Dust falling device and method for heading face

A technology of tunneling face and dust suppression device, which is applied in safety devices, mining devices, dust prevention, etc., can solve the problem of unsatisfactory dust removal effect, and achieve the effect of air volume balance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

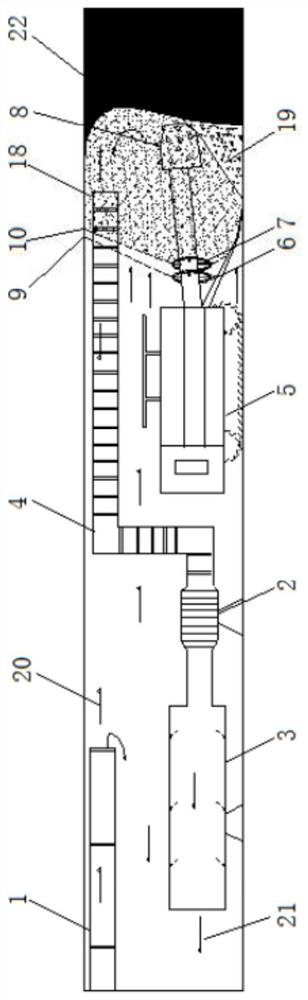

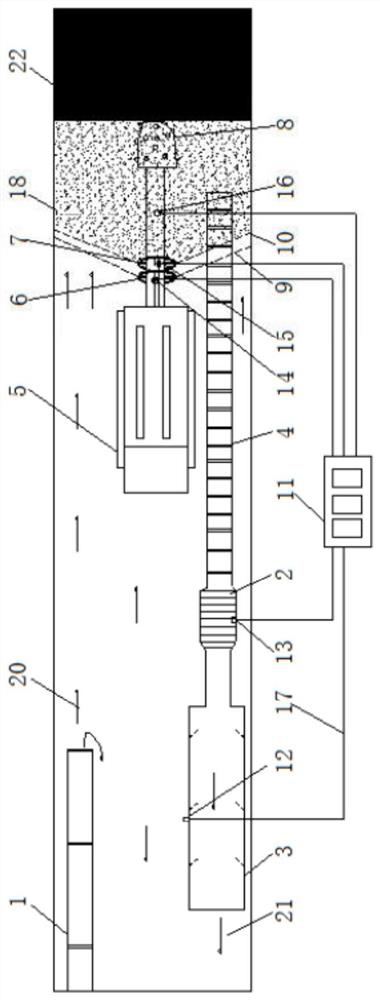

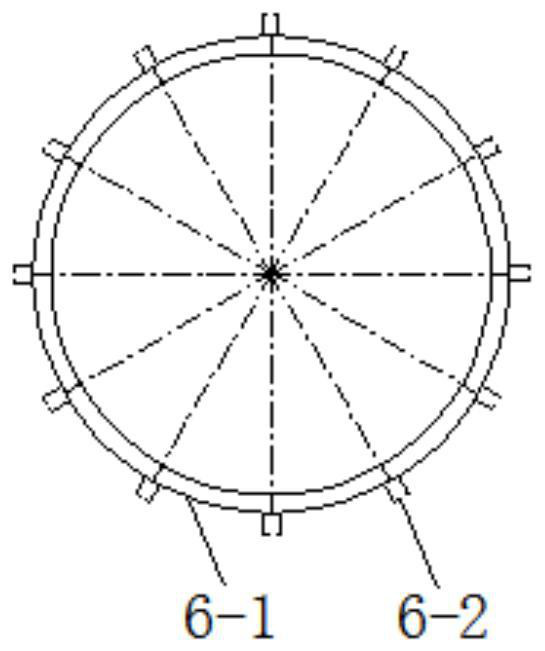

[0034] Such as Figure 1-Figure 4 As shown, the present embodiment proposes a dust suppression device for the excavation working face, which is arranged in the underground roadway and includes a roadheader 5, which drives the rotary head 8 of the roadheader to rotate through the drill pipe; the spray device 7 is arranged on the drill pipe At a position between 81.5m and 2m away from the rotary head of the driving roadheader, the spray device 7 is used to spray umbrella-shaped water mist to the rotary head 8 of the driving roadheader and the excavation work surface (in the direction of the solid coal 22), and at the same time form a spray range The outer contour line 10; the compressed air injection device 6 is arranged on the drill pipe and is located at 0.1m-0.3m behind the spray device 7, and the compressed air injection device 6 is used to spray the umbrella to the rotary head 8 of the driving roadheader and the excavation working face Shaped pressure gas, to improve the co...

Embodiment 2

[0048] The dust reduction method for the tunneling face in this embodiment uses the dust suppression device for the tunneling face as proposed in Embodiment 1. When the roadheader 5 is working, the amount of dust in the roadway increases, and the dust sensor 16 on the mechanical arm of the roadheader 5 monitors the dust. When the content exceeds the critical value, the dust sensor 16 sends a point signal to the central control box 11, and the central control box 11 sends an instruction to open the air curtain electromagnetic switch 14, the water curtain electromagnetic switch 15 and the dust removal fan 2; after the air curtain electromagnetic switch 15 is opened, The barrier formed by the Fengshui curtain limits the diffusion range of dust to a small range close to the excavation work face. Part of the large particle dust is captured by the water curtain, and the small particle dust is intercepted by the air curtain. The dust wind flows through the steel skeleton negative press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com