Construction method of deep burying center ditch for tunnel in extremely cold region

A central water ditch and construction method technology, applied in tunnels, tunnel linings, drainage and other directions, can solve the problems of difficult construction organization, slow construction progress, and large disturbance of surrounding rock, so as to shorten the blasting throwing distance, ensure construction quality, shorten the The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

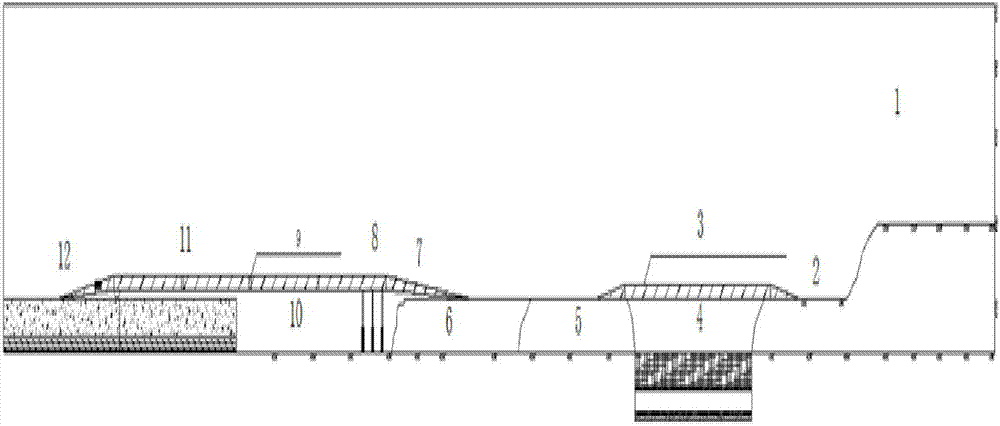

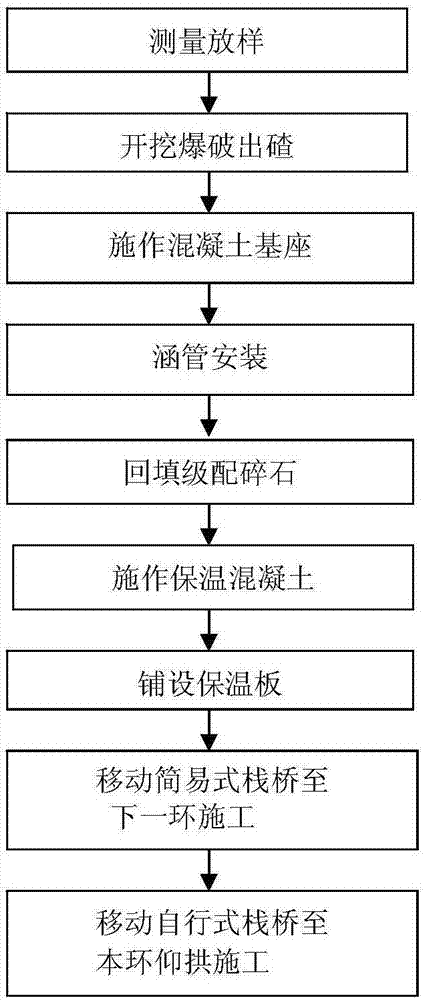

[0032] The specific embodiment of the present invention: a deep buried center ditch of a tunnel in a severe cold area adopts nine steps (see figure 2 ) (nine steps) for construction. Before construction, excavate the working face to the top of the inverted arch, and then use the simple inverted arch trestle and self-propelled inverted arch trestle to carry out the deep-buried central ditch and the inverted arch framing operation (see figure 1 ), including the following steps:

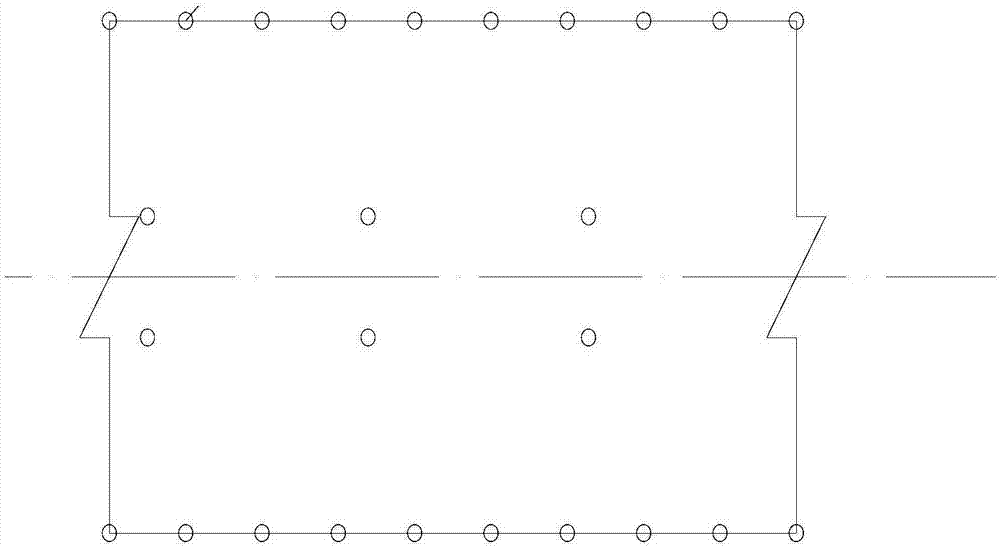

[0033] Step 1. Excavation and blasting: use hole-controlled blasting construction (see image 3 ), vertical deep hole blasting, layered blasting excavation, water ditch blastholes are all inclined to the outside of the hole, and the unit consumption of explosives is 0.6kg / m 3 Control, the blasting area is 4.4m 2 . For each cycle of 4m, the excavation dosage is 11.56kg. Charge 0.15kg in a single hole on both sides, and charge 1.2kg in a single hole in two rows of holes in the middle.

[0034] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com