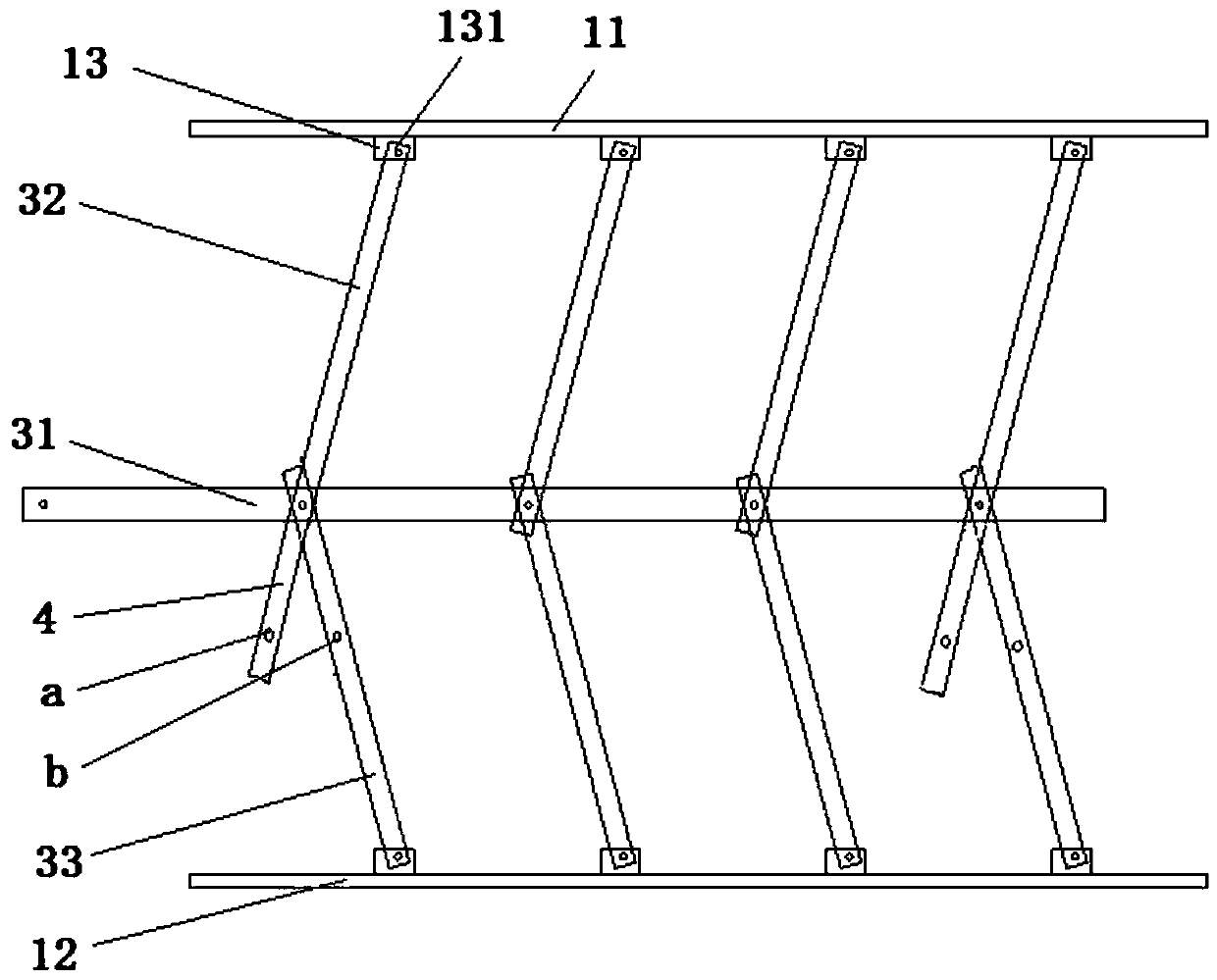

[0031] Such as figure 1 , figure 2 Shown: a box girder inner form that is free from entry and integral quick release, including a left inner form panel 1, a right inner form panel 2 and an inner form support device 3 arranged in the left and right inner form panels 1 and 2, the left inner form The mold panel 1 and the right inner mold panel 2 are respectively composed of an upper inner template 11 and a lower inner template 12 hinged to each other, and the hinges are connected by hinges. Strut 33, tie rod 31 are placed horizontally, one end of upper support rod 32 is hinged with upper inner formwork 11, the other end is hinged with pull rod 31, one end of lower support rod 33 is hinged with lower inner formwork 12, and the other end is hinged with pull bar 31. The joints of the upper and lower struts 32 and 33 are movable structures, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com