In-situ hot-wire chemical gas-phase deposition process for preparing MgB2 superconductor film

A technology of hot wire chemistry and superconducting thin film, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., and can solve the difficult problem of containing MgO impurities in the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

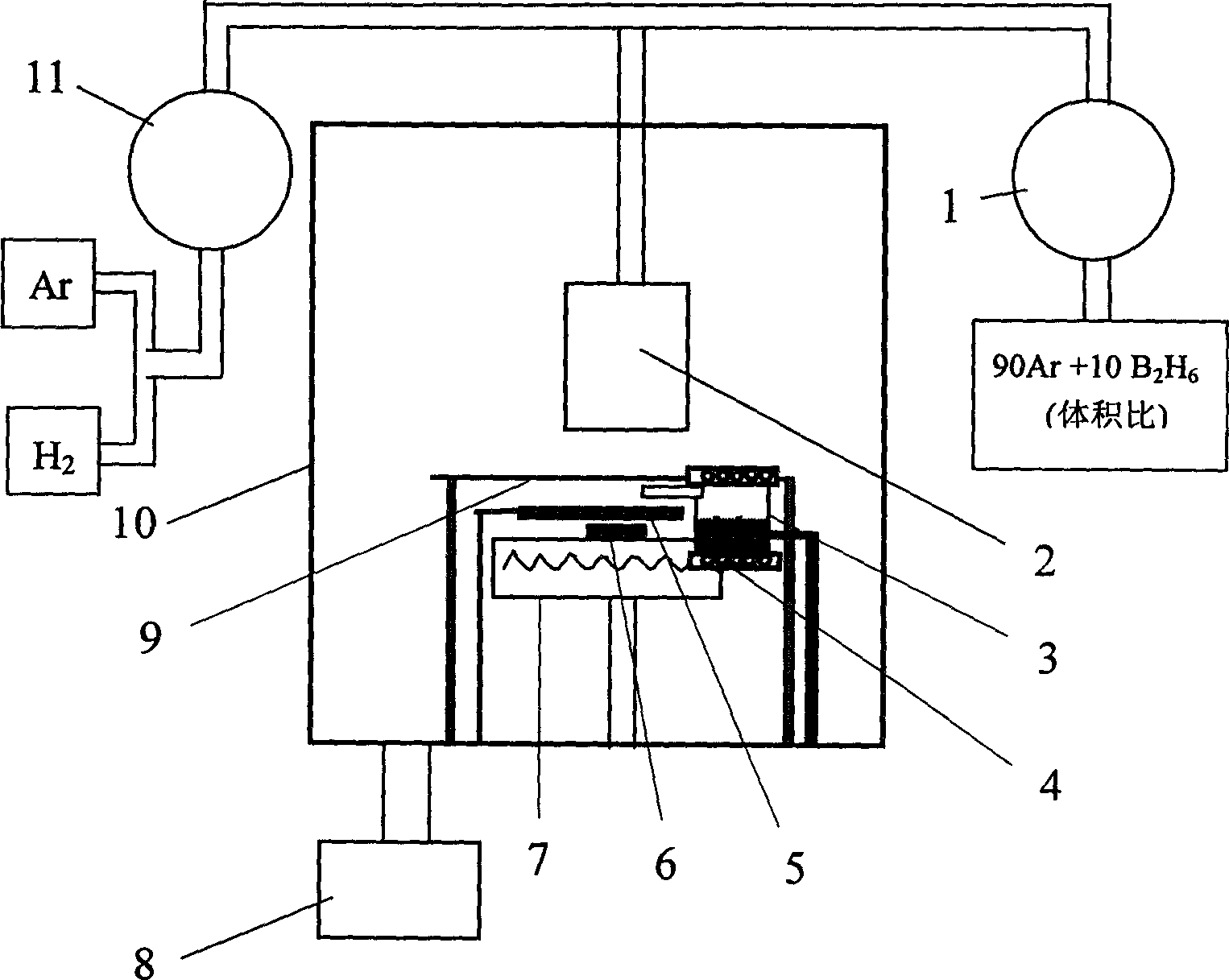

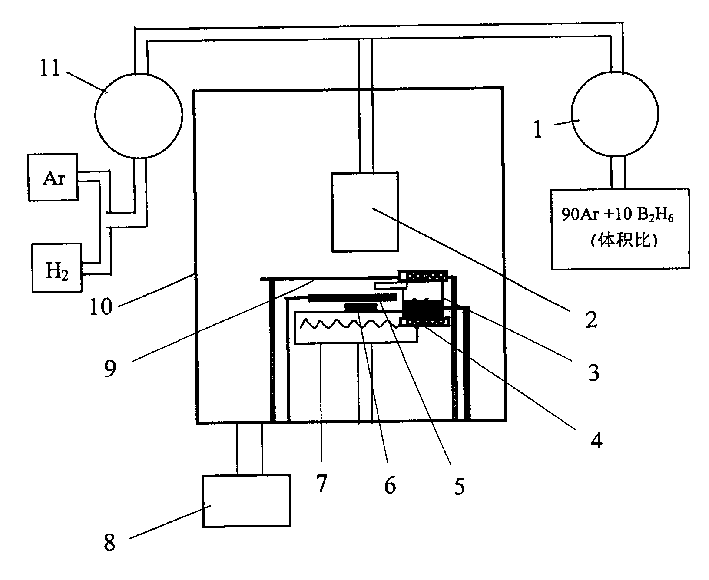

[0007] figure 1 An embodiment disclosed for the present invention (see figure 1 ), the invention uses a gaseous compound containing B and Mg as the reaction gas, so that it is cracked under the action of the hot wire 4, and the reaction generates MgB 2 compound and grow into a thin film on the substrate 6.

[0008] In the present invention, due to the easy oxidation of Mg strips, MgO generally exists on the surface of Mg solids, but it has a melting point much higher than Mg, so it is difficult to evaporate and deposit on the substrate, thereby ensuring the evaporation of pure Mg and inhibiting MgO was formed in the film. However, for currently reported physical methods, such as pulsed laser evaporation deposition and sputtering methods, due to the MgB 2 The target sintering process will inevitably form MgO impurities, so the MgO impurities in the target will inevitably be mixed with MgB 2 At the same time, it is evaporated or sputtered out to form an impurity phase in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com