Shallow-buried large-span water conveying tunnel three-stage five-step digging method

A technology for excavating water conveyance tunnels and benches, which is applied to tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve the problems of prominent construction safety risks, long excavation cycle period, and small excavation forming cross-sections, so as to improve the excavation performance. Cycle time, safeguarding safety and occupational health, reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

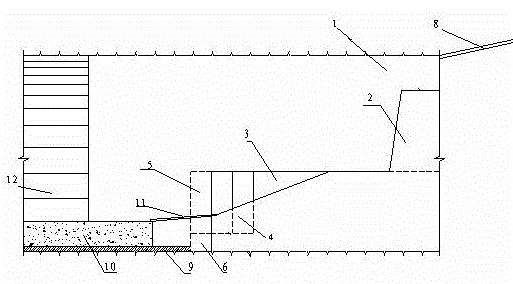

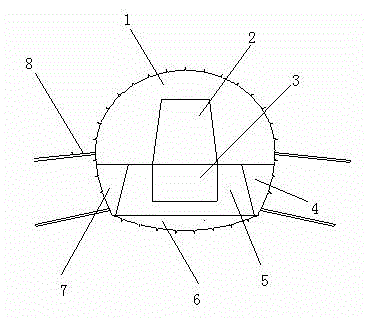

[0019] Three-step five-step excavation method of the present invention is carried out according to the following steps:

[0020] 1) One-step excavation (1 in the illustration): advance support of the upper half of the hole, and excavation of the upper steps: excavate along the tunnel design contour line with the excavator, reserve the core soil 2, and spray concrete on the excavation surface Close, erect the steel arch frame, place concrete prefabricated blocks at the foot of the arch frame, lay steel mesh sheets, install locking foot anchor pipes, and spray concrete to the design thickness;

[0021] 2) Two-step excavation: Excavation of channel 3 in the middle of the tunnel to ensure excavation of slag and traffic at the upper steps, excavation of the central channel into a descending slope, and reserve soil for the side walls on both sides;

[0022] 3) Three-step excavation: Excavation of the left wall 7 of the tunnel, and then the steel grid of the side wall is firmly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com