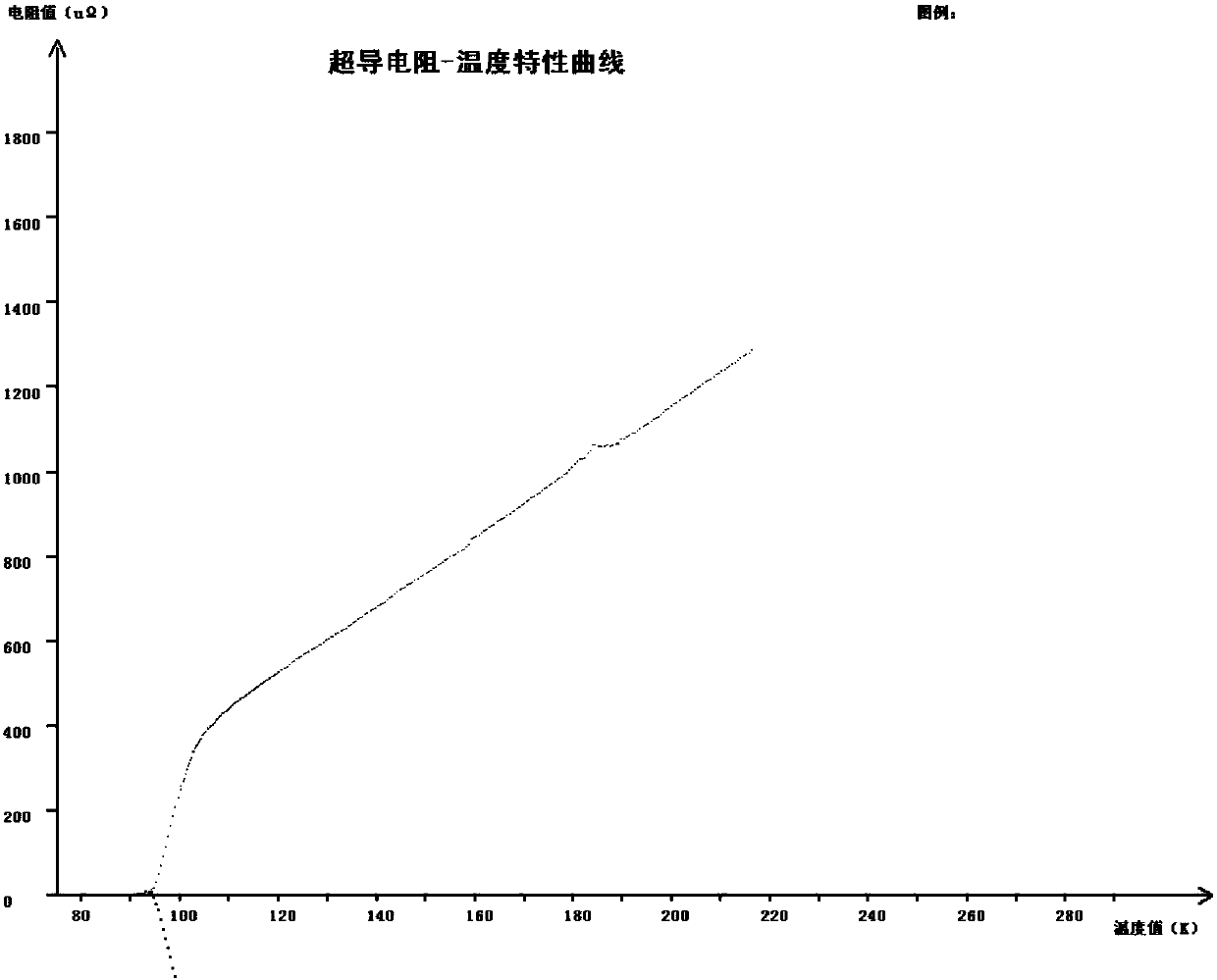

Method of preparing Tl-1223 superconductive thin film

A tl-1223, superconducting thin film technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problem of difficult preparation of Tl-1223 thin film, high consumption of thallium source accompanying burning target , Low experimental repeatability and other problems, to achieve the effect of shortening the heating and cooling time and constant temperature time, short preparation time and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of Tl-1223 superconducting film, substrate is CeO 2 / sapphire, including:

[0036] Step 1. Preparation of thallium-containing amorphous precursor film by sol-gel method: starting materials of thallium, barium, calcium, copper acetate, propionic acid, lactic acid, diethylenetriamine, methanol, etc. Complexing agent and solvent prepare sol; With this sol has CeO 2 A gel film is prepared on the sapphire substrate of the isolation layer, and a precursor film is obtained through drying and thermal decomposition processes. The metal ion molar ratio of Tl, Ba, Ca, and Cu of the prepared precursor film is 1.2:2:2:3.2;

[0037] Step 2. Preparation of a thallium-containing burner target: BaO with a metal ion molar ratio of Ba:Ca:Cu=2:2:3 2 , CaO and CuO as starting materials are mixed and ground, kept at a constant temperature of 890-940°C for 4 hours in a flowing oxygen environment, crushed and then ground after cooling, kept at a constant temperat...

Embodiment 2

[0042] A kind of preparation method of Tl-1223 superconducting film, substrate is CeO 2 / sapphire, including:

[0043] Step 1. Preparation of thallium-containing amorphous precursor film by sol-gel method: starting materials of thallium, barium, calcium, copper acetate, propionic acid, lactic acid, diethylenetriamine, methanol, etc. Complexing agent and solvent prepare sol; With this sol has CeO 2 Prepare a gel film on the sapphire substrate of the isolation layer, and obtain a precursor film through drying and thermal decomposition processes. The metal ion molar ratio of Tl, Ba, Ca, and Cu of the prepared precursor film is 2.5:2:2:3.6;

[0044] Step 2. Preparation of a thallium-containing burner target: BaO with a metal ion molar ratio of Ba:Ca:Cu=2:2:3 2 , CaO and CuO as starting materials are mixed and ground, kept at a constant temperature of 890-940°C for 8 hours in a flowing oxygen environment, crushed and then ground after cooling, kept at a constant temperature of 89...

Embodiment 3

[0049] A kind of preparation method of Tl-1223 superconducting film, substrate is lanthanum aluminate, comprising:

[0050] Step 1. Preparation of an amorphous precursor film containing thallium: BaO with a metal ion molar ratio of Ba:Ca:Cu=2.5:2:3.4 2 or BaO, CaO or CaCO 3 Mix and grind with CuO as the starting material, keep the temperature at 890-940°C for 6h in the flowing oxygen environment, add Tl 2 o 3 Mix and grind the tablets so that the molar ratio of Tl and Ca is Tl:Ca=1.7:2, put them in a sealed crucible, put them together in a sealed quartz tube, keep the temperature at 890-940°C for 6 hours in a flowing oxygen environment, and cool Finally, the sputtering target is obtained; the sputtering target adopts radio frequency magnetron sputtering, and the sputtering gas is high-purity Ar or Ar / O 2 Mixed gas, the sputtering pressure is 2-7Pa, and the sputtering power is 45W; the metal ion molar ratio of Tl, Ba, Ca, and Cu in the prepared precursor film is 1.8:2:2:3.4;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com