Preparation method of FeSe-based superconducting wire

A technology for superconducting wires and wires, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc. flow properties and the effect of increasing the superconducting phase content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment includes the following steps:

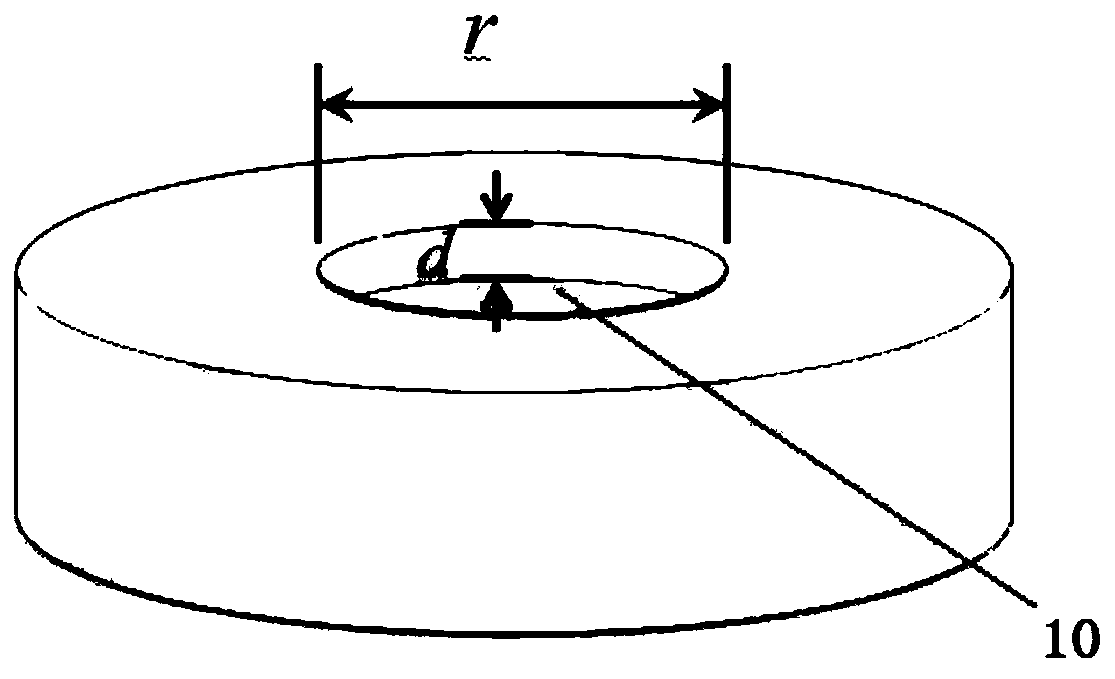

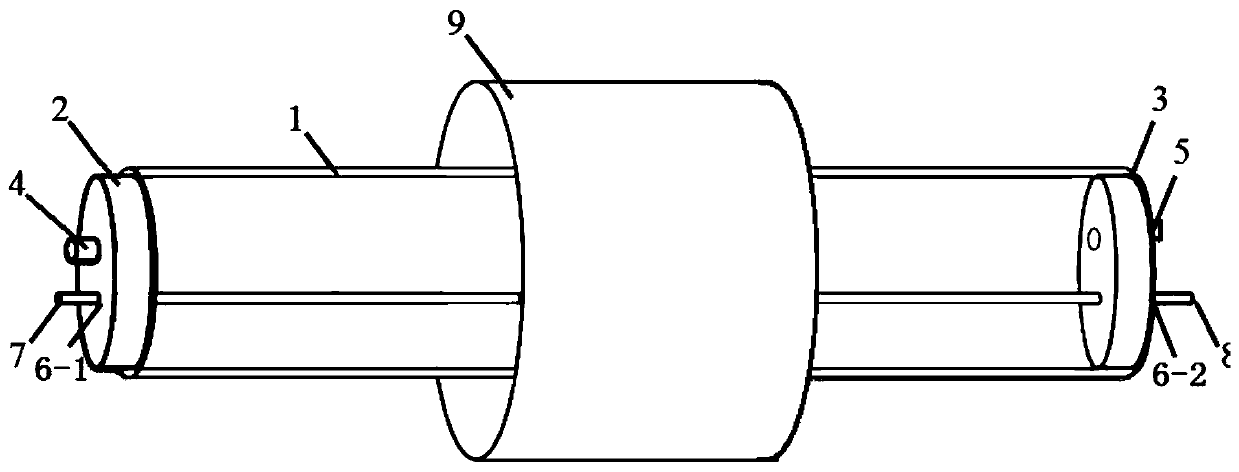

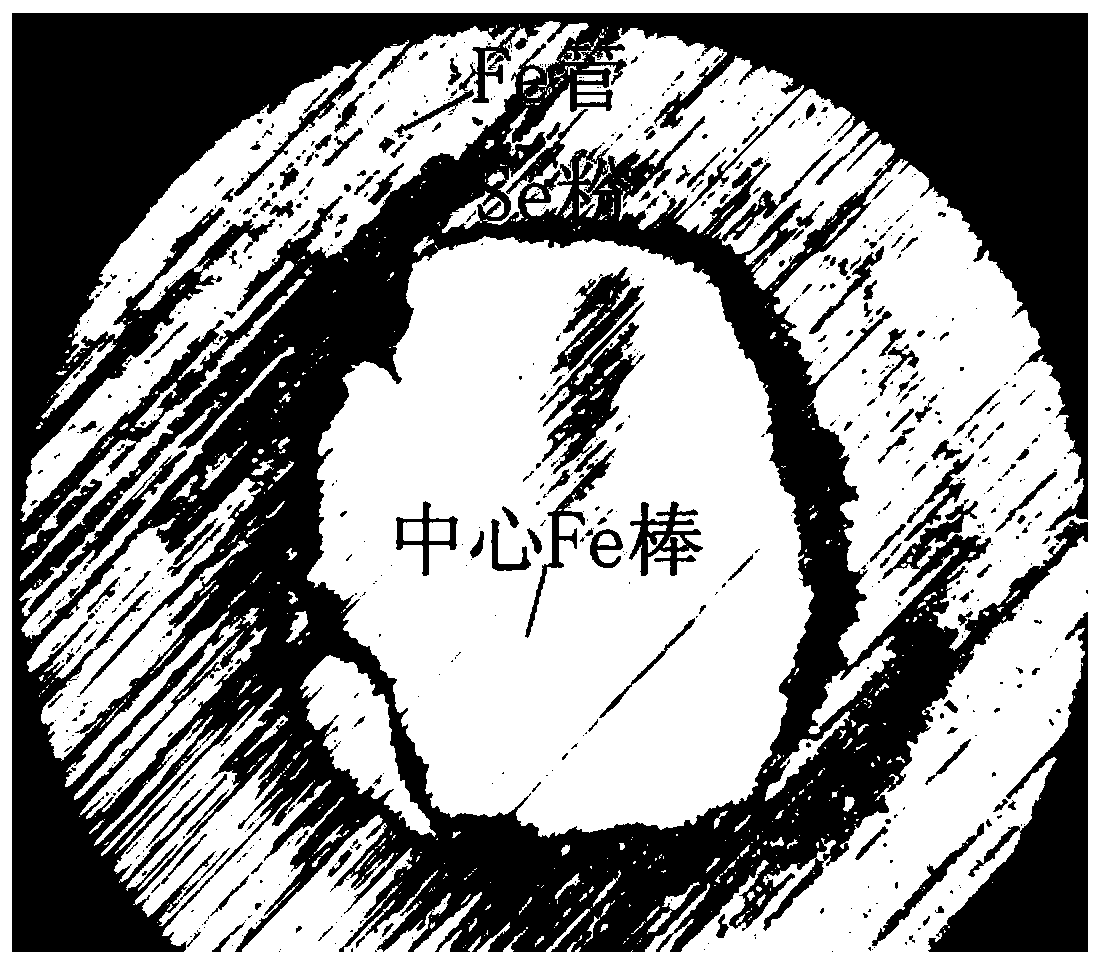

[0040] Step 1. Clean and dry an iron pipe with an outer diameter of 12 mm, an inner diameter of 10 mm and a wall thickness of 1 mm, an iron rod with a diameter of 4.20 mm, and an iron plug in sequence, and place them in an argon-protected glove box, and then Assembling by using a thermal assembly method to obtain a pipe-loading complex; the specific process of the assembly is: using a thermal assembly method to closely assemble one end of the iron rod with an iron plug, and then using a thermal assembly method to assemble with the iron pipe, Make the iron pipe tightly assembled with the iron plug tightly assembled at one end of the iron rod, and ensure that the centerline of the iron rod and iron pipe coincides, and then use the vibration filling method to fill the gap formed by the iron pipe and the iron rod. powder, and plug the upper end of the iron pipe with an iron plug, the vibration frequency of the vibration table ...

Embodiment 2

[0047] This embodiment includes the following steps:

[0048] Step 1. Clean and dry an iron pipe with an outer diameter of 15mm, an inner diameter of 12mm and a wall thickness of 1.5mm, an iron rod with a diameter of 4.20mm, and an iron plug in sequence, and place them in an argon-protected glove box. Then use the thermal assembly method to assemble to obtain the pipe-loading complex; the specific process of the assembly is: use the thermal assembly method to closely assemble one end of the iron rod with an iron plug, and then use the thermal assembly method to assemble with the iron pipe , so that the iron pipe and the iron plug tightly assembled at one end of the iron rod can be tightly assembled, and the centerline of the iron rod and the iron pipe should be coincident, and then the gap formed by the iron pipe and the iron rod should be filled by the vibration filling method Se powder, and plug the upper end of the iron pipe with an iron plug, the vibration frequency of the...

Embodiment 3

[0054] This embodiment includes the following steps:

[0055] Step 1. Clean and dry an iron pipe with an outer diameter of 8mm, an inner diameter of 5mm and a wall thickness of 1.5mm, an iron rod with a diameter of 2.20mm, and an iron plug in sequence, and place them in an argon-protected glove box. Then use the thermal assembly method to assemble to obtain the pipe-loading complex; the specific process of the assembly is: use the thermal assembly method to closely assemble one end of the iron rod with an iron plug, and then use the thermal assembly method to assemble with the iron pipe , so that the iron pipe and the iron plug tightly assembled at one end of the iron rod can be tightly assembled, and the centerline of the iron rod and the iron pipe should be coincident, and then the gap formed by the iron pipe and the iron rod should be filled by the vibration filling method Se powder, and plug the upper end of the iron pipe with an iron plug, the vibration frequency of the vib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com