A kind of aquatic plant seed granule, production method and granulation equipment

A technology for aquatic plants and seed granules, which is applied in the directions of botanical equipment and methods, methods for granulating raw materials, and planting substrates, can solve problems such as increasing seed weight, reducing water level, and seed floating, and reducing equipment footprint. , The effect of reasonable structure design and strong process continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The aquatic plant seed granules of this embodiment are prepared by mixing the following raw materials in weight percentage: 15% of 100-200 mesh calcium-based bentonite; 35% of 30-80 mesh rice wheat stone powder; 4% gelatin; 6% xanthan gum; Aquatic plant seeds with a particle size below 0.1cm 8%; water 32%.

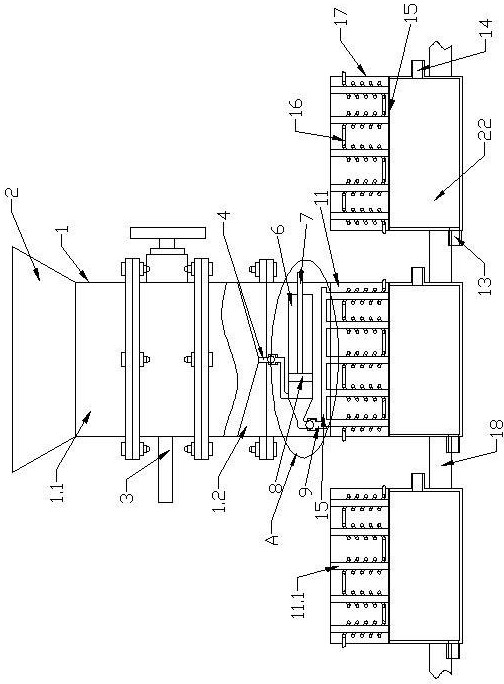

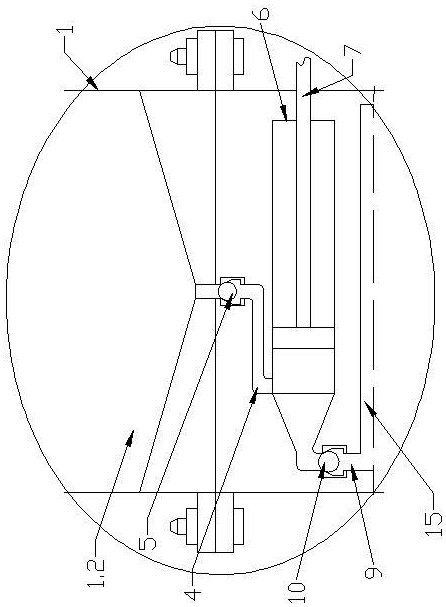

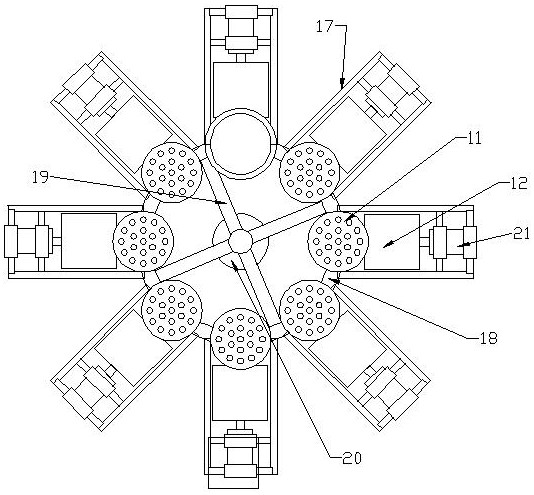

[0042] Preparation method: the above-mentioned aquatic plant seed granules are first mixed with bentonite, stone powder, and aquatic plant seeds in the first mixing zone 1.1, then add all the normal temperature water and stir well, then heat up to 50-70°C and keep warm. On the basis of heat preservation, add pre-heated and dissolved gelatin into a colloidal state, and stir well. During this process, the flap valve is closed. After mixing for a period of time, open the flap valve, and the fluid flows into the second mixing zone. Method for mixing (in the first mixing zone, the stirring paddle is fixed vertically in a conventional way, and in the second mixing zone, t...

Embodiment 2

[0044] Except following difference, all the other are with embodiment one:

[0045] The aquatic plant seed granules of this embodiment are prepared by mixing the following raw materials in weight percentage: 20% bentonite; 40% stone powder; 6% gelatin; 2% xanthan gum; 5% aquatic plant seeds with a particle size below 0.1cm; Water 27%.

Embodiment 3

[0047] Except following difference, all the other are with embodiment one:

[0048] The aquatic plant seed granules of this embodiment are prepared by mixing the following raw materials in weight percentage: 20% bentonite; 35% stone powder; 6% gelatin; 2% xanthan gum; 5% aquatic plant seeds with a particle size below 0.1cm; Water 32%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com