Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Good process continuity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Instant green tea powder processing method

The invention relates to an instant green tea powder processing method which comprises the following steps of: killing out fresh tea leaves by adopting a vacuum microwave method, carrying out superfine grinding after deep freezing, extracting and superfinely filtering by adopting secondary vacuum ultrasonic wave, and freezing and drying to obtain the instant green tea powder. The killing, extraction and drying steps are completed under a vacuum condition, and the action temperature is low, so that the oxidation of effective ingredients in fresh tea leaves can be effectively avoided; and vacuum ultrasonic extraction after freezing and superfine grinding ensures the full leaching of the effective ingredients. The product produced by the processing method has the advantages of high production efficiency, good product color, fresh taste, good dissolvability, incapability of generating tea cream and the like.

Owner:HEBEI STRONG FOOD

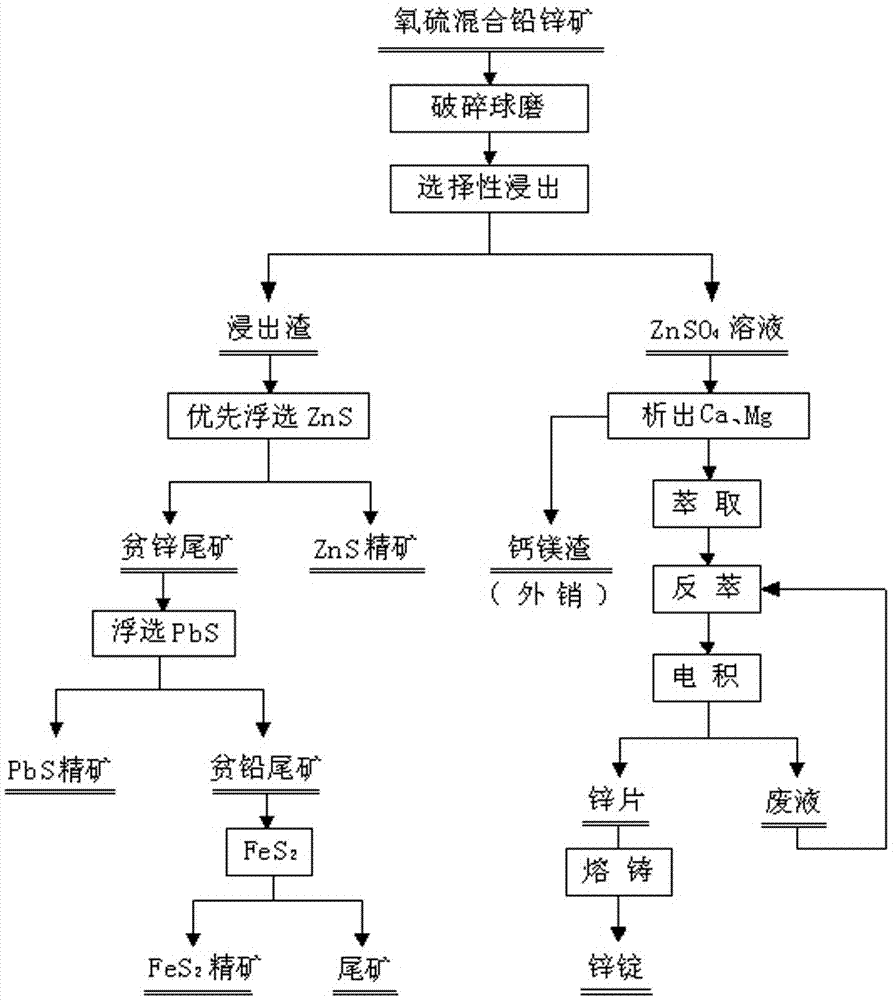

Selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process

ActiveCN103301929AReduce calcium concentrationHarm reductionFlotationWet separationOxygenTotal recovery

The invention discloses a selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process. For oxygen and sulfide mixed lead zinc ore, a zinc wet-method smelting process and a zinc flotation process are combined, zinc oxide in the ore is partially and selectively leached out by the first wet-method smelting process, and then zinc sulfide in the ore is floated out by the flotation process. In order to overcome the difficulty in treating the oxygen and sulfide mixed lead zinc ore, the invention provides the smelting and selection combining process which is short in process flow, reliable in technology, easy to operate and control, relatively low in material consumption and energy consumption for production, high in metal reclaiming efficiency, relatively good in economic benefit and high in practicability, the recovery of lead and zinc in the low-grade complex difficultly-selected oxygen and sulfide mixed lead zinc ore can be greatly improved, and the total recovery of lead and zinc can be up to over 90 percent.

Owner:云南金鼎锌业有限公司

Heat treatment method for steel pieces

InactiveCN101994118AImprove the level ofHigh surface hardnessSolid state diffusion coatingChemical treatmentHigh surface

The invention discloses a heat treatment method for steel pieces, and relates to improvement of a heat treatment method for surfaces of steel pieces. The heat treatment method makes the steel pieces improve the depth of an austenite nitriding / carbonitriding layer and reduce deformation, integrates and fully exerts the advantages of various processes, and overcomes respective disadvantages to complement one another so as to achieve excellent comprehensive usability. In the treatment method for compounding chemical heat treatment (such as carburizing or carbonitriding) and austenite nitriding or austenite carbonitriding technology, a workpiece is heated to be in an austenite state for carburizing or carbonitriding, a preset layer is obtained, and the temperature in the same furnace is reduced to the austenite nitriding temperature between 620 and 720 DEG C for nitriding or carbonitriding treatment, so that the nitrogen concentration on the surface of the workpiece reaches the nitrogen concentration of austenite and the level of the austenite nitriding layer is improved; and the workpiece is directly quenched and aged or directly subjected to isothermal quenching, so that the high-nitrogen austenite is decomposed and high surface hardness and wear resistance are achieved.

Owner:顾安民

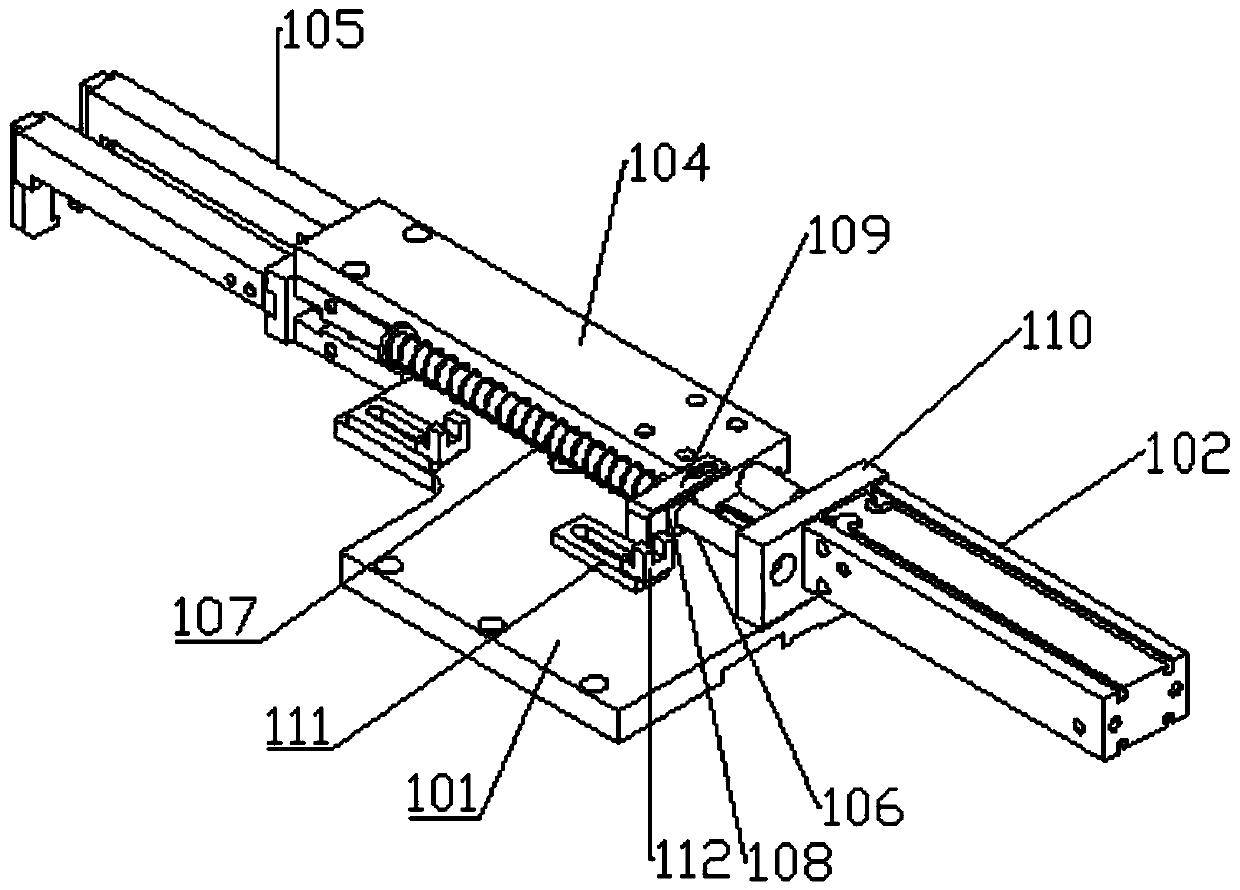

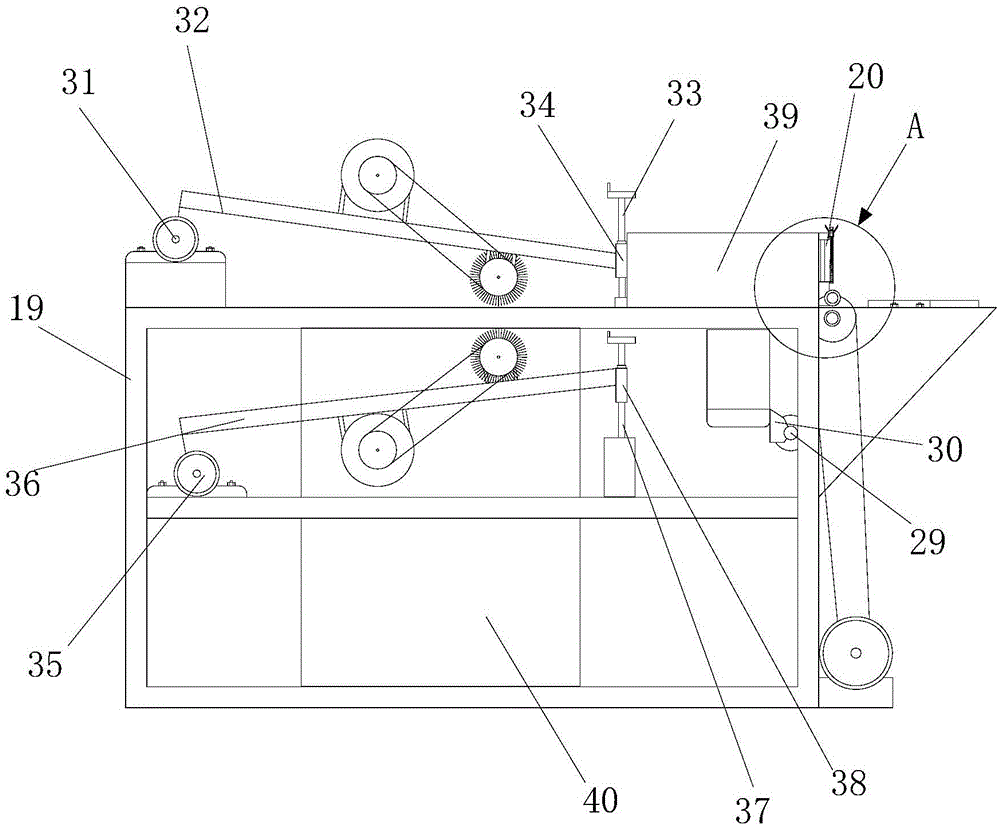

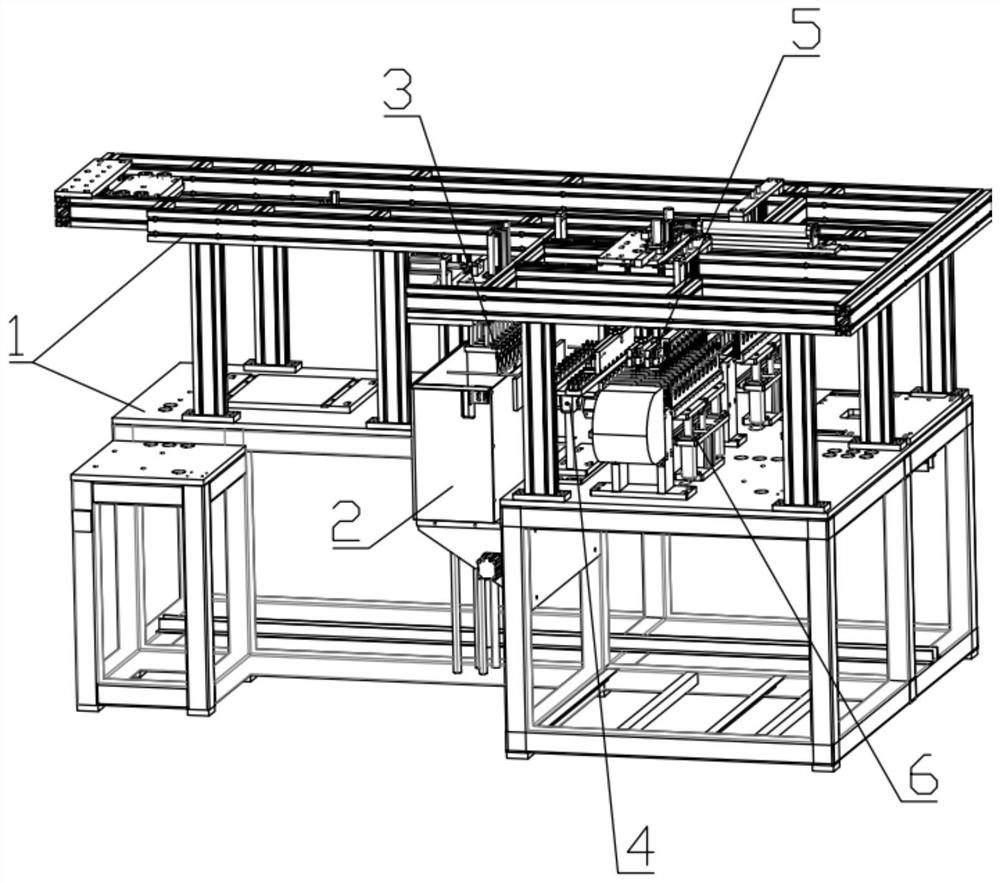

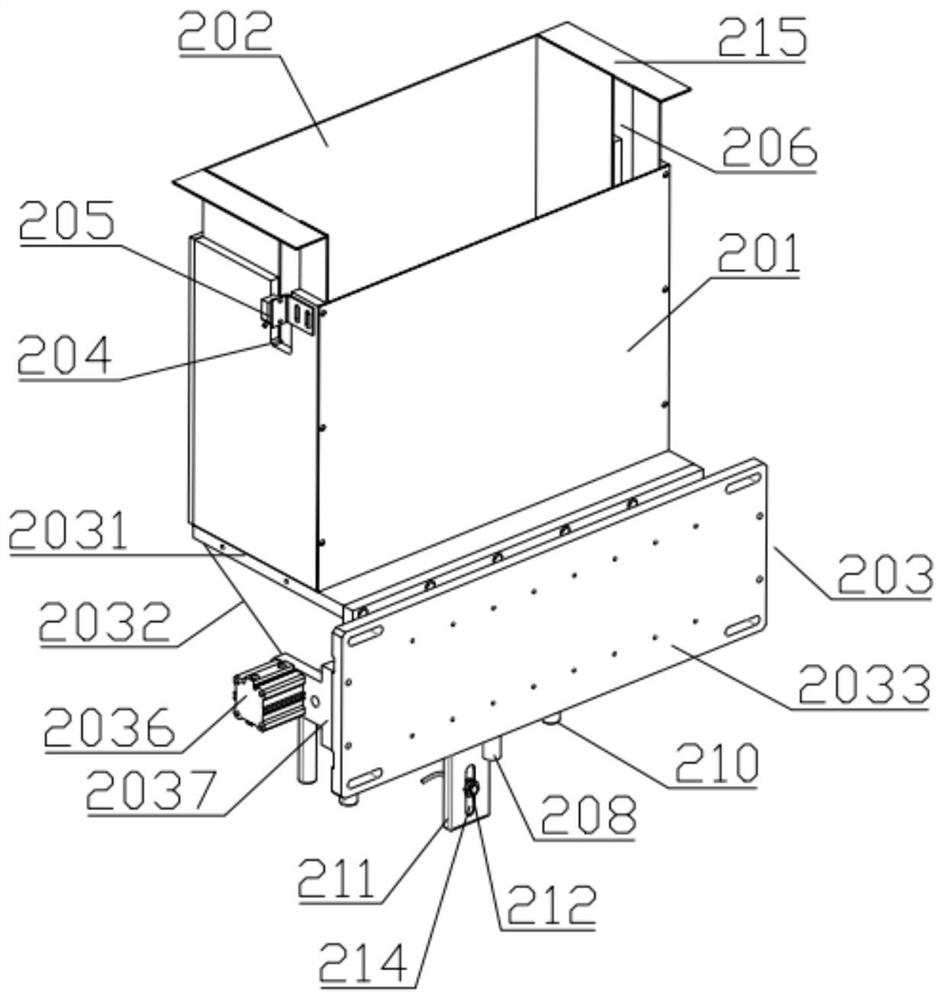

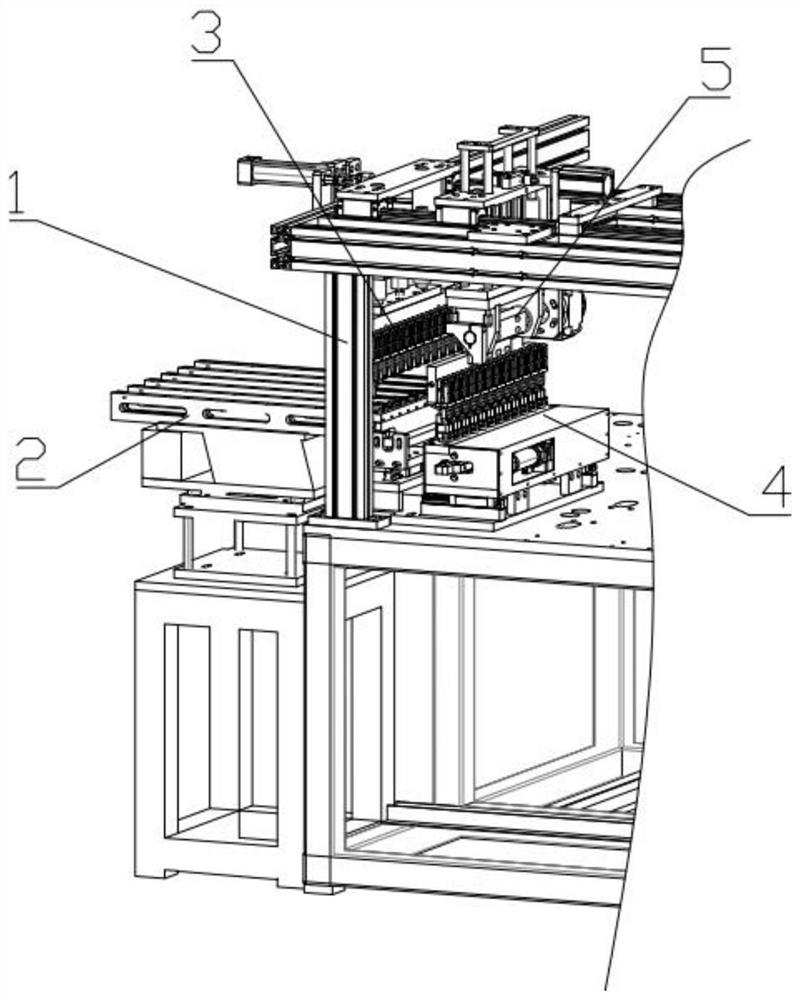

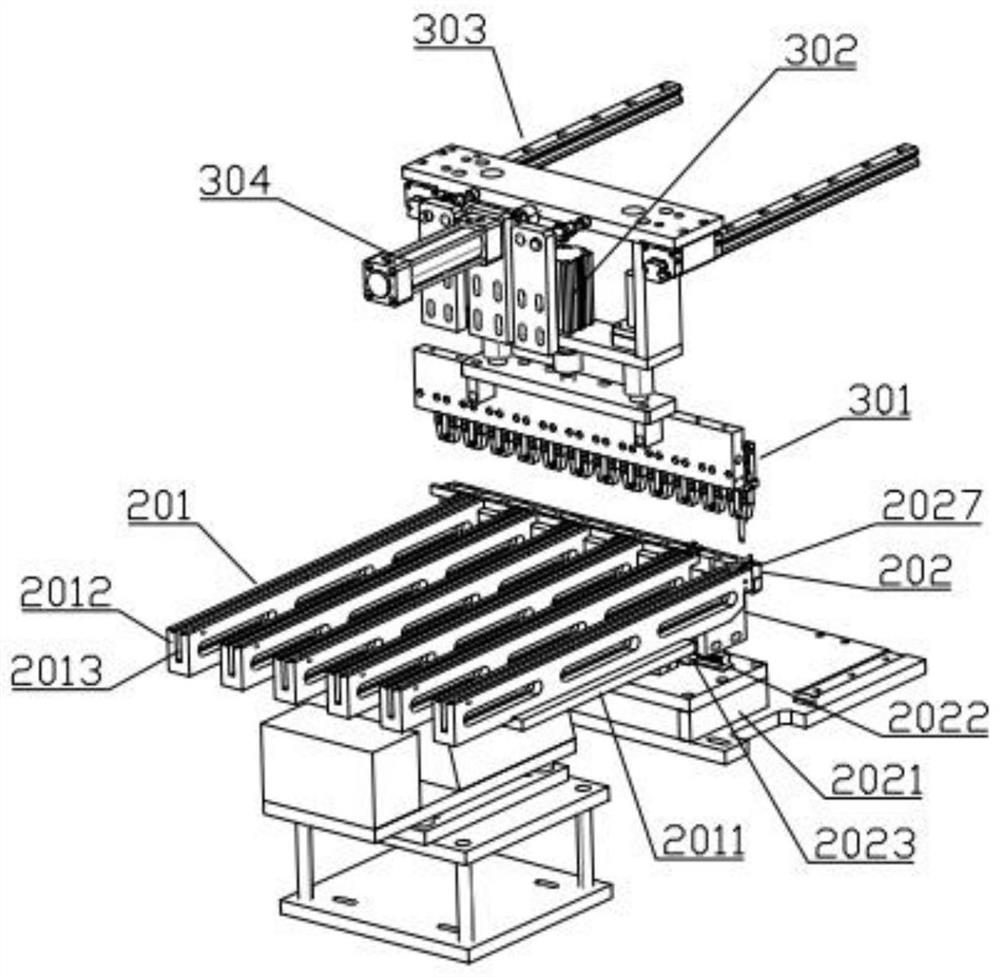

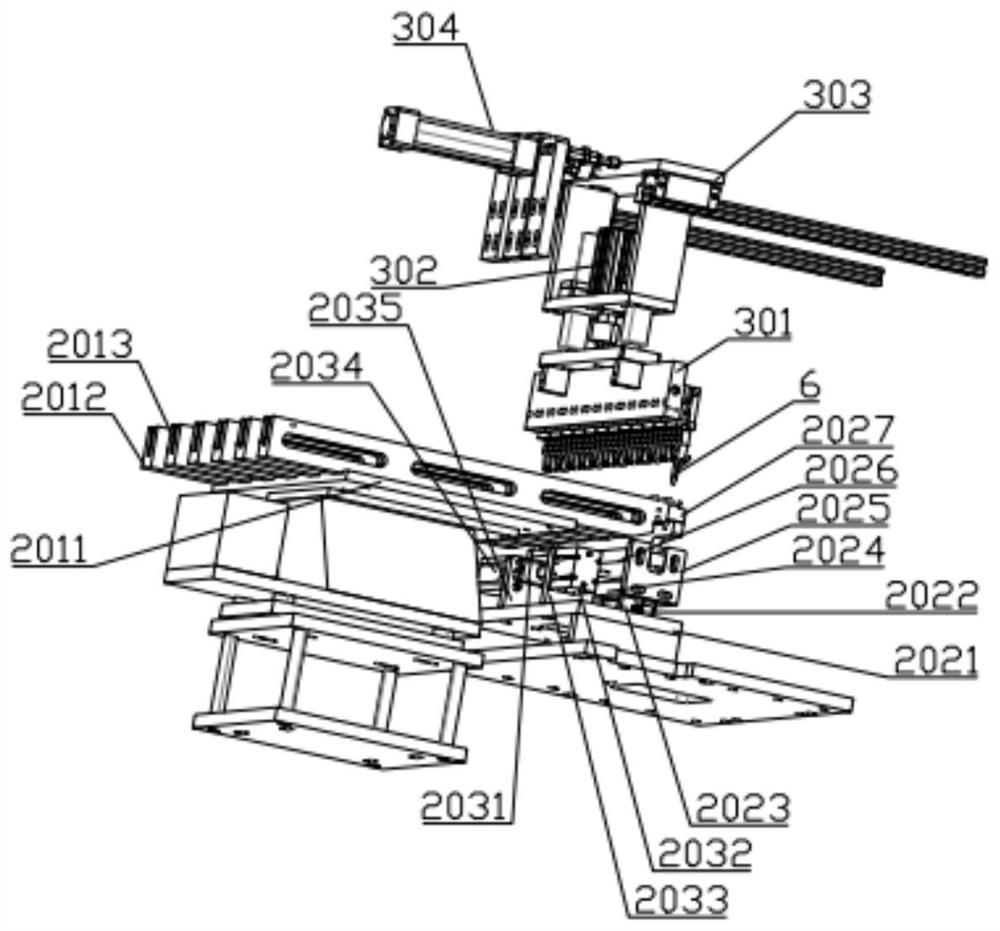

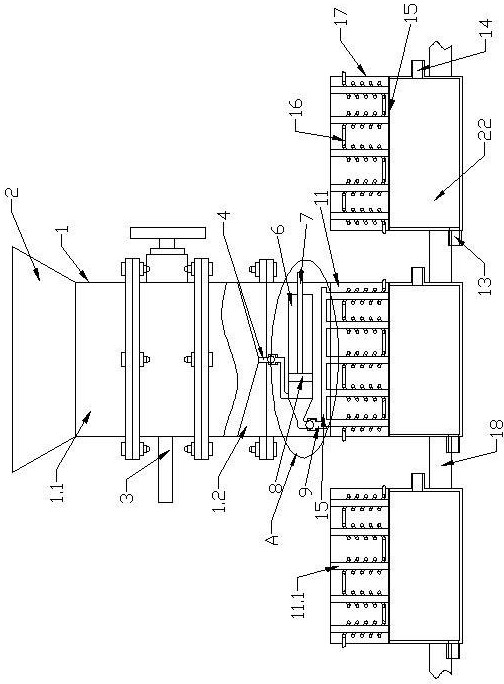

Automatic infusion apparatus packaging production line

PendingCN111717469AEvenly loadedNeatly coiledWrapper twisting/gatheringIndividual articlesInfusion setProcess engineering

The invention relates to the technical field of packaging equipment, in particular to an automatic infusion apparatus packaging production line. The automatic infusion apparatus packaging production line comprises automatic packaging bag feeding and position correcting equipment, automatic packaging bag transferring and opening equipment, automatic packaging bag taking, winding and bagging equipment and automatic packaging bag sealing equipment; the automatic feeding and position correcting equipment is arranged in front of the automatic packaging bag transferring and opening equipment in theX-axis direction; the automatic packaging bag taking, winding and bagging equipment is arranged behind the automatic packaging bag transferring and opening equipment in the X-axis direction; and the automatic packaging bag sealing equipment is arranged on one side of the automatic packaging bag transferring and opening equipment in the Y-axis direction. The automatic infusion apparatus packaging production line is reasonable in overall structure arrangement, high in structural operation relation continuity, high in process continuity, high in automation degree, high in packaging efficiency andhigh in packaging success rate.

Owner:YANTAI KAIBO AUTOMATION TECH

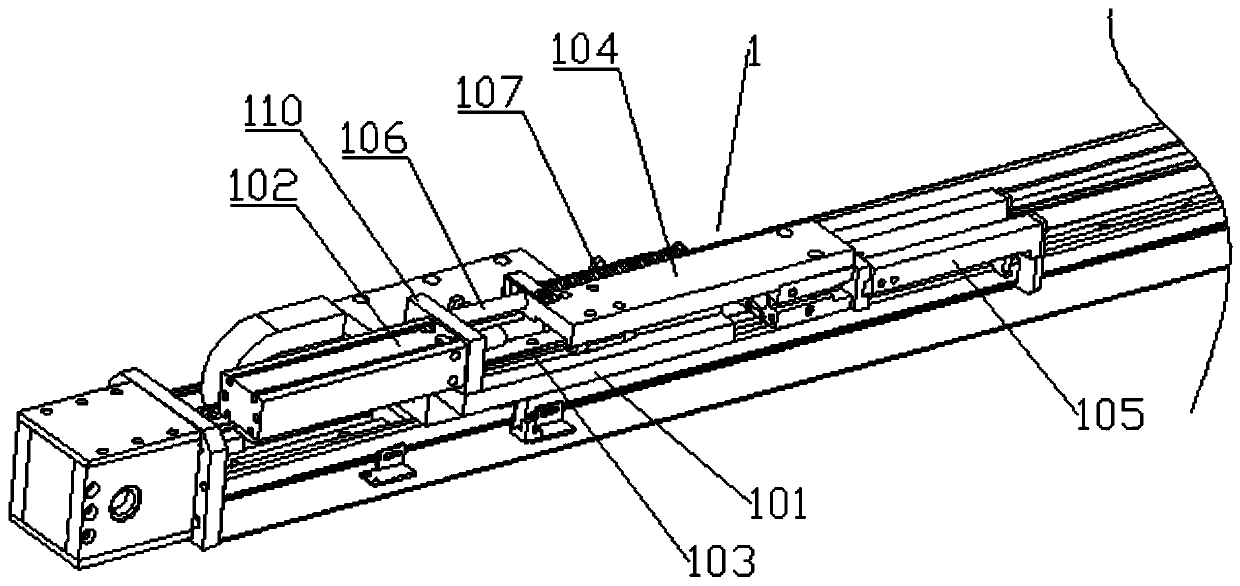

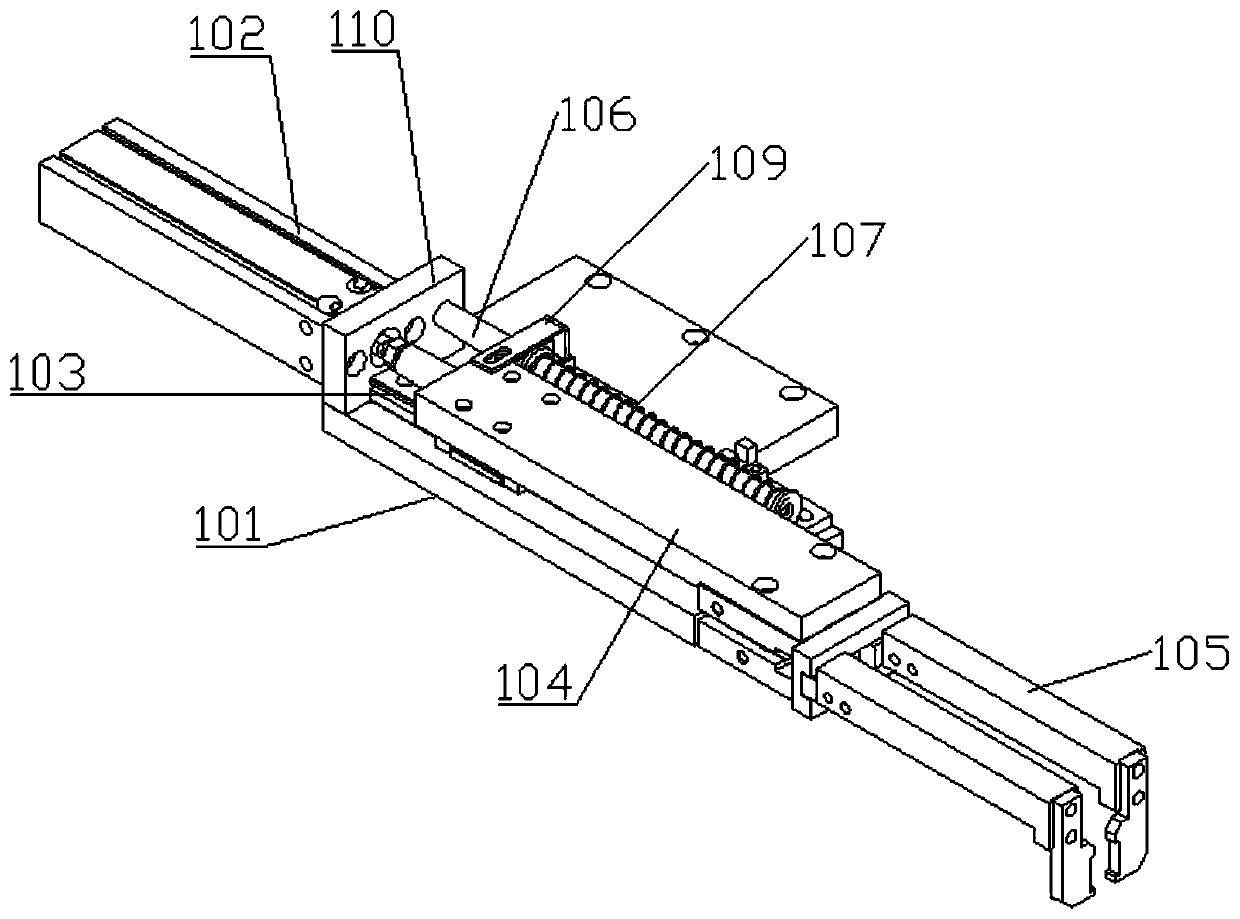

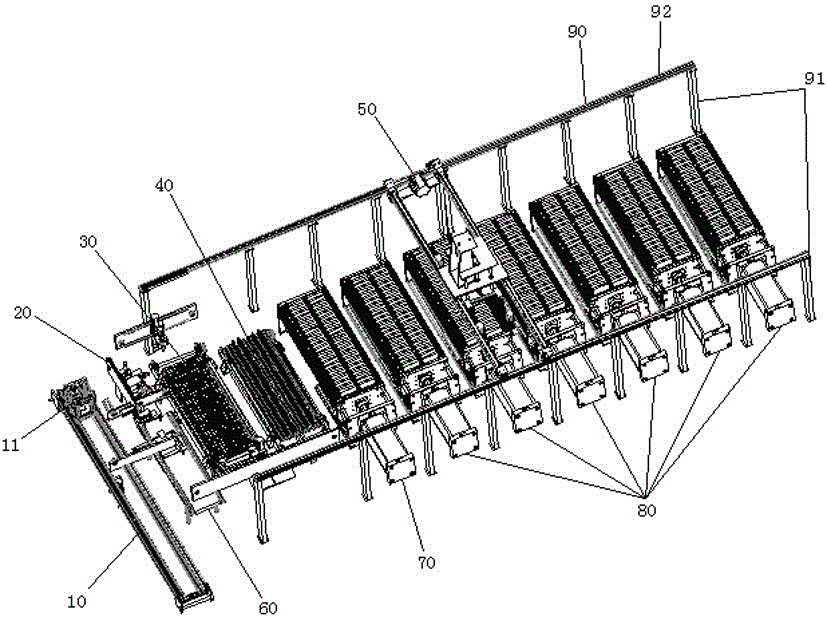

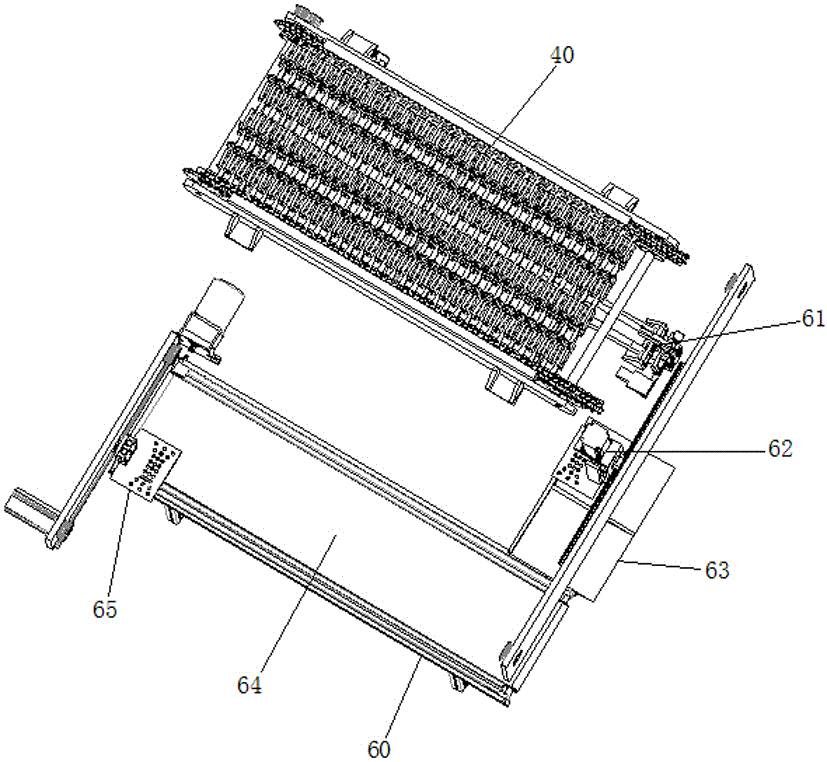

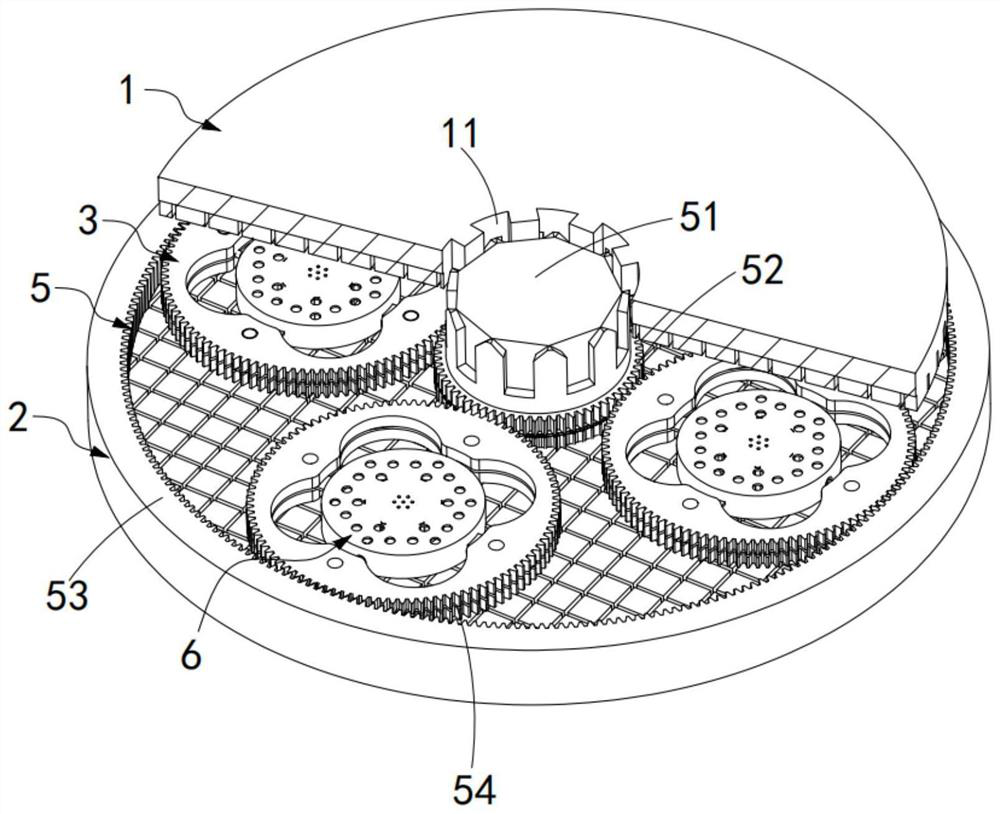

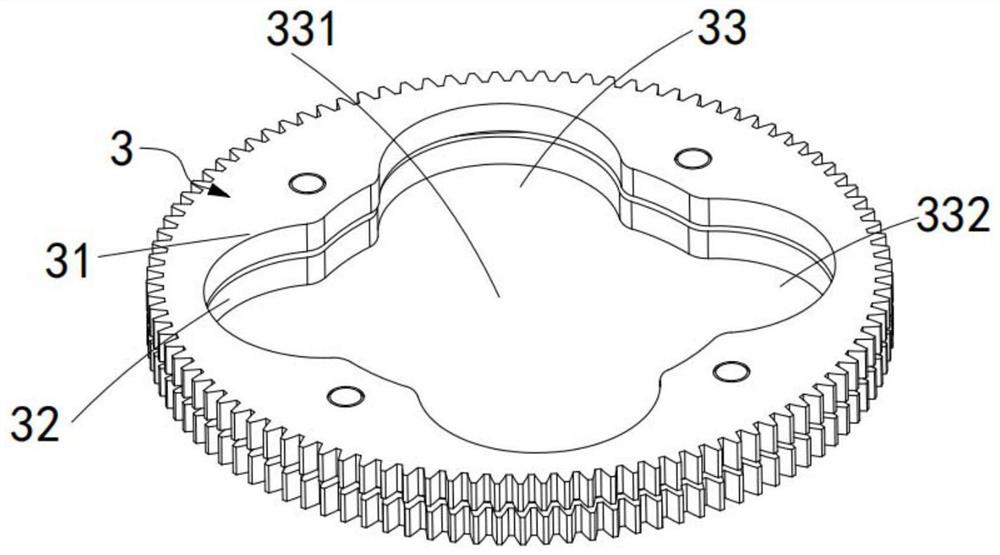

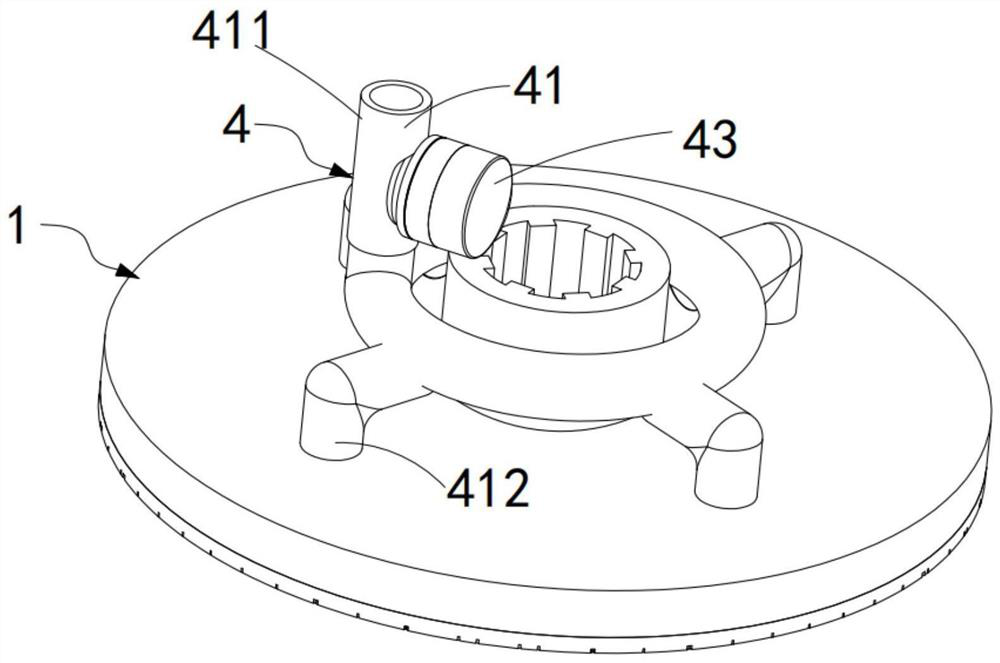

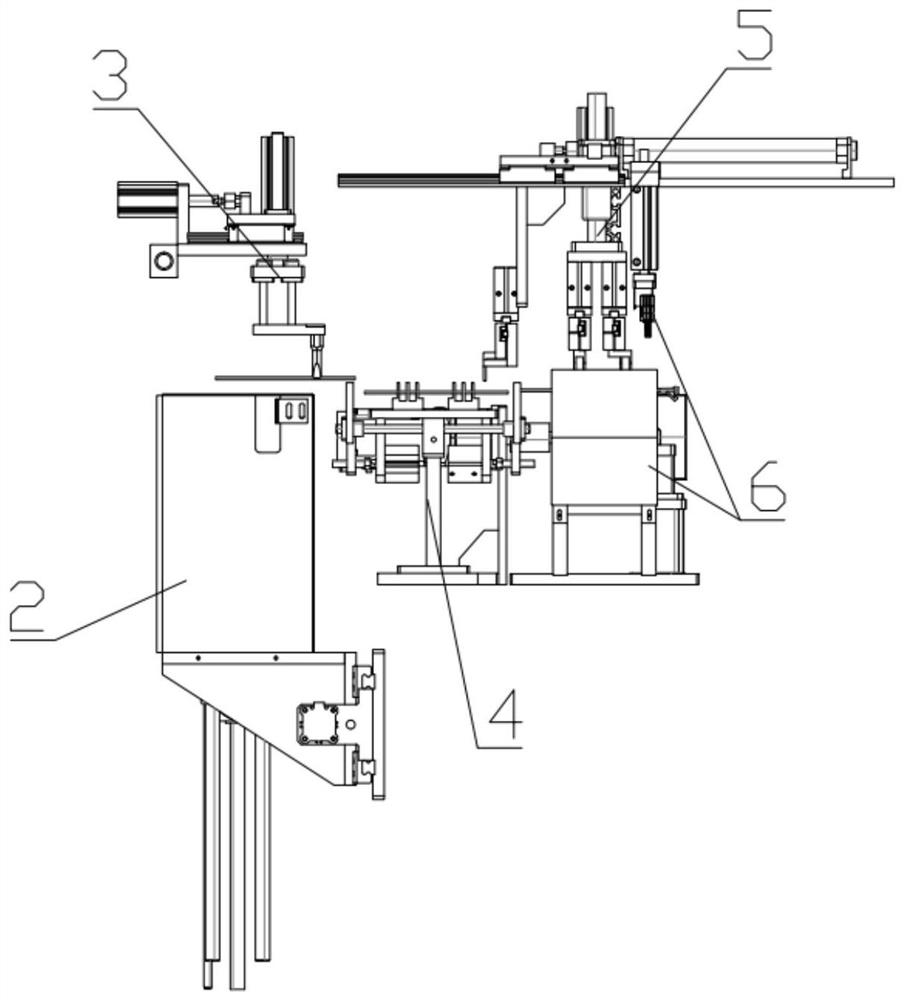

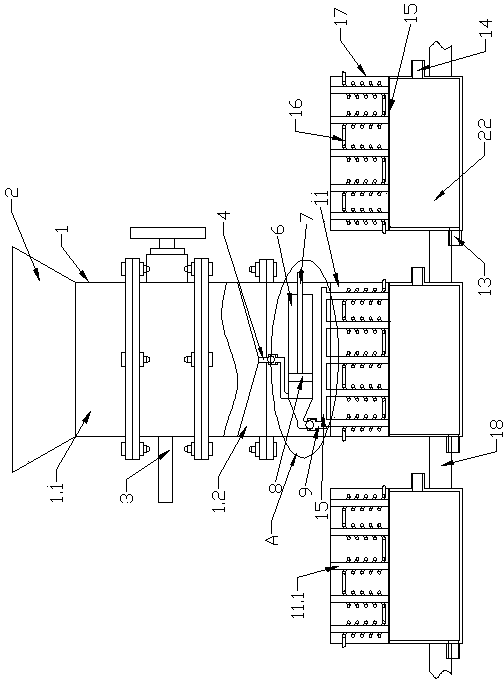

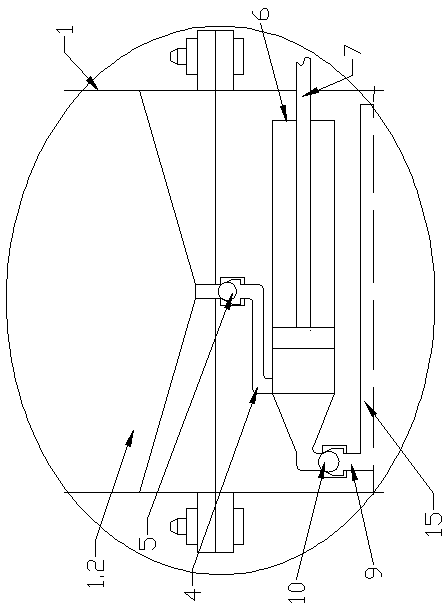

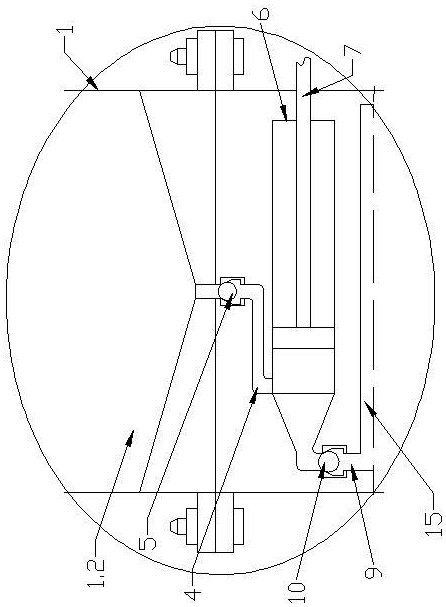

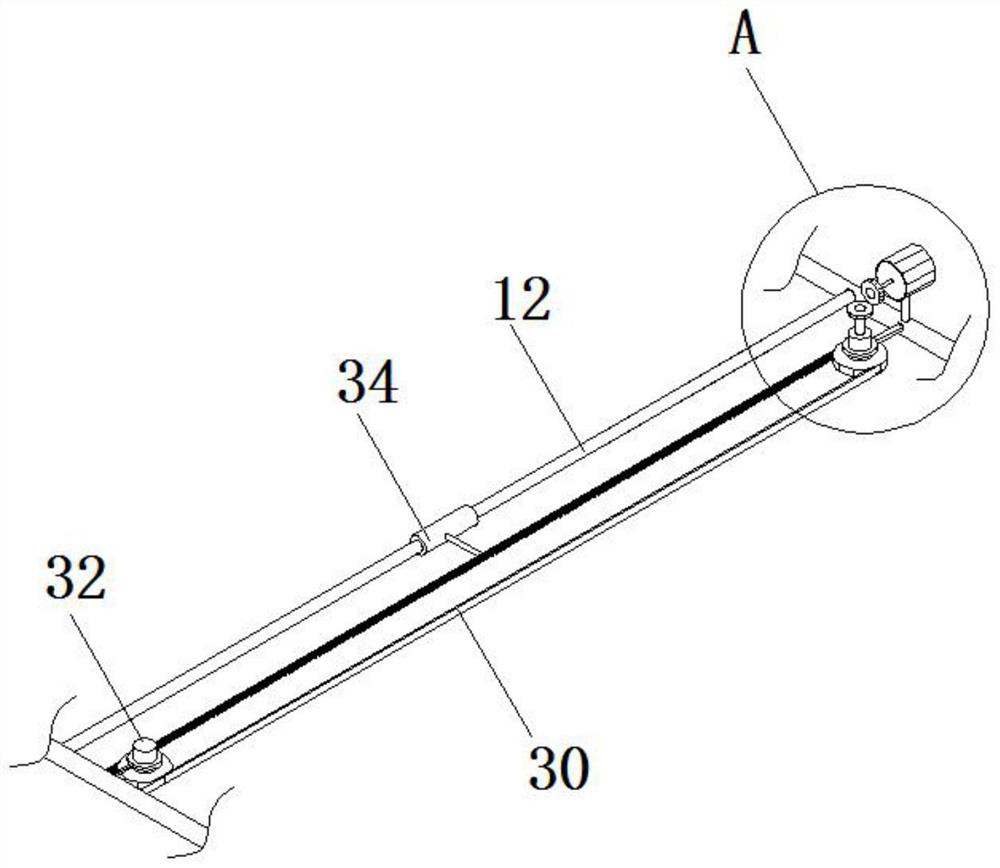

Automatic taking, winding and bagging device for infusion set

The invention relates to the technical field of packaging devices, in particular to an automatic taking, winding and bagging device for an infusion set. The automatic taking, winding and bagging device for the infusion set comprises a rack, an infusion set tensioning mechanism, an infusion set tail taking mechanism, an infusion set head taking mechanism, an infusion set automatic winding mechanism, an infusion set roll transferring mechanism, a bag entering mold and a bag entering pushing mechanism, wherein the infusion set tensioning mechanism, the infusion set tail taking mechanism, the infusion set head taking mechanism, the infusion set automatic winding mechanism, the infusion set roll transferring mechanism, the bag entering mold and the bag entering pushing mechanism are sequentially arranged on the rack from back to front in the X-axis direction. According to the automatic taking, winding and bagging device for the infusion set, the whole taking, winding and bagging process ishigh in process continuity and operation stability; a drip chamber of the infusion set is stably fixed in the winding process, the infusion set is wound tidily, the tightness of coils is consistent, the wound infusion set is tidy and tight, and an infusion set catheter cannot be damaged; and the equipment is high in automation degree, rapid to operate and high in stability in the whole transferring process.

Owner:YANTAI KAIBO AUTOMATION TECH

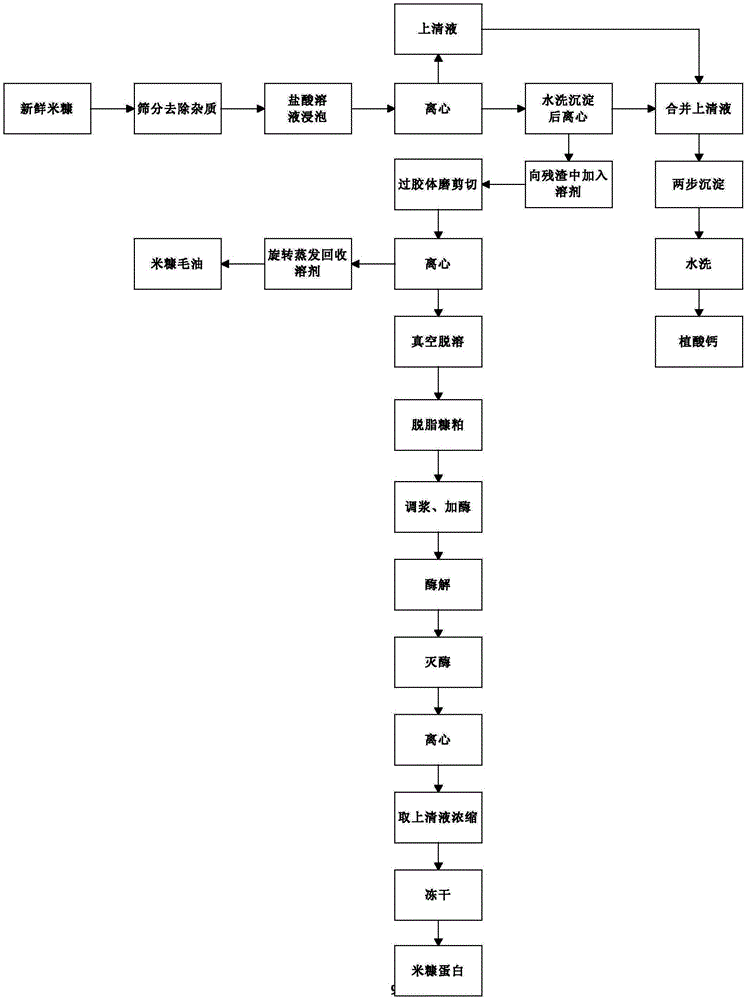

High-efficiency extraction method of nutritional and active substances of rice bran

ActiveCN103833786APrevent rancidityComponents are assignedGroup 5/15 element organic compoundsFatty-oils/fats productionPhytic acidSolvent

The invention provides a high-efficiency extraction method of nutritional and active substances of rice bran. The high-efficiency extraction method comprises the following steps of 1, full-fat rice bran screening impurity-removal, 2, phytic acid extraction by immersion in an acid, 3, rice bran crude oil extraction by high-speed shearing and a complex solvent, and 4, enzyme method-based extraction of a rice bran protein. The high-efficiency extraction method can realize high-efficiency extraction of phytic acid, fat and proteins of full-fat rice bran in an order, realize high-valued complete utilization of full-fat rice bran, improve an added value and avoid resource waste.

Owner:JIANGNAN UNIV

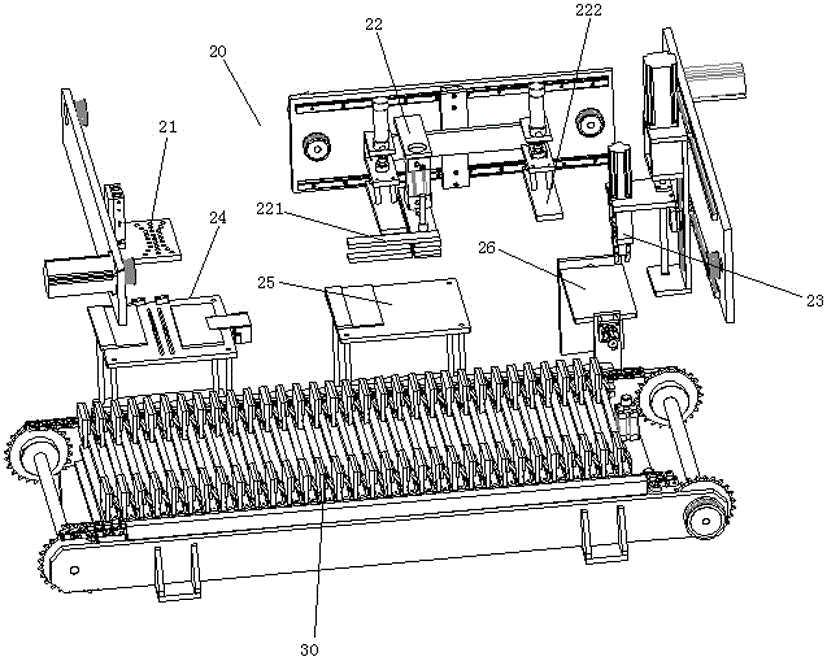

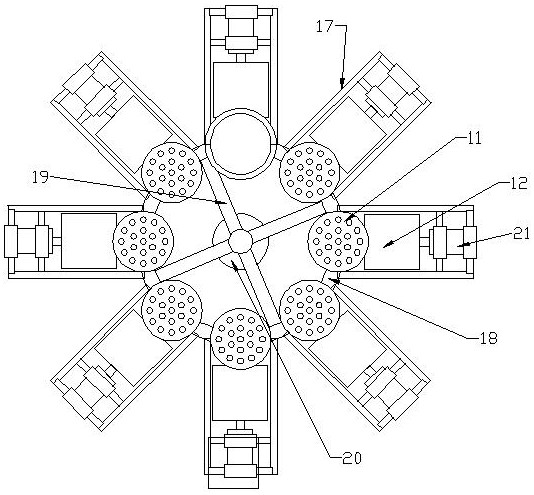

All-in-one machine for polymer lithium battery with functions of formation and capacity grading

PendingCN106129449AGood process continuityGood effectAssembling battery machinesFinal product manufactureCell assemblyManipulator

The invention discloses an all-in-one machine for a polymer lithium battery with functions of formation and capacity grading. The all-in-one machine comprises a cell assembly line, wherein a cell elastic clamp which is fully loaded with cells; a formation and capacity-grading apparatus is arranged on one side of the cell assembly line; the formation and capacity-grading apparatus comprises a material-feeding mechanical arm bracket and a material-discharging mechanical arm bracket; a material-feeding material-waiting frame, a material-discharging material-waiting frame, a group of formation clamps and multiple capacity-grading clamps are arranged in the material-feeding mechanical arm bracket and the material-discharging mechanical arm bracket; the material-feeding material-waiting frame, the material-discharging material-waiting frame, the group of formation clamps and the multiple capacity-grading clamps are arranged in sequence from one side to the other side; a material-feeding mechanism and a material-discharging mechanism are arranged between the material-feeding material-waiting frame and the cell assembly line; the material-feeding mechanism and the material-discharging mechanism are positioned on the front and back sides respectively; and material-moving mechanical arms are arranged on the material-feeding mechanical arm bracket and the material-discharging mechanical arm bracket. The all-in-one machine for the polymer lithium battery with the functions of formation and capacity grading has the advantages of high continuity of capacity-grading processes, high degree of automation, high efficiency, good formation effect, high product quality and the like.

Owner:东莞德方智能装备中心(有限合伙)

High-acid low-sugar sparkling rice wine and preparation method thereof

InactiveCN107881064ARich in vitaminsRich Inorganic SaltMicroorganism based processesAlcoholic beverage preparationChemistrySaccharomyces cerevisiae

The invention discloses high-acid low-sugar sparkling rice wine and a preparation method thereof. The preparation method disclosed by the invention comprises the following steps: adding warm water andalkaline proteinase into sticky rice, regulating the pH value, starting hydrolysis, and washing rice after hydrolysis; cooking the washed rice until any raw core does not exist in the raw materials;cooling the cooked sticky rice with water, adding liqueur koji to be uniformly stirred and saccharified; supplementing new cooked sticky rice and rice after saccharification completion, fermenting atthe temperature of 21-26 DEG C for 2-3 days, supplementing new cooked sticky rice again, adding lactic acid bacteria, and fermenting at a temperature of 18-23 DEG C for 5-7 days; squeezing the mash after fermentation completion, freezing, filtering and sterilizing, adding brewer's yeasts into the sterilized wine liquid, and fermenting at the temperature of 18-20 DEG C for 14-21 days; and freezingthe fermented mash to 5-6 DEG C below zero, maintaining for 4-5 days, detecting the mash pressure, performing membrane filtration under the condition identical to the mash pressure, and filtering, thereby obtaining the high-acid low-sugar sparkling rice wine. The problems that the traditional rice wine is high in sugar degree, low in acidity and complicated in process and the like are solved.

Owner:HUBEI UNIV OF TECH +1

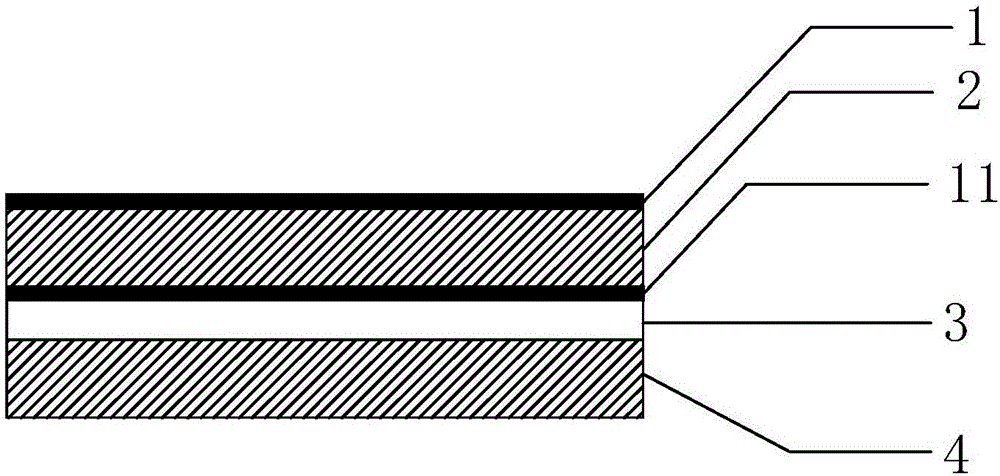

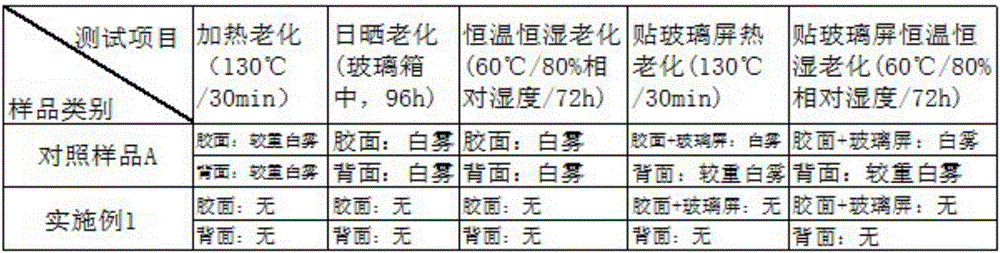

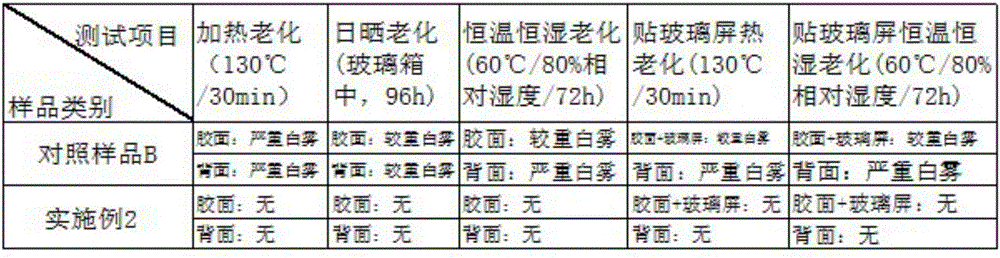

Polyester-based protective film for preventing oligomer preparation and manufacturing method thereof

InactiveCN106366962AImprove cleanlinessGuaranteed Optical PerformanceFilm/foil adhesivesCoatingsPolyesterOligomer

The invention relates to a polyester-based protective film for preventing oligomer preparation and a manufacturing method thereof. The polyester-based protective film comprises a multi-layer composite polyester-based base material and a pressure-sensitive adhesive coating coated on the surface of the composite base material; a crosslinking polyacrylate sealing agent upper surface layer and a crosslinking polyacrylate sealing agent lower surface layer are coated on the upper surface and the lower surface of the multi-layer composite polyester-based base material respectively. The manufacturing method includes the following steps that 1, a crosslinking polyacrylate sealing agent is synthesized; 2, the multi-layer composite polyester-based base material is prepared; 3, the polyester-based protective film for preventing oligomer preparation is prepared. The fogging problem caused by oligomer emigration in the polyester-based base material in the storage, processing and using processes of a conventional protective film is solved, when long-term exposure to sunlight, constant-temperature constant-humidity artificial aging and heating ageing are carried out on the polyester-based protective film for preventing oligomer preparation, the fogging phenomenon on the film face due to oligomer emigration is avoided, and use requirement of high-end glass films is ensured.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

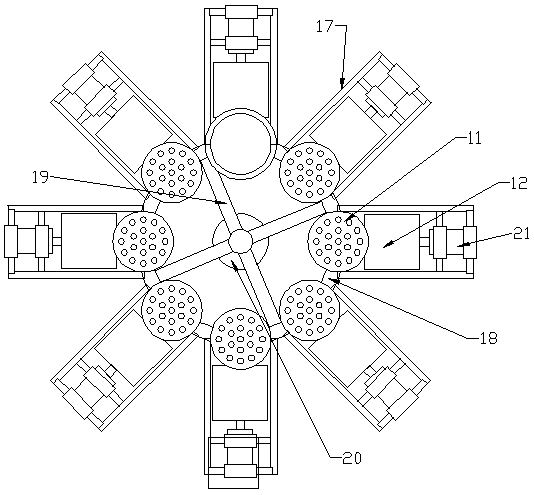

Silicon wafer grinding disc correction device and correction process

ActiveCN111761516AEvenly distributedReduce usageAbrasive surface conditioning devicesEngineeringSilicon chip

The invention relates to the field of silicon wafer grinding device correction machining, in particular to a silicon wafer grinding disc correction device and correction process. The device comprisesan upper grinding disc system, a lower grinding disc system and a plurality of correction wheels arranged between the upper grinding disc system and the lower grinding disc system, and recycling and spraying mechanisms are arranged on the central notches of the correction wheels. The recycling and spraying mechanisms are arranged on the correction wheels, a grinding liquid between the upper grinding disc system and the lower grinding disc system is recycled and then sprayed and utilized through the recycling and spraying mechanisms, grinding liquid distribution between the upper grinding discsystem and the lower grinding disc system is sufficiently guaranteed to be uniform, use of the grinding liquid is reduced while the grinding effect is improved, and the technical problems of low precision, poor efficiency and heavy pollution of an existing grinding correction device are solved.

Owner:ZHEJIANG COWIN ELECTRONICS

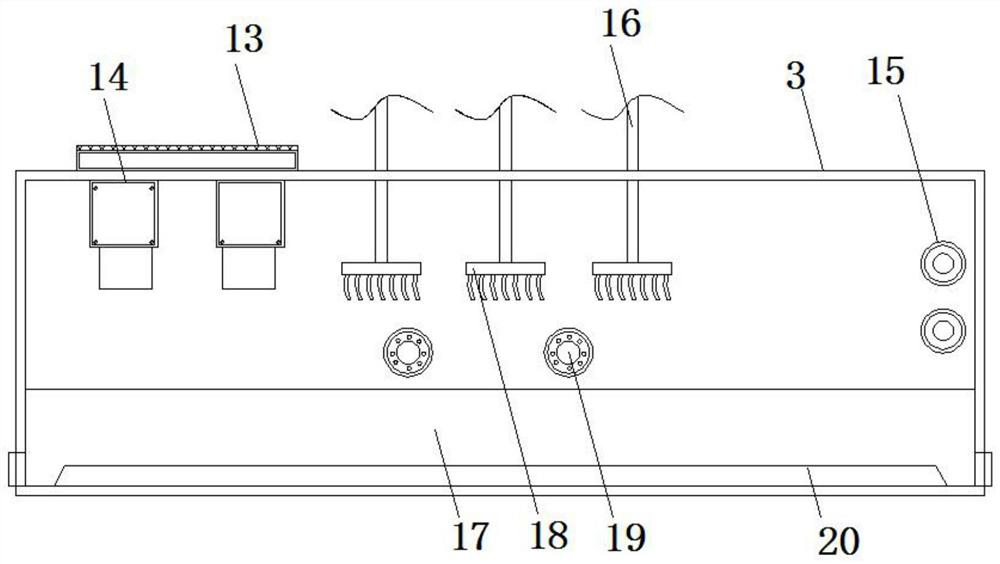

Carbonizing device

ActiveCN105773775AGood process continuityImprove work efficiencyBark-zones/chip/dust/waste removalWood charring/burningEngineeringMechanical engineering

The invention discloses a carbonizing device which comprises a carbonizing mechanism and a dust collection mechanism, wherein the carbonizing mechanism is composed of a first rack and a second rack; a first conveying device, a first carbonizing chamber and a second conveying device are sequentially arranged on the first rack in the conveying direction of a wood board; a second carbonizing chamber and a third conveying device are sequentially arranged on the second rack in the conveying direction of the wood board; the second conveying device is arranged corresponding to the inlet of the second carbonizing chamber; the dust collection mechanism is composed of a third rack; a fourth conveying device, a first group of brush rolls and a second group of brush rolls are sequentially arranged on the third rack in the conveying direction of the wood board; and the fourth conveying device is arranged corresponding to the third conveying device. The carbonizing device can finish two procedures of carbonizing of carbonized wood and dust collection and is good in procedure continuity and high in working efficiency.

Owner:杜丽红

Automatic packaging bag sealing device and using method thereof

PendingCN111348267AImprove stabilityNot easy to dropWrapper twisting/gatheringProcess engineeringTransfer mechanism

The invention relates to the technical field of packaging devices, in particular to an automatic packaging bag sealing device and a using method thereof. The automatic packaging bag sealing device comprises an overturning mechanism, a semi-finished product transferring mechanism, a hot welding mechanism, a discharging mechanism and a conveying mechanism; the semi-finished product transferring mechanism is arranged between the overturning mechanism and the hot welding mechanism, the discharging mechanism is arranged below the hot welding mechanism, and the conveying mechanism is arranged belowthe discharging mechanism; and a packaging bag filled with materials is transferred to the overturning mechanism, the overturning mechanism clamps a bag opening of the packaging bag and drives the packaging bag to turn over to naturally droop, the semi-finished product transferring mechanism clamps the natural-drooped packaging bag and conveys the natural-drooped packaging bag to the hot welding mechanism, and the packaging bag is transferred to the conveying mechanism through the discharging mechanism after being sealed by the hot welding mechanism. According to the automatic packaging bag sealing device and the using method thereof, the operation process is smooth, the technology consistency is high, the stability of the packaging bag in the whole technology operation process is high, the packaging bag is not prone to falling, the working efficiency is greatly improved, and the sealing success rate is extremely high.

Owner:YANTAI KAIBO AUTOMATION TECH

Heat treatment method of steel piece surface

InactiveCN109837500AImprove the level ofHigh surface hardnessSolid state diffusion coatingCarbon potentialSurface layer

The invention discloses a heat treatment method of a steel piece. The heat treatment method is characterized by comprising the steps: after being loaded into a furnace, the workpiece is carburized atthe temperature of 840-920 DEG C, and the carbon potential is controlled; after the predetermined seepage layer depth is reached, the workpiece is cooled along with the furnace to the range of 620-720DEG C to be subjected to austenitic nitriding; gas is decomposed through ammonia or ammonia hydrogenation, and the nitrogen decomposition rate, furnace gas components and the temperature are controlled; firstly, the workpiece is heated to be in an austenitic state to be subjected to nitriding or carbonitriding, and a predetermined seepage layer is obtained; then the temperature is decreased to bethe austenitic nitriding temperature of 560-640 DEG C in the same furnace for nitriding or carbonitriding treatment, and thus the nitrogen concentration of surface layer austenite of the workpiece isincreased to the level of an austenitic nitriding layer; and then direct quenching and aging within the range of 200-300 DEG C or direct isothermal quenching in the temperature interval of 200-300 DEG C is conducted.

Owner:郝文龙

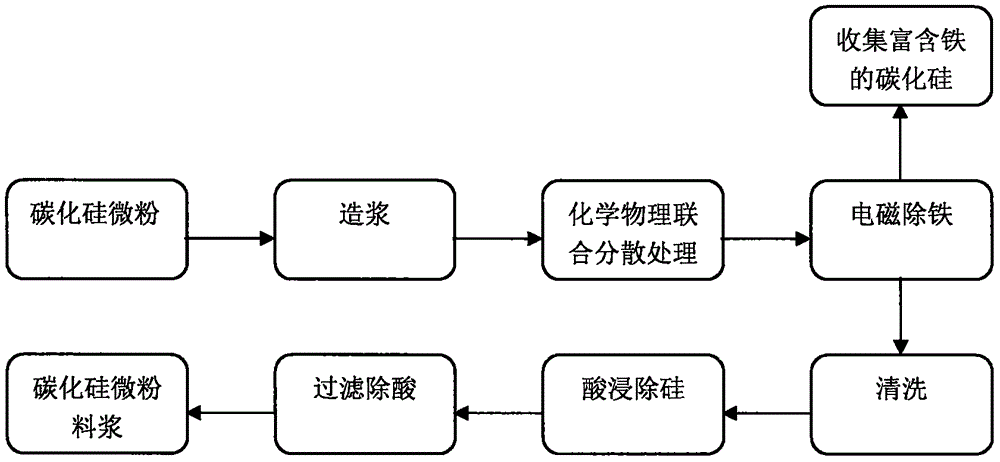

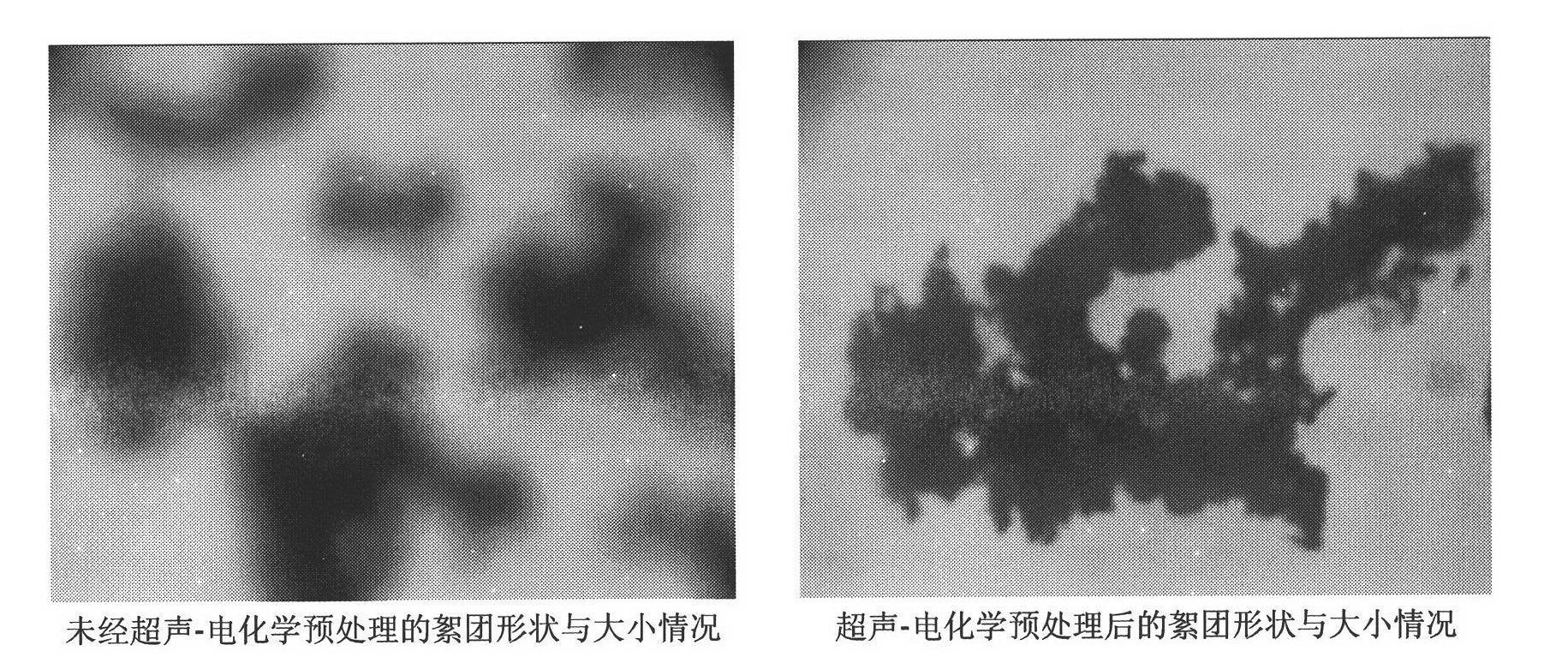

Method for removing iron and silicon impurities in silicon carbide micropowder for crystalline silicon wire cutting

The invention relates to a method for removing iron and silicon impurities in silicon carbide micropowder for crystalline silicon wire cutting. The iron and silicon impurities in the silicon carbide powder are removed through combination of physical iron removal and chemical silicon removal. The method comprises the specific process as follows: the silicon carbide micropowder ground by a Raymond mill is mixed with deionized water for slurry making; a dispersant is added to obtained silicon carbonate micropowder slurry for stirring dispersion treatment; the dispersed silicon carbonate micropowder slurry is pumped into an electromagnetic separator for iron removal by magnetic separation; then the iron-removed and purified silicon carbonate micropower slurry is washed with water; acid is added to the silicon carbonate micropower slurry for acid leaching; finally, the purified silicon carbonate micropowder slurry is obtained through filtration. The method is simple to operate, high in production efficiency, low in cost and good in environmental benefit, and the use chemicals are reduced. The treated silicon carbonate powder product is stable in quality and suitable for industrial production, and the technical indexes meet the process requirement.

Owner:JIANGXI ENK NEW MATERIAL CO LTD

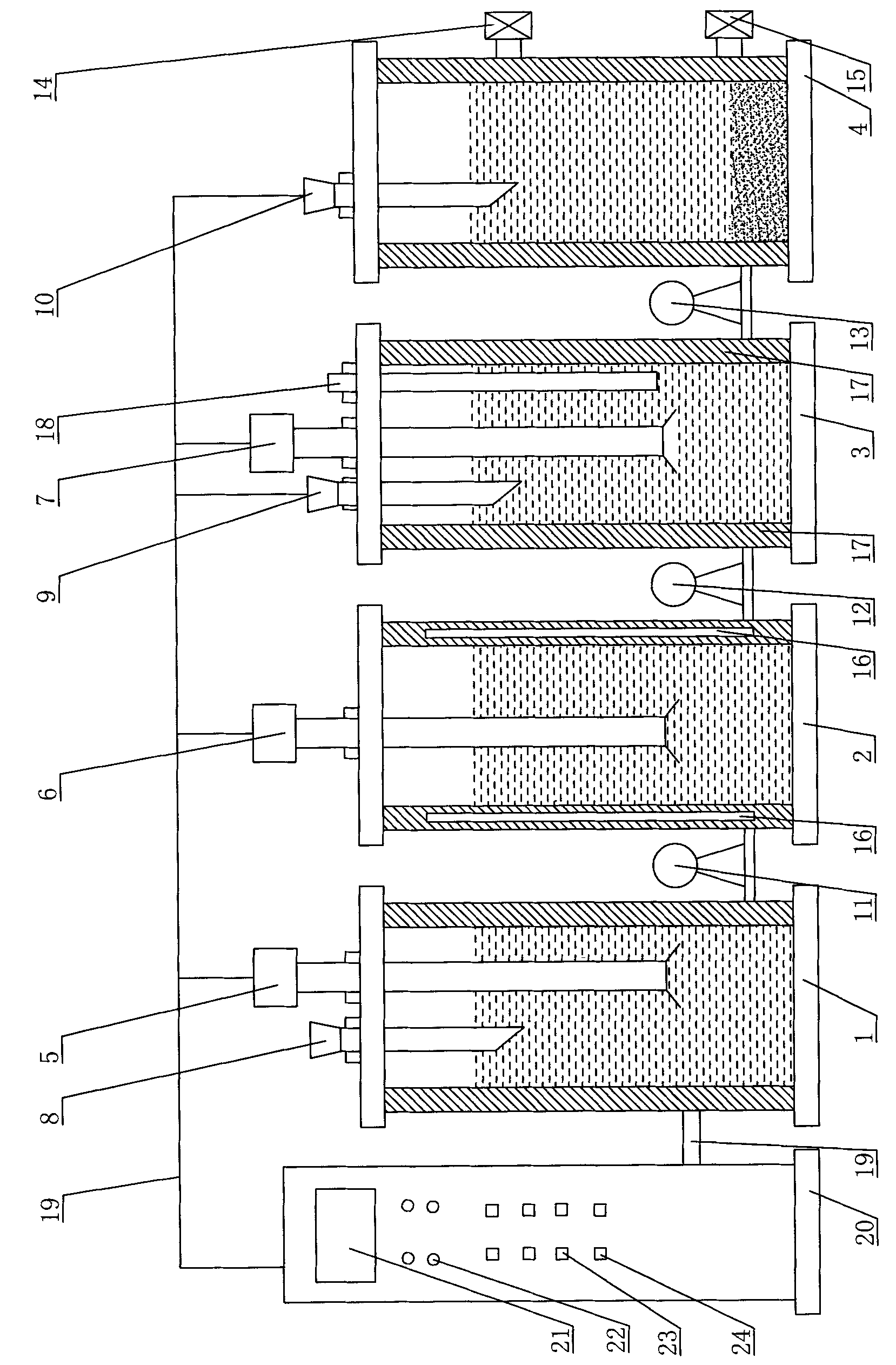

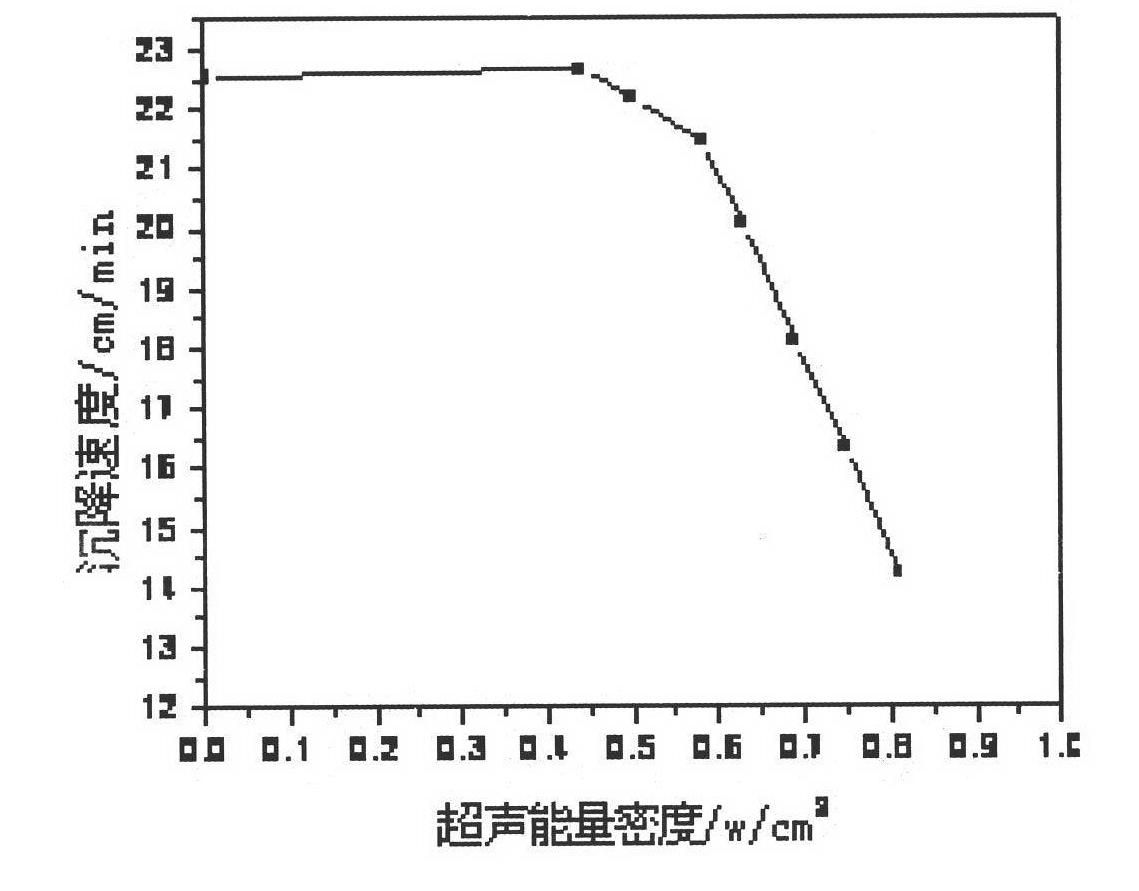

A method of ultrasonic electrolysis flocculation slime water

InactiveCN102276027AGood process continuityAccelerateWater/sewage treatment by flocculation/precipitationElectrocoagulationCoal product

The invention relates to a method for ultrasonic treatment, electrolysis and flocculation of slime water. The method is characterized in that an ultrasonic treatment, electrolysis and flocculation technology is utilized to treat slime water according to the actual situation of slime water treatment to obtain coal slime, the coal slime is dried to obtain an industrial raw material with high additional value, and the treated water is collected for use. The treatment method has the advantages of continuous process, high speed, high efficiency, high sedimentation rate (increased by 60% compared with the prior art) and low water turbidity (reduced by 60%), can be industrially applied in coal separation field, and is a very ideal treatment method of slime water; and the washed and separated coal product has good purity and fewer impurities, and can be used as a raw material in the pharmacy, fine chemistry industry and high-additional-value industries.

Owner:TAIYUAN UNIV OF TECH

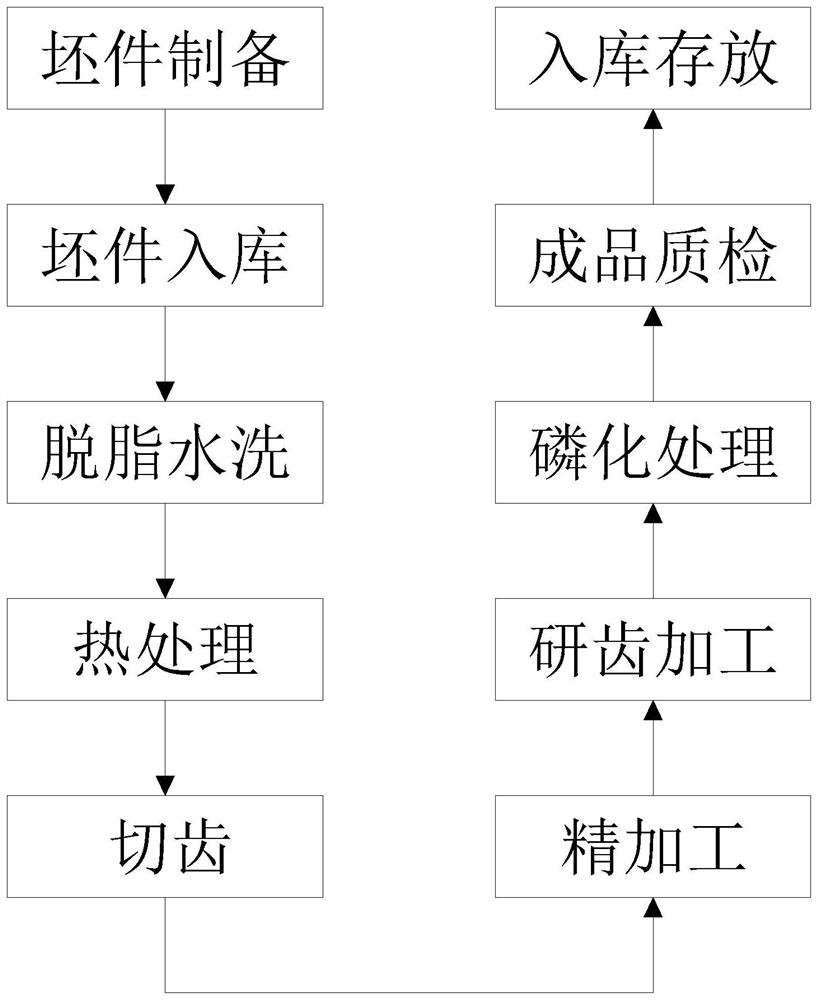

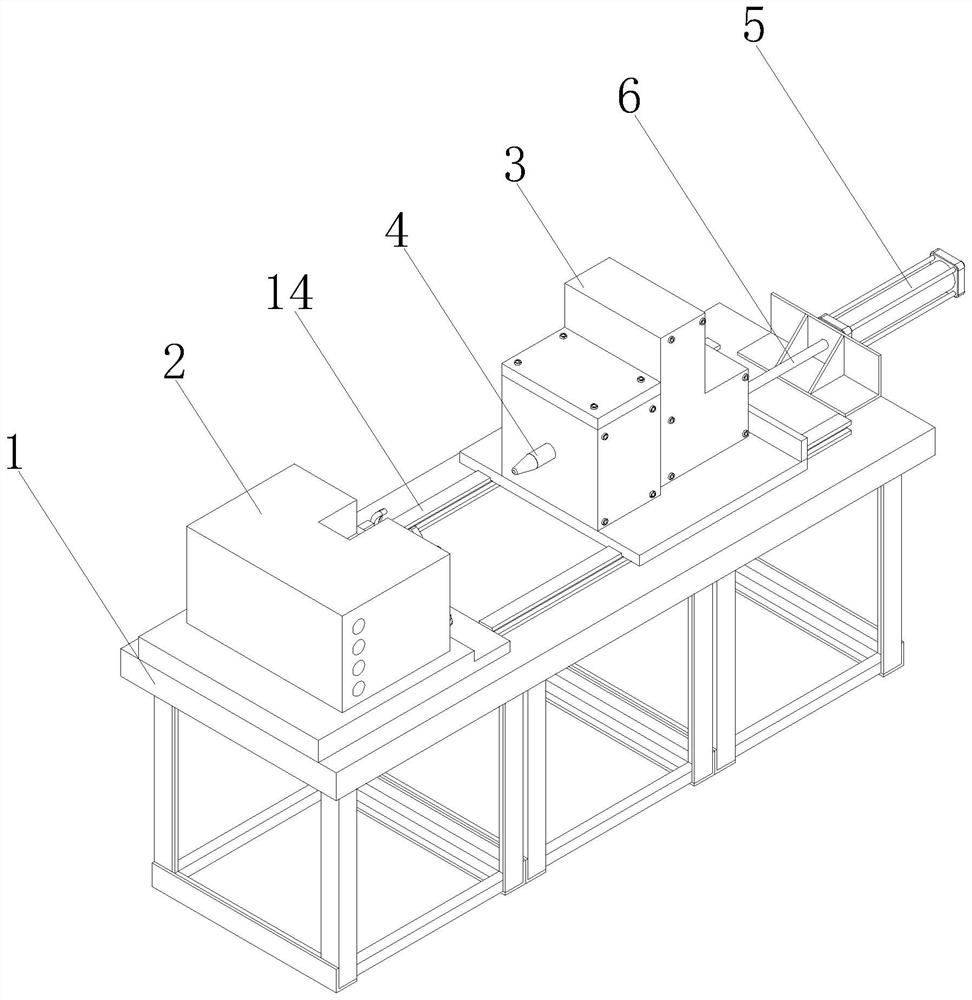

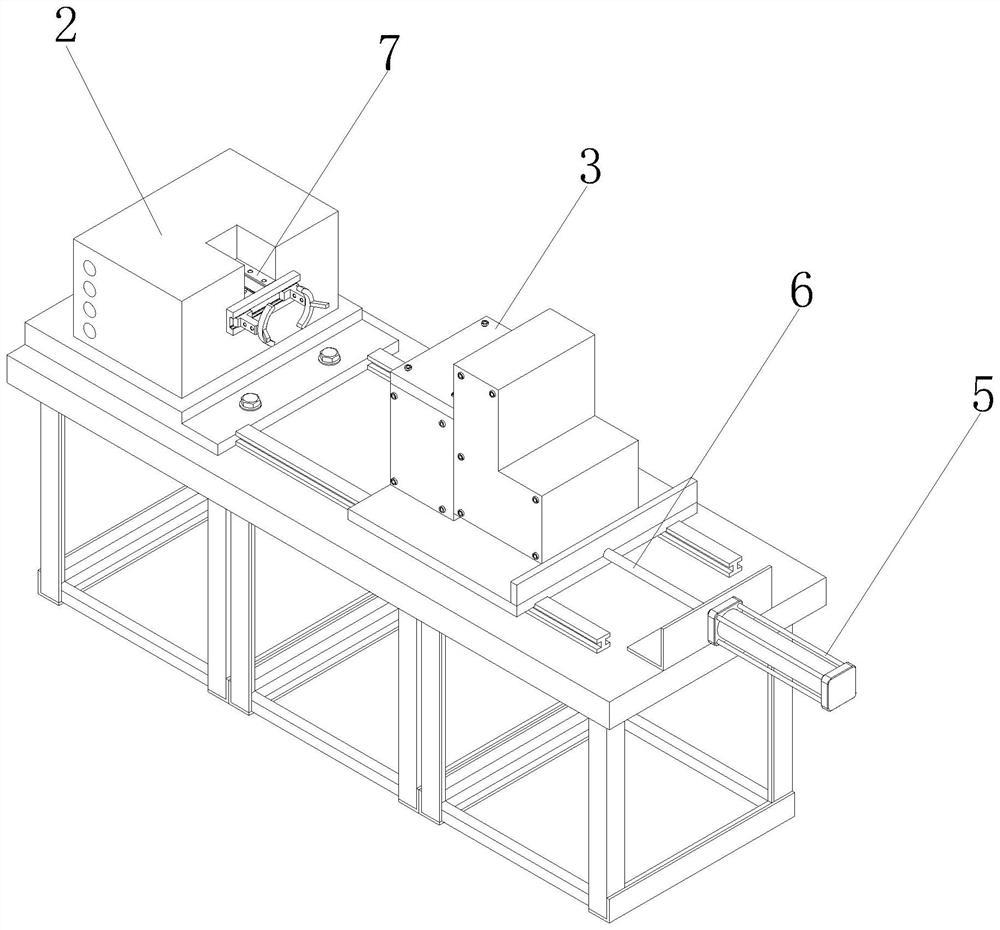

Manufacturing method of arc-shaped bevel gear

ActiveCN114309822AHigh precisionGuarantee the quality of finished productsGear-cutting machinesGear teethGear wheelBevel gear

The invention discloses a manufacturing method of an arc-shaped bevel gear, which relates to the technical field of gear manufacturing and comprises the following steps of blank preparation, blank warehousing, degreasing and washing, heat treatment, gear cutting, finish machining, gear lapping machining, phosphating treatment, finished product quality inspection and warehousing storage. The method has the beneficial effects that the steps are simple, the technological process continuity is good, the production efficiency is effectively improved through coordinated operation of equipment and manpower, the manufacturing period is shortened, burrs can be removed, errors can be trimmed by grinding and polishing the connecting part and the teeth of the semi-finished gear, and the product quality is improved. The precision of the finished arc-shaped bevel gear is effectively improved, the defective rate is reduced, and therefore the finished product quality of the arc-shaped bevel gear is guaranteed.

Owner:浙江新昌汇盟机械有限公司

Pretreatment system before assembly of infusion apparatus short pipe

PendingCN112975327AImprove preprocessing efficiencyCoordinationMetal working apparatusControl engineeringInfusion set

The invention relates to the technical field of infusion apparatus short pipe and three-way pipe assembling equipment, in particular to a pretreatment system before assembly of an infusion apparatus short pipe. The pretreatment system before the assembly of the infusion apparatus short pipe comprises a rack, and an infusion apparatus short pipe automatic feeding stock bin, an infusion apparatus short pipe taking device, an infusion apparatus short pipe aligning device, an infusion apparatus short pipe transferring device and an infusion apparatus short pipe position correcting device arranged on the rack; the infusion apparatus short pipe automatic feeding bin, the infusion apparatus short pipe aligning device and the infusion apparatus short pipe position correcting device are sequentially arranged on the rack in the first direction; the infusion apparatus short pipe taking device is arranged above the infusion apparatus short pipe automatic feeding bin; the infusion apparatus short pipe transferring device is arranged above the infusion apparatus short pipe aligning device and the infusion apparatus short pipe position correcting device; and the infusion apparatus short pipe transferring device moves between the infusion apparatus short pipe taking device and the infusion apparatus short pipe position correcting device. According to the pretreatment system before the assembly of the infusion apparatus short pipe provided by the invention, all the devices are high in coherence, functions are improved, and the infusion apparatus short pipe pretreatment efficiency is improved.

Owner:YANTAI KAIBO AUTOMATION TECH

Treatment method of sulfuric acid high arsenic and thallium acid wastewater

PendingCN113264603ALow costEasy to masterWater treatment parameter controlWater treatment compoundsSulfidationWastewater

The invention provides a treatment method of sulfuric acid high arsenic and thallium acid wastewater, the treatment method comprises the following steps: adding limestone into sewage for neutralization, entering a first-stage thickener, carrying out underflow filter pressing to obtain first-stage neutralized slag, adding permeate water into clear liquid, carrying out second-stage oxidation reaction, then carrying out second-stage secondary neutralization, entering a second-stage thickener, carrying out underflow filter pressing, obtaining second-stage neutralized slag, enabling the clear liquid to sequentially enter a third-section pH adjusting tank, a third-section first-stage neutralizing tank, a third-section oxidation tank and a third-section second-stage neutralizing tank to enter a third-section thickener, peforming underflow filter pressing to obtain third-stage neutralized slag, enabling the clear liquid to sequentially enter a fourth-section vulcanization tank 1 and a fourth-section vulcanization tank 2 to enter a fourth-section thickener, performing underflow filter pressing to obtain fourth-stage slag, enabling the clear liquid to enter a pressurized water tank, and recycling. The method has the advantages of strong application operability, strong process flow continuity, segmented treatment and simple operation, and is suitable for treating polluted acid (waste water) with high arsenic and thallium content.

Owner:SHUI KOU SHAN NONFERROUS METALS LTD

Fructus momordicae fruit juice and preparation method thereof

PendingCN108094772AImprove enzymatic hydrolysis efficiencyIncrease the juice yieldFood scienceUltra high pressureFruit juice

Owner:GUILIN NATURAL INGREDIENTS CORP

Pretreatment system for infusion apparatus three-way pipes before assembly

PendingCN113102976AEasy to moveIncrease feeding rateMaterial gluingMetal working apparatusInfusion setMechanical engineering

The invention relates to the technical field of three-way pipe pretreatment devices, in particular to a pretreatment system for infusion apparatus three-way pipes before assembly. The pretreatment system for the infusion apparatus three-way pipes before assembly comprises a rack, and a three-way pipe feeding device, a three-way pipe taking and transferring device, a three-way pipe rotating and aligning device and a three-way pipe overturning device which are arranged on the rack, the three-way pipe feeding device and the three-way pipe rotating and aligning device are sequentially installed on the rack, the three-way pipe taking and transferring device is installed at the part, above the three-way pipe feeding device and the three-way pipe rotating and aligning device, of a body of the rack, and the three-way pipe overturning device is installed at the part, above the three-way pipe rotating and aligning device, of the body of the rack. According to the pretreatment system, a large amount of materials can be fed at a time, the three-way pipes are convenient to align in the feeding process, and the flow continuity of feeding, aligning, grabbing and transferring is high. The devices are compact in structural design, easy to operate, coherent in action and high in assembling precision, and the assembling efficiency of the three-way pipes and a infusion apparatus short pipe is greatly improved.

Owner:YANTAI KAIBO AUTOMATION TECH

A kind of efficient extraction method of rice bran nutrition and active substances

ActiveCN103833786BGuarantee the quality of follow-up processingPrevent rancidityGroup 5/15 element organic compoundsFatty-oils/fats productionPhytic acidSolvent

The invention provides a high-efficiency extraction method of nutritional and active substances of rice bran. The high-efficiency extraction method comprises the following steps of 1, full-fat rice bran screening impurity-removal, 2, phytic acid extraction by immersion in an acid, 3, rice bran crude oil extraction by high-speed shearing and a complex solvent, and 4, enzyme method-based extraction of a rice bran protein. The high-efficiency extraction method can realize high-efficiency extraction of phytic acid, fat and proteins of full-fat rice bran in an order, realize high-valued complete utilization of full-fat rice bran, improve an added value and avoid resource waste.

Owner:JIANGNAN UNIV

Aquatic plant seed granules, production method and granulating equipment

ActiveCN111066412AEasy to rootGood process continuityTransportation and packagingMixersXanthan gumGelatin

The invention discloses aquatic plant seed granules, a production method and granulating equipment. Seed granules are prepared from bentonite, stone powder, gelatin, xanthan gum, aquatic plant seeds of which the particle diameter is 0.1cm or below and water. The aquatic plant seeds and other raw materials are mixed to form mixtures, then the mixtures are subjected to underwater sowing in the formof granules having certain weight, and compared with a manner of direct broadcast sowing of the aquatic plant seeds, the manner disclosed by the invention can easily enable the seeds to enter silt under water to take root.

Owner:大湖水环境治理股份有限公司

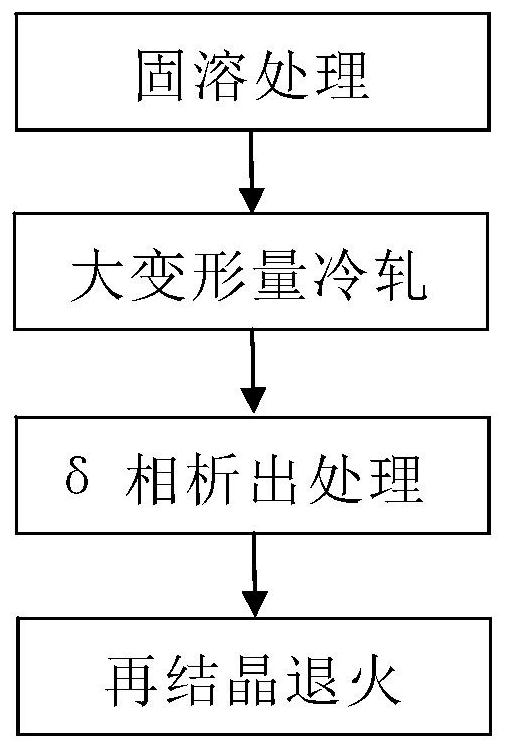

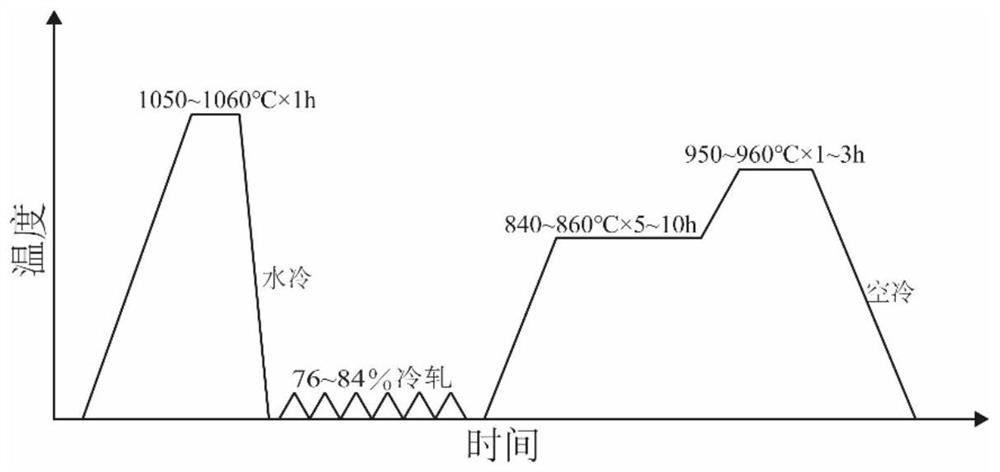

Grain refinement method for GH4169 high-temperature alloy plate

ActiveCN114381679AEase of mass productionSuitable for mass productionFurnace typesMetal rolling arrangementsSolution treatmentHeat conservation

The invention provides a grain refinement method of a GH4169 high-temperature alloy plate, which comprises the following steps: solution treatment: the treatment temperature is 1050-1060 DEG C, the heat preservation time is 0.5-1 hour, and water cooling is carried out; performing large-deformation cold rolling, wherein the cold rolling reduction rate is controlled to be 75-85%; delta-phase precipitation treatment: the treatment temperature is 840-860 DEG C, and the heat preservation time is 5-10 hours; recrystallization annealing is conducted, specifically, the temperature is increased to 950-960 DEG C at the heating rate of 10-15 DEG C / min; and the heat preservation time is 1-3 hours. The grain refinement method for the GH4169 high-temperature alloy plate is simple in process, low in cost and remarkable in grain refinement effect.

Owner:NORTHEASTERN UNIV

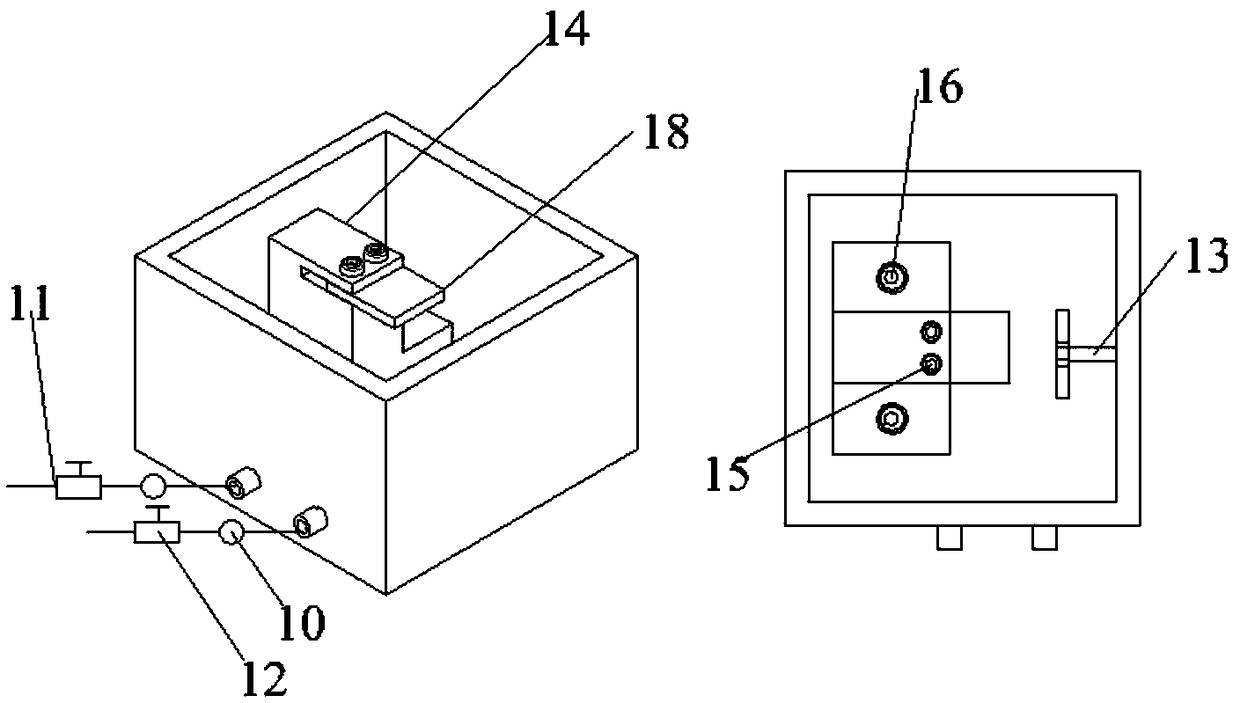

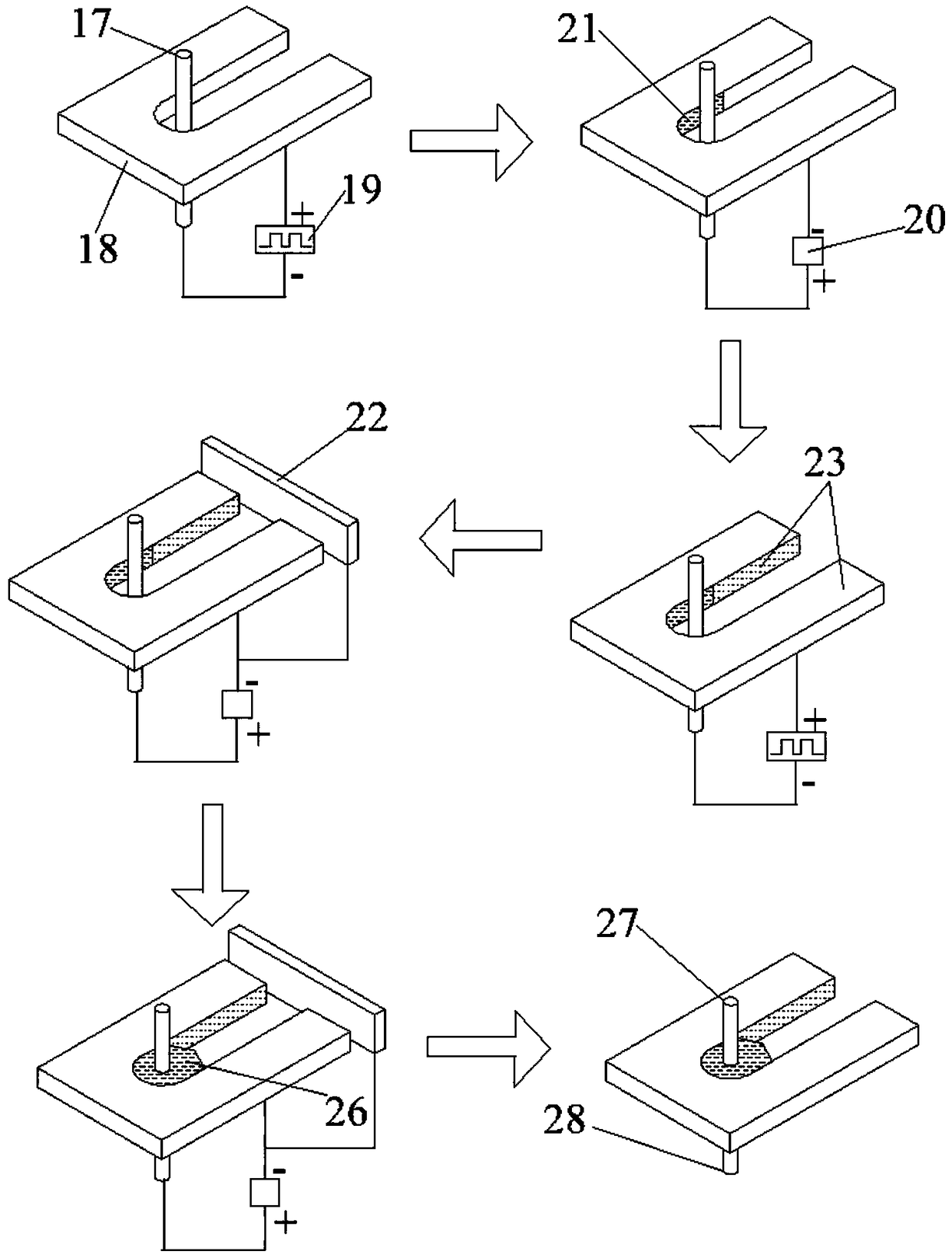

Electrodeposition Auxiliary Measuring Method for Gap in Micro Electrolytic Wire Cutting

ActiveCN107511546BWon't disturbHigh precisionMeasurement/indication equipmentsElectrical-based auxillary apparatusElectricityWire cutting

The invention relates to a wire electrochemical micro-machining gap electro-deposition auxiliary measuring method and belongs to the technical field of precise and micro electrochemical processing. The wire electrochemical micro-machining gap electro-deposition auxiliary measuring method is characterized by comprising the following processes that two different electrochemical deposition methods are utilized, namely, metal ions are deposited from the end of a wire electrochemical micro-machining micro seam structure or the surface of a used microscale line electrode till processing gaps are filled completely, and the position of the microscale line electrode relative to the end surface of the micro seam structure is completely fixed. From the direction of the workpiece thickness, the processing gaps are subjected to layered polish-grinding, actual measuring and data correction, and the distribution model of the processing gaps is established through mathematical modeling and image reconstruction. The wire electrochemical micro-machining gap electro-deposition auxiliary measuring method has the important significance on the wire electrochemical micro-machining theoretical research.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

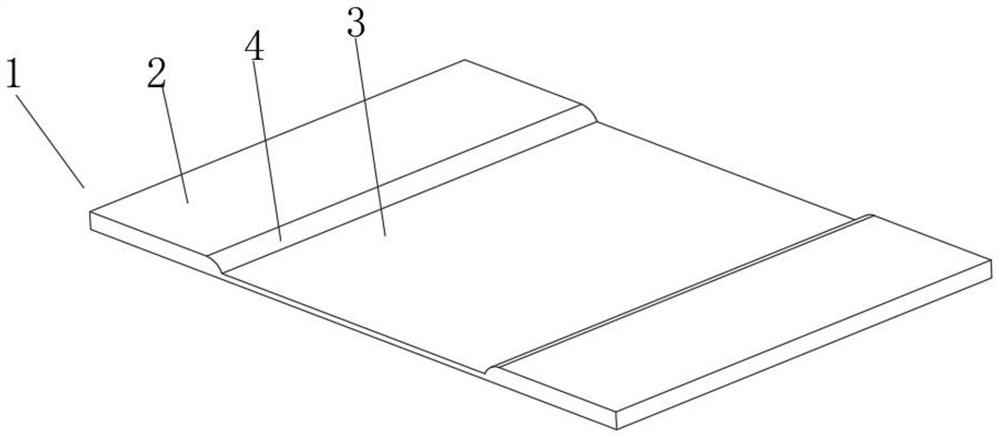

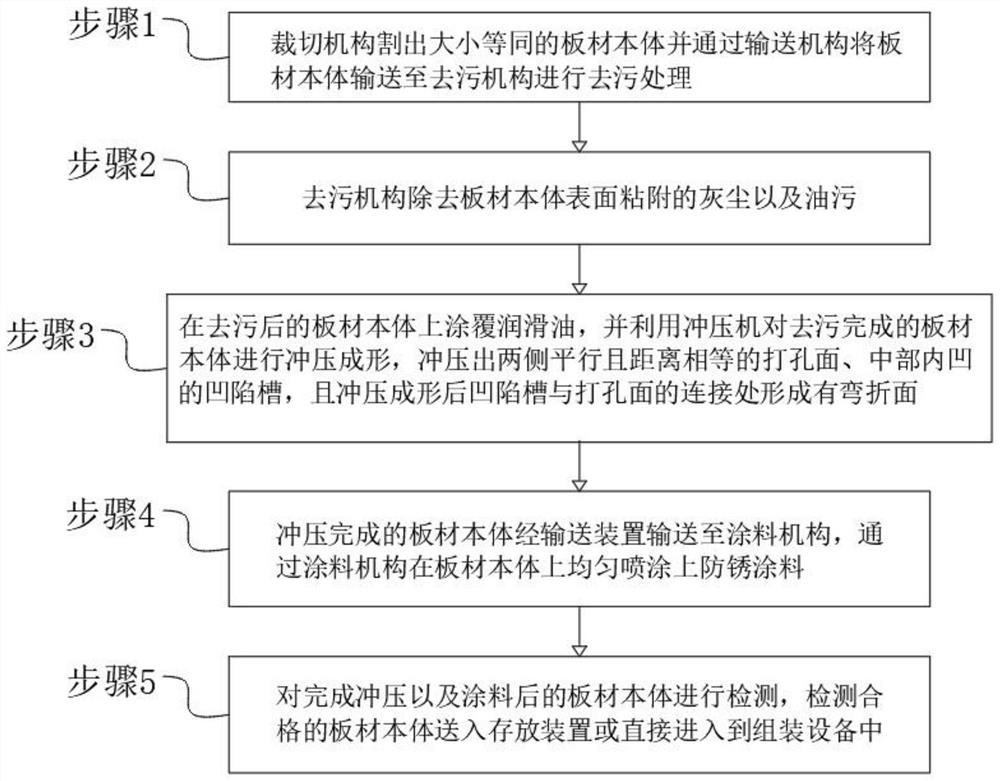

Plate for hoop production and processing technology of plate

The invention relates to the technical field of clamp production, and particularly discloses a plate for clamp production and a machining process of the plate, the plate comprises a plate body, the plate body comprises riveting piece parts, a strip part and a bending face, the strip part is formed in the middle of the plate body in a punching mode, and the riveting piece parts are provided with two faces and are integrally formed on the left side and the right side of the plate body respectively; the two bending surfaces are formed at the connecting positions of the strip part and the two riveting piece parts respectively, and the bending surfaces are arc surfaces protruding outwards; according to the plate, the whole plate body can be effectively bent through the end faces, thinner than the riveting piece parts on the two sides, of the strip parts at first during bending, the plate body can be bent along with the radian of the bent face during bending, the stability of the plate body during bending is further improved, and the bending quality of the plate body is improved. The situation that the radian of the plate body is not enough or the plate body is torn during follow-up bending forming is avoided, and therefore the plate body can be more conveniently used for hoop production.

Owner:SHENZHEN HEMERS NEW MATERIAL TECH CO LTD

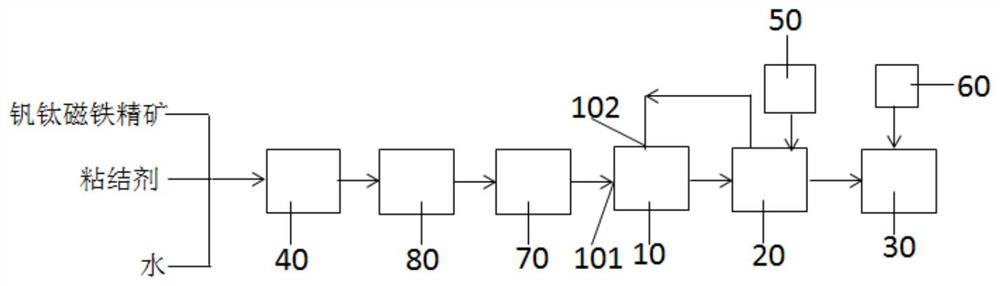

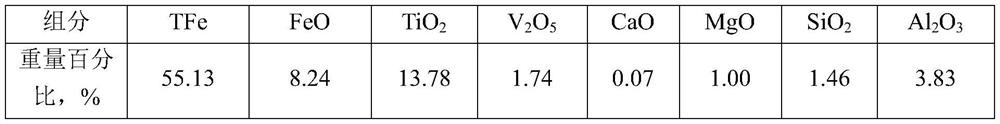

Smelting system and smelting method for vanadium-titanium magnetite concentrate

PendingCN111676341AShort processGood process continuityRotary drum furnacesEngineeringReducing agent

The invention provides a smelting system and a smelting method for vanadium-titanium magnetite concentrate. The smelting system for the vanadium-titanium magnetite concentrate comprises an oxidizing roasting device, a reducing smelting device, and an induction melting device; the oxidizing roasting device is provided with a first feeding hole, an oxidizing gas inlet and an oxidizing roasting product outlet; the reducing smelting device is provided with a second feeding hole, a reducing gas inlet and a metalized material outlet; the second feeding hole communicates with the oxidizing roasting product outlet through a first feeding pipeline; the induction melting device is provided with a third feeding hole, a non-carbon-based reducing agent inlet, a protective gas inlet and a vanadium-containing metal; the protective gas inlet is used for introducing an insert gas; and the third feeding hole communicates with the metalized material outlet, and is used for further reducing a metalized material discharged from the reducing smelting device. The smelting system has the advantages of high vanadium yield, low recycling cost, low recycling difficulty, simple equipment and the like.

Owner:CHINA ENFI ENGINEERING CORPORATION

A kind of aquatic plant seed granule, production method and granulation equipment

ActiveCN111066412BEasy to rootGood process continuityTransportation and packagingMixersXanthan gumGelatin

The invention discloses an aquatic plant seed granule, a production method and granulation equipment, wherein the seed granule is prepared from bentonite; stone powder; gelatin; xanthan gum; aquatic plant seeds with a particle diameter below 0.1 cm; and water. The invention mixes the aquatic plant seeds with other raw materials, and carries out underwater sowing in the form of particles with a certain weight. Compared with directly sowing the aquatic plant seeds, it is easier for the seeds to enter the underwater mud and take root.

Owner:大湖水环境治理股份有限公司

Machining and producing device for sealing strip on automobile glass

ActiveCN112775056ATo overcome the problem of easy to make the sealing strip entangledImprove processing efficiencyCleaning using toolsCleaning using liquidsElectric machineryStructural engineering

The invention discloses a machining and producing device for a sealing strip on automobile glass. The machining and producing device comprises a machining box, a box cover is detachably arranged on the upper portion of the machining box, an opening is formed in the upper portion of the box cover, a plurality of cleaning plate transmission rods vertically penetrate through the interior of the opening, the upper surfaces of the cleaning plate transmission rods are fixedly connected with the bottom end faces of movable matching rods arranged outside cleaning brush supporting rods in a sleeving mode, the bottoms of the cleaning plate transmission rods are fixedly connected with the upper surface of a cleaning plate with a brush arranged at the bottom, and a drying piece is further arranged on the side of the cleaning plate. The two ends of each movable matching rod are fixedly connected with cleaning brush supports arranged in an inverted-U shape, the two cleaning brush supports are symmetrically arranged on the upper surface of the box cover, the multiple movable matching rods are arranged between the two cleaning brush supports at equal intervals, and a third motor is arranged at the position, at any one of the two ends of the multiple movable matching rods, of each cleaning brush support. According to the machining and producing device for the sealing strip on the automobile glass, the machining quality is guaranteed, the equipment practicability is high, and wide popularization can be achieved.

Owner:山东水星博惠汽车部件股份有限公司

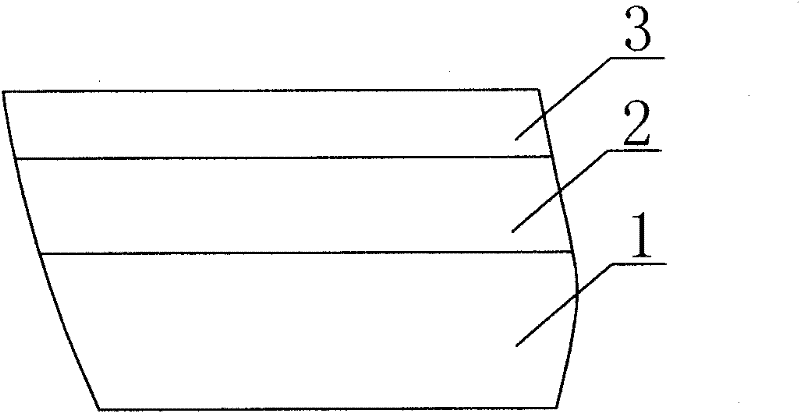

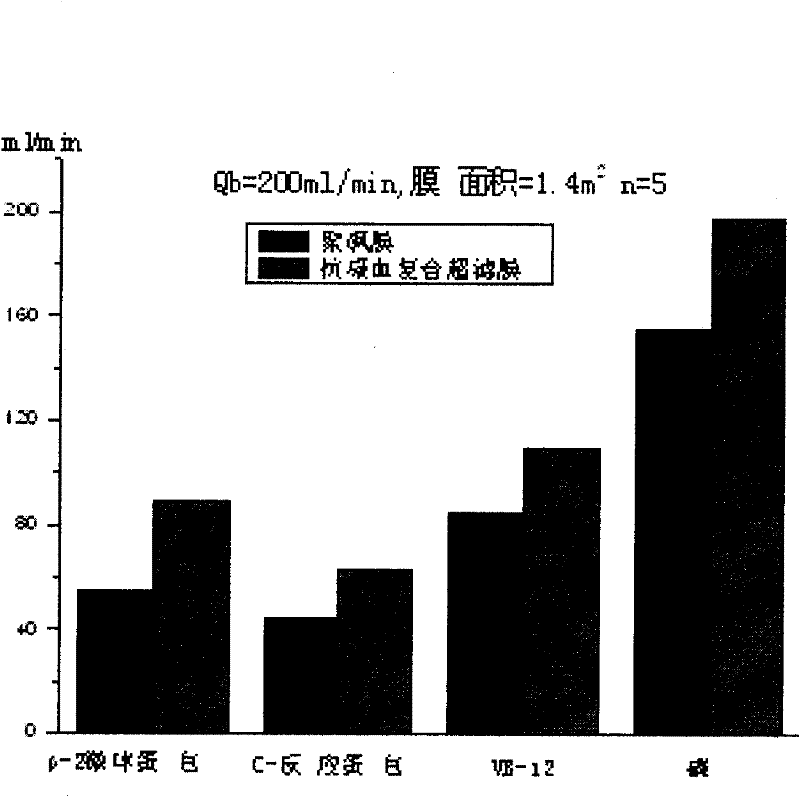

Anti-coagulation composite ultrafiltration membrane and preparation method thereof

InactiveCN101804307BStable physical and chemical propertiesImprove mechanical propertiesSemi-permeable membranesUltrafiltrationMicrometer

The invention relates to an anti-coagulation composite ultrafiltration membrane, which comprises a supporting layer, a polysulfone-based membrane layer and a sulfonated chitosan membrane layer, wherein the thicknesses of the supporting layer, the polysulfone-based membrane layer and the sulfonated chitosan membrane layer range from 30 to 100 micrometers; the thickness of the sulfonated chitosan membrane layer is between 0.01 and 0.5 micrometer, and the viscosity-average molecular weight of the sulfonated chitosan membrane layer is 30,000 to 300,000. The anti-coagulation composite ultrafiltration membrane of the invention is improved in membrane surface performance, hydrophily, mechanical strength and anti-coagulation performance, has high bioactivity, blood compatibility and anti-coagulation performance and uses a greatly reduced amount of or no heparin in a blood purification process. The membrane preparation process is simple and can realize industrial production.

Owner:江苏朗生生命科技有限公司

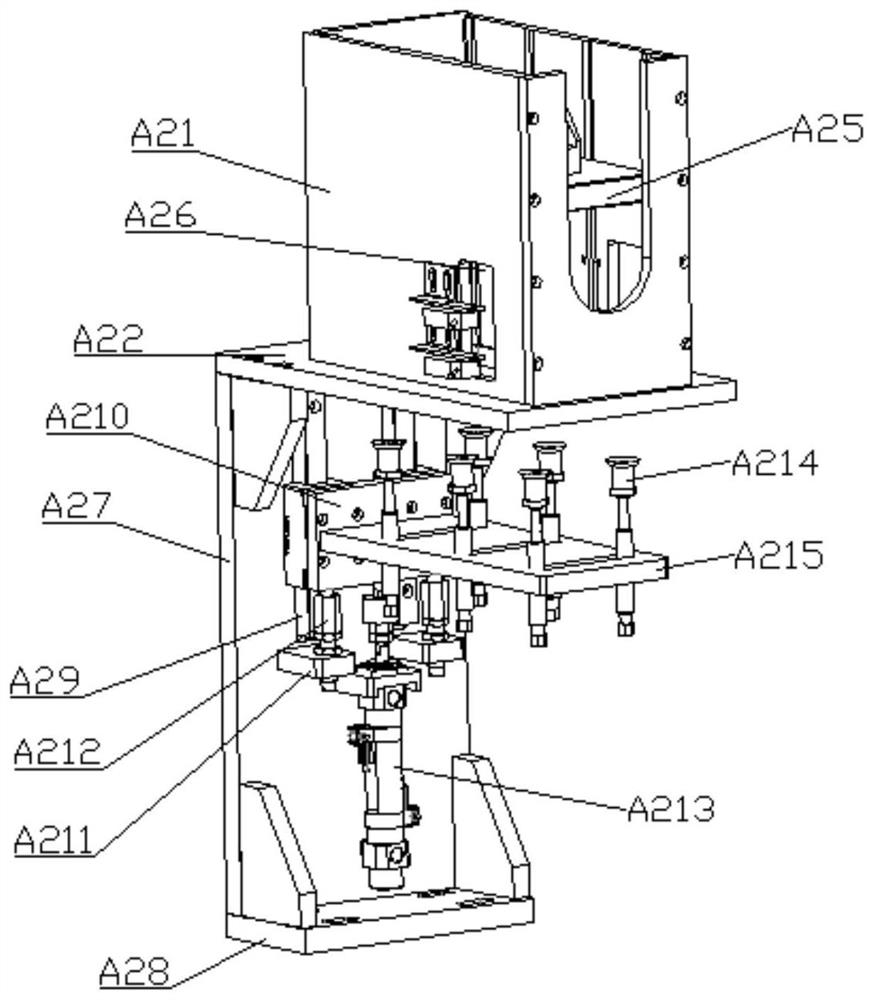

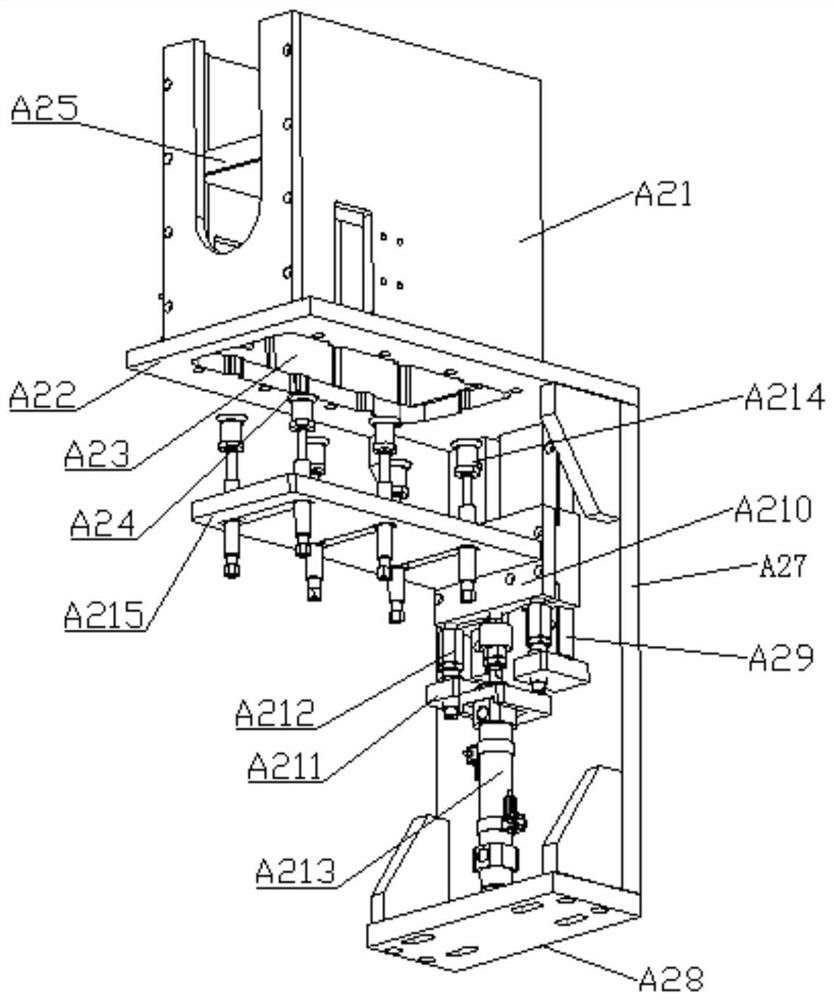

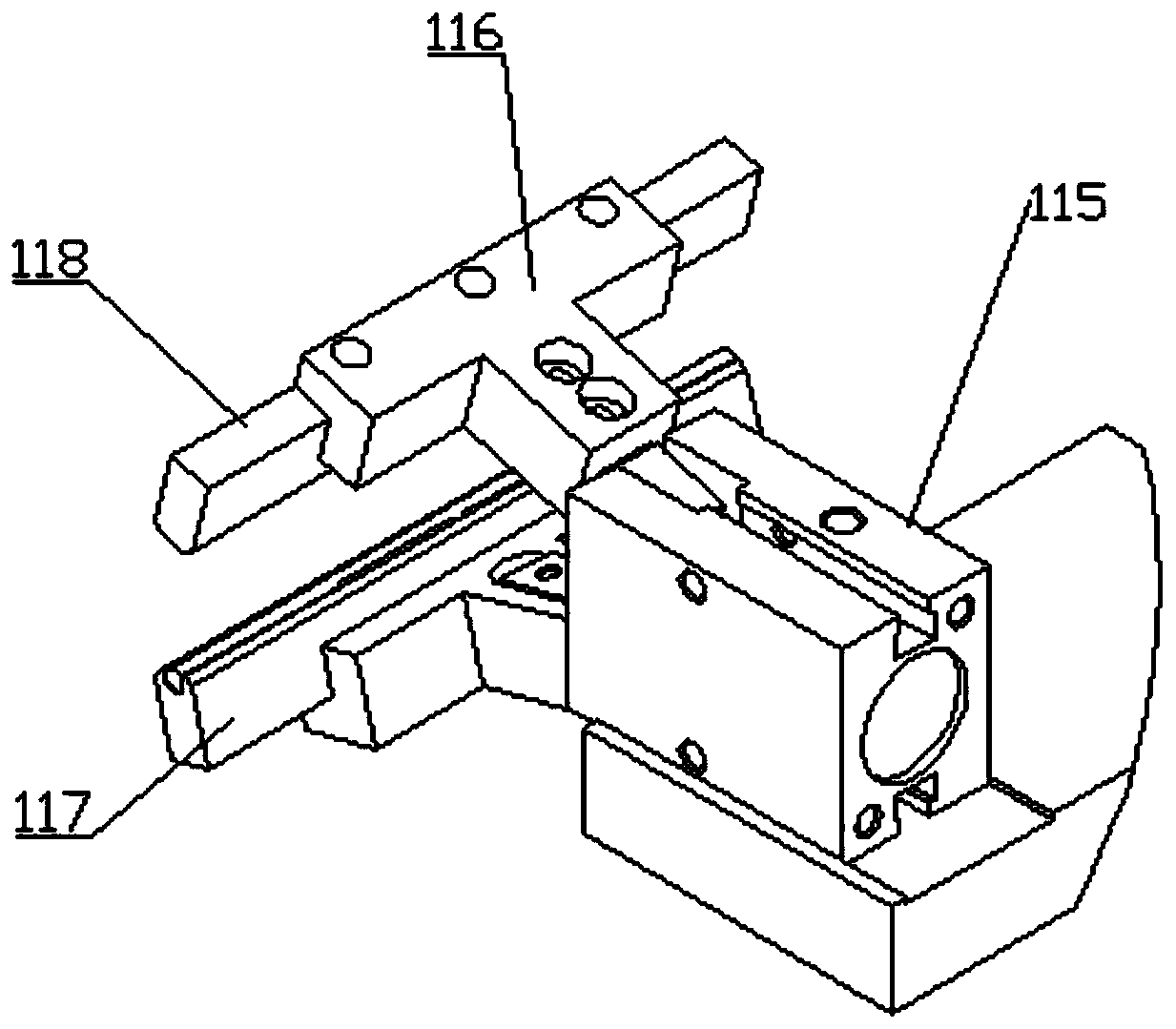

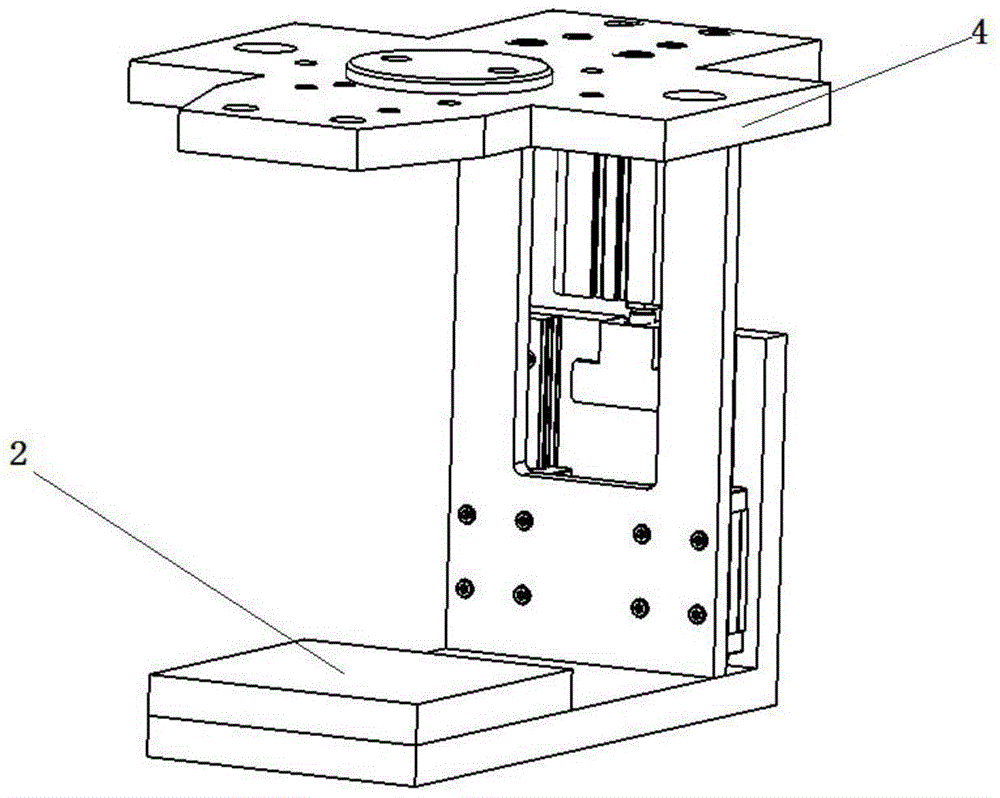

A device for on-line installation of automotive windshield metal studs

InactiveCN104959797BGood process continuityImprove work efficiencyVehicle componentsMetal working apparatusEngineeringMetal nail

The invention relates to a device used for installing metal nails of an automobile windscreen online. The device comprises a supporting frame, a rotating mechanism, a picking-up mechanism used in cooperation with the rotating mechanism, and a pressing joint plate. The picking-up mechanism is installed on a five-axis mechanical arm through a connecting plate. A pressing joint air cylinder is arranged at one side of the connecting plate and is in transmission connection with the pressing joint plate. The rotating mechanism comprises a motor arranged on the supporting frame, a rotating table in transmission connection with the motor, a rotating arm fixedly connected with the rotating table, a locating material disc A and a locating material disc B, wherein the locating material disc A and the locating material disc B are arranged at the two ends of the rotating arm in parallel. The rotating arm is arranged on the supporting frame through the rotating table in the mode of being capable of rotating by 360 degrees. The locating material disc A and the locating material disc B are provided with a plurality of locating grooves a and a plurality of locating grooves b respectively, wherein the locating grooves a and the locating grooves b are used for placing the metal nails. Compared with the prior art, the device is simple and compact in structure, economical, practical, high in automation degree, capable of effectively improving the bonding stability of the metal nails, and wide in application range.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com