Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Excellent superconductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

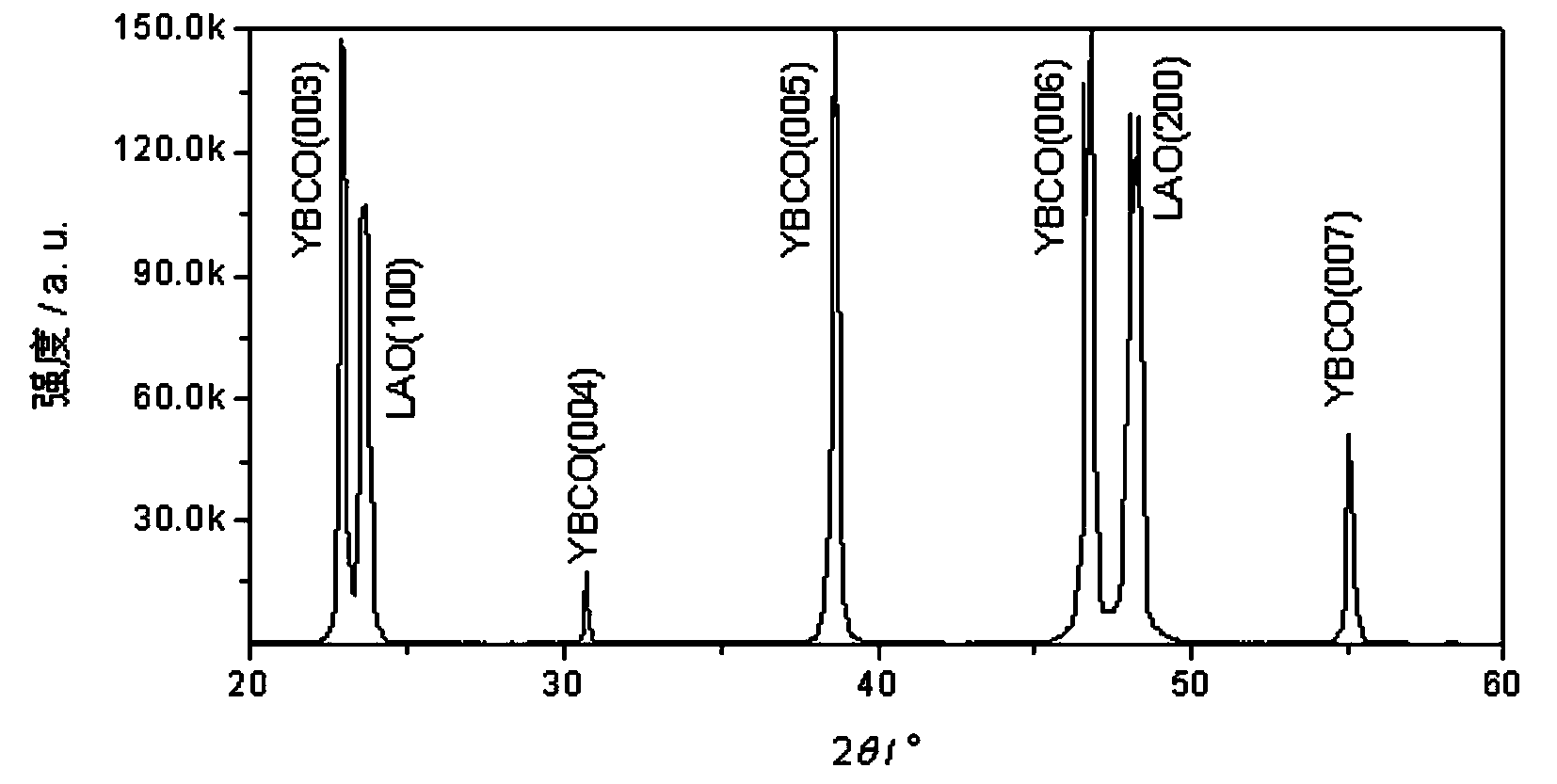

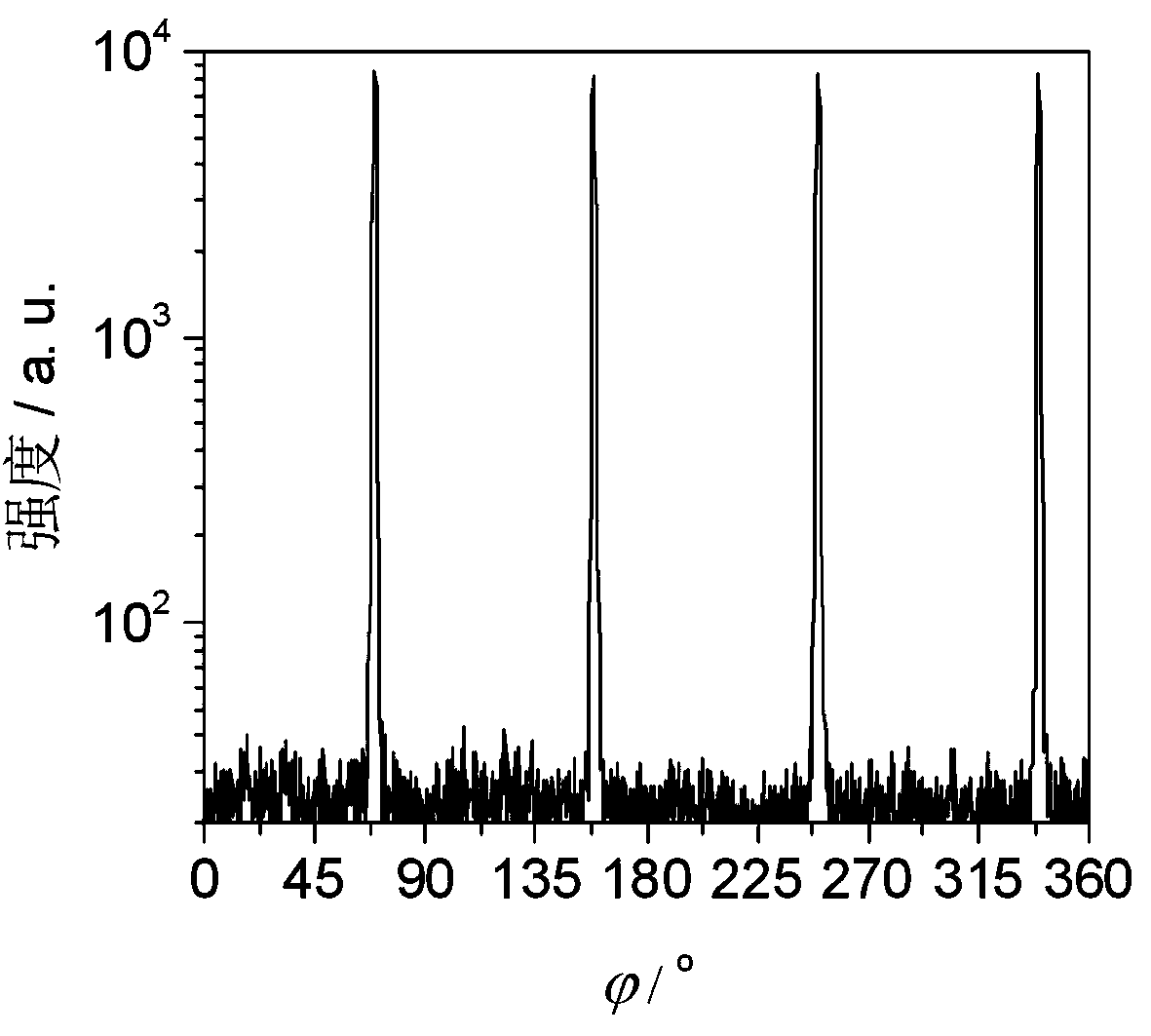

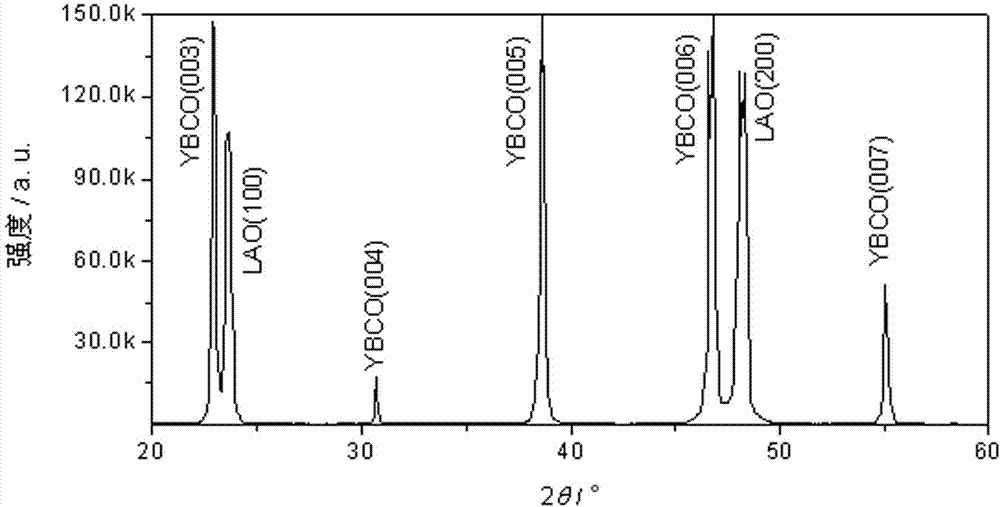

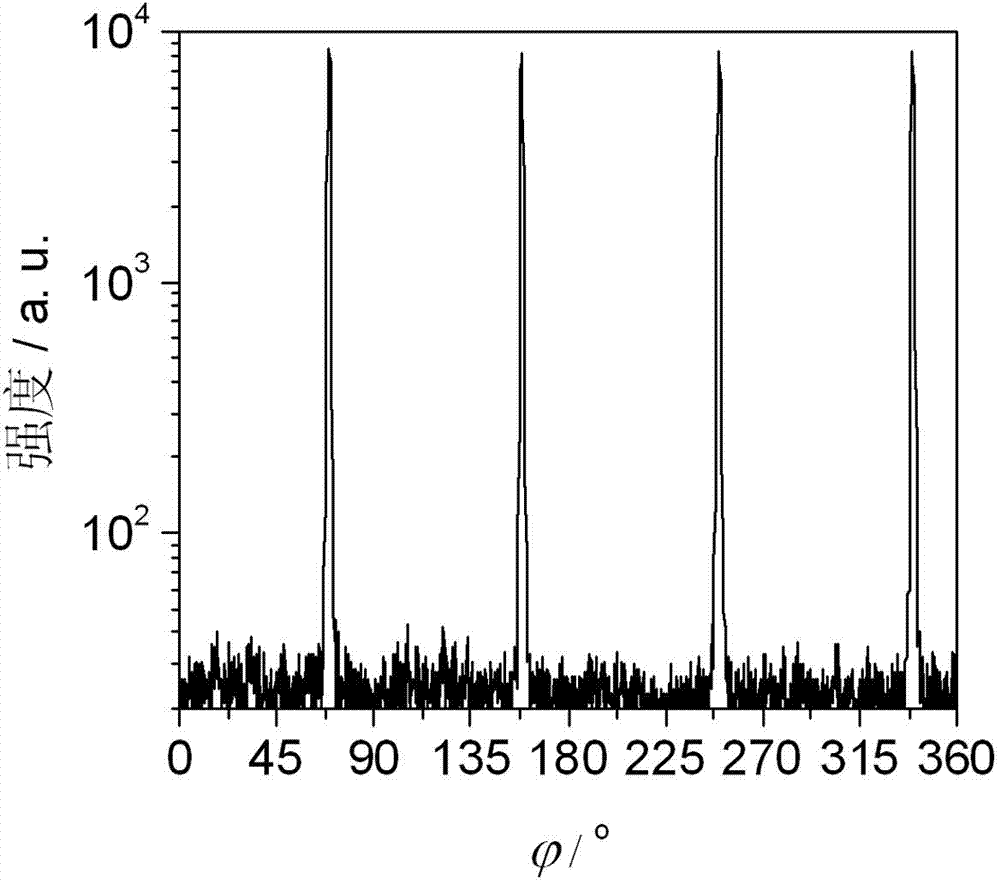

Method for improving critical current for continuously preparing YBCO (Yttrium Barium Copper Oxide) strip

ActiveCN102560378BSolve the problem of increasing cubic texture variationImprove uniformityVacuum evaporation coatingSputtering coatingYttrium barium copper oxideOptoelectronics

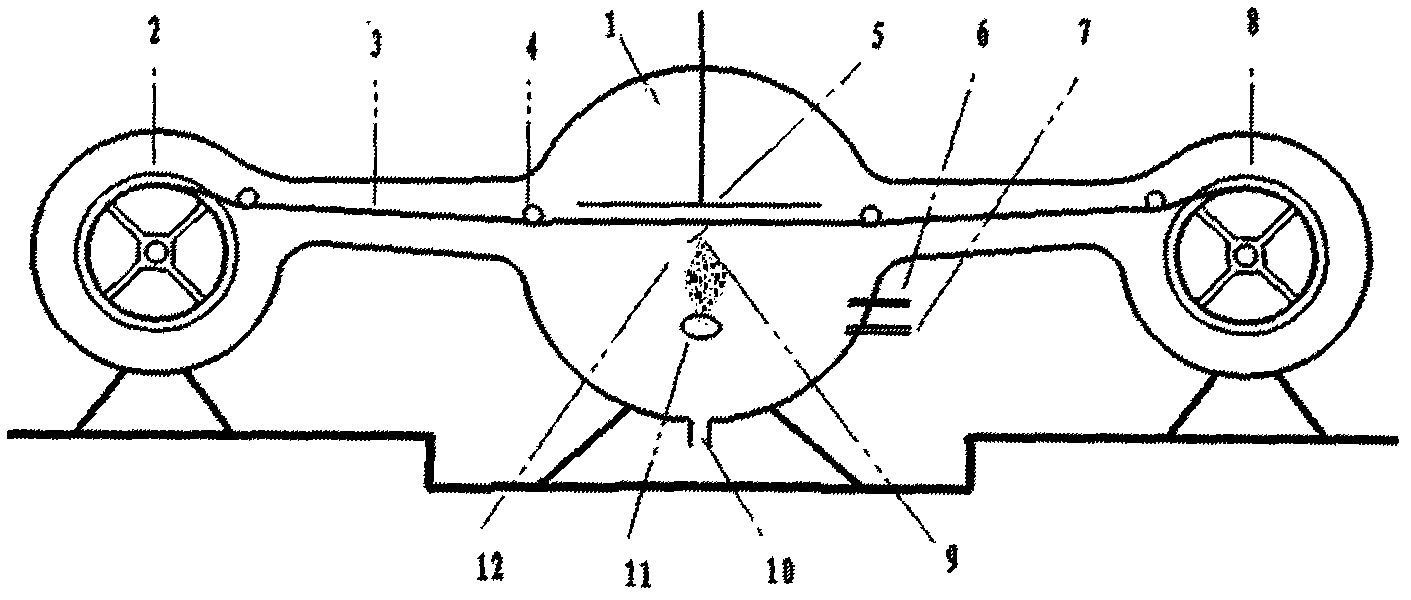

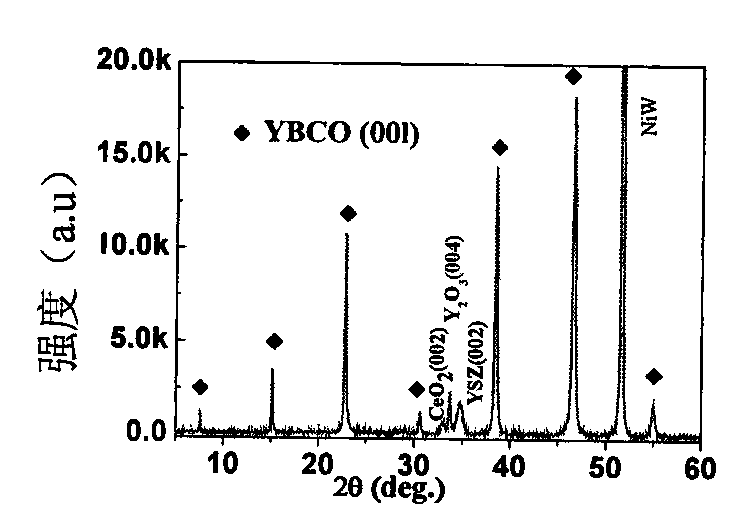

The invention relates to a method for improving a critical current for continuously preparing a YBCO (Yttrium Barium Copper Oxide) strip, which comprises the following steps of: (1) in a vacuum chamber of equipment for continuously preparing a YBCO superconducting layer, fixing a metal substrate on a guide belt; (2) using YBCO as a target material, wherein the target-substrate distance is in the range of 40 to 60mm; (3) regulating a laser optical path before vacuumizing; (4) when the vacuum degree in the vacuum chamber is superior to 3*10<-4>Pa, heating the metal substrate to the temperature of 750 to 770 DEG C and controlling the pure oxygen atmosphere into 20 to 30Pa; (5) depositing a first layer of YBCO thin film under the laser frequency of 10 to 20Hz and at the traveling speed of 0.1 to 0.4mm / s, then depositing a plurality of layers of YBCO thin films, and when depositing the next layer of YBCO thin film every time, respectively rising the temperature of the metal substrate in the process of depositing the previous layer of YBCO thin film by 10 to 20 DEG C and depositing the next layer of YBCO thin film under the laser frequency of 10 to 40 Hz and at the traveling speed of 0.1 to 0.2mm / s; and (6) carrying out in-situ annealing to prepare the YBCO superconducting layer. According to the invention, the layered deposition is adopted, the temperature is properly risen between the layers, the problem of variation of a cube texture of the YBCO layer along with the increase of the thickness is solved, and the superconducting performance is effectively improved.

Owner:GRIMAT ENG INST CO LTD

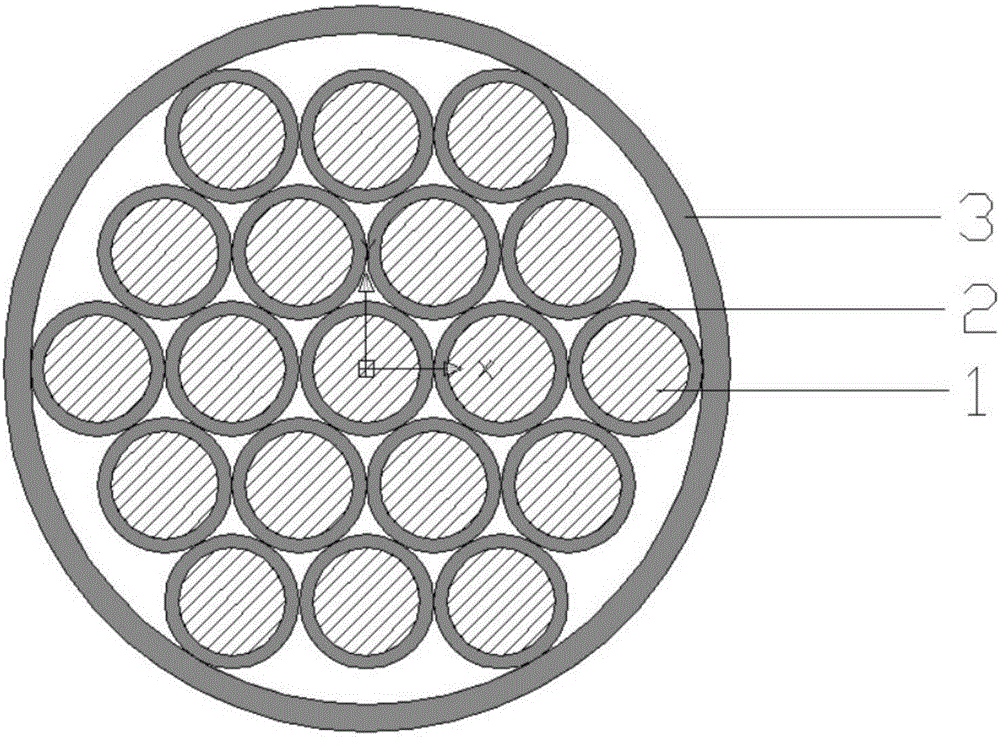

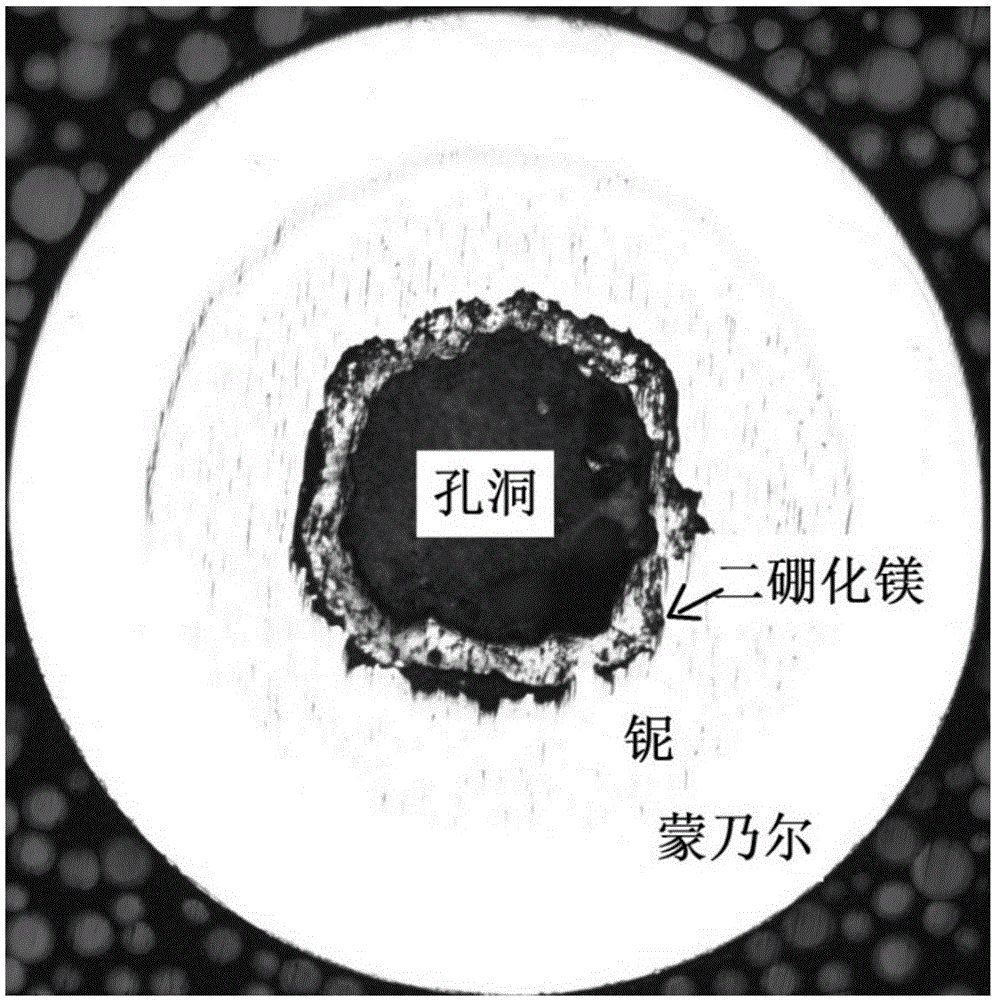

Manufacturing method for practical multi-core MgB2 composite superconductive wire rods

InactiveCN105845278AGuaranteed performanceLarge scaleSuperconductors/hyperconductorsSuperconductor devicesCopperSwaging

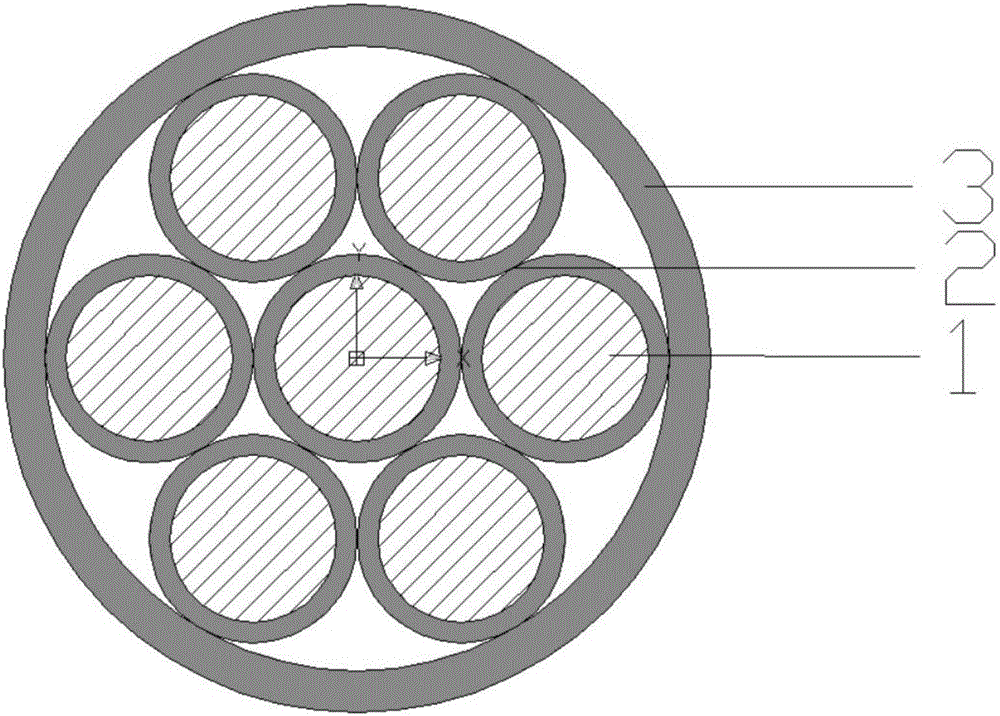

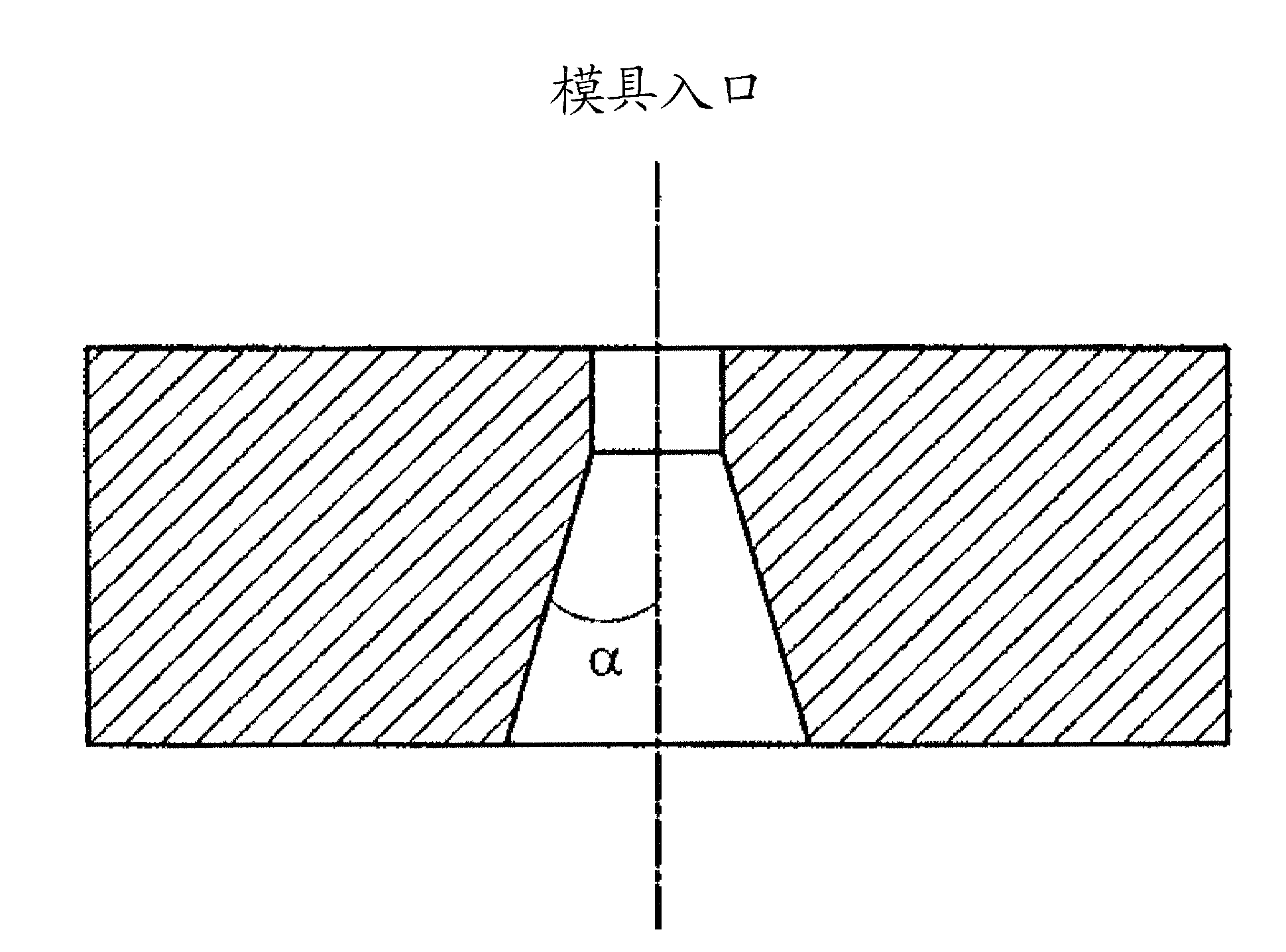

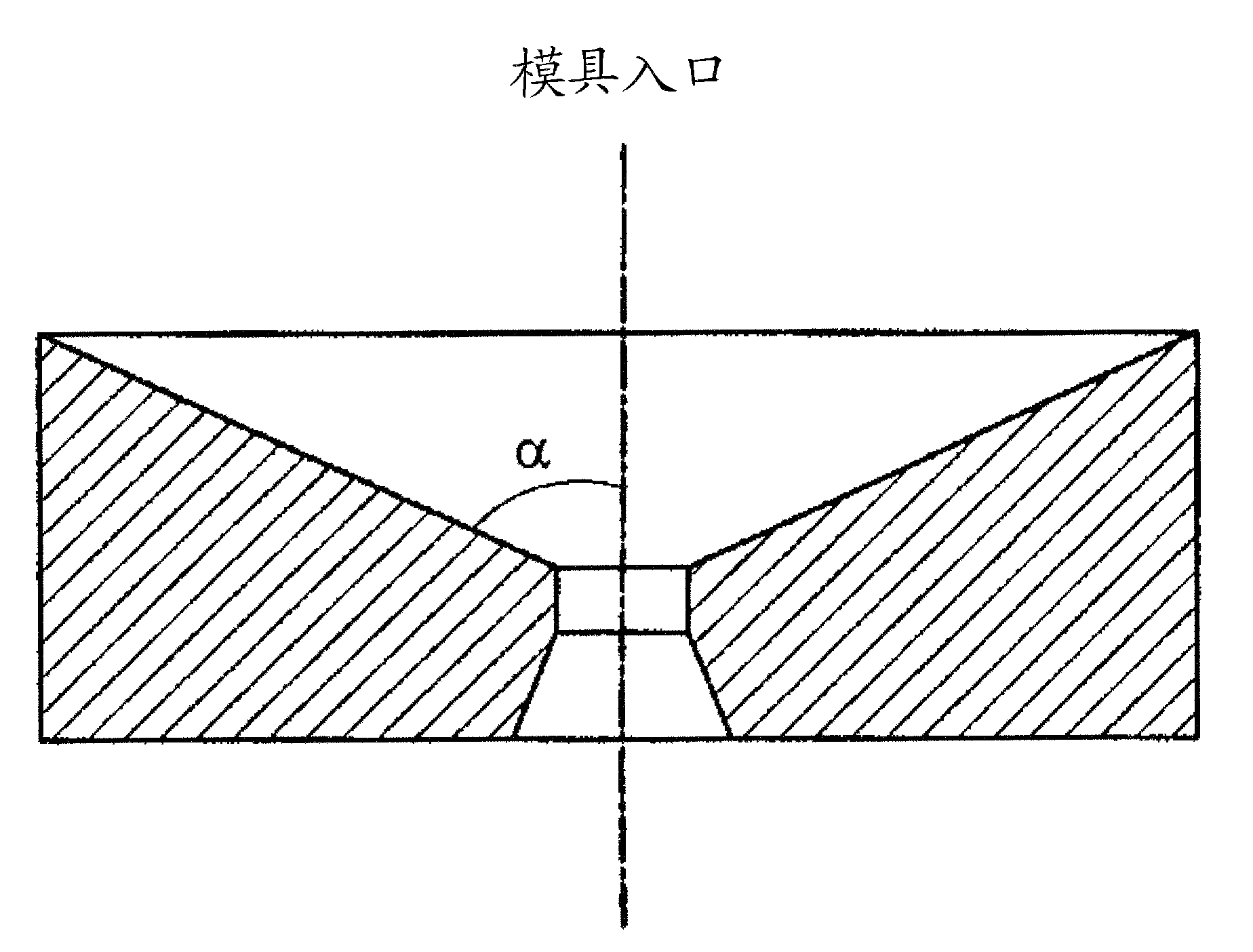

The invention discloses a manufacturing method for practical multi-core MgB2 composite superconductive wire rods. The method is performed through the following steps: 1) obtaining precursor powder by mixing and ball milling; 2) filling the powder into a Fe pipe; 3) obtaining single core wire rods through the process of drawing and intermediate annealing; 4) obtaining a multi-core wire rod by carrying out rotary swaging and drawing to the plurality of single core wire rods after they are coated with coalesced copper bands; and 5) obtaining a multi-core MgB2 superconductive wire rod through sintering in vacuum. The manufacturing method of the invention combines the advantages of a PIT method and a CTFF method wherein high quality single wire rods are manufactured through the PIT method and based on the single wire rods and through the CTFF method, a large sized multi-core MgB2 superconductive wire rod is manufactured effectively. According to the invention, the large sized multi-core MgB2 superconductive wire rod ensures both the quality of the single core wire rods and high manufacturing efficiency, meeting the practical need of superconductive materials and enabling the superconductive materials to be used in practice.

Owner:SOUTHEAST UNIV

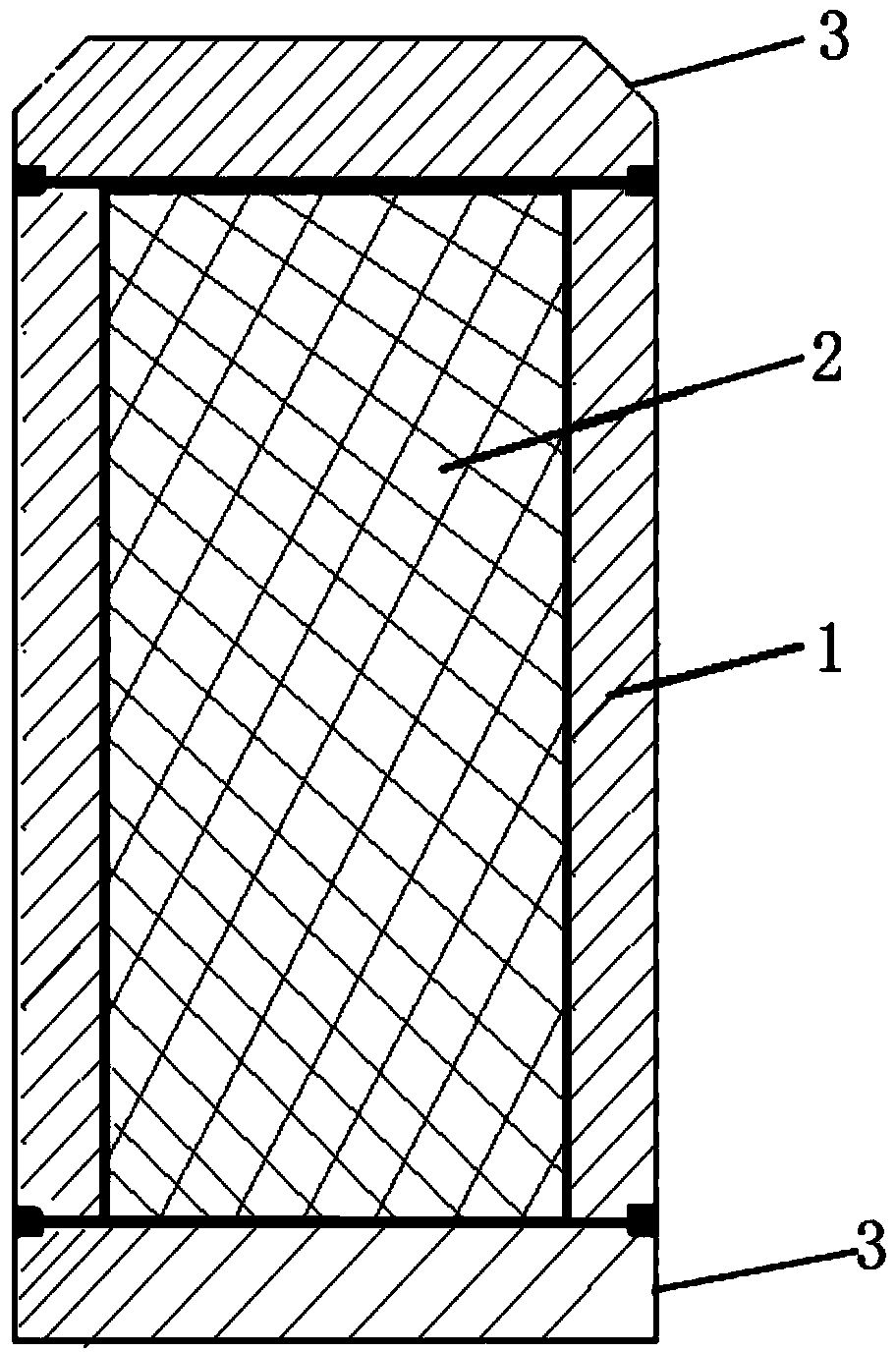

NbTi/Cu superconducting composite pipe and preparation method thereof

InactiveCN104201278ATo achieve a unified specification standardExcellent superconductivitySuperconductor detailsSuperconductor device manufacture/treatmentIngotJoint stability

The invention discloses an NbTi / Cu superconducting composite pipe. The outer layer of the composite pipe is made of oxygen-free copper while the inner layer thereof is made of a niobium-titanium superconducting material. The invention also relates to a preparation method of the composite pipe. The preparation method comprises the steps of: pressing an NbTi alloy ingot into the oxygen-free copper pipe to assemble a composite ingot, and sealing and welding the two ends of the composite ingot by using oxygen-free copper cover plates; performing thermal extrusion process on the well-assembled composite ingot to form an NbTi / Cu composite rod; performing cold drawing process on the composite rod to enable the diameter to be 10-20 mm; performing aging heat treatment on the composite rod after the cold drawing; carrying on the cold drawing process of the composite rod after the heat treatment until the needed outer diameter size is obtained; cutting off the composite rod after the cold drawing in a fixed length, carrying out straightening ;process to form an NbTi / Cu composite rod; cutting off the composite rod in a fixed length, and drilling holes with needed diameter from the center of the composite rod along the axial direction until the NbTi / Cu superconducting composite pipe is obtained. The produced NbTi / Cu superconducting composite pipe is suitable for an NbTi superconducting joint, the resistance of the joint can be reduced efficiently, the joint stability and reliability can be improved, and production in batches is facilitated.

Owner:西安艾菲尔德复合材料科技有限公司

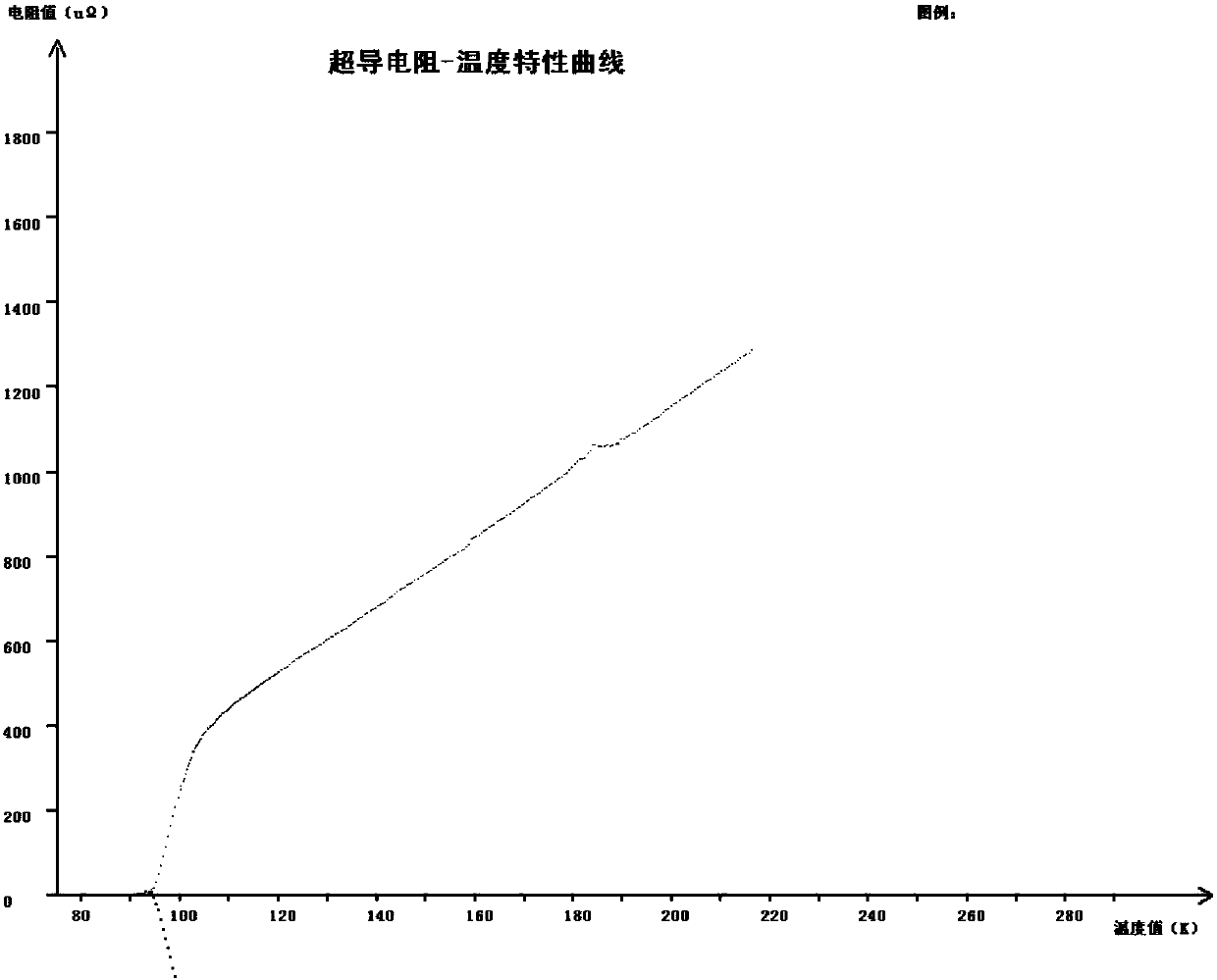

Method of preparing Tl-1223 superconductive thin film

ActiveCN107602112AFlat surfaceExcellent superconductivitySuperconductors/hyperconductorsSuperconductor devicesThalliumOxygen

The invention discloses a method of preparing a Tl-1223 superconductive thin film. In the invention, a thallium-containing amorphous precursor film and a thallium-containing sintering accompanying target are sealed and coated with a silver foil or a gold foil, and then sintering is carried out in a sealed argon gas or a flowing oxygen environment. In the method, phase forming temperature zone of low-temperature phases, such as Tl-1212 and Tl-2212, can be crossed quickly and Tl-1223 superconductive phase temperature zone is directly reached, thus producing a pure-phase thin film. The method isshort in temperature increase / decrease time and constant temperature time and is low in production cost.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Method for manufacturing large-scale MgB2 single-core superconducting wire

InactiveCN103928192AHigh densityGuaranteed lengthSuperconductors/hyperconductorsSuperconductor devicesSwagingCarbon steel

The invention relates to a method for manufacturing a large-scale MgB2 single-core superconducting wire. According to the method, Mg powder and B powder are used as raw materials, a low-carbon steel pipe with a certain specification is cleaned, the Mg powder and the B powder are placed in a ball-milling tank in a glove box filled with argon according to a molar ratio of 1.1:2, a certain number of mill balls are added for ball milling, the cleaned low-carbon steel pipe is then filled with the evenly mixed raw powder, vibration is conducted with a vibration device and the raw powder is compacted with a tamper, the opening is sealed, and then a wire with Mg and B mix powder wrapped in low-carbon steel with a certain diameter and length is obtained through rotary swaging, drawing and intermediate annealing; the MgB2 single-core superconducting wire can be obtained after the wire is sintered under 800 DEG C - 900 DEG C for 10 min - 20 min. Large-scale MgB2 single-core superconducting wires with diameters ranging from 0.95 mm to 1.05 mm and lengths of 1000 m can be manufactured with the method, and the wires have a good electrical property and mechanical property.

Owner:SOUTHEAST UNIV

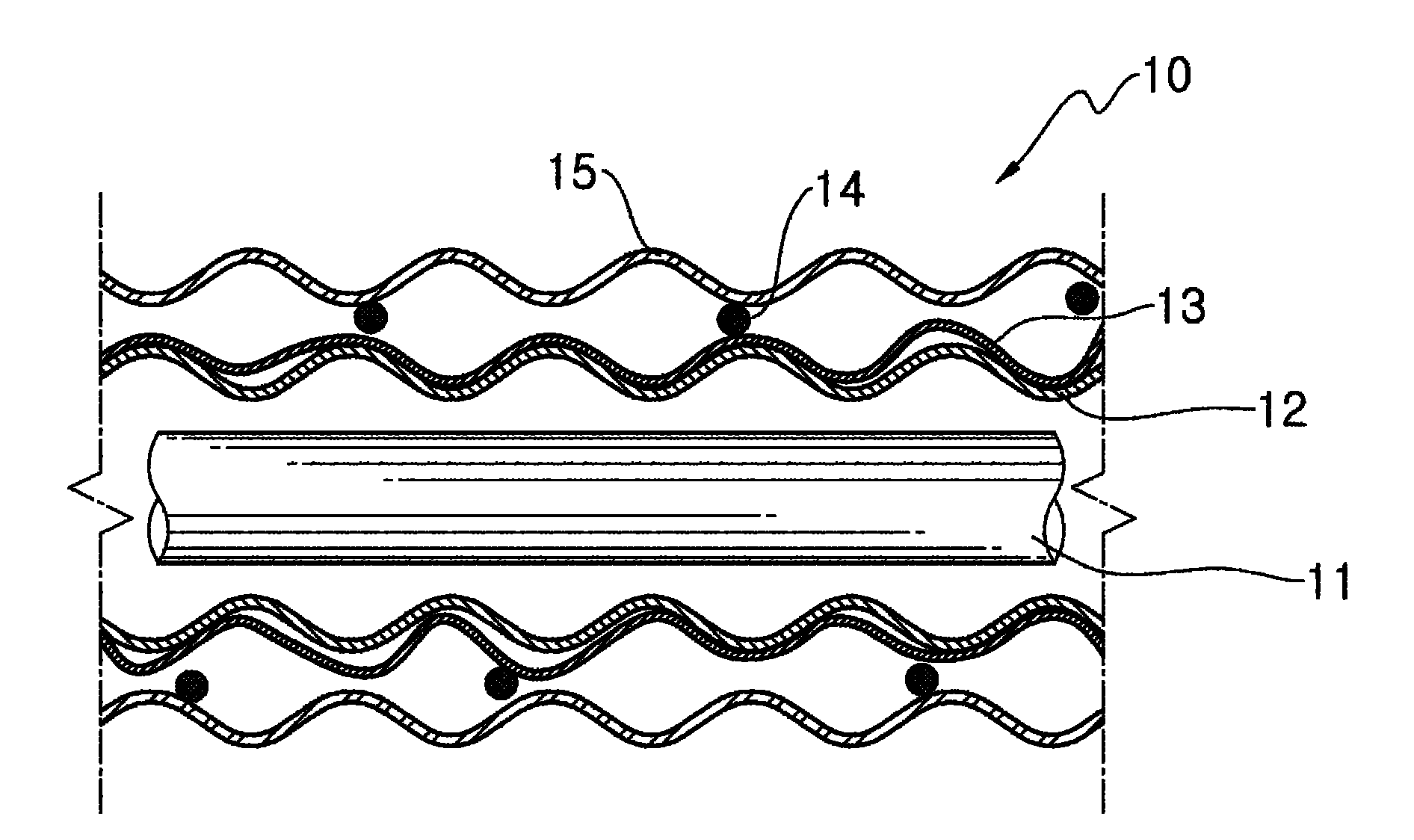

Superconducting cable with aluminum cryostat

InactiveCN102163477AControl Surface RoughnessMinimizes radiant heat energySuperconductors/hyperconductorsSuperconductor devicesElectrical conductorSurface roughness

Provided is a superconducting cable with aluminum cryostat configured to improve superconductivity by increasing reflectivity of cryostats and enhancing cooling performance. The superconducting cable includes: a core provided with a conductor; and a cryostat surrounding a periphery of the core. A material of the cryostat is aluminum or an aluminum alloy and a surface roughness of the cryostat is 30 microns or less in terms of RMS value.

Owner:LG CABLE LTD (KR)

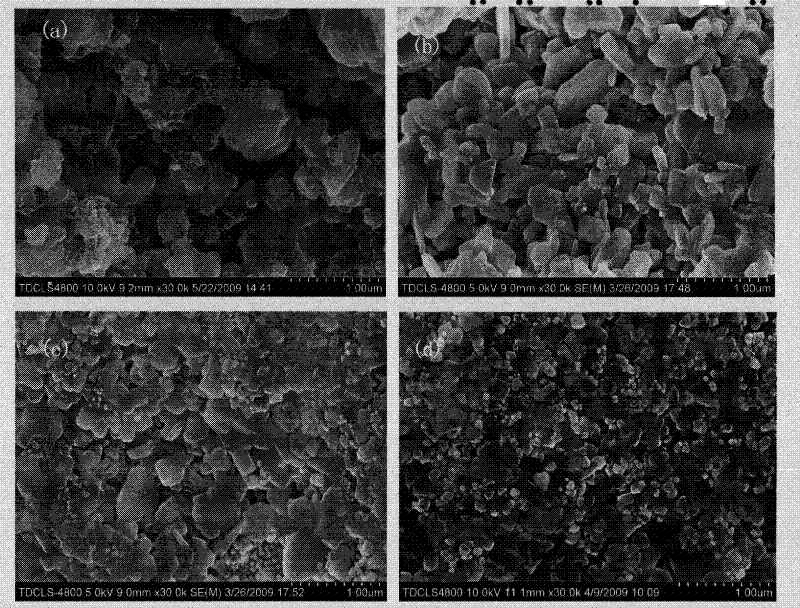

Method for improving critical current of YBCO thick film

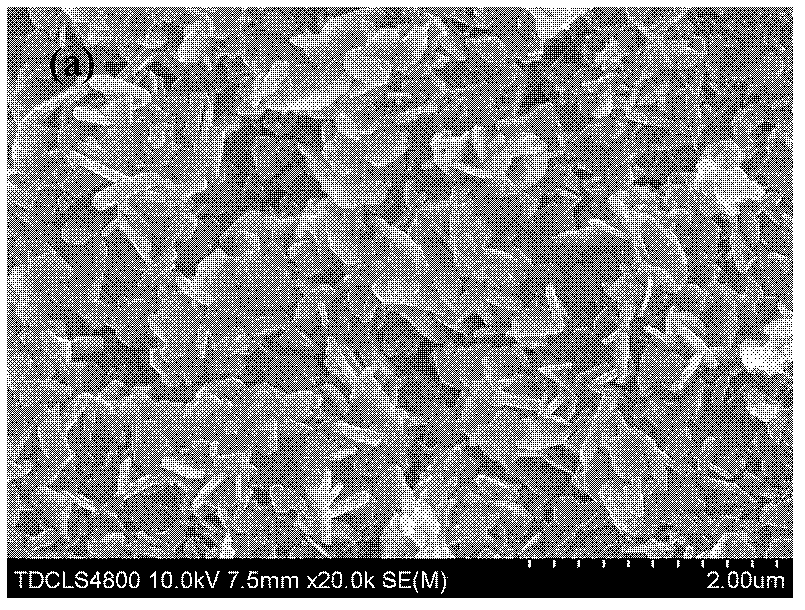

InactiveCN105695940AHigh heating temperatureImprove textureVacuum evaporation coatingSputtering coatingVacuum pumpingOptoelectronics

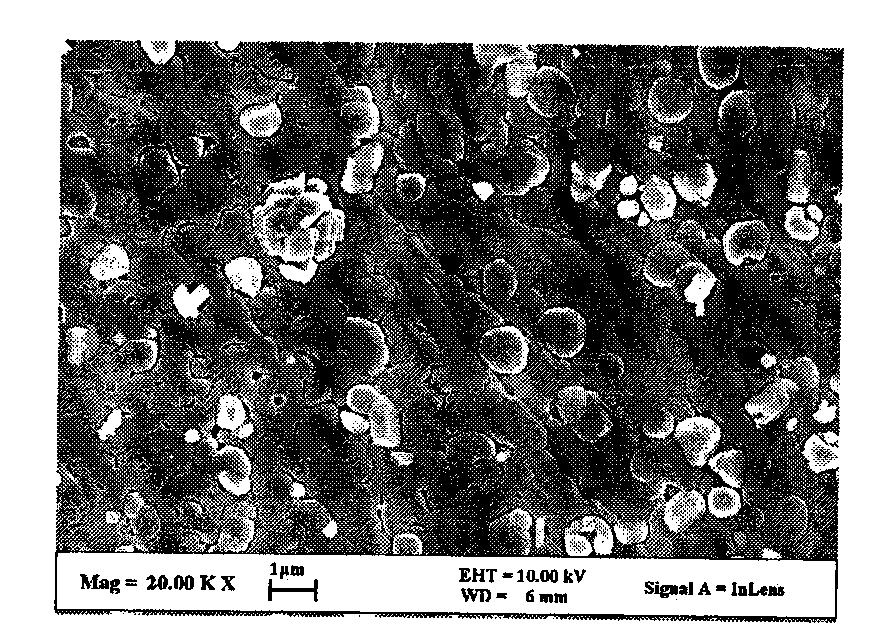

A method for producing a YBCO superconducting layer thick film on a metal baseband substrate comprises the following steps: 1, adopting a metal baseband with an isolating layer as a sample substrate; 2, adopting YBCO as a target material, and controlling the target-substrate distance to be 40-60mm; 3, carrying out vacuum pumping until the vacuum degree in a vacuum cavity is better than 3*10<-4>Pa, heating the metal baseband substrate to 750-770DEG C, and keeping the temperature unchanged; 3, introducing oxygen to the vacuum cavity, controlling the pressure of pure oxygen atmosphere to be 20-30Pa, and keeping the pressure; 4, producing the YBCO film on the metal baseband substrate with the isolating layer through using a pulsed laser deposition (PLD) technology, depositing the YBCO film at a laser frequency of 10-20Hz, heating the metal baseband substrate to make the temperature be 5-10DEG C higher than an original temperature, keeping the temperature, continuously depositing the YBCO film under same conditions after the temperature is stable, and changing a traditional continuous deposition mode to an intermittent deposition mode; and 5, carrying out in situ annealing on the deposited YBCO films in order to produce the YBCO superconducting layer thick film on the metal baseband substrate with an isolating layer. The YBCO film produced by using the above laser method has the advantages of good texture, good surface morphology and high electric performance.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Graphene catalyst applied to improve ionic conductivity of lithium polymer battery

InactiveCN107394259AImprove ionic conductivityIncrease capacityCell electrodesSecondary cells servicing/maintenanceInternal resistanceLithium-ion battery

The invention discloses a graphene catalyst applied to improve ionic conductivity of a lithium polymer battery. The graphene catalyst is prepared by the following steps of: (1) material selection, (2) preparation of diamine POSS (polyhedral oligomeric silsesquioxane), (3) preparation of octaphenyl POSS, (4) preparation of graphite oxide and (5) preparation of the graphene catalyst. The catalyst effectively improves the capacity of the battery and a working platform, can effectively avoid passivation of Li ions on an electrode to form an oxide, and prolongs a service life of the battery; the internal resistance is reduced greatly, so that an internal heating phenomenon of the battery is reduced; when a problem appears in the battery, the problem can be embodied timely and appears as ballooning without explosion; the safety and stability of the battery are improved; and at the same time, the graphene catalyst has excellent performances such as superconductivity, mechanical properties and heat resistance.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

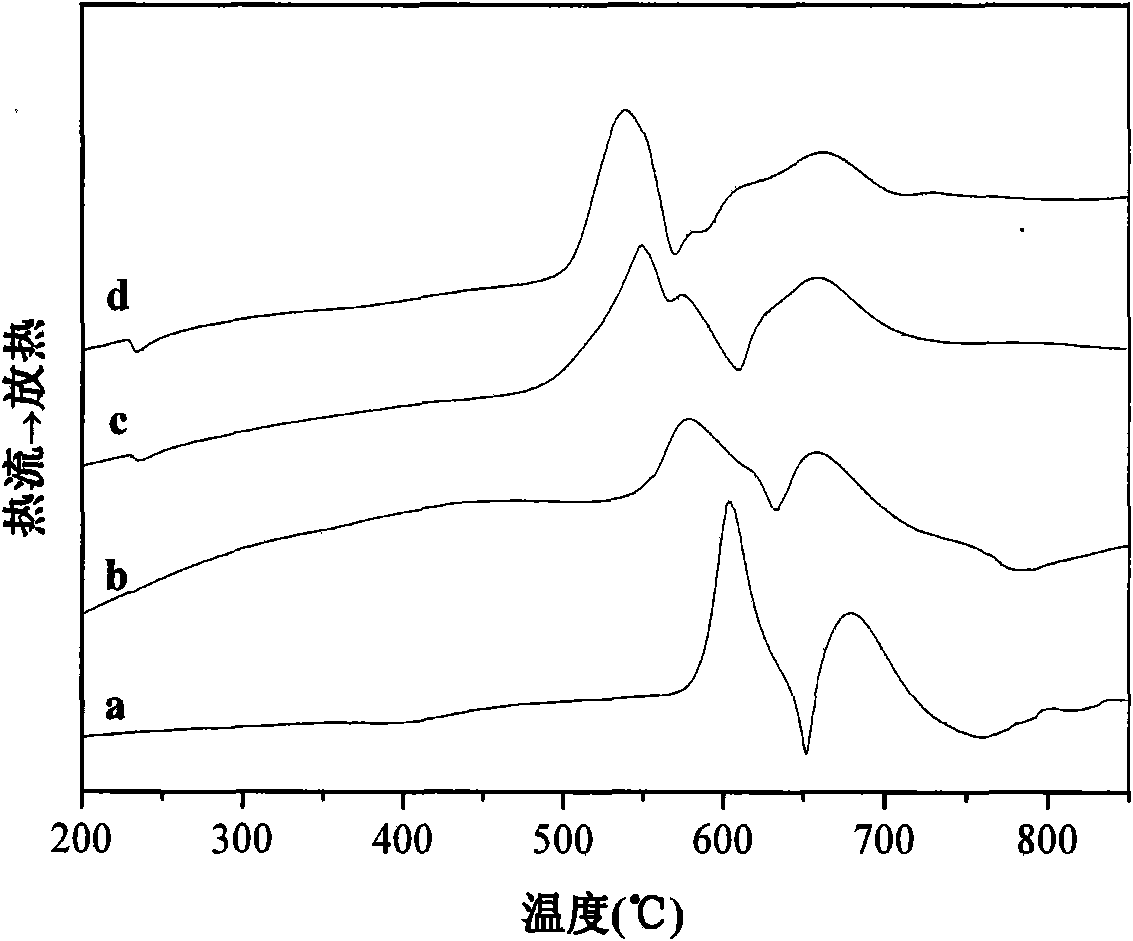

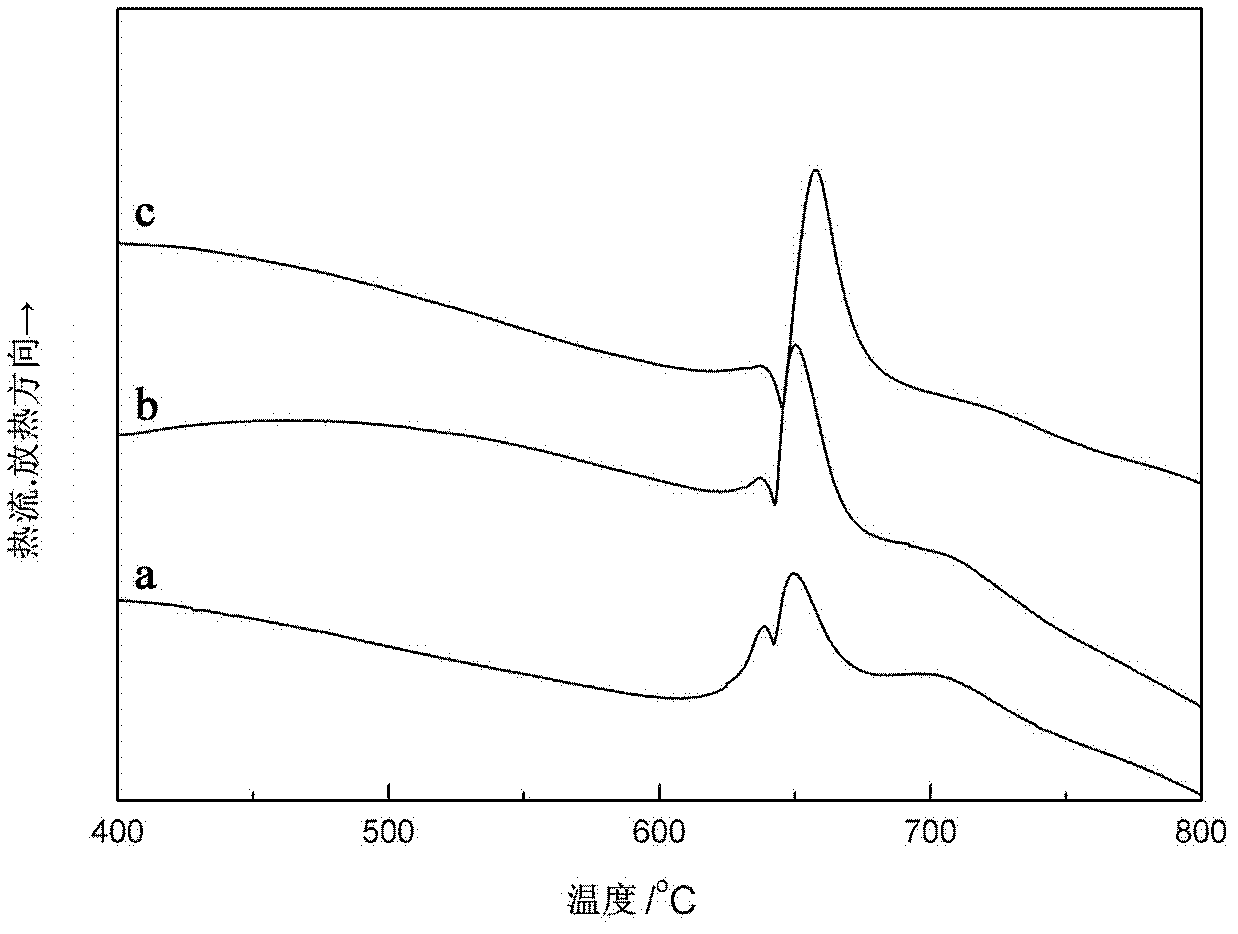

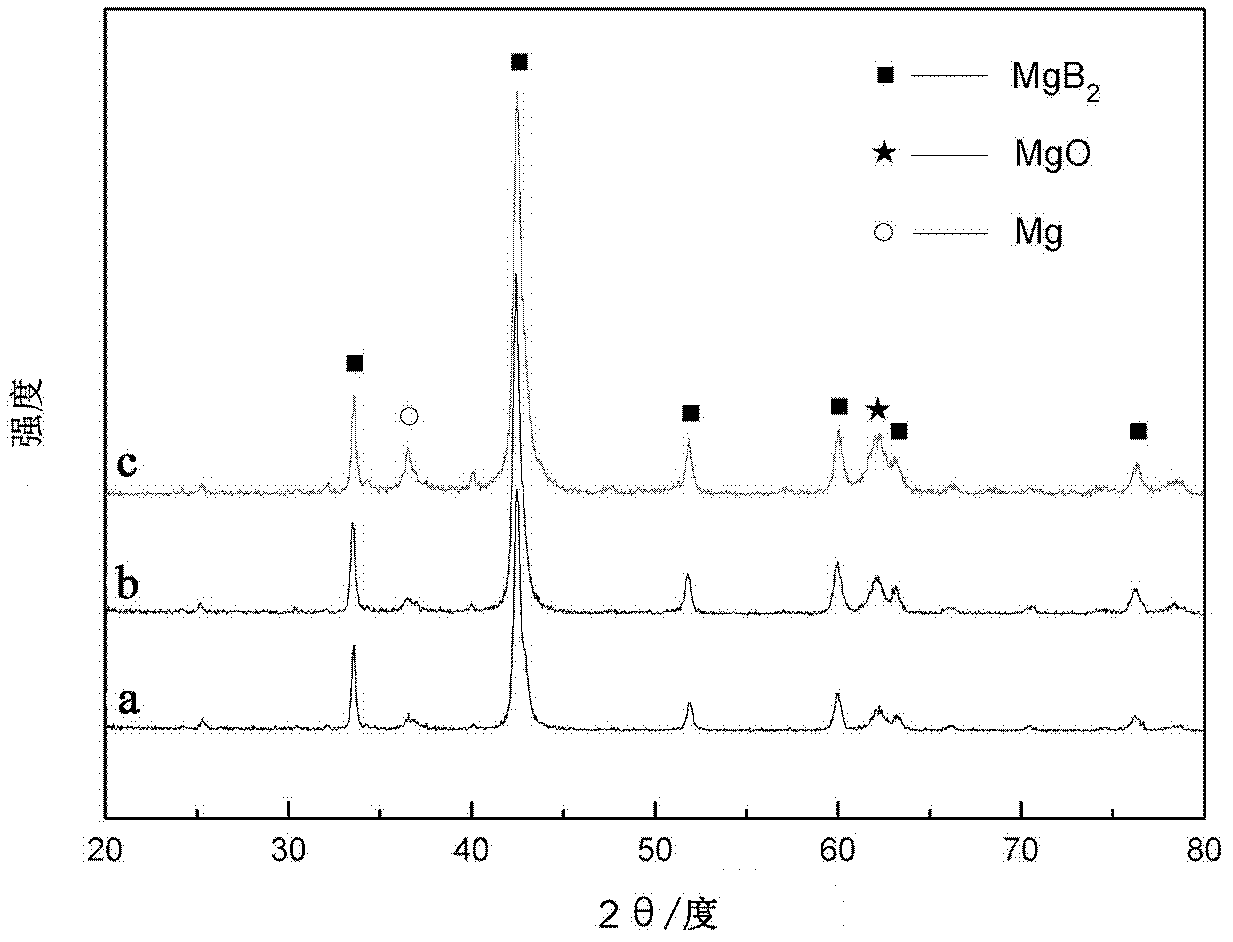

Metal Sn doped MgB2 superconductor and high-temperature rapid preparation method thereof

InactiveCN101591172AMaintain the superconducting transition temperature valueGood superconducting propertiesSuperconductivityAtomic ratio

The invention relates to a metal Sn doped MgB2 superconductor and a high-temperature rapid preparation method thereof. A structural formula of the superconductor is (Mg1.02B2)1-xSnx, wherein x=0.01-0.05. The method comprises the following steps: fully mixing Mg powder, B powder and Sn powder according to atomic ratio, pressing and preparing the mixture into a cylindrical flake under the pressure of 2 to 10 MPa, and then putting the cylindrical flake into a high temperature differential scanning calorimeter or a tubular sintering furnace for sintering; and continuously heating the cylindrical flake to 850 to 900 DEG C at heating rate of 5 to 20 DEG C per minute for sintering treatment, and cooling the cylindrical flake to room temperature at cooling rate of 30 to 40 DEG C per minute. The practical application field of MgB2 is in an around 3T magnetic field, so the method improves the superconductivity of the MgB2 superconductor in a short time by doping metal Sn and using a high-temperature sintering method. The preparation method is simple, has low cost of the raw materials and short preparation time, and is a quite potential research method; and simultaneously, the obtained superconductor has obvious superconductivity.

Owner:TIANJIN UNIV

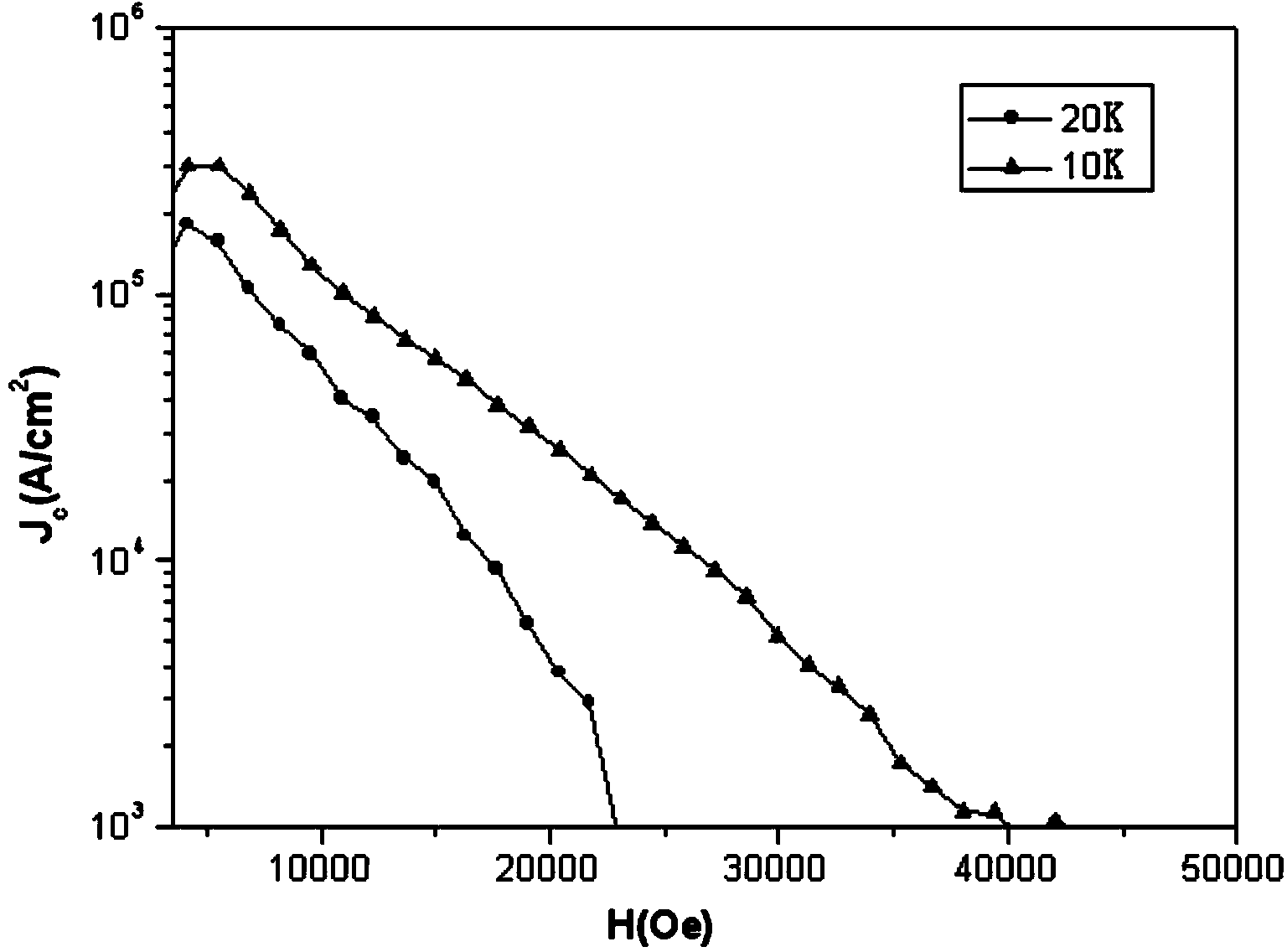

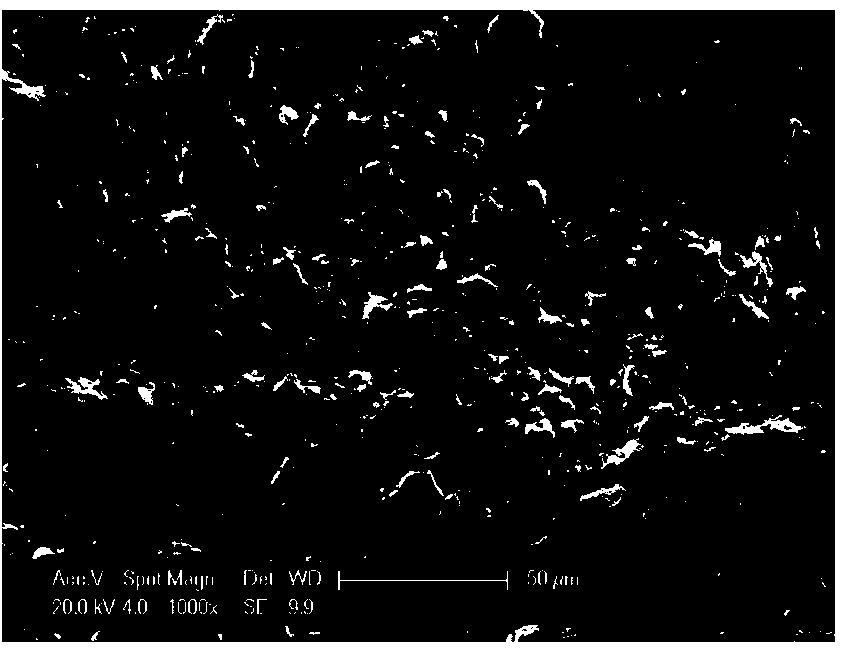

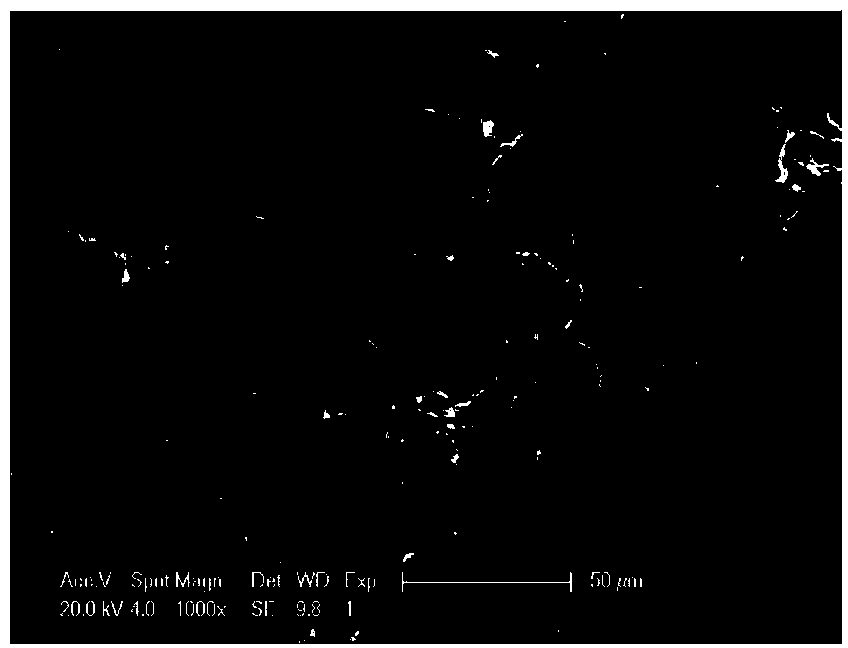

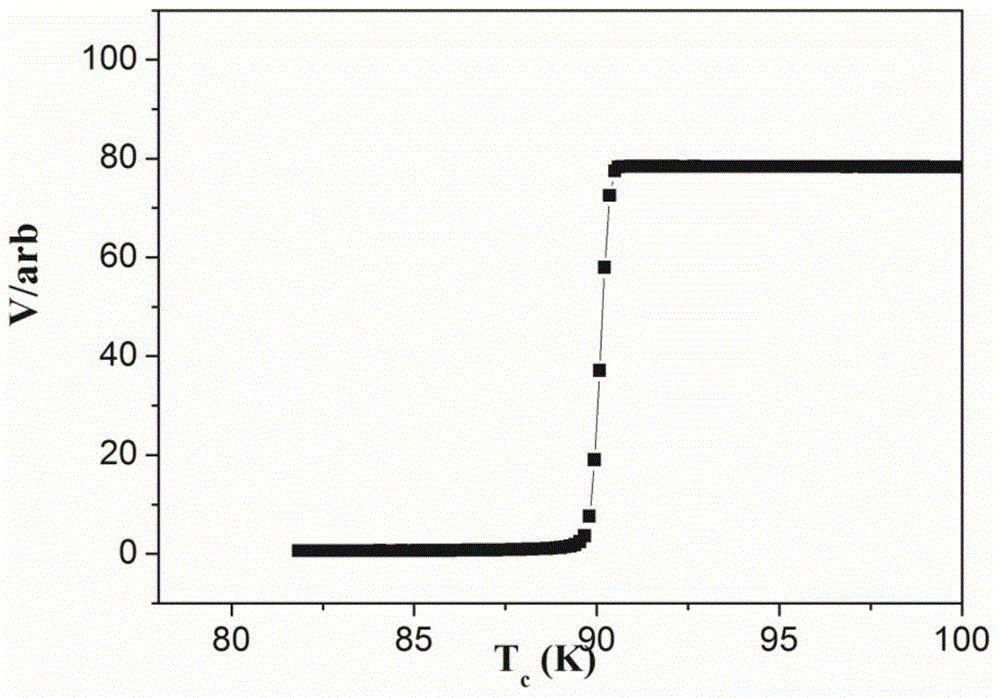

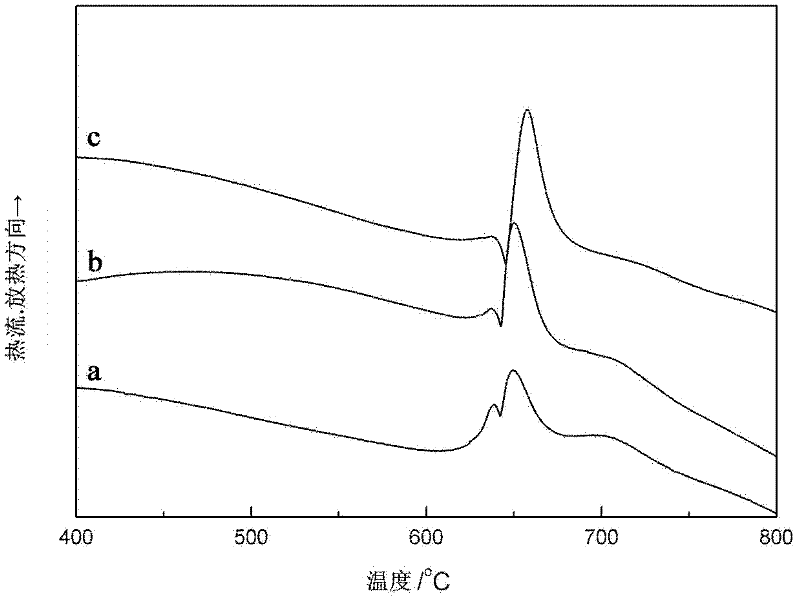

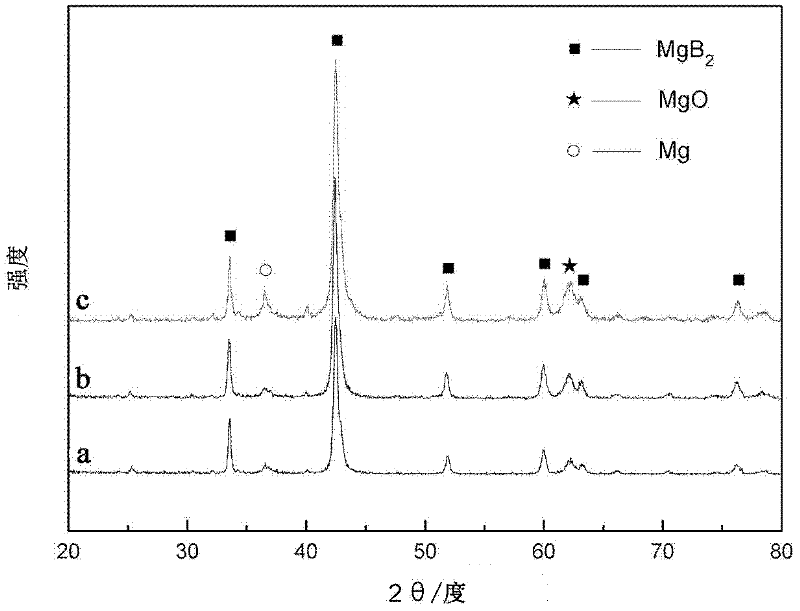

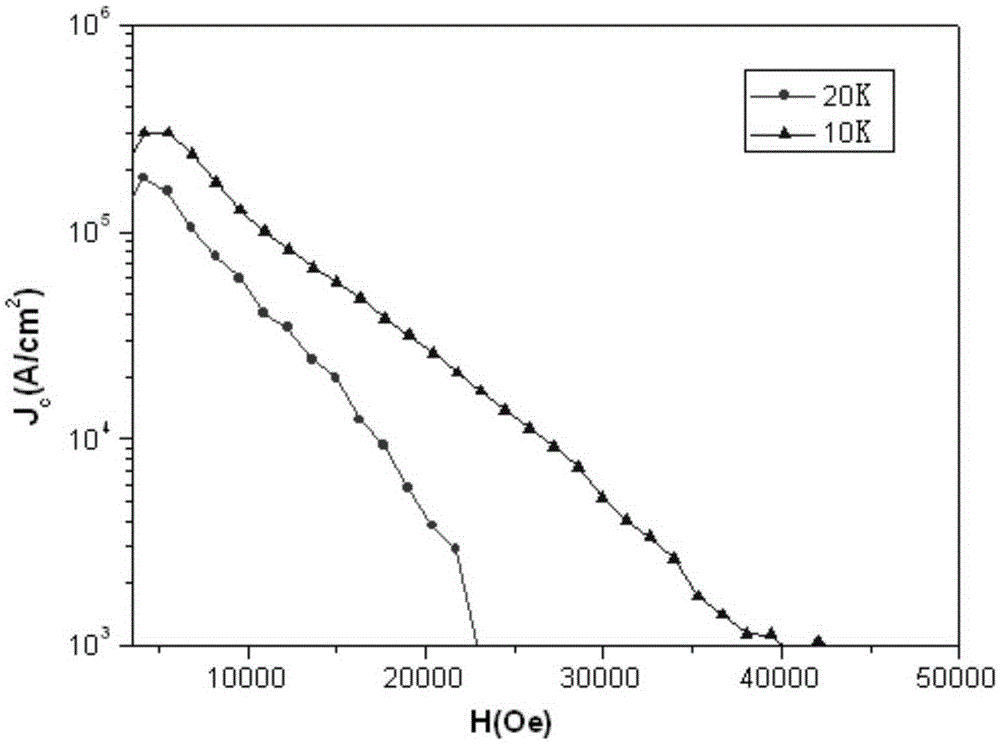

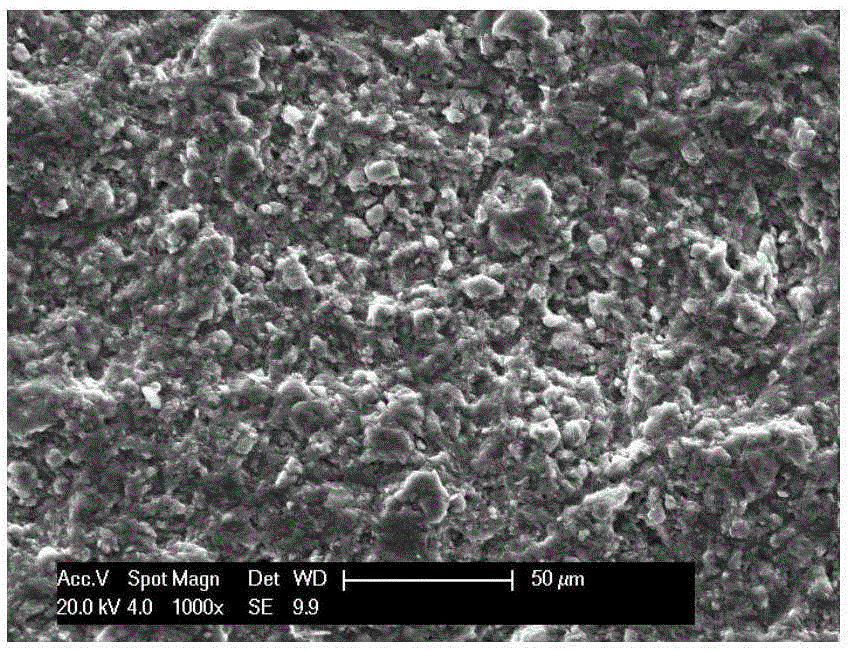

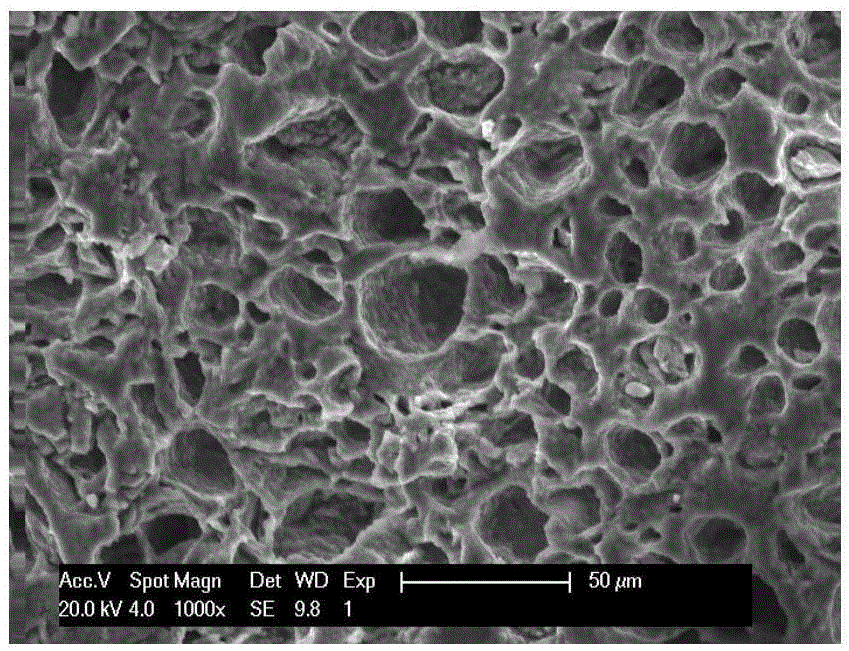

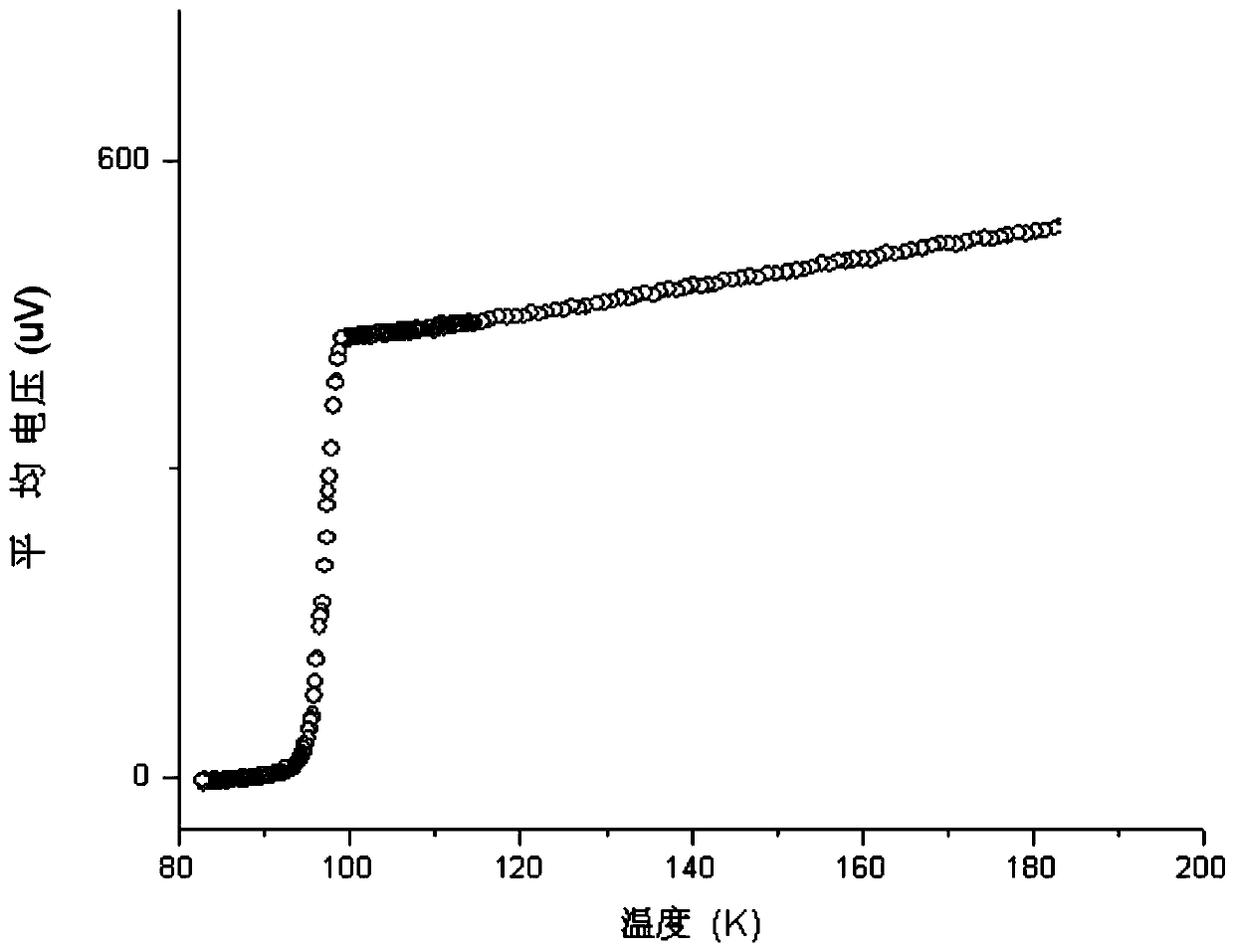

Glycine-doped MgB2 superconductor with high critical current density and preparation method thereof

ActiveCN102531610AExcellent superconductivityIncrease the critical current densitySuperconductor elements usagePower flowRoom temperature

The invention relates to a glycine-doped MgB2 superconductor with high critical current density and a preparation method thereof. The preparation method of the glycine-doped MgB2 superconductor includes fully mixing Mg powder, B powder and glycine particles, and obtaining mixed powder of MgB2+Gly of 2-8%; pressing the mixed powder into cylindrical slices under the pressure of 2-10MPa, and placingthe slices in a high-temperature differential scanning calorimeter or a pipe-shaped sintering furnace to carry out sintering; continuously heating at a heating rate of 5-20 DEG C / min to 750-850 DEG C, sintering and keeping warm for 0.5-1h, and cooling to the room temperature at a cooling speed of 30-40 DEG C / min. On the premise that the superconducting transition temperature Tc is not reduced to the greatest extent, novel carbon-containing compound glycine doping is adopted to achieve C replacement effect, and the high-performance MgB2 superconductor is obtained. The shortcoming that traditional C doping reduces the critical current density under a low field is overcome, the critical current density is improved under the whole magnetic field, and a superconductor with superior superconductivity is obtained.

Owner:TIANJIN UNIV

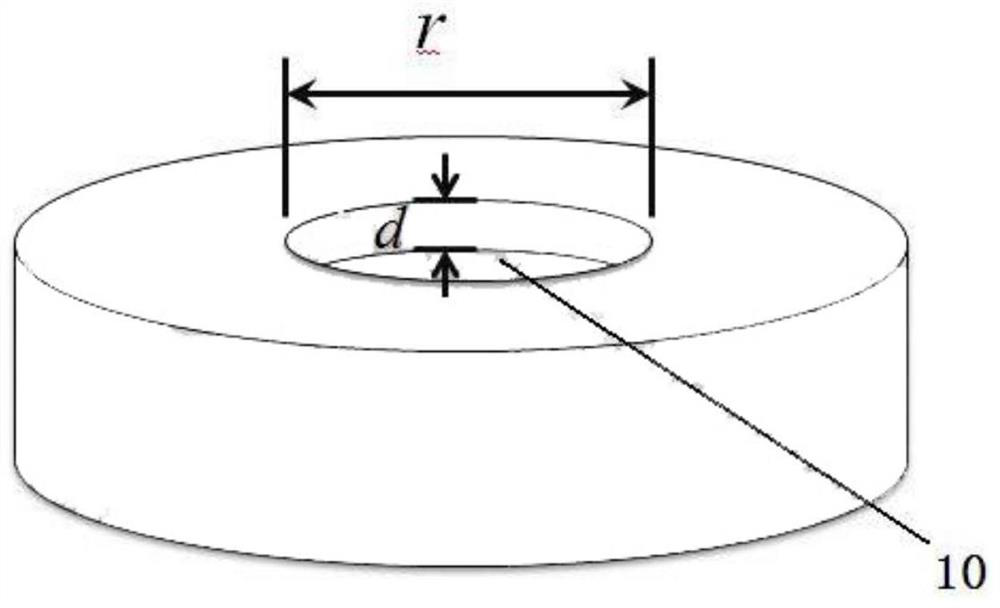

Superconductor cold pressing connecting method

InactiveCN103920983AReduce decompositionIncrease vacanciesConductorsMetal working apparatusHigh temperature superconductingUltimate tensile strength

The invention discloses a superconductor cold pressing connecting method, relates to a superconductor connecting method, and belongs to the technical field of superconductor connecting. The superconductor cold pressing connecting method solves the problems that a high-temperature superconducting material obtained according to an existing welding method is low in strength and the superconducting performance is reduced. The superconductor cold pressing connecting method comprises the first step of rubbing down and polishing the end faces of two circular-bar-shaped superconductors, the second step of processing superconductor powder into a cake shape, and the third step of carrying out welding in an ice pressure welding mode. The superconductor cold pressing connecting method is used for connecting the superconductors.

Owner:SOUTHWEAT UNIV OF SCI & TECH

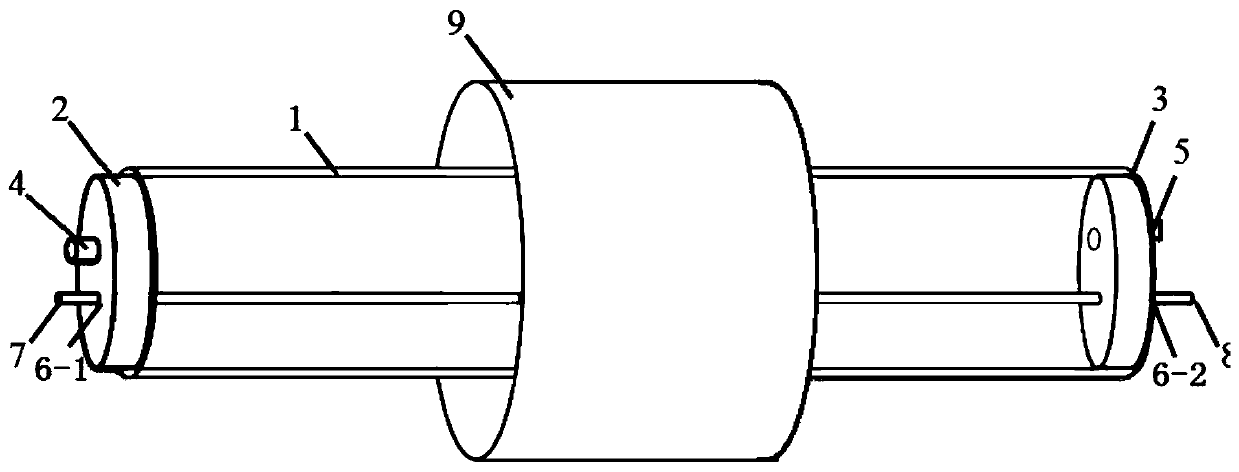

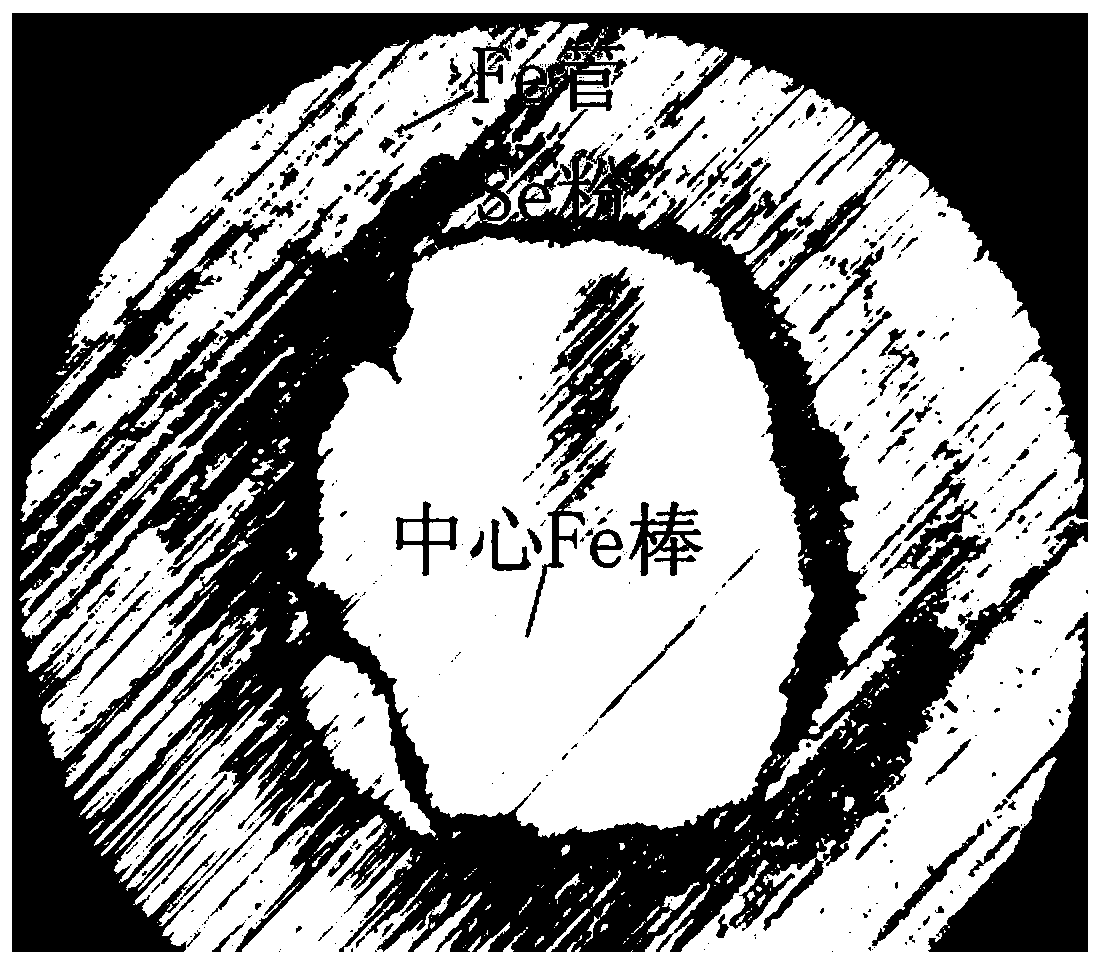

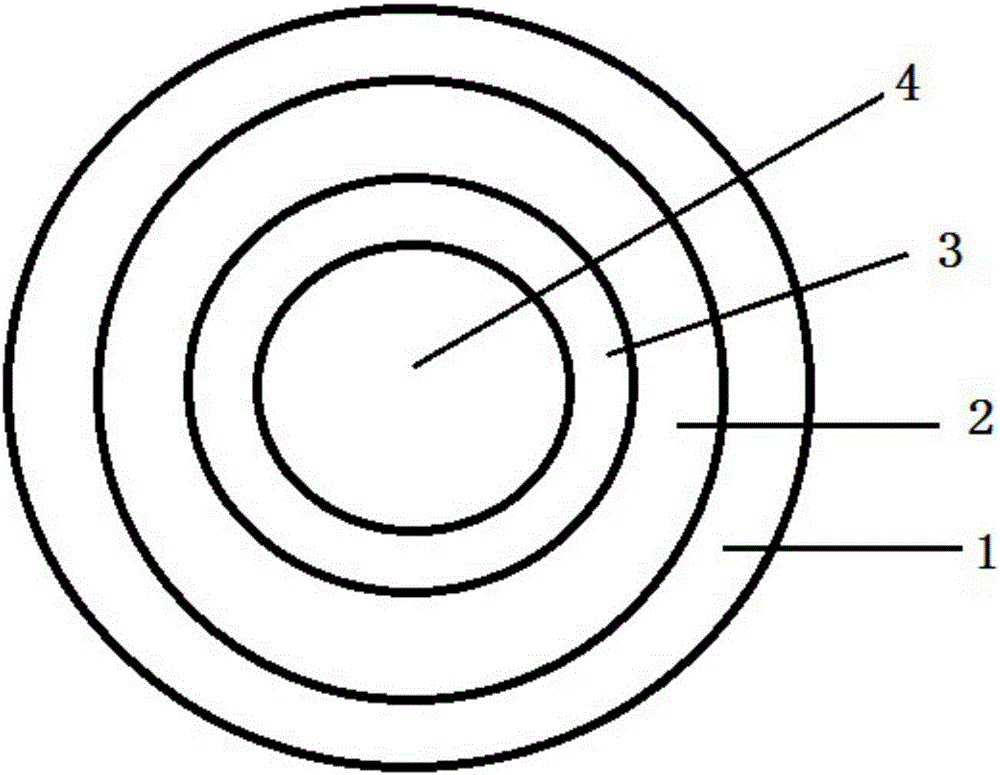

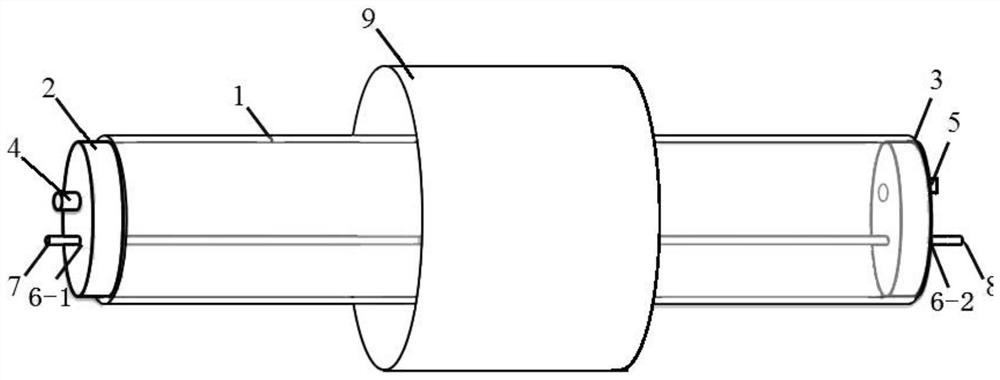

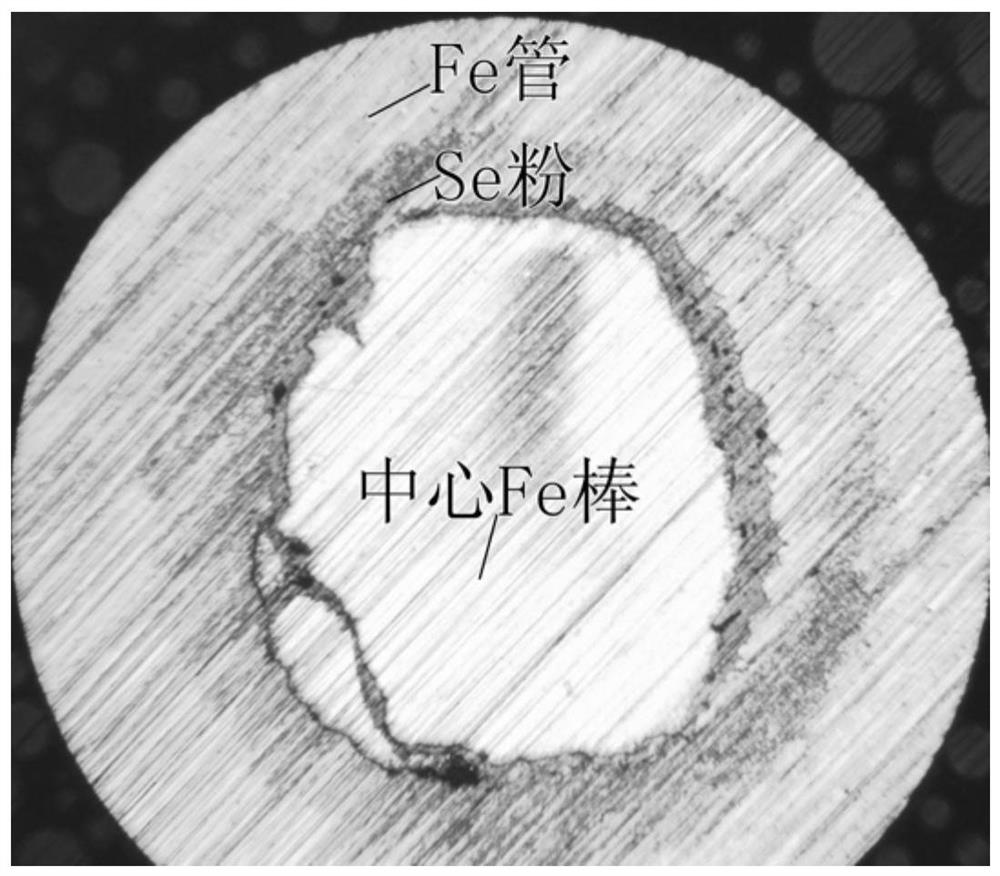

Preparation method of FeSe-based superconducting wire

ActiveCN110867283APromote oxidation precipitationGuaranteed annealing effectSuperconductors/hyperconductorsFurnace typesMetallurgyWire rod

The invention discloses a preparation method of a FeSe-based superconducting wire. The method comprises the following steps: 1, assembling an iron tube, an iron rod and an iron plug to obtain a tubingcomplex; 2, sealing the two ends of the tubing complex, and then obtaining a single-core FeSe-based wire through rotary swaging and drawing in sequence; 3, sintering the single-core FeSe-based wire to obtain a FeSe-based wire; and 4, annealing the FeSe-based wire to obtain a FeSe-based superconducting wire. According to the invention, the single-core FeSe-based wire is formed through powder charging by adopting a vibration tubing method and cold processing, and the iron rod diffuses into the molten Se powder in the subsequent sintering process to generate a compact FeSe layer and form a central hole, so that the intergranular connectivity is improved; and the oxidizing atmosphere is introduced through the central hole to be in full contact with the FeSe-based superconducting phase for annealing, so that the precipitation of interstitial iron is promoted, the superconductivity of the FeSe-based superconducting wire is improved, and the current-carrying performance of the FeSe-based superconducting wire is further improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

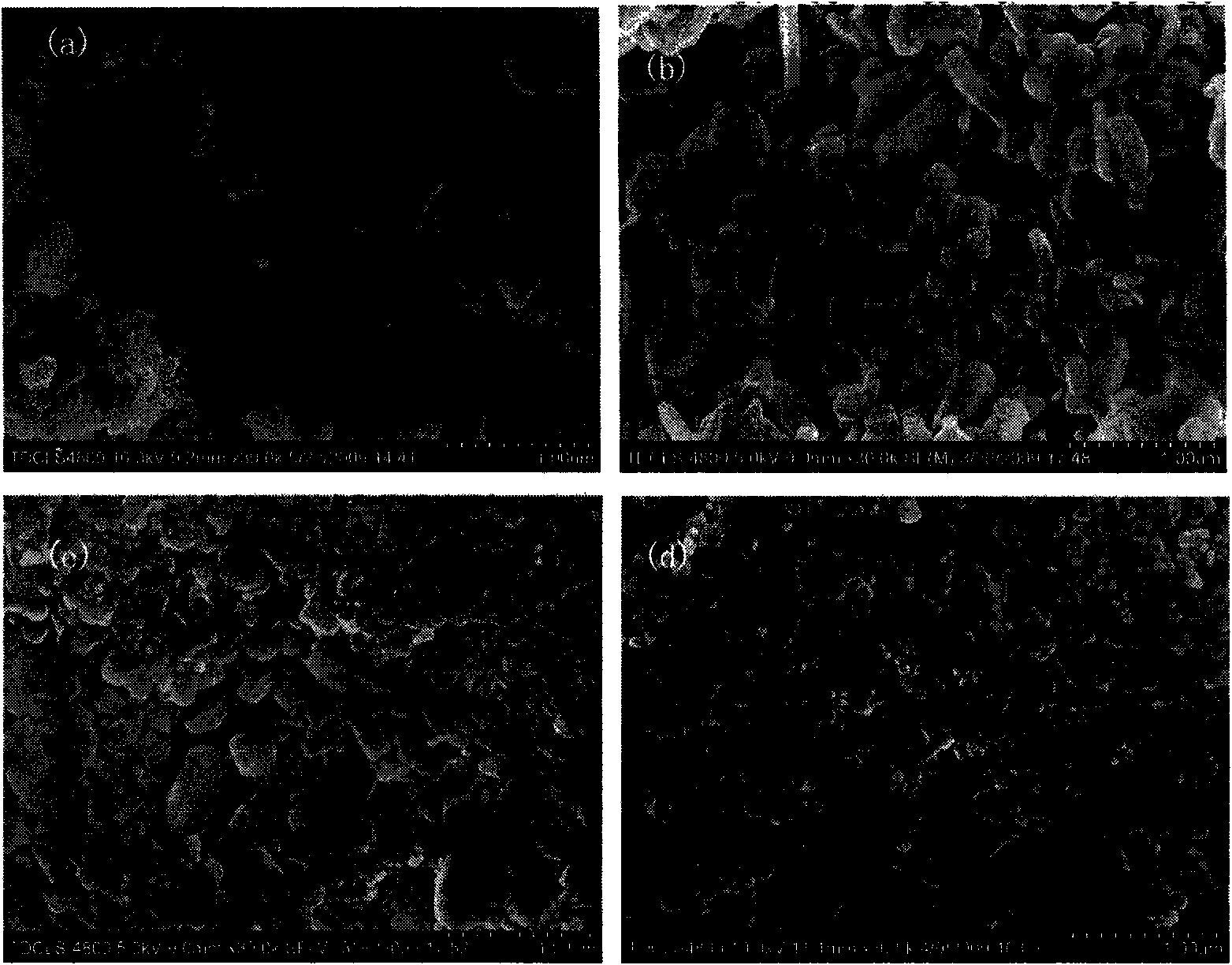

Method for preparing YBCO (yttrium barium copper oxide) film by taking ethanol as solvent through low-fluorine MOD (metal organic deposition) method

InactiveCN103352212AExcellent superconductivityReduce the risk of vandalismLiquid/solution decomposition chemical coatingBarium solutionYttrium barium copper oxide

The invention discloses a method for preparing a YBCO (yttrium barium copper oxide) film by taking ethanol as a solvent through a low-fluorine MOD (metal organic deposition) method, and belongs to the technical field of materials. The method comprises the following steps: (1) dissolving yttrium acetate and barium trifluoroacetate in water to prepare a yttrium barium solution, boiling and concentrating; (2) adding ethanol, boiling and concentrating; (3) repeating the step (2) for 4-6 times to prepare a yttrium barium ethanol solution; (4) dissolving copper isocaprylate in ethanol to prepare a copper ethanol solution; (5) mixing the copper ethanol solution with the yttrium barium ethanol solution, filtering, reheating and concentrating to prepare a precursor solution; (6) applying the precursor solution to a substrate by spin coating, pyrolyzing and crystallizing. The method has the advantages of low environmental pollution, high production efficiency and the like, and has a good application prospect.

Owner:NORTHEASTERN UNIV

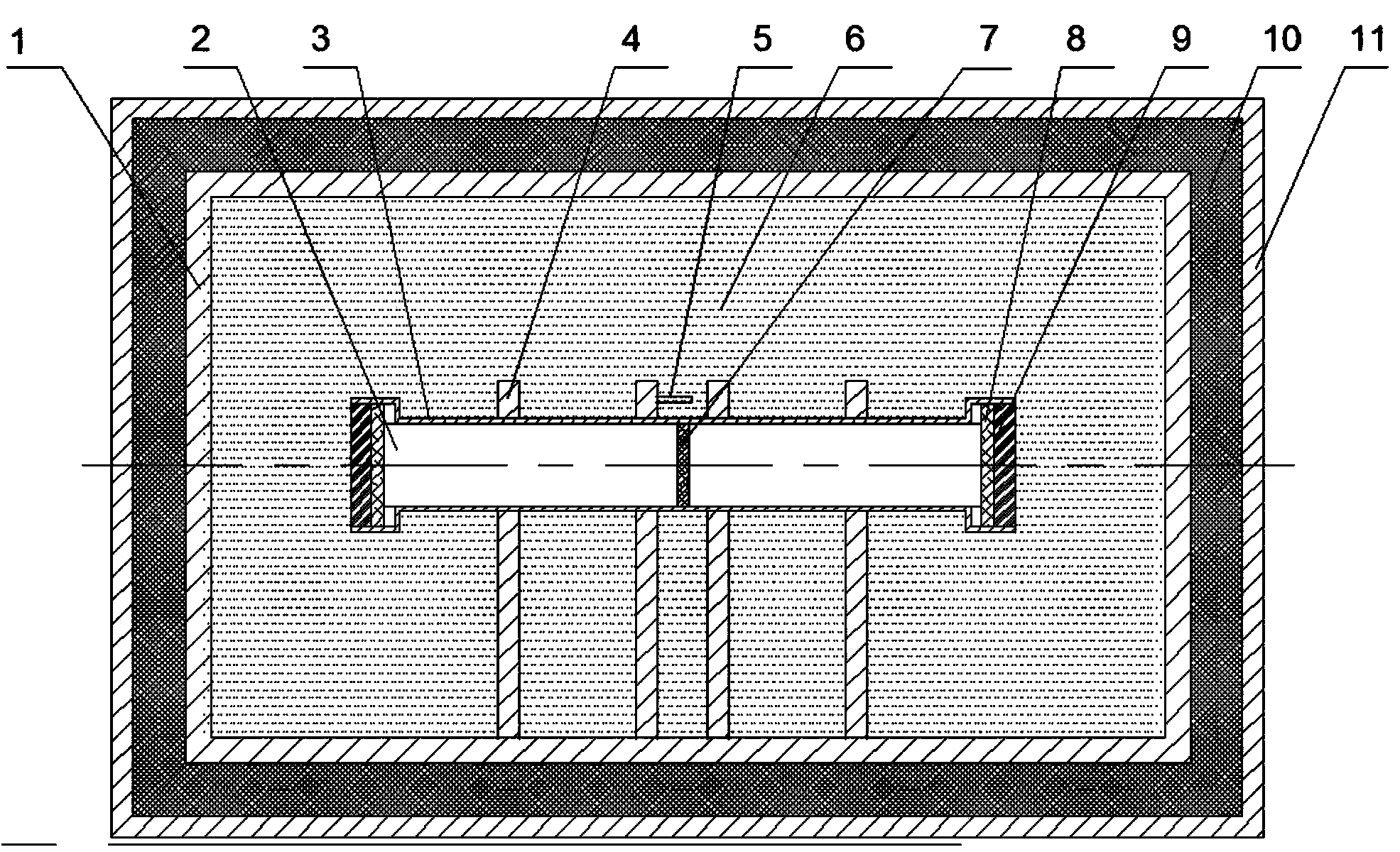

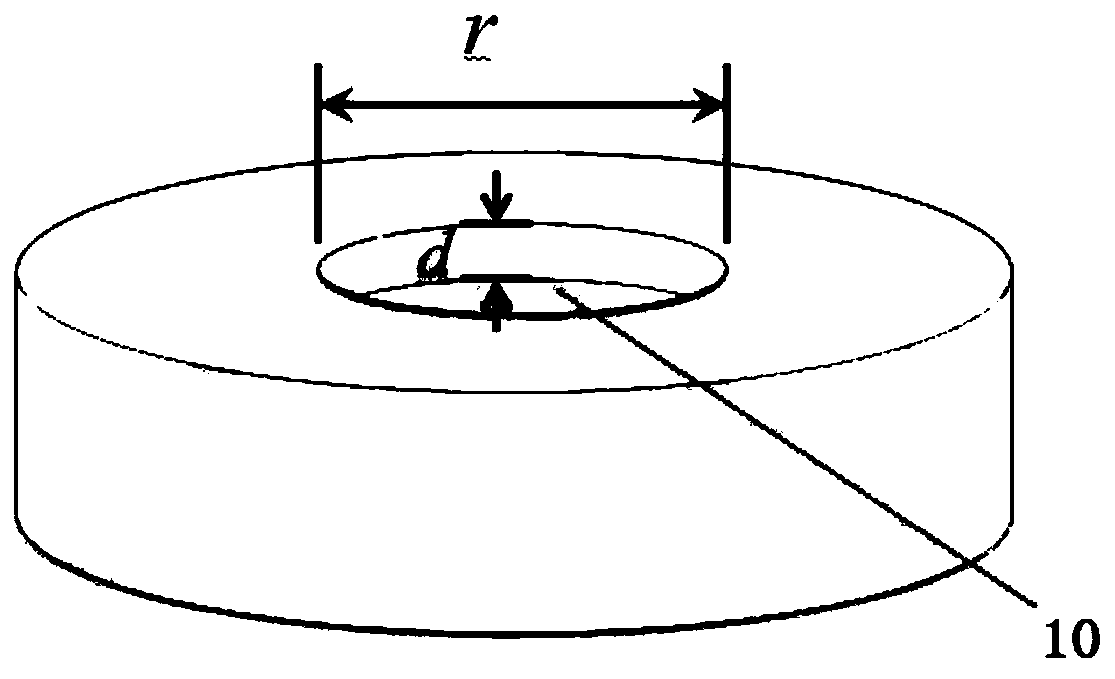

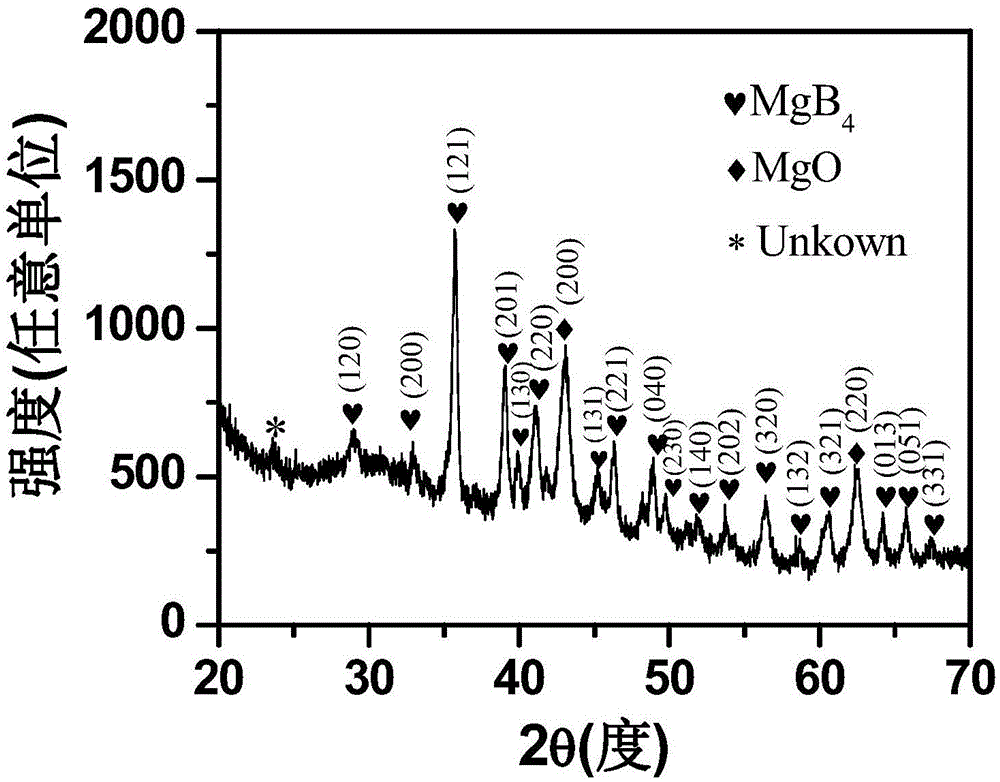

Magnesium diffusion preparation method for magnesium diboride superconducting wire rod based on MgB<4> precursor powder

ActiveCN106128632AIncrease the superconducting phase filling rateSuperconducting phase filling rate increasedSuperconductors/hyperconductorsSuperconductor devicesWire rodFilling rate

Disclosed is a magnesium diffusion preparation method for a magnesium diboride superconducting wire rod based on MgB<4> precursor powder. The preparation method is based on a center magnesium diffusion technology; and MgB<4> is used as the precursor powder to replace the conventional boron precursor powder. The preparation method mainly comprises the steps of 1, performing ball milling and uniform mixing on original powder, then pressing the mixed powder into circular sheets by a powder compressing machine, and finally performing vacuum sintering and crushing on the circular sheets to obtain MgB<4> powder; and 2, fixing a magnesium rod in the center of a metal tube, filling the space between the magnesium rod and the metal tube with the MgB<4> powder, sealing the two ends of the tube, and then carrying out rotary calcining, pulling and drawing and vacuum thermal processing to obtain a MgB<2> wire rod. The MgB<2> wire rod superconducting core prepared by the preparation method is high in density; and meanwhile, the MgB<2> wire rod has high critical current density, superconducting phase filling rate and engineering critical current density, and excellent superconducting performance in medium and high magnetic fields.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Graphene composite material and preparation method thereof

The invention discloses a graphene composite material and a preparation method thereof. The graphene composite material is prepared from the following components in parts by weight: 50 parts by weight of graphene, 25 to 29 parts by weight of polycarbonate, 5 to 9 parts by weight of 1-ethyl-3-methylimidazoleonium tetrafluoroborate, 32 to 36 parts by weight of nickel sulfate, 2 to 6 parts by weight of acetonitrile, 38 to 42 parts by weight of polyvinyl alcohol, 7 to 9 parts by weight of cellulose grafted acrylamide polymer, 16 to 22 parts by weight of starch-polyacrylate grafted copolymer, 7 to 9 parts by weight of polyacrylic acid-acrylonitrile, 20 to 24 parts by weight of potassium permanganate, 3 to 5 parts by weight of tungsten carbide and 4 to 6 parts by weight of high-strength carbon fibers. The preparation method disclosed by the invention has the advantages of high yield, no pollution and uniform graphitization; in addition, the graphitization degree is improved; the graphene composite material has the characteristics of excellent superconducting electrical properties, heat dissipation performance, superhigh toughness, light weight, high-temperature resistance, flame-retardant property, anti-oxidation property, acid and alkali resistance, mechanical damage resistance and the like.

Owner:湖南金阳烯碳新材料股份有限公司

A preparation method of large-scale mgb2 single-core superconducting wire

InactiveCN103928192BHigh densityGuaranteed lengthSuperconductors/hyperconductorsSuperconductor devicesMechanical propertyCarbon steel

Owner:SOUTHEAST UNIV

A kind of preparation method of FeSe-based superconducting wire rod

ActiveCN110867283BExcellent superconductivityFully contactedSuperconductors/hyperconductorsFurnace typesWire rodMetallurgy

The invention discloses a preparation method of a FeSe-based superconducting wire. The method comprises the following steps: 1, assembling an iron tube, an iron rod and an iron plug to obtain a tubingcomplex; 2, sealing the two ends of the tubing complex, and then obtaining a single-core FeSe-based wire through rotary swaging and drawing in sequence; 3, sintering the single-core FeSe-based wire to obtain a FeSe-based wire; and 4, annealing the FeSe-based wire to obtain a FeSe-based superconducting wire. According to the invention, the single-core FeSe-based wire is formed through powder charging by adopting a vibration tubing method and cold processing, and the iron rod diffuses into the molten Se powder in the subsequent sintering process to generate a compact FeSe layer and form a central hole, so that the intergranular connectivity is improved; and the oxidizing atmosphere is introduced through the central hole to be in full contact with the FeSe-based superconducting phase for annealing, so that the precipitation of interstitial iron is promoted, the superconductivity of the FeSe-based superconducting wire is improved, and the current-carrying performance of the FeSe-based superconducting wire is further improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Glycine-doped MgB2 superconductor with high critical current density and preparation method thereof

ActiveCN102531610BExcellent superconductivityIncrease the critical current densitySuperconductors/hyperconductorsSuperconductor devicesGlycinePower flow

The invention relates to a glycine-doped MgB2 superconductor with high critical current density and a preparation method thereof. The preparation method of the glycine-doped MgB2 superconductor includes fully mixing Mg powder, B powder and glycine particles, and obtaining mixed powder of MgB2+Gly of 2-8%; pressing the mixed powder into cylindrical slices under the pressure of 2-10MPa, and placingthe slices in a high-temperature differential scanning calorimeter or a pipe-shaped sintering furnace to carry out sintering; continuously heating at a heating rate of 5-20 DEG C / min to 750-850 DEG C, sintering and keeping warm for 0.5-1h, and cooling to the room temperature at a cooling speed of 30-40 DEG C / min. On the premise that the superconducting transition temperature Tc is not reduced to the greatest extent, novel carbon-containing compound glycine doping is adopted to achieve C replacement effect, and the high-performance MgB2 superconductor is obtained. The shortcoming that traditional C doping reduces the critical current density under a low field is overcome, the critical current density is improved under the whole magnetic field, and a superconductor with superior superconductivity is obtained.

Owner:TIANJIN UNIV

Rapid sintering preparation method of tl-2212 superconducting thin film

ActiveCN107437579BAvoid crackingFlat surfaceSuperconductor detailsLiquid/solution decomposition chemical coatingThalliumThin membrane

The invention discloses a rapid sintering preparation method of Tl-2212 superconducting thin film. Silver foil or gold foil is used to seal and wrap the amorphous precursor film containing thallium and the burning target containing thallium, and the Sintering in the environment. The invention includes four processes including the preparation of a precursor film, the preparation of a thallium source accompanying firing target, the rapid temperature-raising sintering of the precursor film in an argon / oxygen environment, and the oxygen-supplementing heat treatment of a primary sample. Compared with the traditional sintering method, the sintering conditions for growing Tl‑2212 thin films using this technology are not affected by the deposition method of the precursor film, the powder particle size of the starting material of the thallium source accompanying firing target and its preparation method, avoiding the Due to the replacement of the manufacturer's raw materials and the pioneering film deposition method, it is necessary to re-explore the sintering process for a long time. At the same time, the method also greatly reduces the amount of the thallium source accompanying the burning target, shortens the heating and cooling time and constant temperature time, reduces the production cost, and improves the repeatability of the experiment.

Owner:GUANGXI TEACHERS EDUCATION UNIV

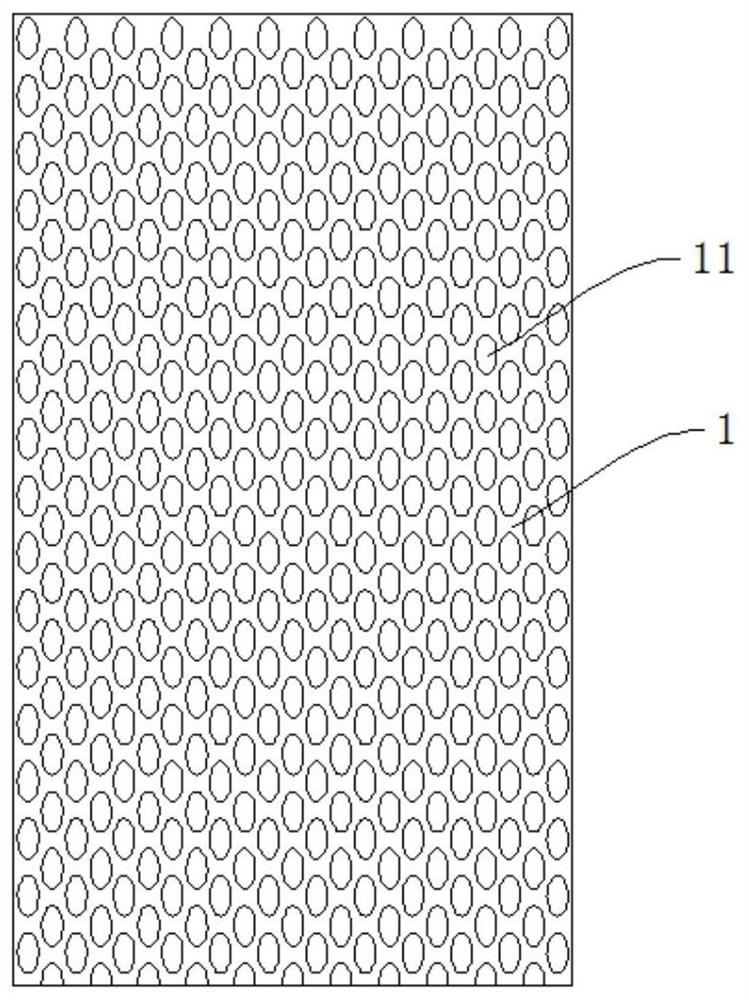

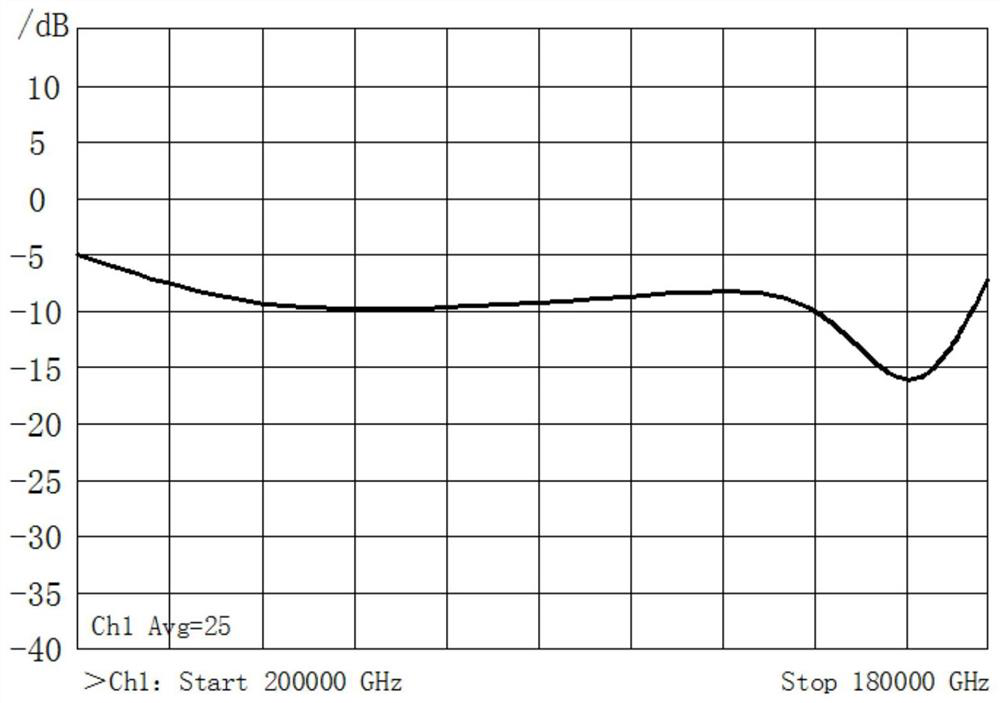

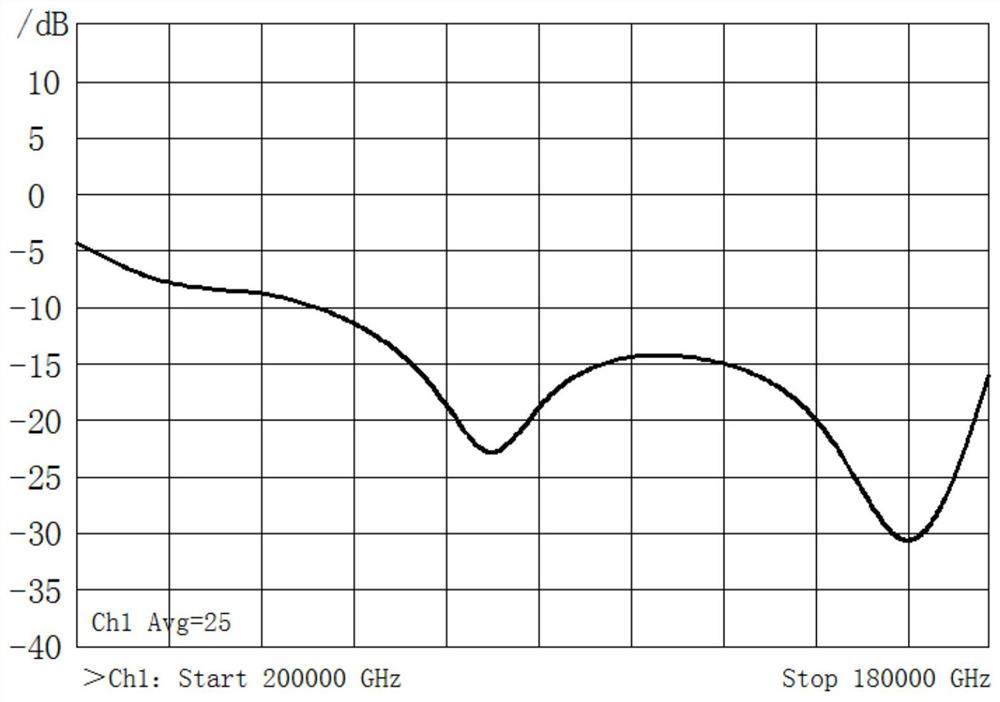

Foam base material for anti-millimeter wave radar camouflage net and processing technology of foam base material

The invention relates to a foam base material for an anti-millimeter wave radar camouflage net and a processing technology of the foam base material, and belongs to the technical field of camouflage nets. The foam material is prepared by the steps: mixing the following components: 60-80 parts by mass of polyethylene or polypropylene or polyolefin, 1-10 parts by mass of modified carbon nanotubes, 1-5 parts by mass of modified graphene, 1-5 parts by mass of rare earth, 1-10 parts by mass of a flame retardant, 1-10 parts by mass of a foaming agent, 2-20 parts by mass of a sensitizing agent and 2-5 parts by mass of an antioxidant, and then sequentially performing extrusion, irradiation and high-temperature foaming; and finally, pressing small rice grains on the single surface or double surfaces of a sheet. According to the invention, the prepared foam base material is provided with the small rice grains, so that the absorption and shielding effects on the millimeter-wave radar at a high frequency band can be realized.

Owner:安徽财纳伽善科技有限公司

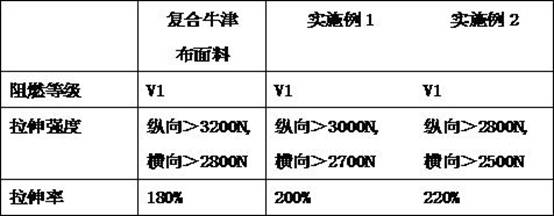

Superconducting electric shielding coating for electronic wave prevention camouflage net

The invention relates to a superconducting electric shielding coating for an electronic wave prevention camouflage net, and belongs to the technical field of camouflage nets. The coating is prepared by mixing the following components of 50-70 parts by mass of polyurethane, 1-10 parts by mass of acrylic acid, 1-10 parts by mass of modified carbon nanotubes, 1-10 parts by mass of modified graphene, 1-5 parts by mass of rare earth, 1-10 parts by mass of a flame retardant, 1-6 parts by mass of an anti-yellowing agent and 1-5 parts by mass of color paste. The prepared coating has the advantages of good flame retardance, high strength, tensile resistance and the like, and can be directly applied to the surface of a foam base material of the camouflage net to serve as a net surface to replace an existing composite oxford cloth net surface, so that the camouflage net is more convenient to manufacture, and meanwhile, the effect of light weight is achieved.

Owner:安徽财纳伽善科技有限公司

Method for preparing YBCO (yttrium barium copper oxide) film by taking ethanol as solvent through low-fluorine MOD (metal organic deposition) method

InactiveCN103352212BExcellent superconductivityReduce the risk of vandalismLiquid/solution decomposition chemical coatingBarium solutionYttrium barium copper oxide

The invention discloses a method for preparing a YBCO (yttrium barium copper oxide) film by taking ethanol as a solvent through a low-fluorine MOD (metal organic deposition) method, and belongs to the technical field of materials. The method comprises the following steps: (1) dissolving yttrium acetate and barium trifluoroacetate in water to prepare a yttrium barium solution, boiling and concentrating; (2) adding ethanol, boiling and concentrating; (3) repeating the step (2) for 4-6 times to prepare a yttrium barium ethanol solution; (4) dissolving copper isocaprylate in ethanol to prepare a copper ethanol solution; (5) mixing the copper ethanol solution with the yttrium barium ethanol solution, filtering, reheating and concentrating to prepare a precursor solution; (6) applying the precursor solution to a substrate by spin coating, pyrolyzing and crystallizing. The method has the advantages of low environmental pollution, high production efficiency and the like, and has a good application prospect.

Owner:NORTHEASTERN UNIV LIAONING

A kind of superconductor cold-compression joining method

InactiveCN103920983BReduce decompositionIncrease vacanciesConductorsMetal working apparatusHigh-temperature superconductivityUltimate tensile strength

Owner:SOUTHWEAT UNIV OF SCI & TECH

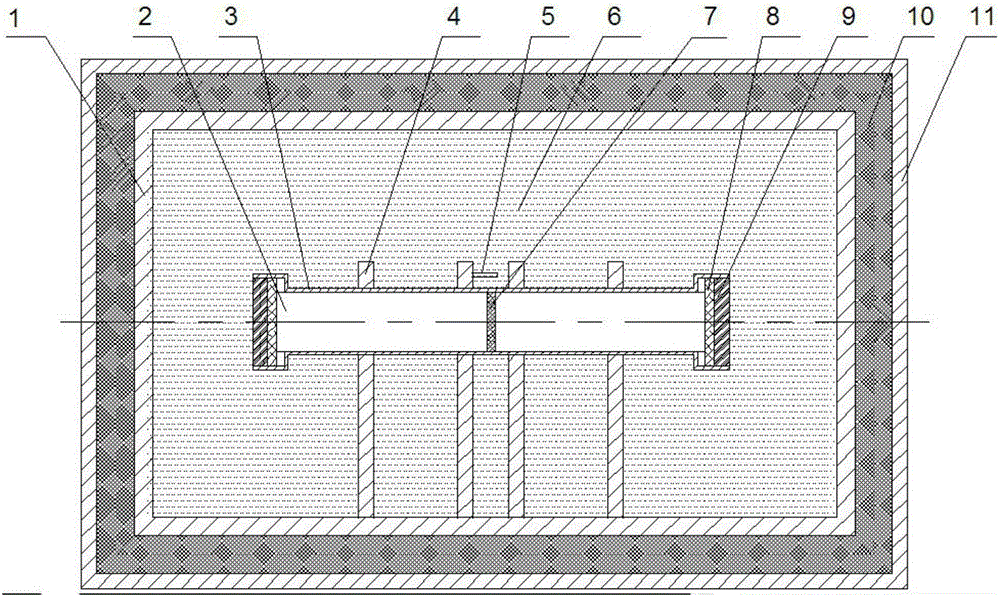

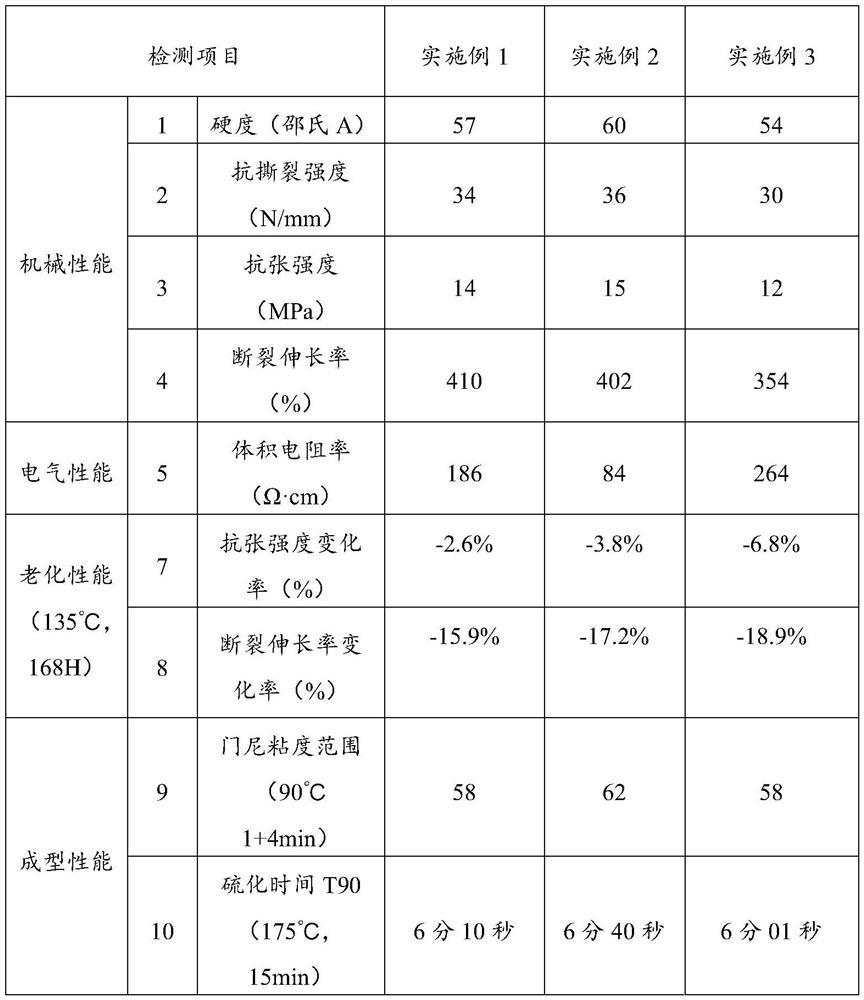

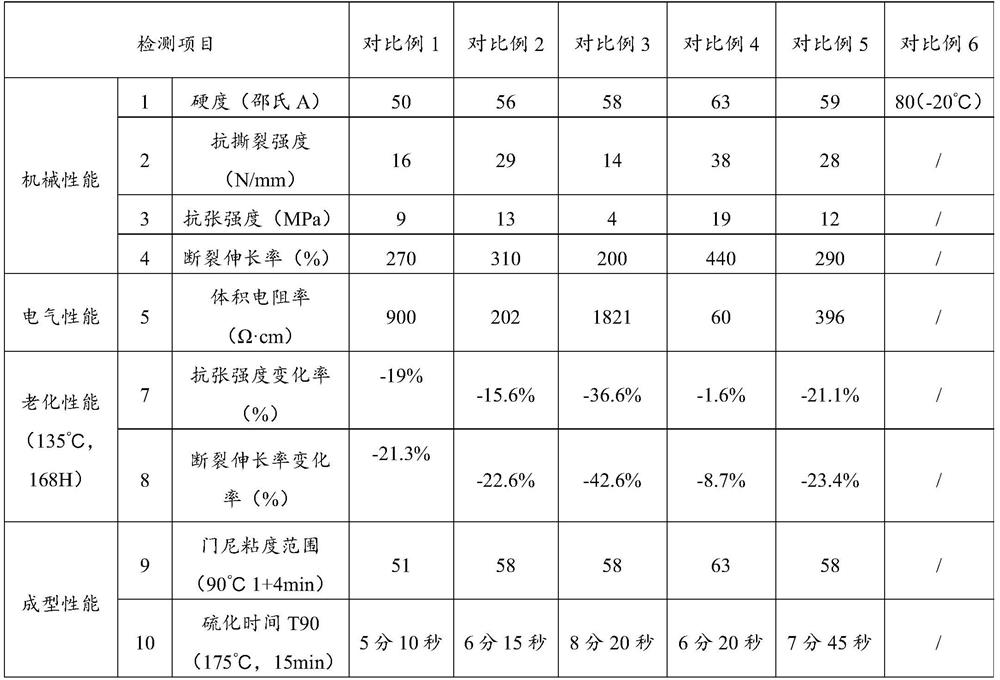

A kind of semi-conductive rubber and its preparation method and application

ActiveCN113372657BReduce dosageReduced mechanical propertiesClimate change adaptationPolymer sciencePolymer chemistry

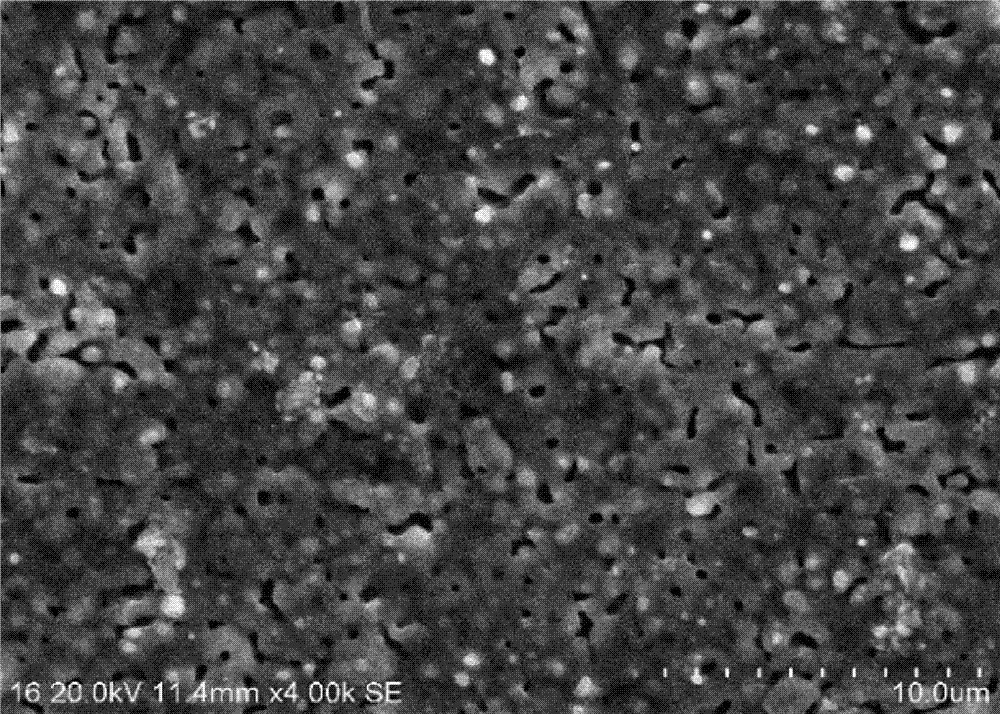

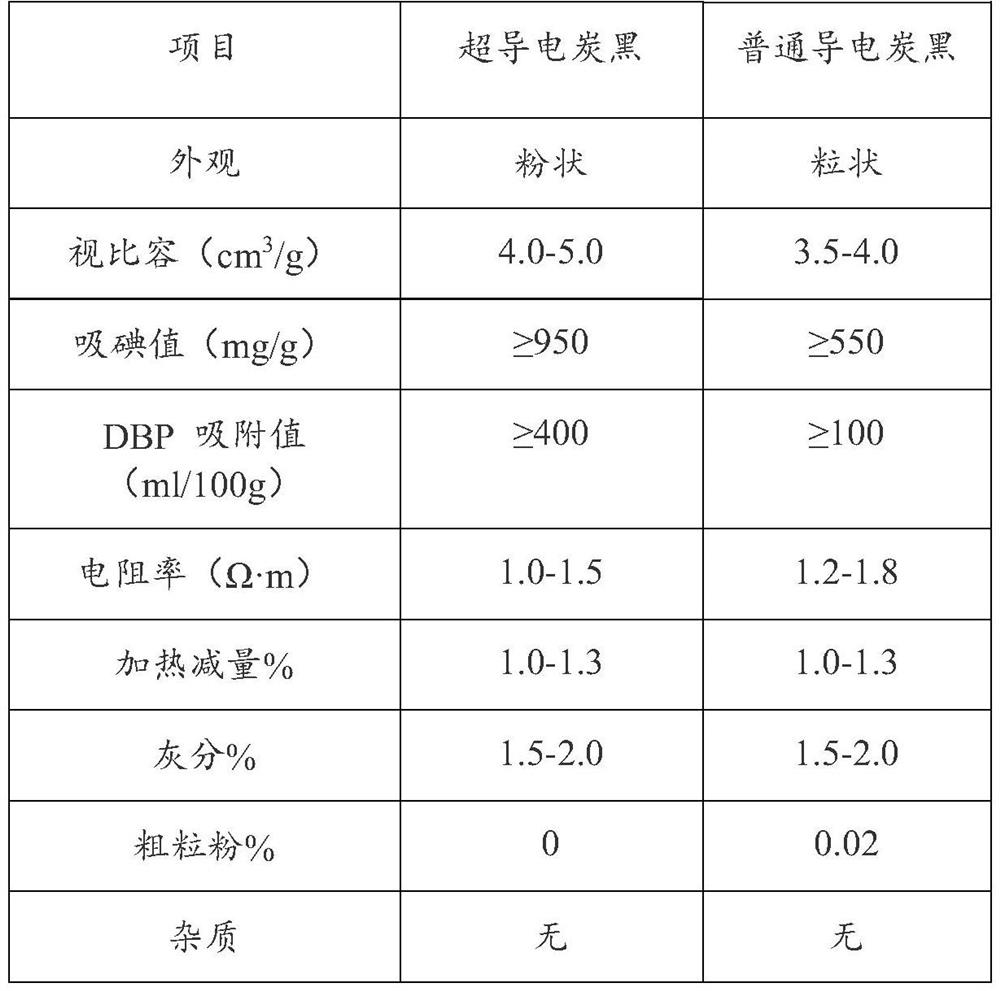

The invention provides a semiconductive rubber, a preparation method and application thereof. The semiconductive rubber of the present invention has a volume resistivity of ≤500Ω·cm and a Shore A hardness of ≤75, and the raw material for the semiconductive rubber contains superconductive carbon black. In order to obtain low hardness technical indicators, in formula design, the amount of reinforcing agent is usually reduced, such as reducing the amount of carbon black. However, the reduction of the amount of carbon black will not only reduce the mechanical properties and aging properties of the rubber, but also increase the volume resistivity of the rubber, thus failing to meet the performance requirements of semi-conductivity. To solve this problem, the present invention uses superconducting carbon black with large specific surface area and superconducting properties. Due to its large specific surface area, superconducting carbon black has good reinforcing effect and excellent electrical conductivity. Even if it is added in a small amount, it can make the mechanical and electrical properties of rubber meet the requirements.

Owner:长沙长缆电工绝缘材料有限公司

Metal Sn doped MgB2 superconductor and high-temperature rapid preparation method thereof

InactiveCN101591172BGood superconducting propertiesLow costMetal boridesStudy methodsStructural formula

The invention relates to a metal Sn doped MgB2 superconductor and a high-temperature rapid preparation method thereof. A structural formula of the superconductor is (Mg1.02B2)1-xSnx, wherein x=0.01-0.05. The method comprises the following steps: fully mixing Mg powder, B powder and Sn powder according to atomic ratio, pressing and preparing the mixture into a cylindrical flake under the pressure of 2 to 10 MPa, and then putting the cylindrical flake into a high temperature differential scanning calorimeter or a tubular sintering furnace for sintering; and continuously heating the cylindrical flake to 850 to 900 DEG C at heating rate of 5 to 20 DEG C per minute for sintering treatment, and cooling the cylindrical flake to room temperature at cooling rate of 30 to 40 DEG C per minute. The practical application field of MgB2 is in an around 3T magnetic field, so the method improves the superconductivity of the MgB2 superconductor in a short time by doping metal Sn and using a high-temperature sintering method. The preparation method is simple, has low cost of the raw materials and short preparation time, and is a quite potential research method; and simultaneously, the obtained superconductor has obvious superconductivity.

Owner:TIANJIN UNIV

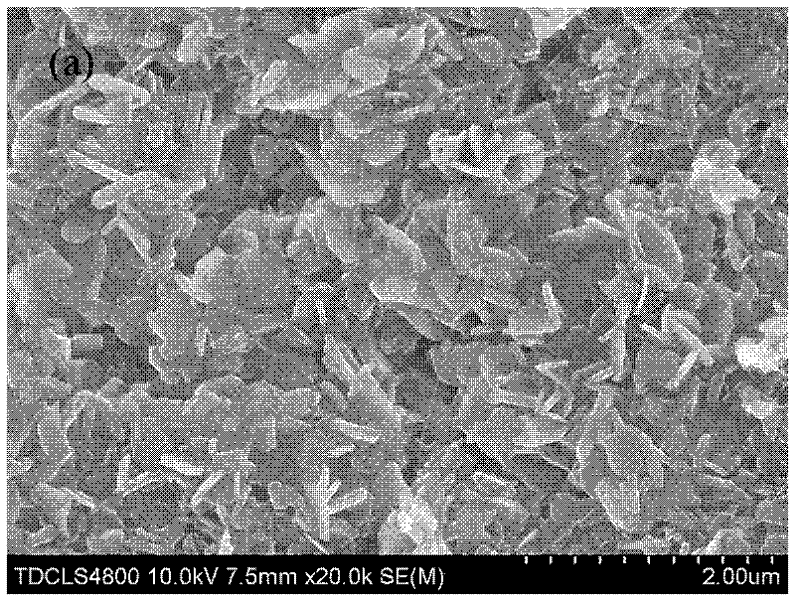

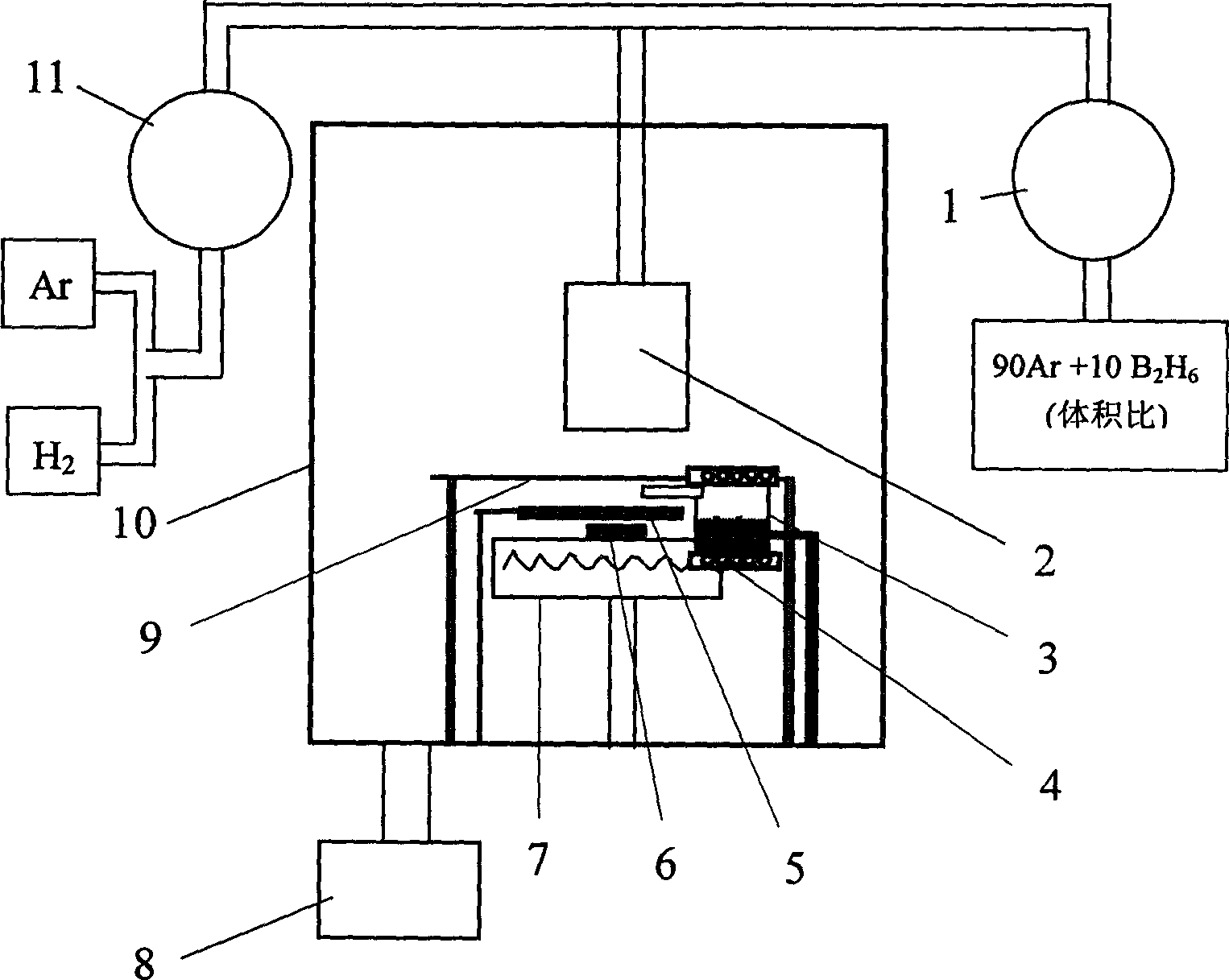

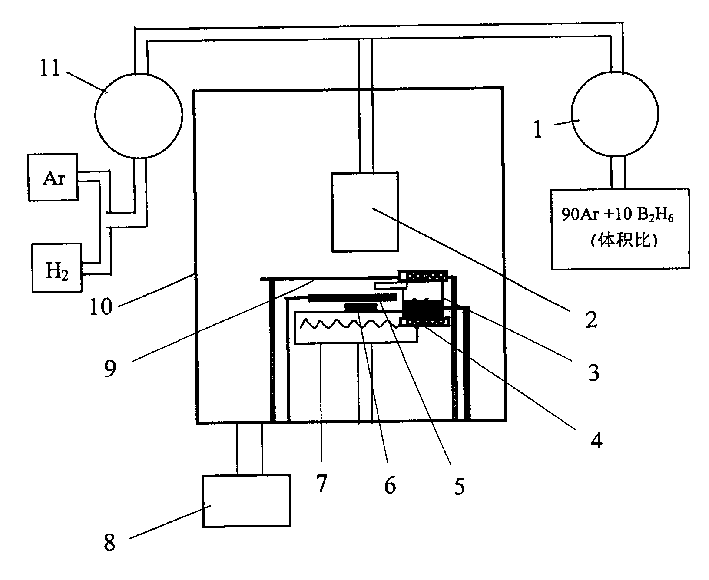

In-situ hot-wire chemical gas-phase deposition process for preparing MgB2 superconductor film

InactiveCN1168847CInhibition formationExcellent superconductivityChemical vapor deposition coatingGas phaseCompound (substance)

A superconductor MgB2 film is prepared by in-situ hot-wire chemical gas-phase deposition method, which is characterized by that the gas-state compound containing B and Mg takes part in splitting reaction under the action of hot wire to generate MgB2 compound, which is growing on substrate to become film. Said superconductor film has features of no MgO phase in it and 35K of zero resistance change temp.

Owner:YANSHAN UNIV

A kind of graphene composite material and preparation method thereof

The invention discloses a graphene composite material and a preparation method thereof. The graphene composite material is prepared from the following components in parts by weight: 50 parts by weight of graphene, 25 to 29 parts by weight of polycarbonate, 5 to 9 parts by weight of 1-ethyl-3-methylimidazoleonium tetrafluoroborate, 32 to 36 parts by weight of nickel sulfate, 2 to 6 parts by weight of acetonitrile, 38 to 42 parts by weight of polyvinyl alcohol, 7 to 9 parts by weight of cellulose grafted acrylamide polymer, 16 to 22 parts by weight of starch-polyacrylate grafted copolymer, 7 to 9 parts by weight of polyacrylic acid-acrylonitrile, 20 to 24 parts by weight of potassium permanganate, 3 to 5 parts by weight of tungsten carbide and 4 to 6 parts by weight of high-strength carbon fibers. The preparation method disclosed by the invention has the advantages of high yield, no pollution and uniform graphitization; in addition, the graphitization degree is improved; the graphene composite material has the characteristics of excellent superconducting electrical properties, heat dissipation performance, superhigh toughness, light weight, high-temperature resistance, flame-retardant property, anti-oxidation property, acid and alkali resistance, mechanical damage resistance and the like.

Owner:湖南金阳烯碳新材料股份有限公司

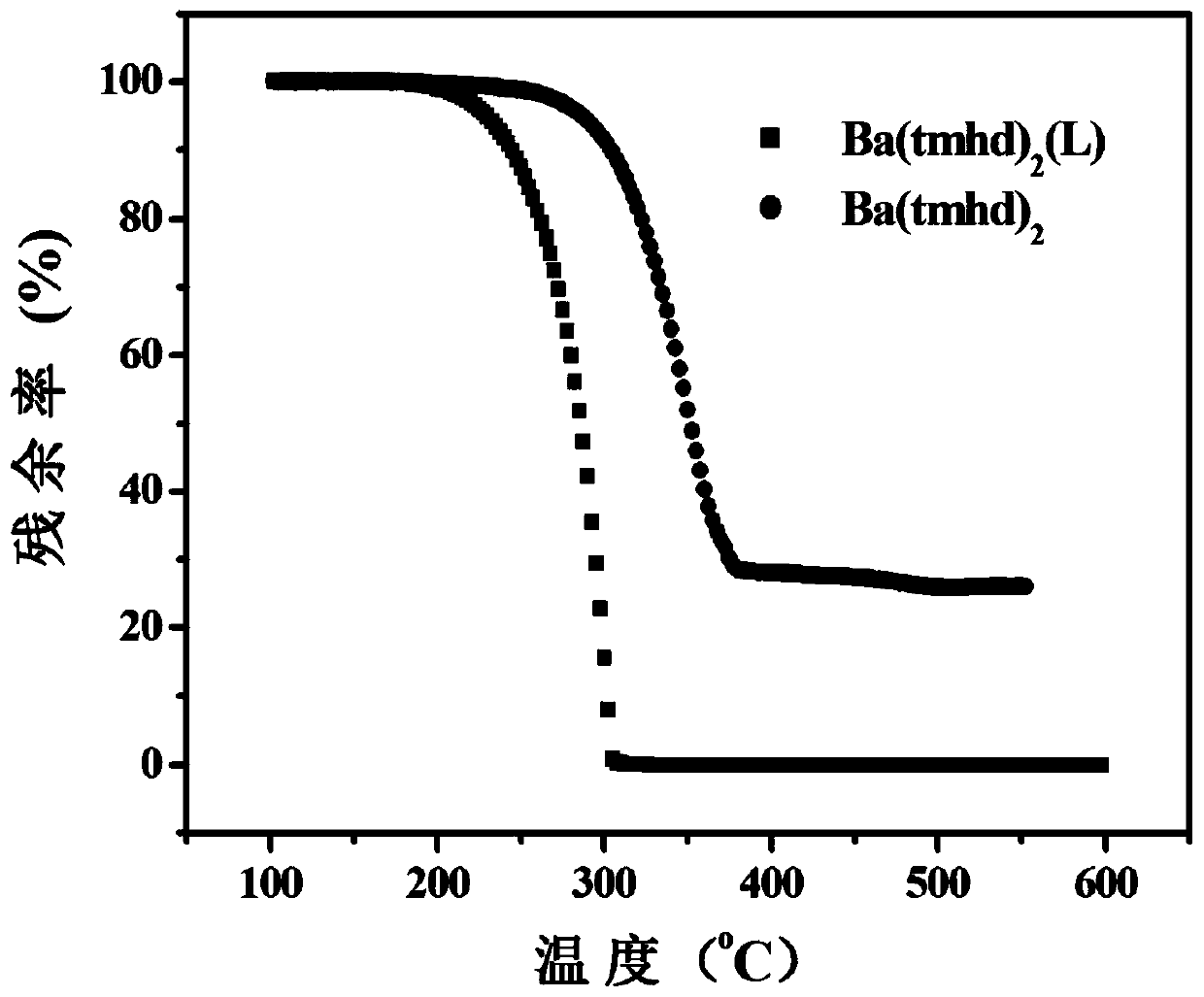

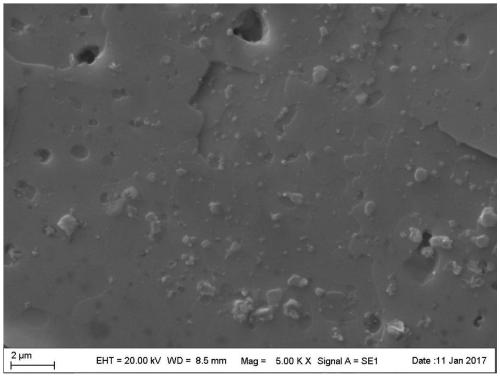

A kind of preparation method and application of highly volatile composite ligand barium precursor salt

InactiveCN108707159BEasy to manufactureImprove stabilitySuperconductors/hyperconductorsSuperconductor devicesBarium saltMethyl group

Owner:BEIJING JIAOTONG UNIV +1

Preparation method of tl-1223 superconducting thin film

ActiveCN107602112BFlat surfaceExcellent superconductivitySuperconductors/hyperconductorsSuperconductor devicesThalliumOxygen

The invention discloses a method of preparing a Tl-1223 superconductive thin film. In the invention, a thallium-containing amorphous precursor film and a thallium-containing sintering accompanying target are sealed and coated with a silver foil or a gold foil, and then sintering is carried out in a sealed argon gas or a flowing oxygen environment. In the method, phase forming temperature zone of low-temperature phases, such as Tl-1212 and Tl-2212, can be crossed quickly and Tl-1223 superconductive phase temperature zone is directly reached, thus producing a pure-phase thin film. The method isshort in temperature increase / decrease time and constant temperature time and is low in production cost.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Preparation method of tl-2223 superconducting thin film

ActiveCN107482110BFlat surfaceAvoid crackingSuperconductor detailsLiquid/solution decomposition chemical coatingPhysical chemistryThallium

The invention discloses a preparation method of a Tl-2223 superconducting thin film. Silver foil or gold foil is used to seal and wrap an amorphous precursor film containing thallium and a burning target containing thallium, and place the film in a sealed argon or oxygen flow environment. Sintering; wherein, the metal ion molar ratio of Tl, Ba, Ca, Cu of the amorphous precursor film containing thallium is 2.4~4.5:2:2:3.2~3.8; Tl:Ba:Ca:Cu=0.8~1.2:2:1~2:2~3 Ba, Ca, Cu oxides and Tl 2 o 3 Made by sintering. The present invention can quickly cross the phase forming temperature zone of Tl-1212, Tl-2212, Tl-1223 and other low-temperature phases, and directly reach the superconducting phase temperature zone of Tl-2223, thereby preparing a pure-phase film, which has heating and cooling time and constant temperature time Advantages of short length and low production cost.

Owner:GUANGXI TEACHERS EDUCATION UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com